Rubber composition and tire produced using same, and process of producing rubber composition

一种橡胶组合物、制造方法的技术,应用在特殊轮胎、轮胎零部件、运输和包装等方向,能够解决没有考虑混炼条件等问题,达到改进低发热性和耐磨耗性、低发热性优良、偶联功能活性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0183] (Preparation and Purpose of Rubber Composition)

[0184] The rubber composition of the present invention may contain various additives commonly used in the rubber industry, such as sulfur, vulcanization accelerators, softeners, process oils, anti-aging agents, anti-scorch agents, within the range of not impairing the advantageous effects of the present invention as required , Zinc China, anti-caking agents, foaming agents, foaming aids and resins.

[0185] The rubber composition of the present invention can be obtained by kneading with an open kneader such as a roll or a closed kneader such as a Banbury mixer, and can be obtained in Vulcanized after molding, so it can be applied to various rubber products. The rubber composition can be applied to tire members such as tire treads, under treads, carcass, sidewalls, sidewall reinforcing rubber members, and bead fillers, and is particularly preferably applied to low heat build-up, Tread rubber for fuel-saving tires, large...

Embodiment

[0276] The present invention will be described in more detail below with reference to examples, but the present invention is not limited to the examples.

[0277] The loss tangent (tan δ) and abrasion resistance of the rubber composition after vulcanization were measured in the following manner, the amount of organic acid remaining in E-SBR and the modified styrene-butadiene copolymer rubber (modified SBR ) microstructure (ie, bound vinyl content and bound styrene content).

[0278] (1) Tangent of loss angle (tanδ)

[0279] For Examples 1-47 and Comparative Examples 1-5, under the conditions of a dynamic strain of 1%, a frequency of 10 Hz and a temperature of 50° C., a dynamic spectrometer (dynamic spectrometer) manufactured by Rheometrics, Inc., U.S. was used to measure For the rubber composition, tan δ is expressed as an index with the reciprocal of tan δ of the controls (Comparative Examples 1, 2, 3, 4 and 5 and Example 22) being 100. A larger index value means lower exot...

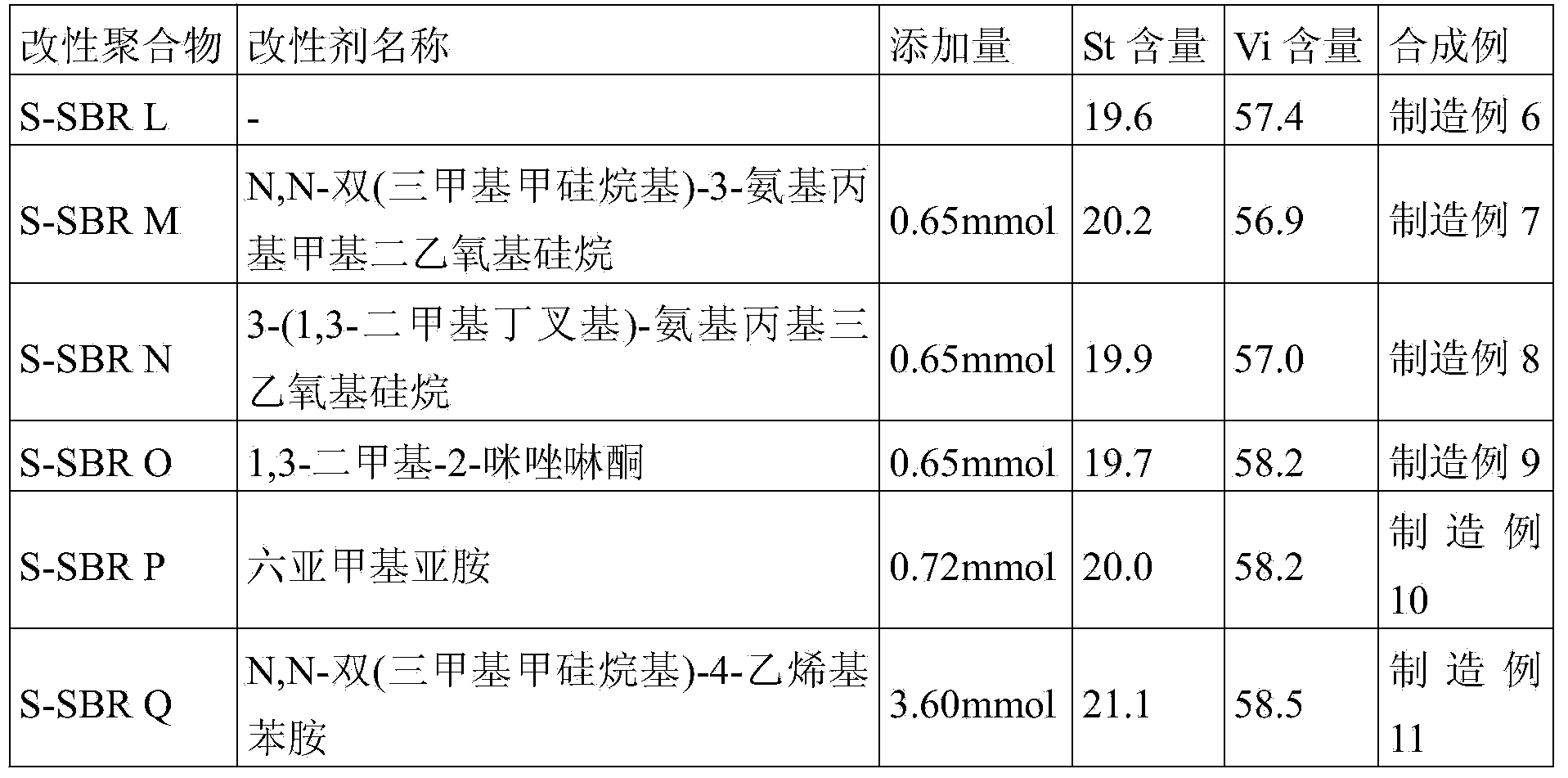

manufacture example 1

[0292] In an 800mL pressure-resistant glass container that has been dried and replaced with nitrogen, put the cyclohexane solution of 1,3-butadiene and the cyclohexane solution of styrene so that the 1,3-butadiene in the container 60 g of alkenes and 15 g of styrene were put into 0.70 mmol of 2,2-ditetrahydrofurylpropane, and further 0.70 mmol of n-butyllithium (BuLi) was added, and then it was polymerized in a warm water bath at 50°C for 1.5 hours . The polymerization conversion here is almost 100%.

[0293] Post-polymerization processing

[0294] Then, a solution of 2,6-di-tert-butyl-p-cresol (BHT) in isopropanol was added to the polymerization reaction system to terminate the polymerization reaction. Thereafter, the product was vacuum-dried to provide a solution-polymerized SBR (S-SBR). The resulting solution-polymerized S-SBR had a bound styrene content of 20% and a bound vinyl content of 55% of the butadiene moiety. Solution-polymerized S-SBR was used as the rubber co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| iodine adsorption | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com