Backheating method and backheating structure for heat pump air conditioner

A heat pump air conditioner and heat exchanger technology, applied in heating methods, air conditioning systems, heat recovery systems, etc., can solve problems such as increased friction between fluid and wall surface, increased irreversible loss, complex heat recovery structure, etc., to achieve stable refrigerant flow state, Effect of reducing irreversible loss and improving cooling or heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

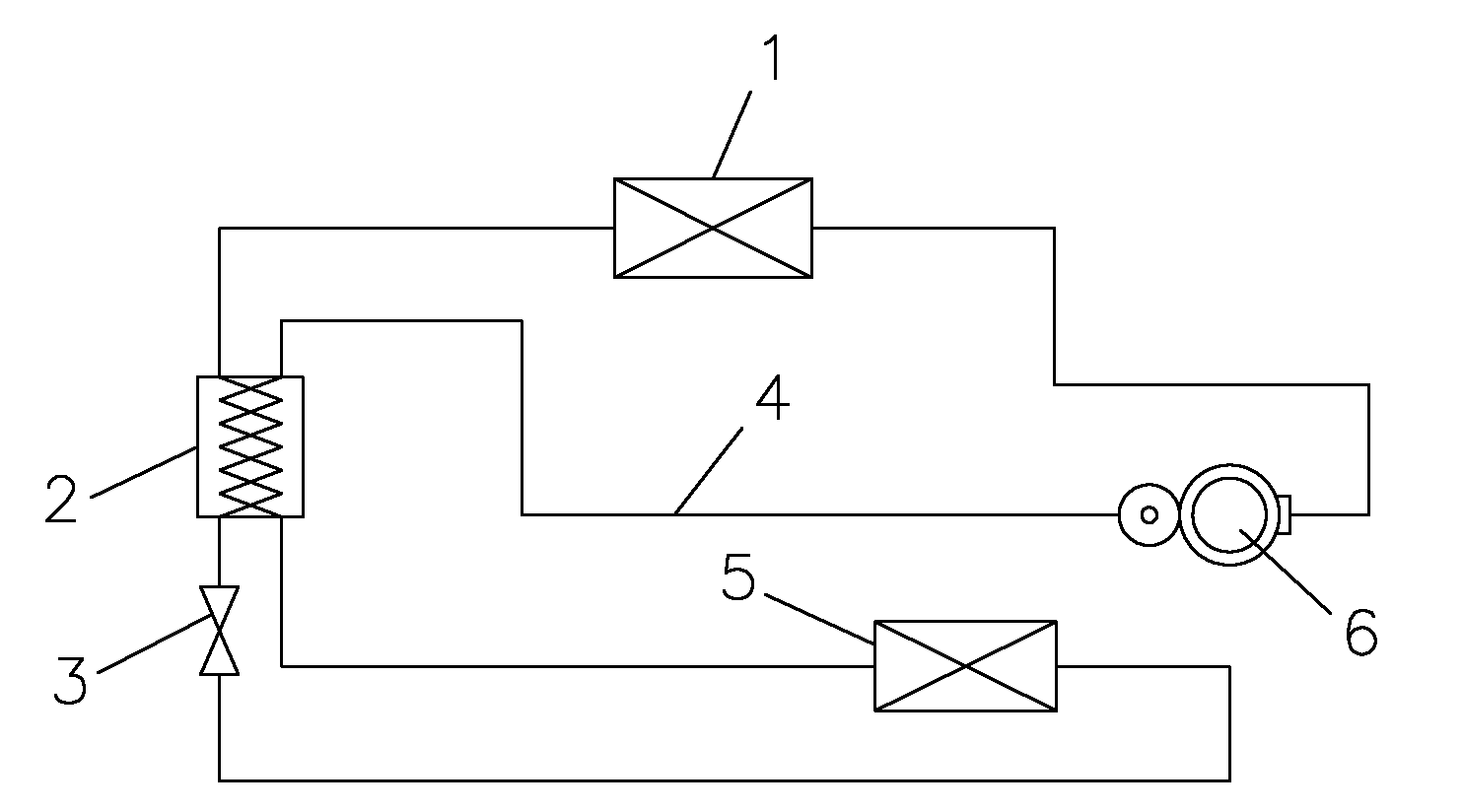

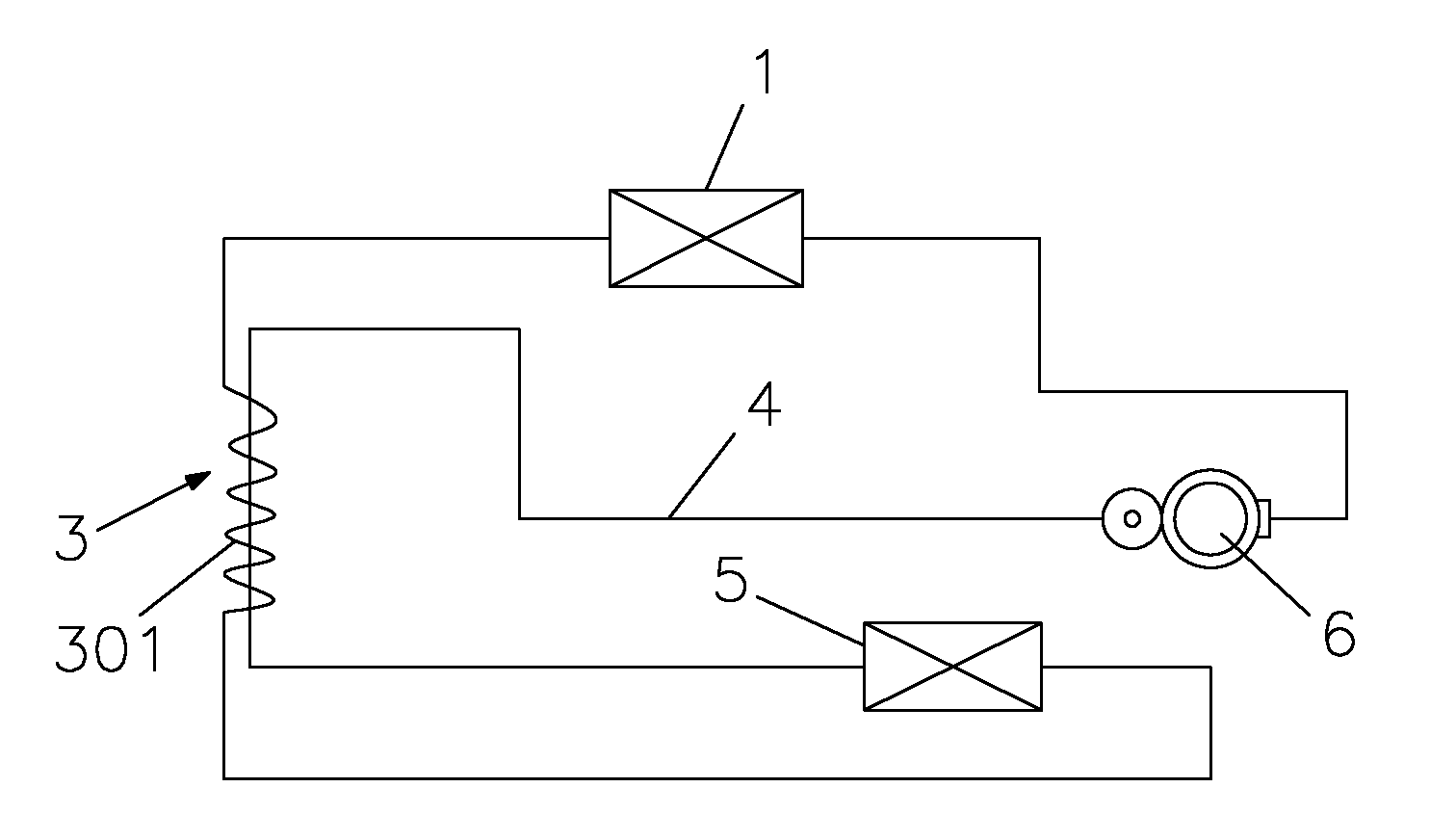

Embodiment 1

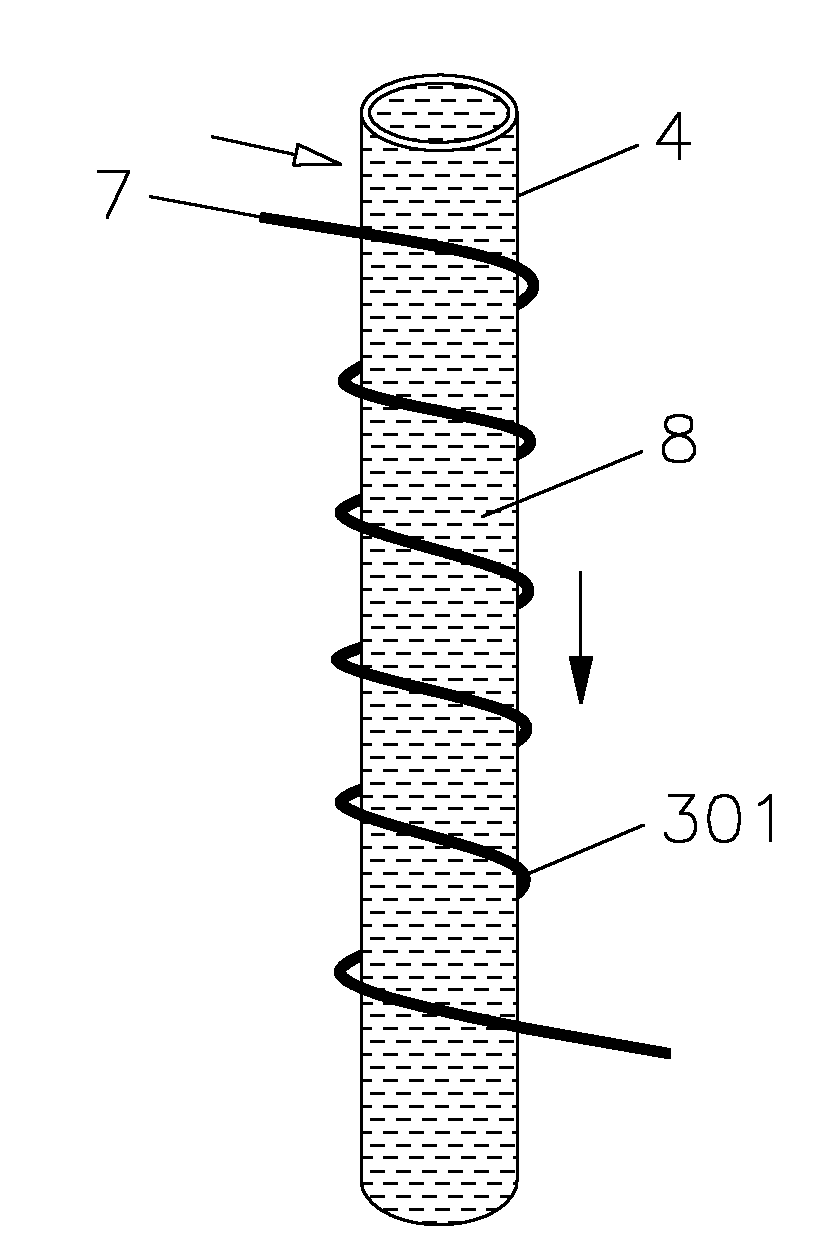

[0023] Such as image 3 As shown, the throttle capillary 301 is wound on the outer wall of the compressor suction pipe 4 . combine figure 2 and image 3 As shown, when the heat pump air conditioner is in the cooling mode or the heating mode, the relatively high-temperature refrigerant 7 enters the throttling capillary 301 from the heat exchanger A1 (acting as a condenser at this time), thereby being sucked together with the compressor while throttling. The relatively low-temperature refrigerant 8 in the gas pipe 4 performs heat exchange, and the throttled refrigerant enters the heat exchanger B5 (at this time as an evaporator) for evaporation and heat exchange. After the heat exchange, the relatively low-temperature refrigerant 8 enters the suction pipe of the compressor 4. It also exchanges heat with the relatively high-temperature refrigerant 7 that is throttling from the heat exchanger A1, and finally returns to the compressor 6 for recompression, thereby completing the ...

Embodiment 2

[0026] Such as Figure 4 As shown, the throttling capillary 301 is placed in the lumen of the compressor suction pipe 4, and the two ends of the throttling capillary 301 protrude from the compressor suction pipe 4 to connect with the heat exchanger A1 and the heat exchanger B5 respectively. combine figure 2 and Figure 4 As shown, when the heat pump air conditioner is in the cooling mode or the heating mode, the relatively high-temperature refrigerant 7 enters the throttling capillary 301 from the heat exchanger A1 (acting as a condenser at this time), thereby being sucked together with the compressor while throttling. The relatively low-temperature refrigerant 8 in the gas pipe 4 performs heat exchange, and the throttled refrigerant enters the heat exchanger B5 (at this time as an evaporator) for evaporation and heat exchange. After the heat exchange, the relatively low-temperature refrigerant 8 enters the suction pipe of the compressor 4. It also exchanges heat with the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com