Outer packaging material for high-punching-depth battery device and battery

A battery device and outer packaging technology, which is applied in the field of aluminum-plastic film production, can solve problems such as cracking, concentrated deformation, and rough surface of aluminum foil, and achieve the effects of reducing size distribution, improving crystal uniformity, and deepening the forming limit depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

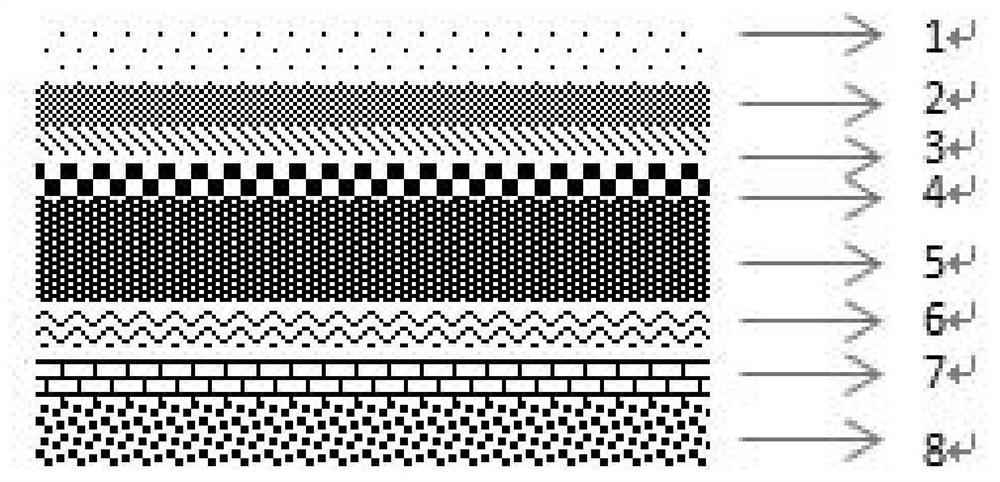

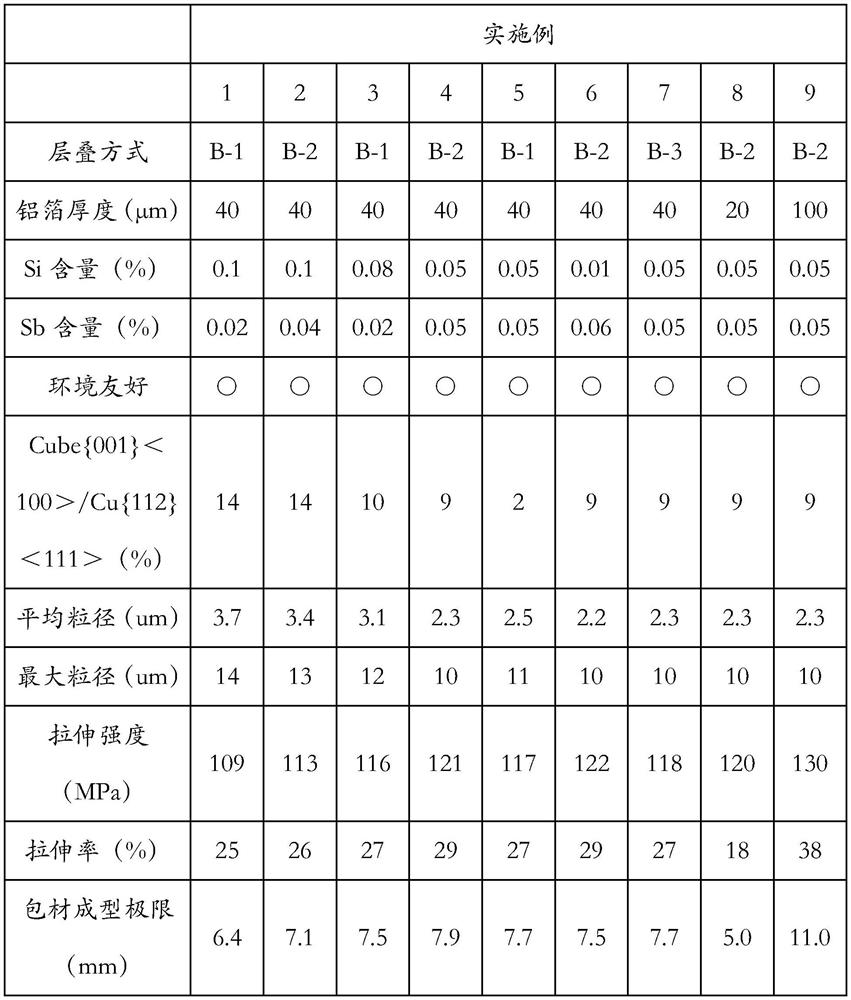

[0123] Use the aluminum alloy foil described in Table 2 to form a composite film, the lamination method is B-1, the thickness is 40 μm, the Si content is 0.1%, the Sb content is 0.02%, and the plane orientation Cube{001} / Cu{112}=14%. The composition is: base material layer (25 μm) / adhesive layer A (3 μm) / aluminum alloy foil layer / adhesive layer B / heat-sealing layer (40 μm).

[0124] Wherein, the thickness of the aluminum alloy foil layer is 20 μm, 40 μm, or 100 μm.

[0125] The lamination method is as follows. For the substrate layer, biaxially stretched PBT (polybutylene terephthalate) having a thickness of 25 µ was used. The surface of the substrate layer in contact with the adhesive layer A was previously subjected to corona treatment. On the substrate layer, the aluminum alloy foil layer is composited by a dry composite method. Specifically, a two-component polyurethane adhesive (polyol compound and aromatic isocyanate compound) was coated on one surface of the aluminum...

Embodiment 2

[0132] Use the aluminum alloy foil described in Table 2 to form a composite film, the lamination method is B-2, the thickness is 40 μm, the Si content is 0.1%, the Sb content is 0.04%, and the plane orientation Cube{001} / Cu{112}=14%.

[0133] The stacking method is the same as in Example 1.

Embodiment 3

[0135] Use the aluminum alloy foil described in Table 2 to form a composite film, the lamination method is B-1, the thickness is 40 μm, the Si content is 0.08%, the Sb content is 0.02%, and the plane orientation Cube{001} / Cu{112}=10%.

[0136] The stacking method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com