Alloy steel SDH55 for shield machine tools and production method thereof

A shield machine tool, SDH55 technology, applied in alloy materials and their preparation, alloy steel for tools and their preparation fields, can solve the problems of poor wear resistance and insufficient toughness of steel, and achieve increased wear resistance and hardenability. and thermal strength, the effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

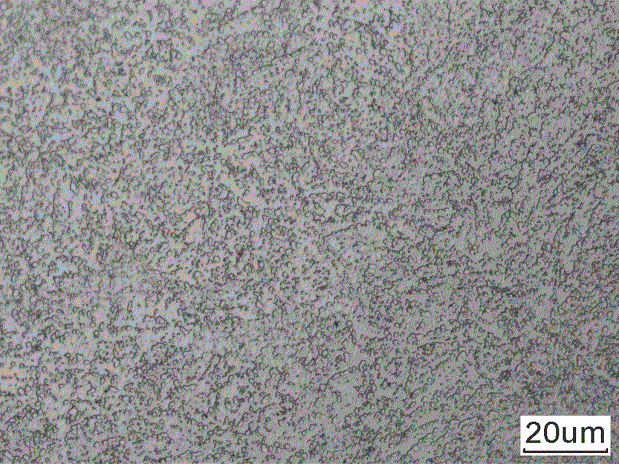

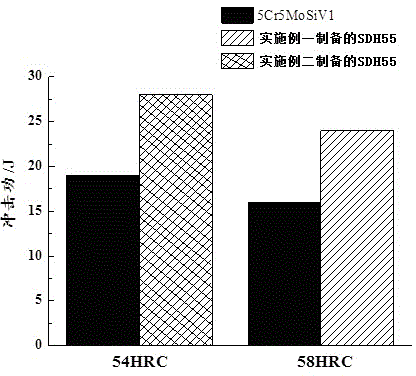

[0031] In this example, see figure 1 and image 3 , a method for preparing alloy steel SDH55 for shield machine cutters, comprising the steps of:

[0032] a. Steel ingot smelting: batching is based on the mass percentage of each alloy raw material component element of alloy steel SDH55 for shield machine tools. The chemical composition of the alloy is composed of the following elements: C content is 0.42%, Si content is 0.37%, Mn The content of Cr is 0.30%, the content of Cr is 5.8%, the content of Mo is 2.55%, the content of V is 0.80%, and the rest of the alloy components are Fe and unavoidable impurity elements. %; After batching, the raw materials of each alloy component are put into an electric arc furnace for smelting, then refining, and then vacuum degassing treatment, and finally pouring alloy steel SDH55 steel ingots for shield machine tools for use;

[0033] b. Electroslag remelting: use the alloy steel SDH55 steel ingot for shield machine tools prepared in step a ...

Embodiment 2

[0054] This embodiment is basically the same as Embodiment 1, especially in that:

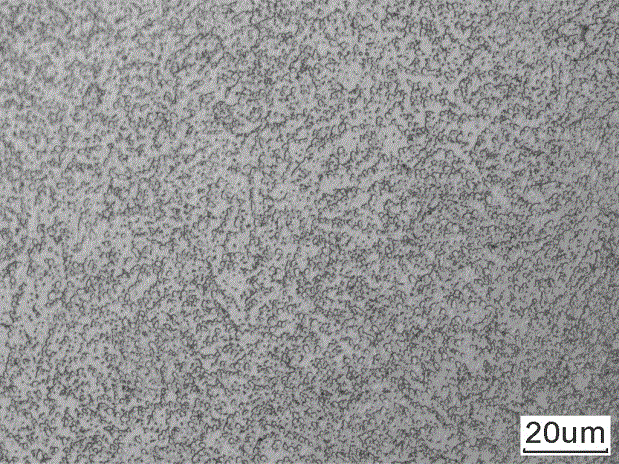

[0055] In this example, see figure 2 and image 3 , a method for preparing alloy steel SDH55 for shield machine cutters, comprising the steps of:

[0056] a. Steel ingot smelting: batching is based on the mass percentage of each alloy raw material component element of alloy steel SDH55 for shield machine tools. The chemical composition of the alloy is composed of the following elements: C content is 0.46%, Si content is 0.4%, Mn The content of Cr is 0.27%, the content of Cr is 5.5%, the content of Mo is 2.6%, the content of V is 0.51%, and the rest of the alloy components are Fe and unavoidable impurity elements. %; After batching, the raw materials of each alloy component are put into an electric arc furnace for smelting, then refining, and then vacuum degassing treatment, and finally pouring alloy steel SDH55 steel ingots for shield machine tools for use;

[0057] b. Electroslag remelting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com