Patents

Literature

64results about How to "Flow state is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

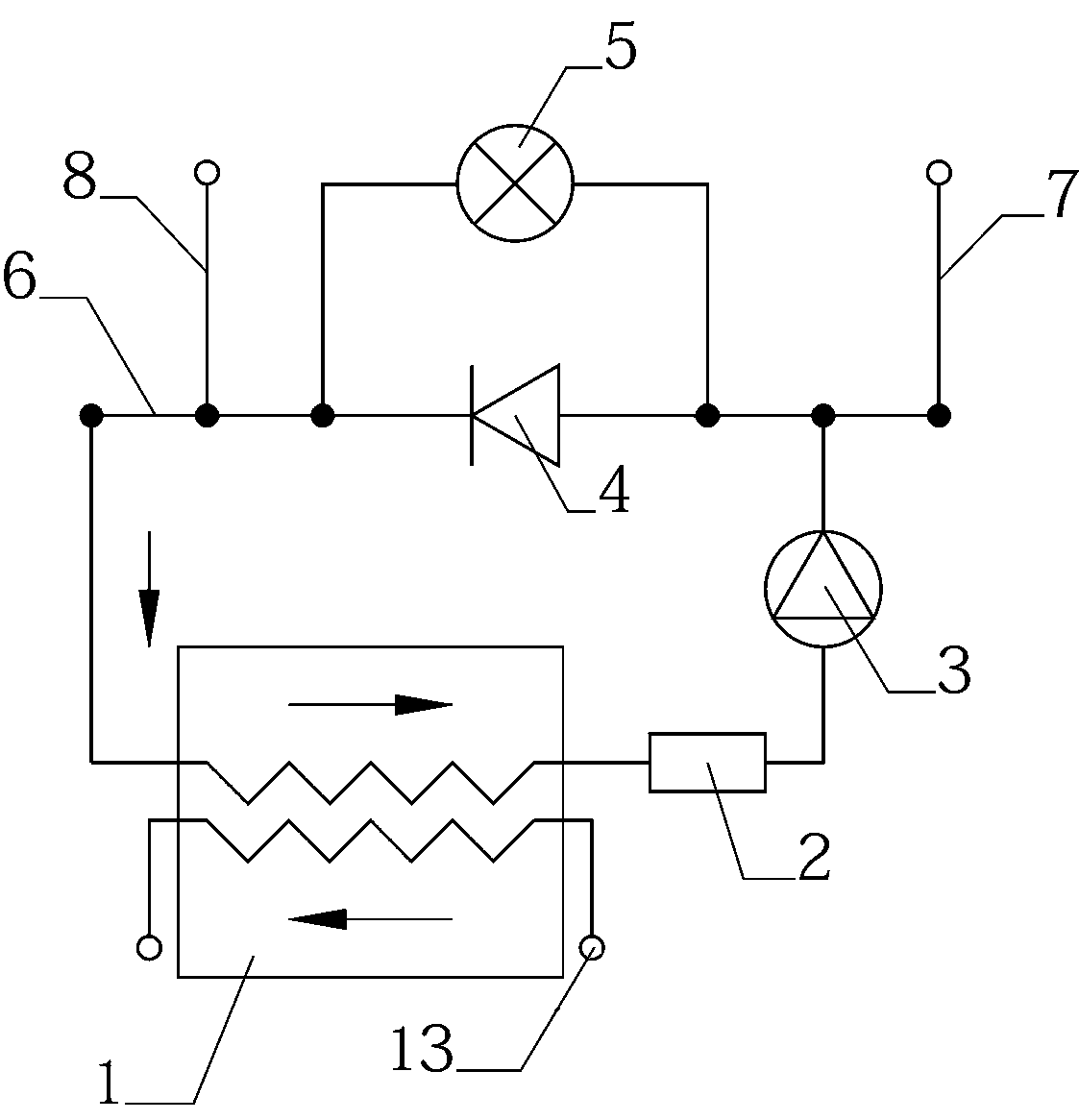

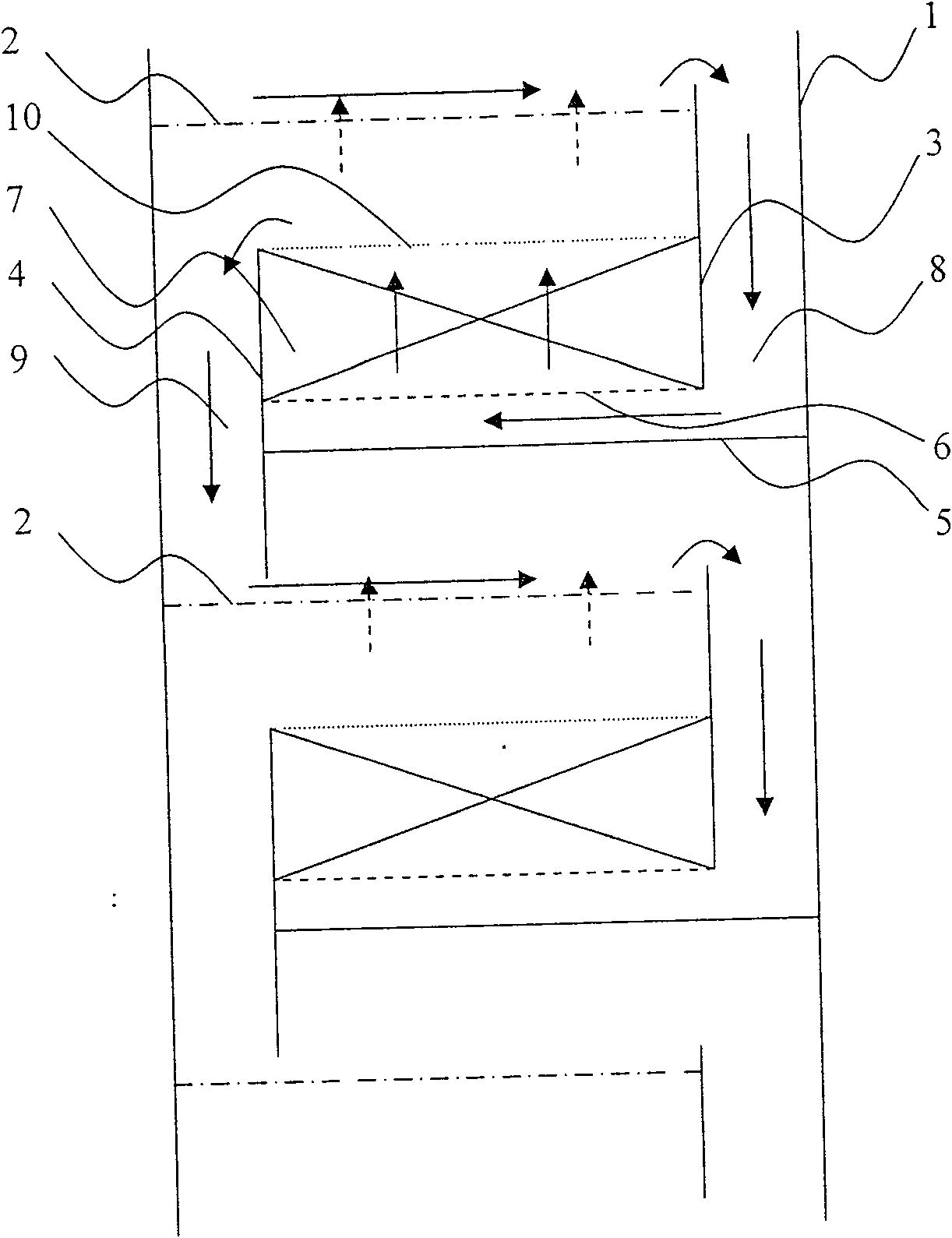

Backheating method and backheating structure for heat pump air conditioner

InactiveCN101979938AReduce the temperatureReduce vaporizationHeat recovery systemsFluid circulation arrangementEvaporationEngineering

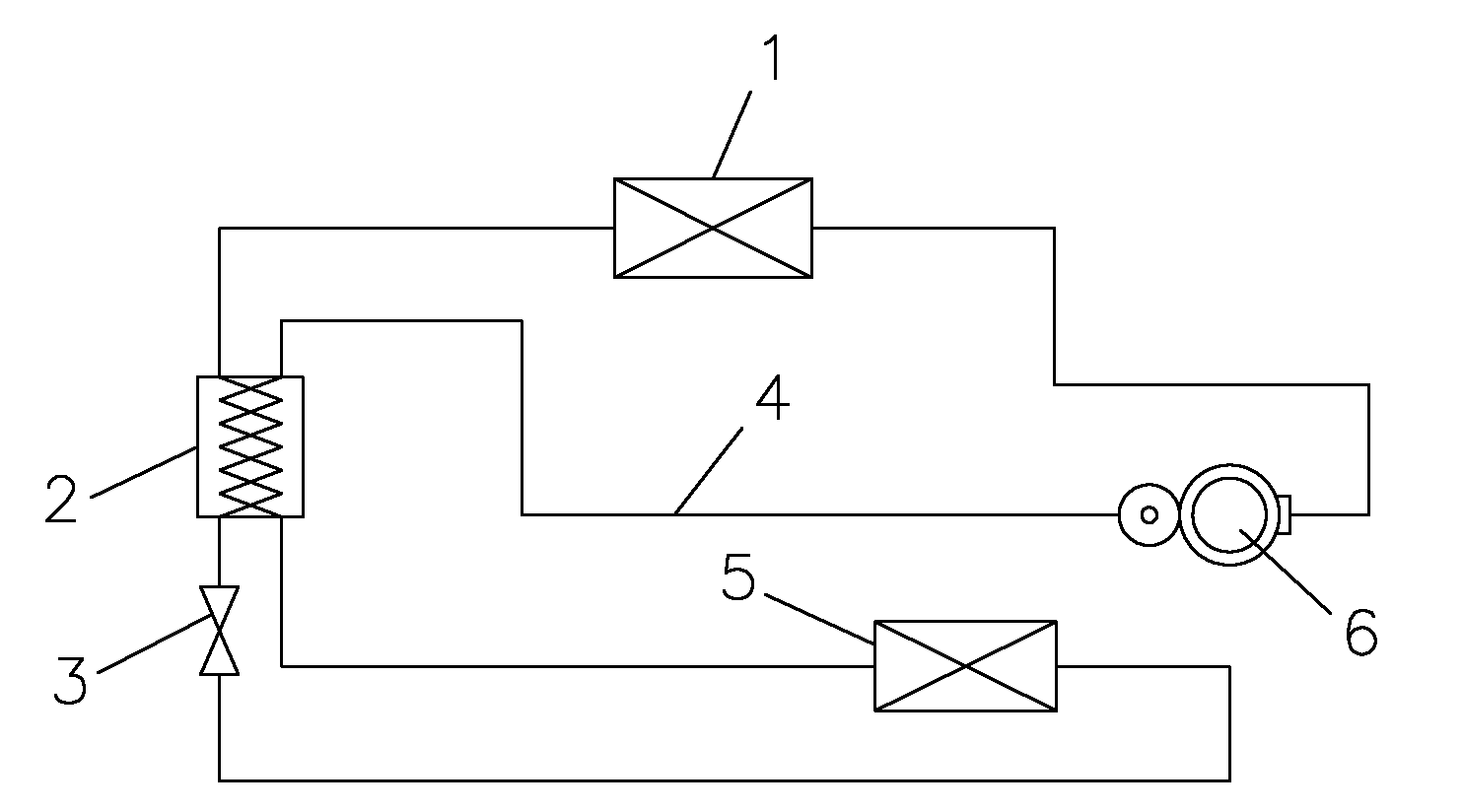

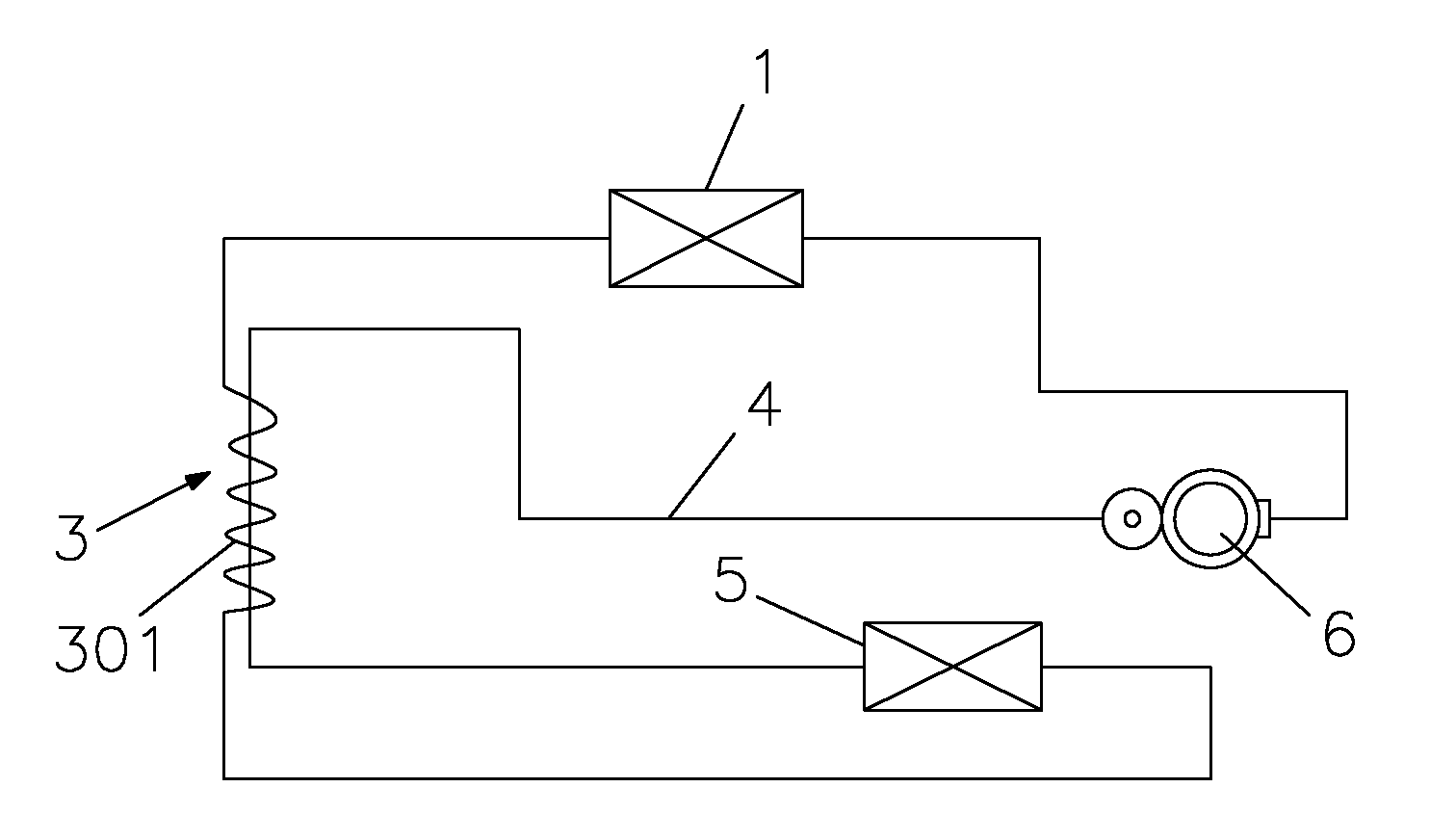

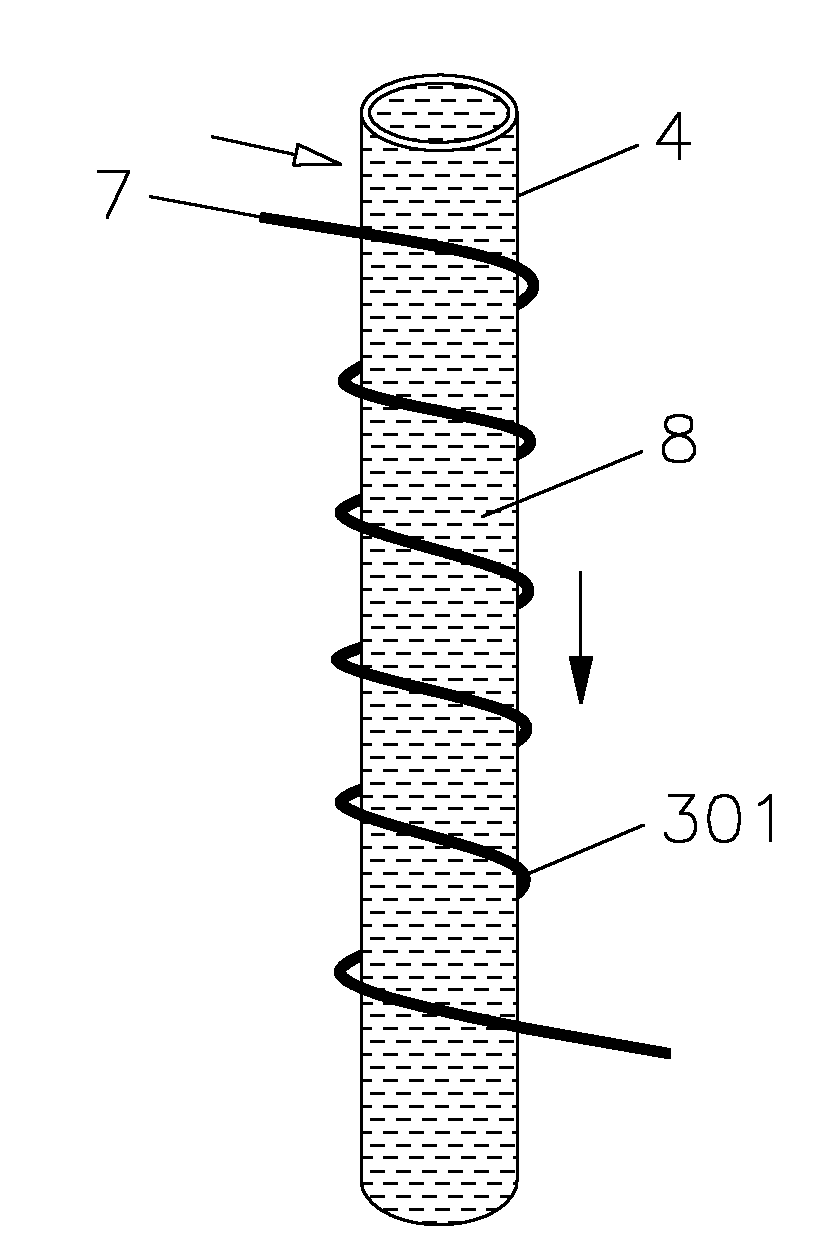

The invention discloses a backheating method and a backheating structure for a heat pump air conditioner, which can improve the performance of the air conditioner. The backheating structure comprises heat exchangers A and B, a compressor, and a throttling element connected between the heat exchangers A and B, wherein the heat exchanger B is connected with the compressor by an air suction pipe of the compressor; and a higher-temperature coolant in the throttling element performs heat exchange with a lower-temperature coolant in the air suction pipe of the compressor. In the backheating method and the backheating structure, the temperature of the coolant in the throttling element can be reduced by performing backheating in a throttling process, thereby retarding the evaporation of the coolant and the change of the dryness of the coolant, making more stable the flow regime of the coolant and reducing inevitable loss; and the dryness of the coolant at an outlet of the throttling element is reduced, namely, the degree of subcooling of the air conditioner is increased, so the cooling capacity of the air conditioner can be improved. The backheating method and the backheating structure for the heat pump air conditioner can improve the cooling or heating performance of the heat pump air conditioner; and the backheating structure is simplified to a certain extent so as to be convenient to manufacture and save the cost.

Owner:四川长虹空调有限公司

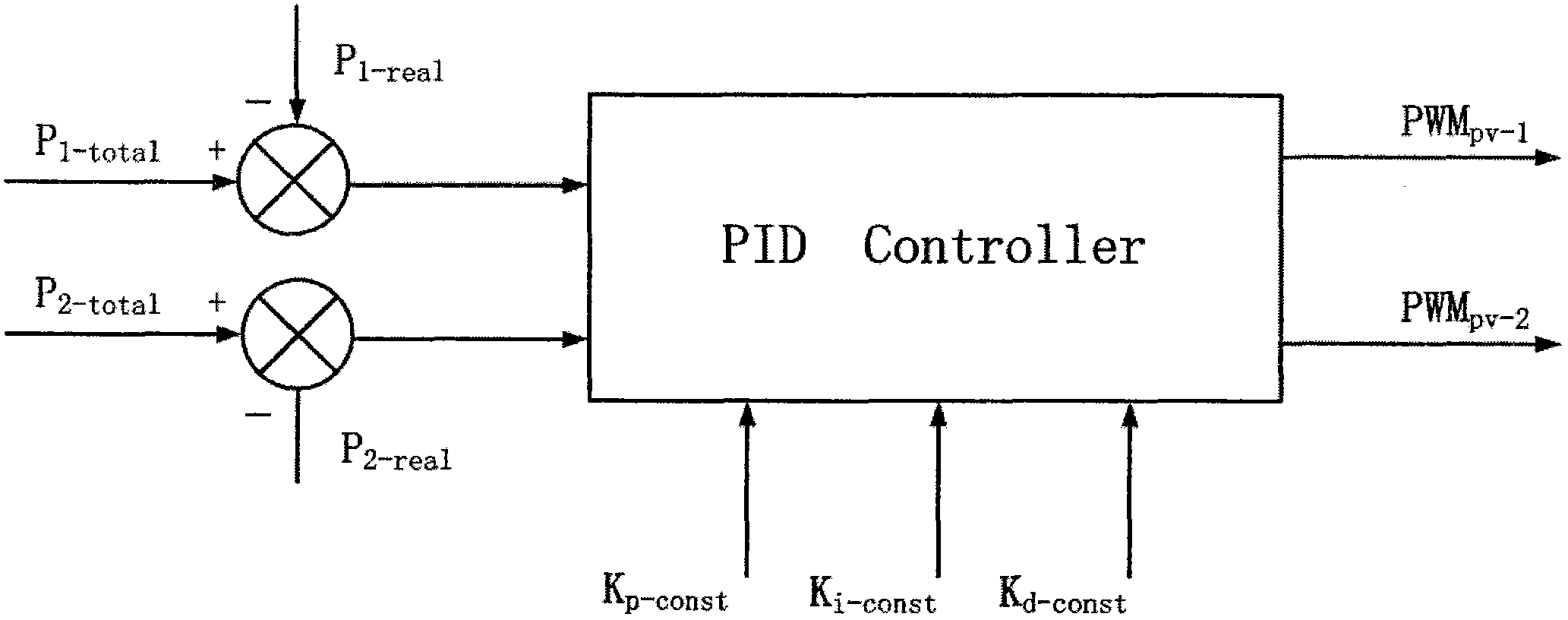

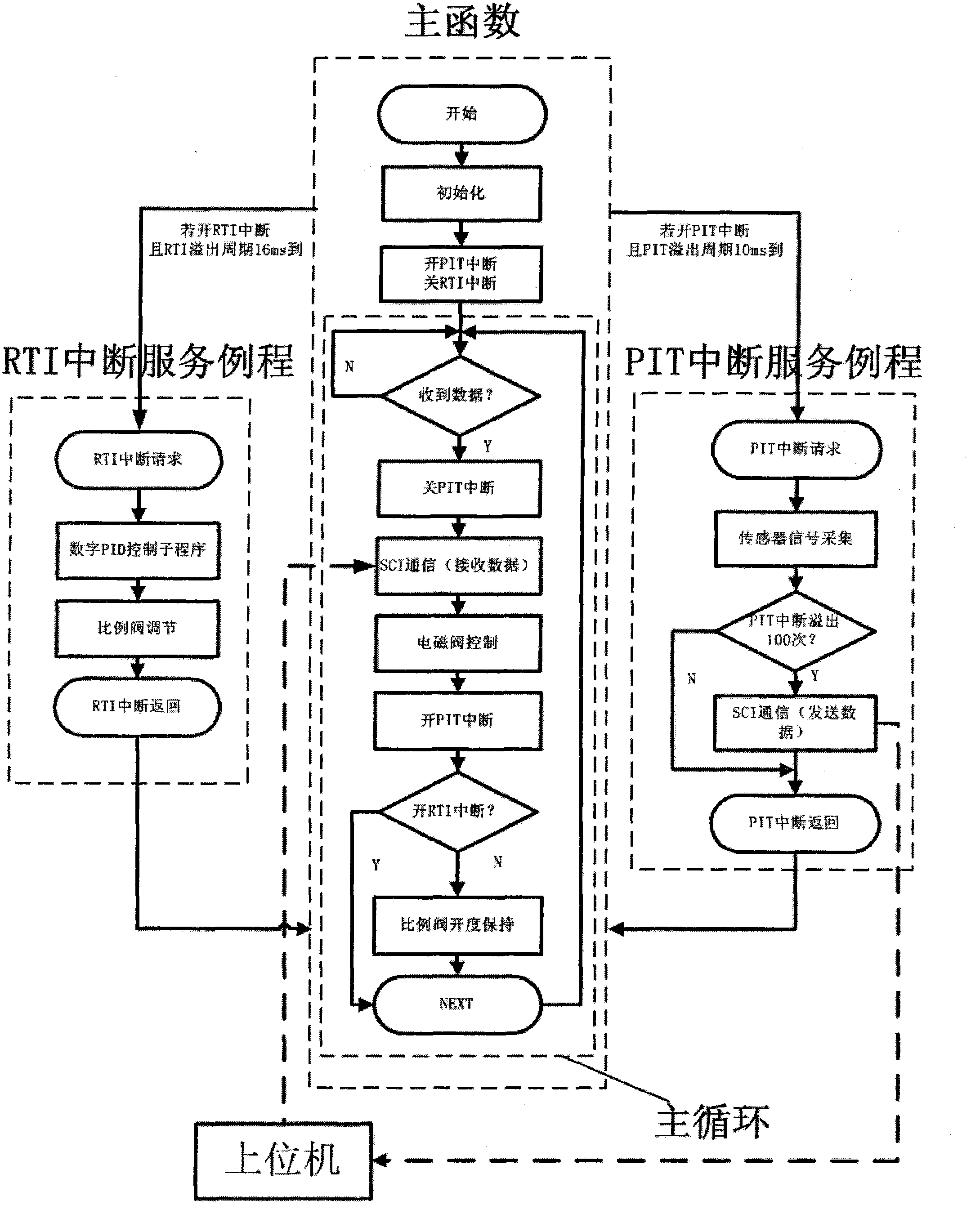

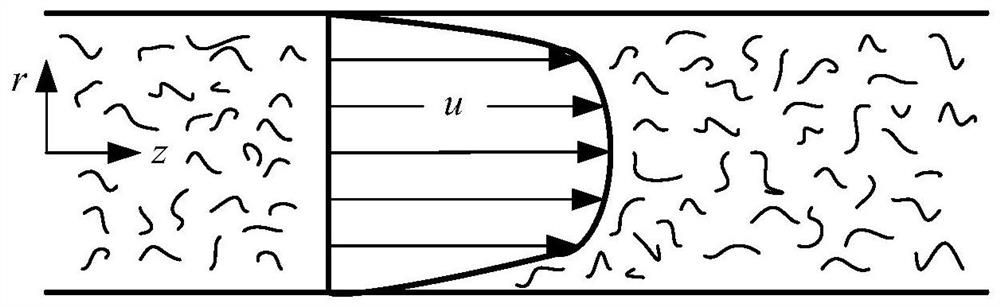

Partial flow equivalently-dynamic diluting and sampling system for diesel engine exhaust particles and control method

InactiveCN103018079ARealize the collection and measurement functionHigh control precisionProgramme controlComputer controlParticulatesClosed loop feedback

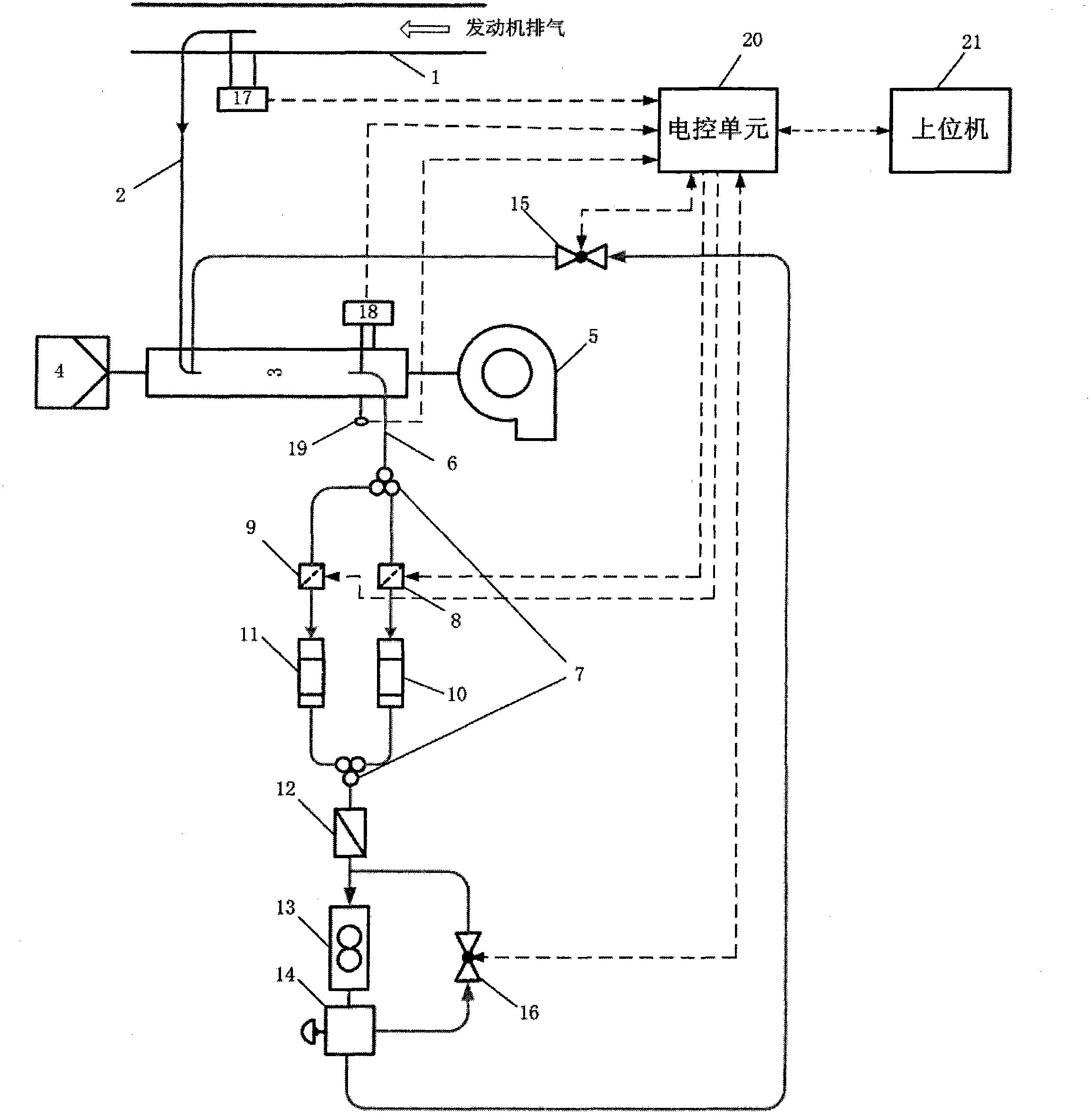

The invention discloses a partial flow equivalently-dynamic diluting and sampling system for diesel engine exhaust particles and a control method, belonging to the technical field of engine emission tests. The partial flow equivalently-dynamic diluting and sampling system is used for splitting the flow of engine exhaust with a constant ratio and introducing the engine exhaust in a diluting air duct by virtue of a flow-splitting and diluting pipeline with closed-loop feedback control, mixing the engine exhaust with clean air to form uniform diluted exhaust gas, introducing the diluted exhaust gas with a constant ratio in a sampling channel filter paper retainer by virtue of a particle sampling pipeline with closed-loop feedback control, collecting the exhaust particles by sampling filter paper placed in the retainer, and then detecting the emission level and the constituents of the diesel engine particles; the partial flow equivalently-dynamic diluting and sampling system can realize two-way transmission for data by an upper computer and a lower computer via an RS232 serial port communication protocol and a customized data format; and compared with the existing test system for diesel engine exhaust particles, the system has no need of a mass flow meter and an exhaust concentration analyser, and has the advantages of being high in control accuracy and low in test and maintenance costs.

Owner:JILIN UNIV

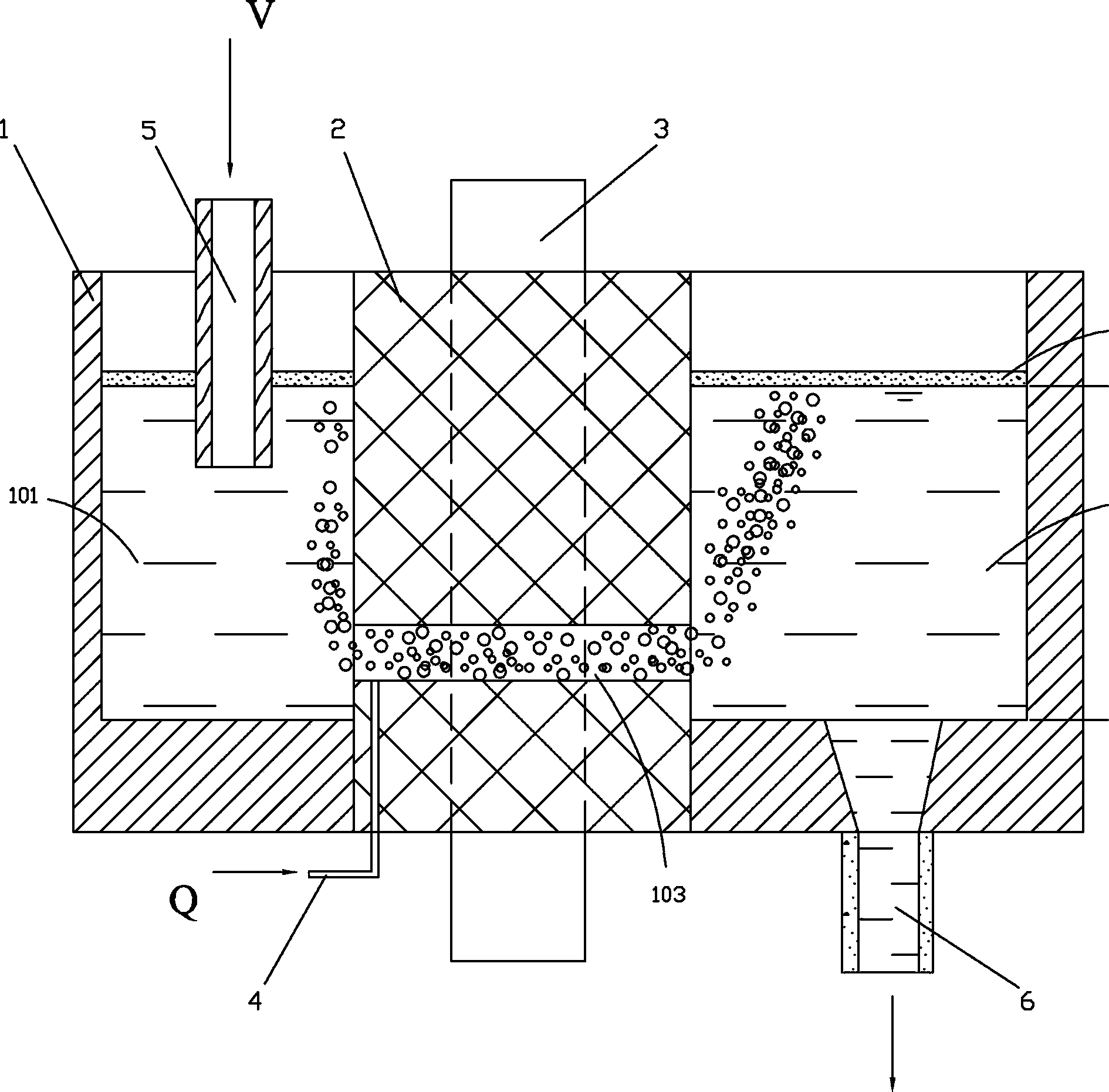

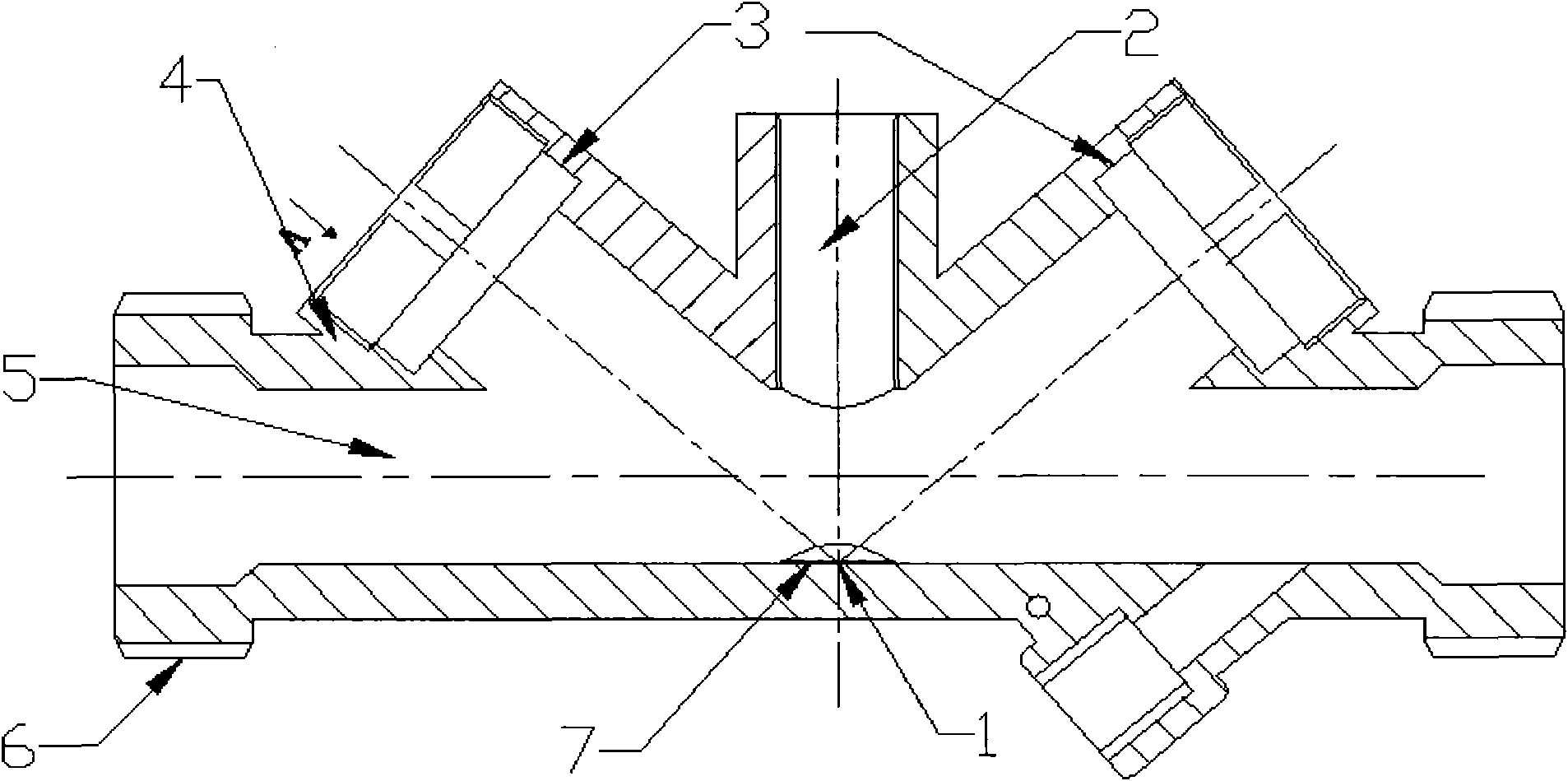

Channel type induction heating pouring basket and pouring method thereof

ActiveCN104249149APromote cohesion and buoyancyConstant levelMelt-holding vesselsMetallurgyInduction heater

The invention discloses a channel type induction heating pouring basket and a pouring method thereof. The channel type induction heating pouring basket comprises a pouring basket body, an induction heater and at least two air blowing pipes, wherein the inner part of the pouring basket body is separated into a molten steel containing cavity which is used for receiving large-basket molten steel and a molten steel pouring cavity which is used for pouring the molten steel by a refractory material, and at least two channels which are used for communicating the molten steel containing cavity with the molten steel pouring cavity are arranged in the lower part of the refractory material in parallel; the height of each channel is lower than 1 / 3 of the height of an inner cavity of the pouring basket body; an induction coil of the induction heater is arranged between the two channels in a penetrating way; the at least air blowing pipes are arranged in the refractory material of the pouring basket body, and outlets of the at least two air blowing pipes are correspondingly formed in inlet ends, which are positioned at the side of the molten steel cavity, of the channels. The channel type induction heating pouring basket disclosed by the invention can be applied to a continuous pouring whole process for removing impurities and enabling the temperature of the molten steel to be uniform.

Owner:BAOSHAN IRON & STEEL CO LTD

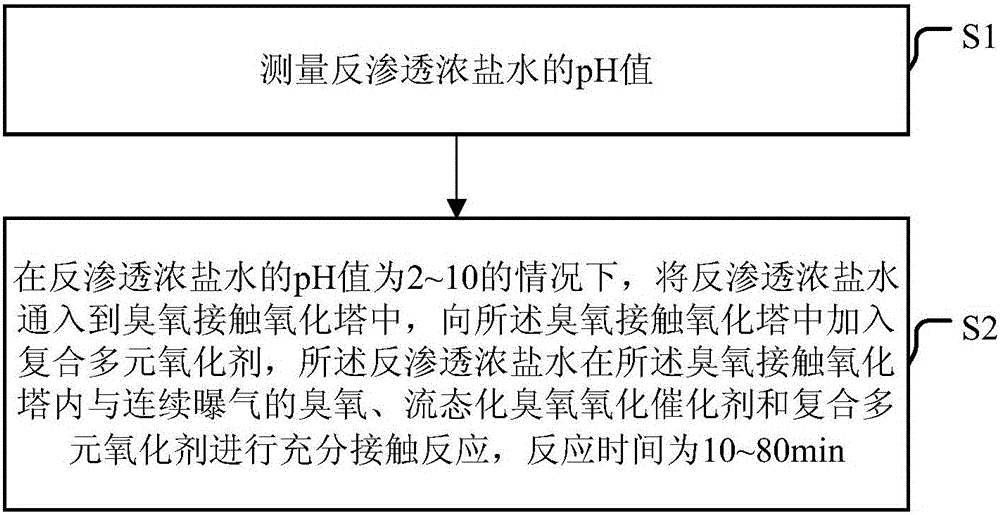

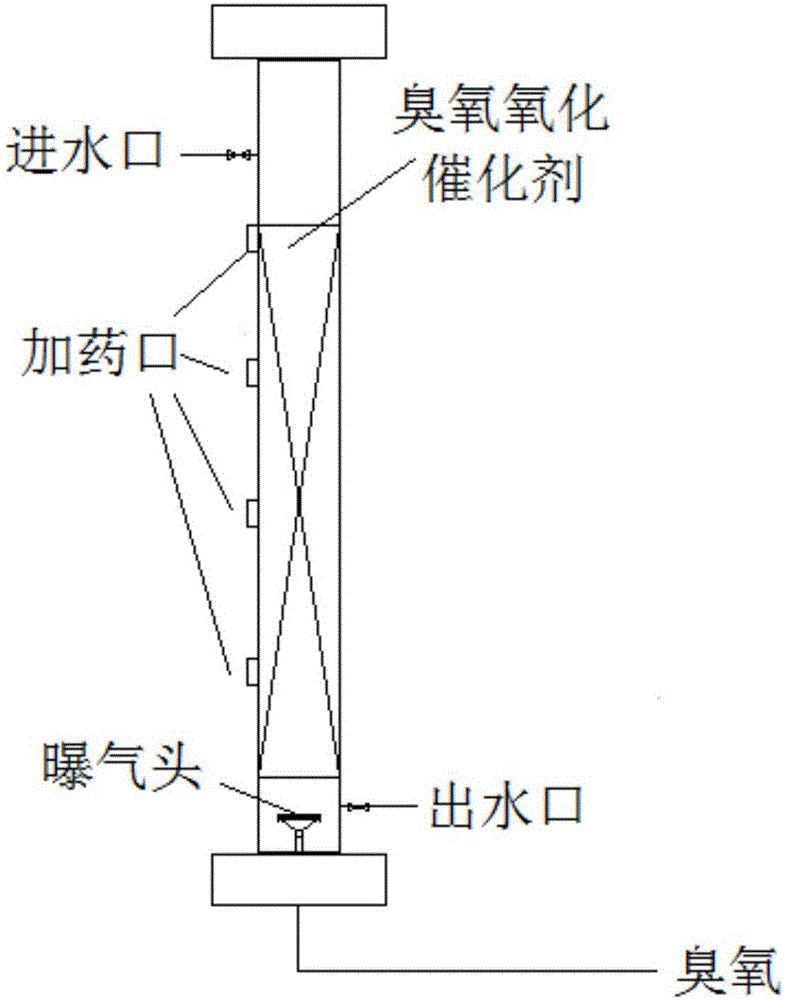

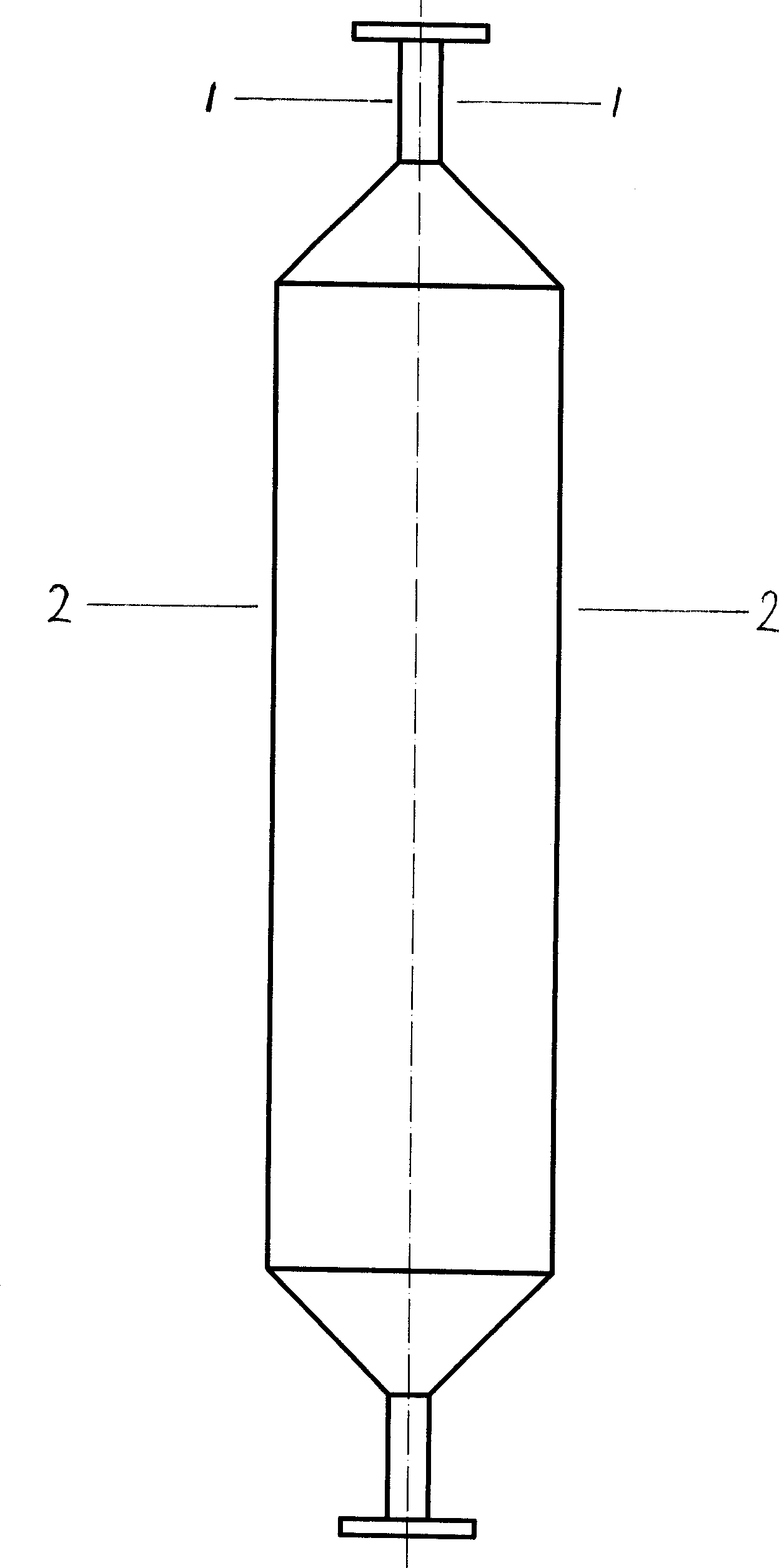

Catalytic oxidation treatment method of reverse-osmosis strong brine

InactiveCN105731629AFlow state is stableHigh catalytic efficiencyWater/sewage treatment apparatusWater/sewage treatment by oxidationReverse osmosisCatalytic oxidation

The embodiment of the invention discloses a catalytic oxidation treatment method of reverse-osmosis strong brine. The method includes the following steps of measuring the pH value of reverse-osmosis strong brine, introducing reverse-osmosis strong brine into an ozone contact oxidation tower when the pH value of reverse-osmosis strong brine is 2 to 10, adding compound multi-element oxidant into the tower, and conducting sufficient contact reaction on reverse-osmosis strong brine, continuous aeration ozone, a liquid ozone oxide catalyst and compound multi-element oxidant in the ozone contact oxidation tower for 10-80 minutes. The ozone contact oxidation tower is designed vertically, a water inlet is formed in the upper portion of the tower, a water outlet is formed in the lower portion of the tower, an ozone aeration head is arranged at the bottom of the tower, a bearing layer is arranged in the tower and filled with an ozone oxidation catalyst, and an addition opening of compound multi-element oxidant is formed in the outer wall of the tower. By means of the method, the mass transfer effect of gas, liquid and solid is enhanced, and the catalysis efficiency of the ozone oxidation catalyst is greatly improved.

Owner:POTEN ENVIRONMENT GRP

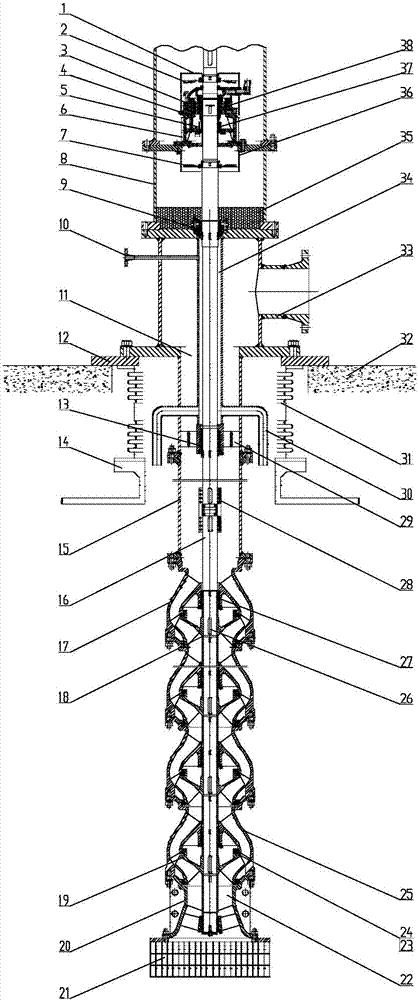

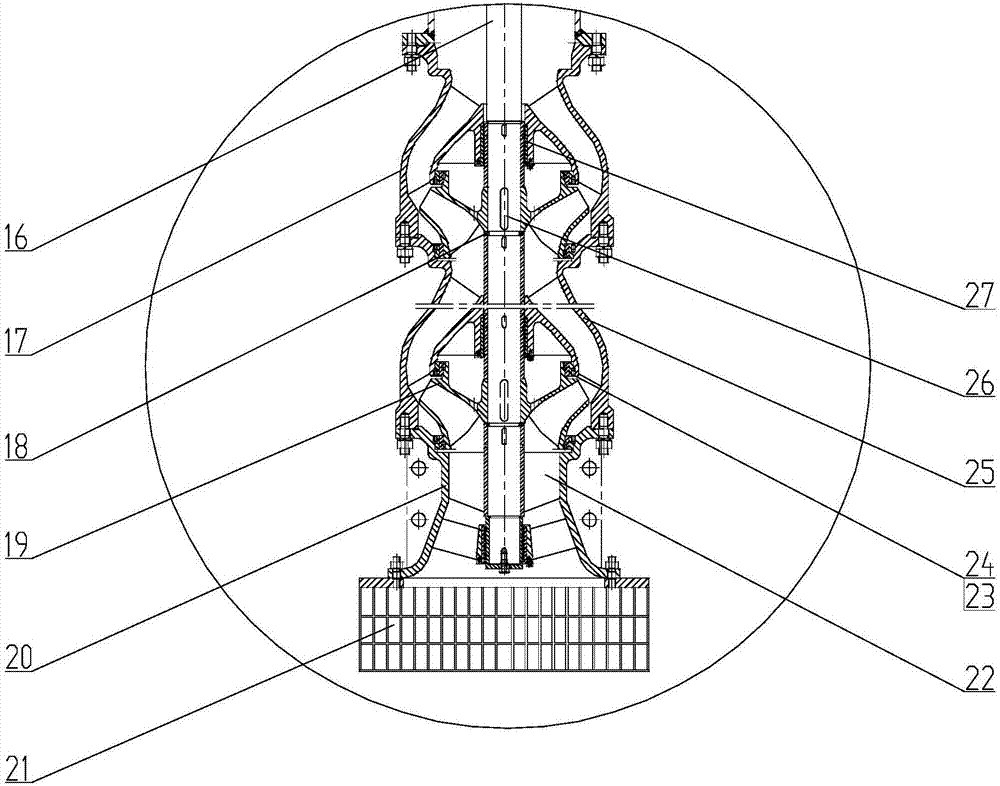

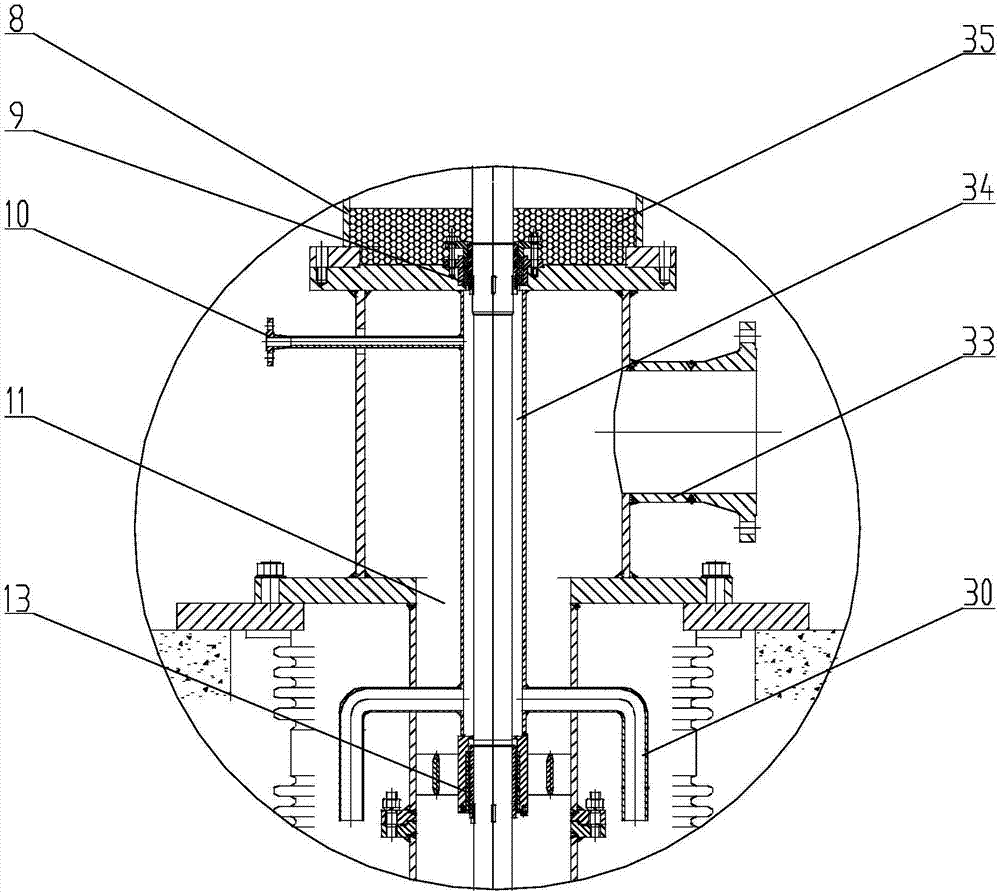

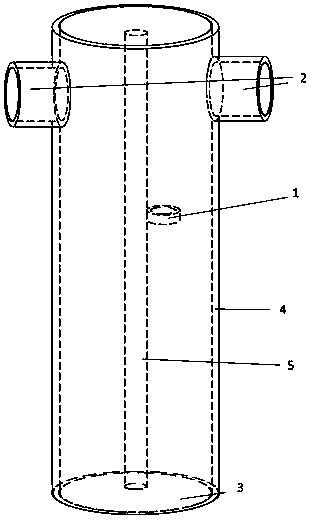

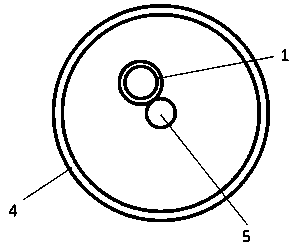

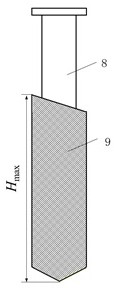

Solar thermal power high-temperature long shaft molten salt pump

PendingCN107355389AFlow state is stableMaximize power generationSpecific fluid pumpsPump componentsThermal dilatationMolten salt

The invention discloses a solar thermal power high-temperature long shaft molten salt pump. The solar thermal power high-temperature long shaft molten salt pump comprises a pump shaft, a hydraulic part, a supporting vibration reduction structure, a fluid seal structure and a bearing cooling device are sequentially arranged on the pump shaft from bottom to top, a suction segment is arranged at the front end of the hydraulic part, a blade grid type filter is arranged on the front end of the suction segment, a tail stage flow guide shell is arranged at the tail end of the hydraulic part, the tail end of the tail stage flow guide shell and the front end of a supporting pipe of the supporting vibration reduction structure are fixedly connected, and the tail end of the supporting pipe of the supporting vibration reduction structure is fixedly connected with the bottom of the outlet segment of the fluid seal structure through a flange plate. The solar thermal power high-temperature long shaft molten salt pump is designed to be in the center flow-out manner, thermal expansion uniformity under the high-temperature state can be ensured, through solution schemes of reliable fluid seal design, reasonable cooling structures, flange type expansion joint vibration reduction configuration and the like, safe, reliable and efficient running of the solar thermal power high-temperature long shaft molten salt pump is ensured, and meanwhile, various property indexes are met.

Owner:DALIAN DEEP BLUE PUMP CO LTD

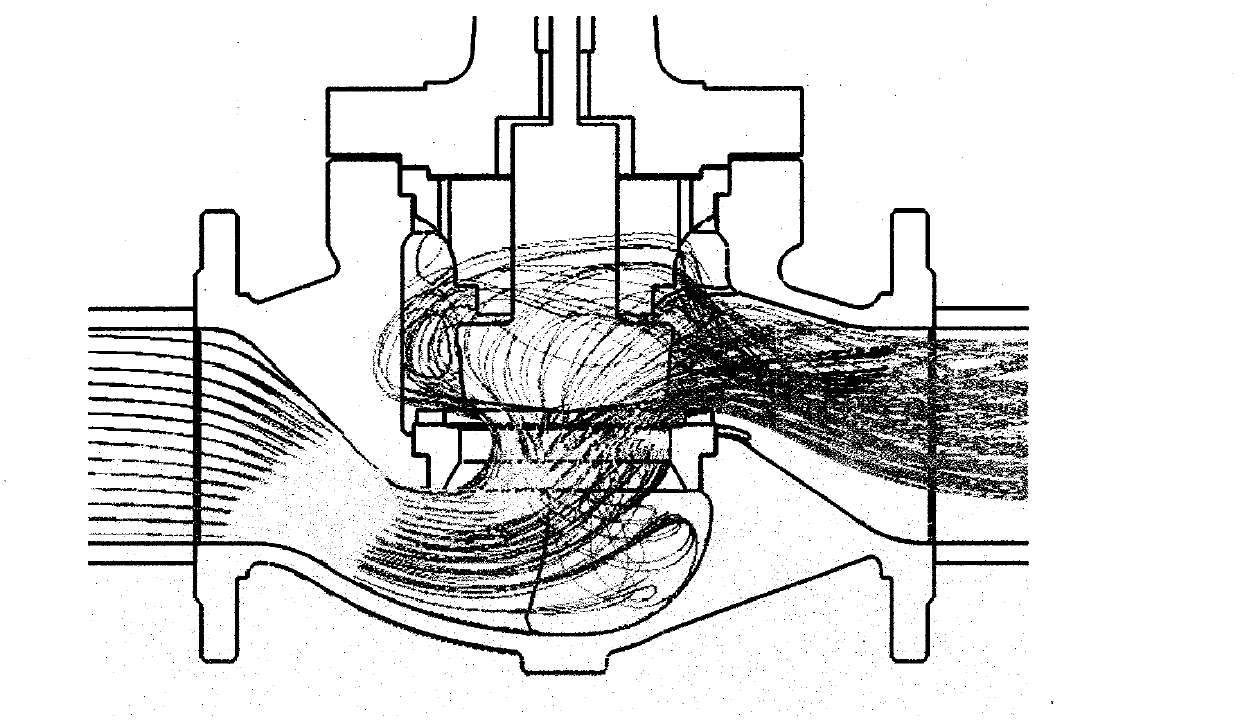

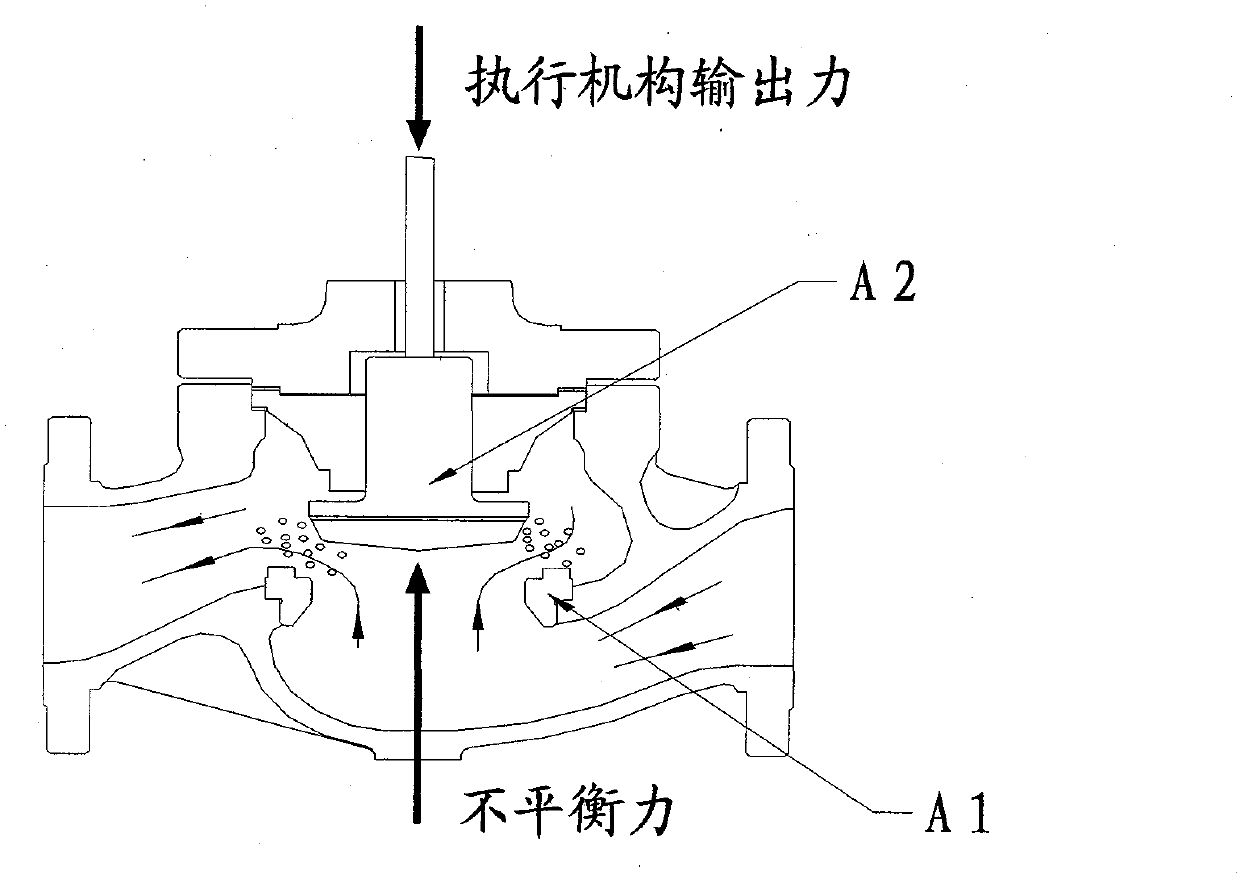

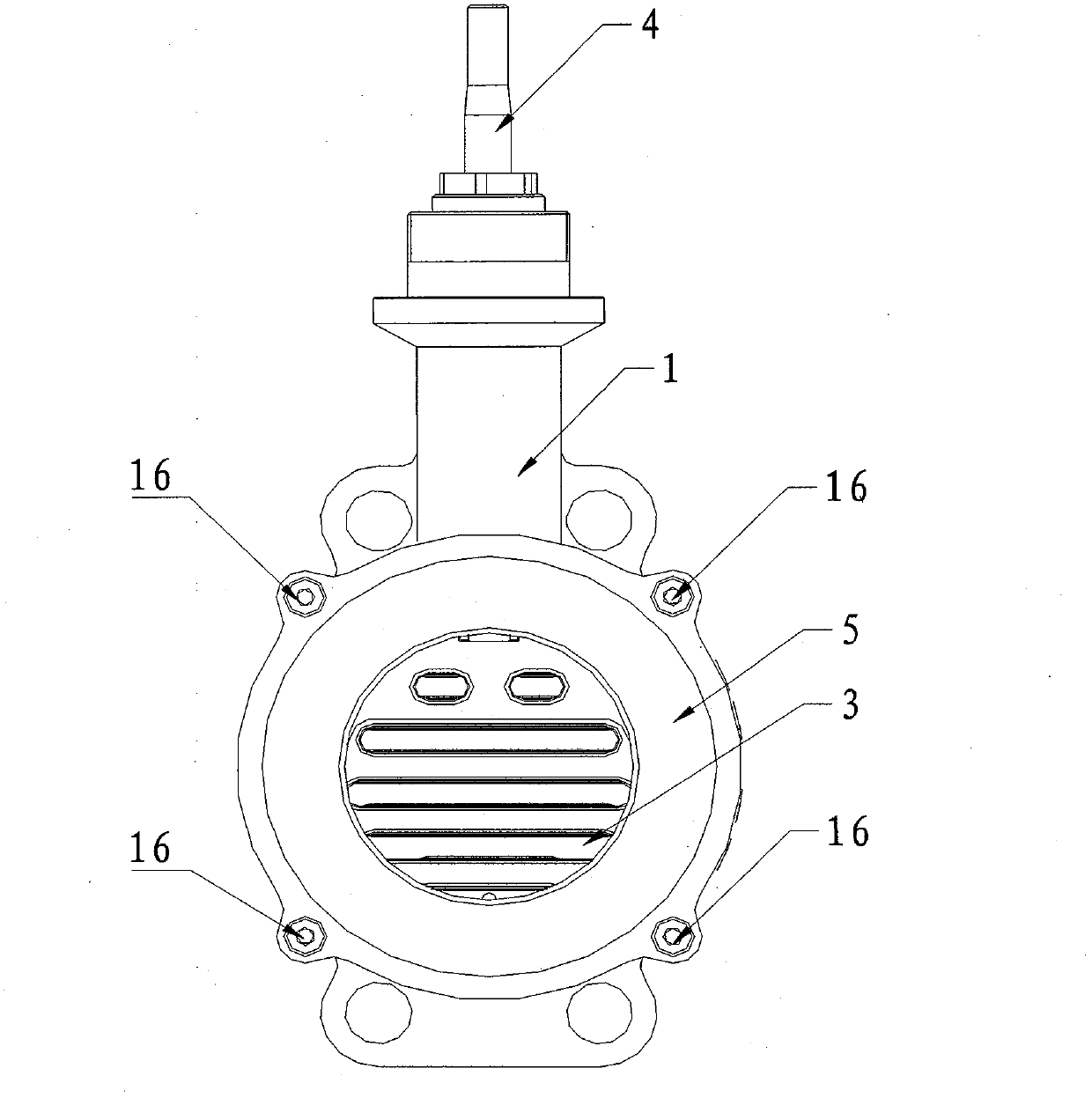

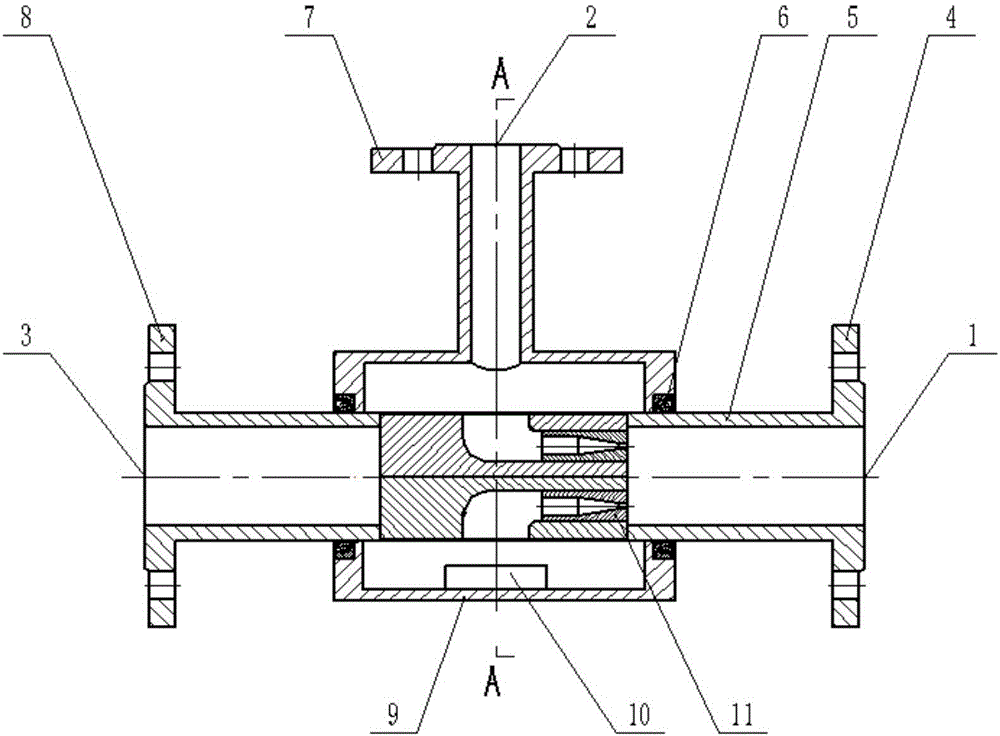

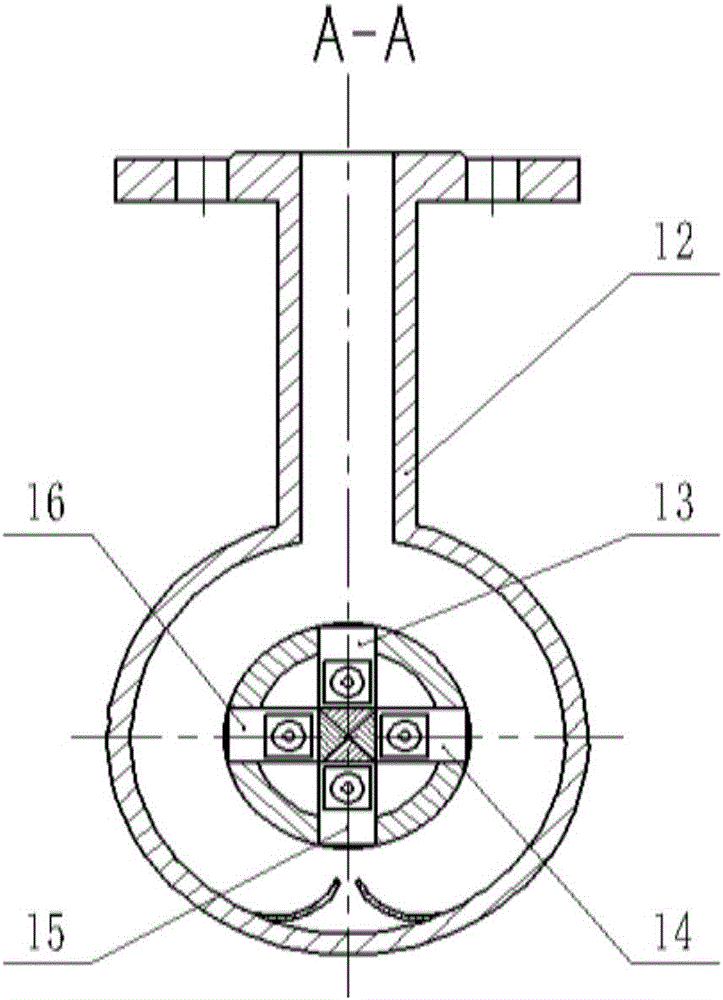

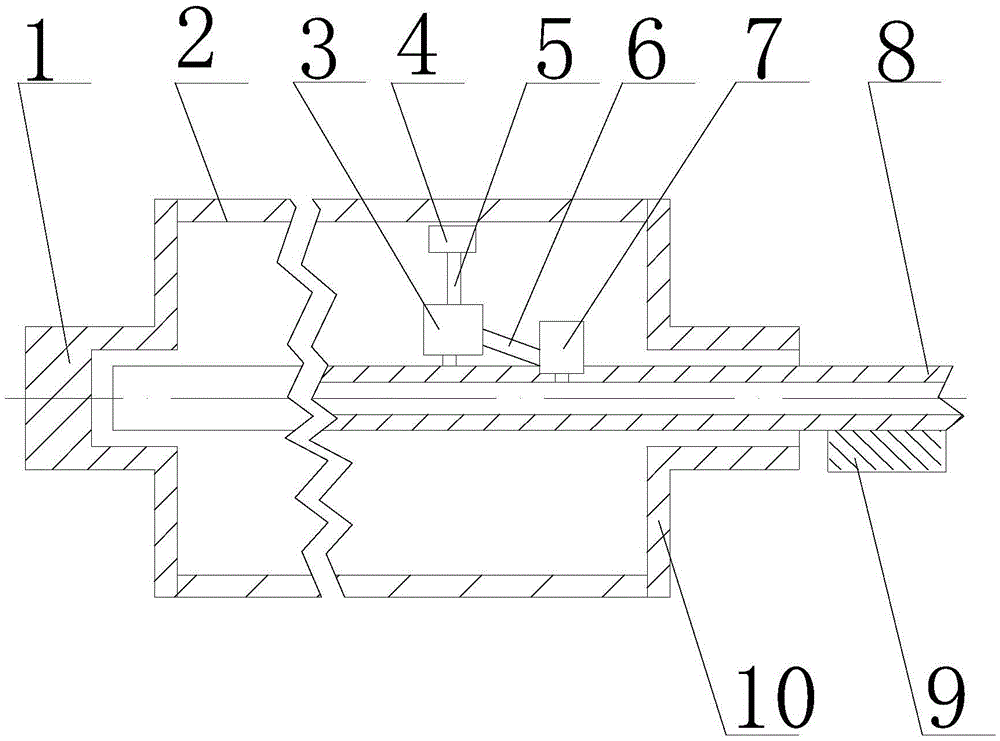

Regulating valve

The invention provides a regulating valve. The regulating valve comprises a valve body, wherein a valve seat is fixedly arranged inside the valve body, valve seat throttling openings which are used for fluid to flow through are formed in the valve seat, a pressing cover is fixedly arranged at one side of the valve body, a gap is formed inside the valve body by the pressing cover and the valve seat, a sliding plate which can slide up and down along the valve seat is inserted into the gap, a planar sealing pair is formed by the sliding plate and the valve seat, sliding plate throttling openings corresponding to the valve seat throttling openings are formed in the sliding plate, the valve seat throttling openings and the sliding plate throttling openings are staggered when the sliding plate moves up and down relative to the valve seat, so as to control the pressure and flow of the fluid flowing through the regulating valve, and a retaining ring which is used for compacting the sliding plate and the valve seat is further arranged between the sliding plate and the pressing cover. According to the regulating valve, when the fluid flows through the valve, the phenomena of gas etching and cavitation difficultly occur, the flushing damage to sealing faces is little, and the condition that the regulating accuracy of the regulating valve is poor due to the effect of unbalanced force during the opening / closing of a valve core is reduced.

Owner:CHONGQING CHUANWU INSTR

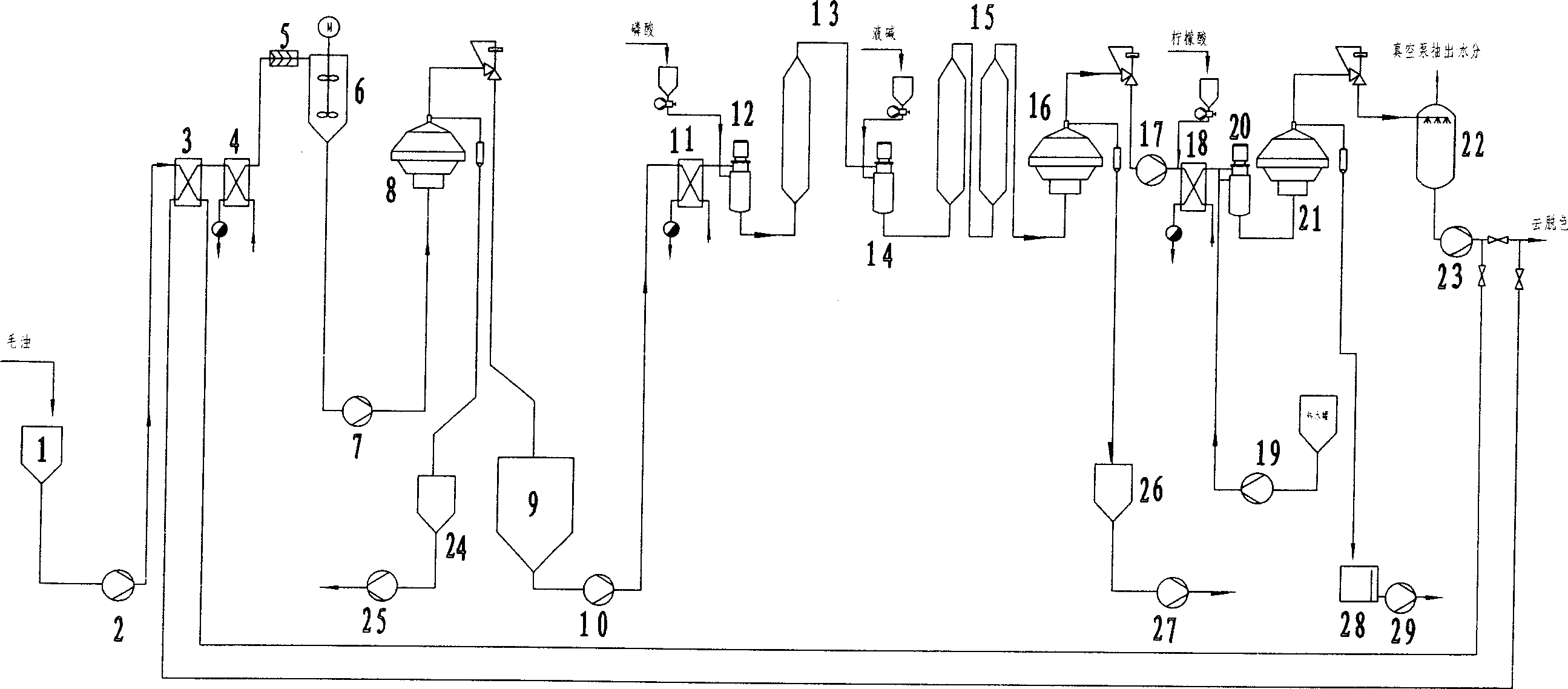

Continuous oil fat refining process

ActiveCN1896204AStrenuous exerciseEvenly dispersedFatty acid esterificationOil and greaseContinuous reactor

A continuous grease refinery process is carried out by felt oil-water debonding, acid refining, alkali refining, desoaping, washing and drying. It substitutes continuous acid refining reactor or / and continuous alkali refining reactor with alkali delay pot. It has homogeneous mix, proper contact time and full reaction.

Owner:SHANDONG XIWANG FOOD

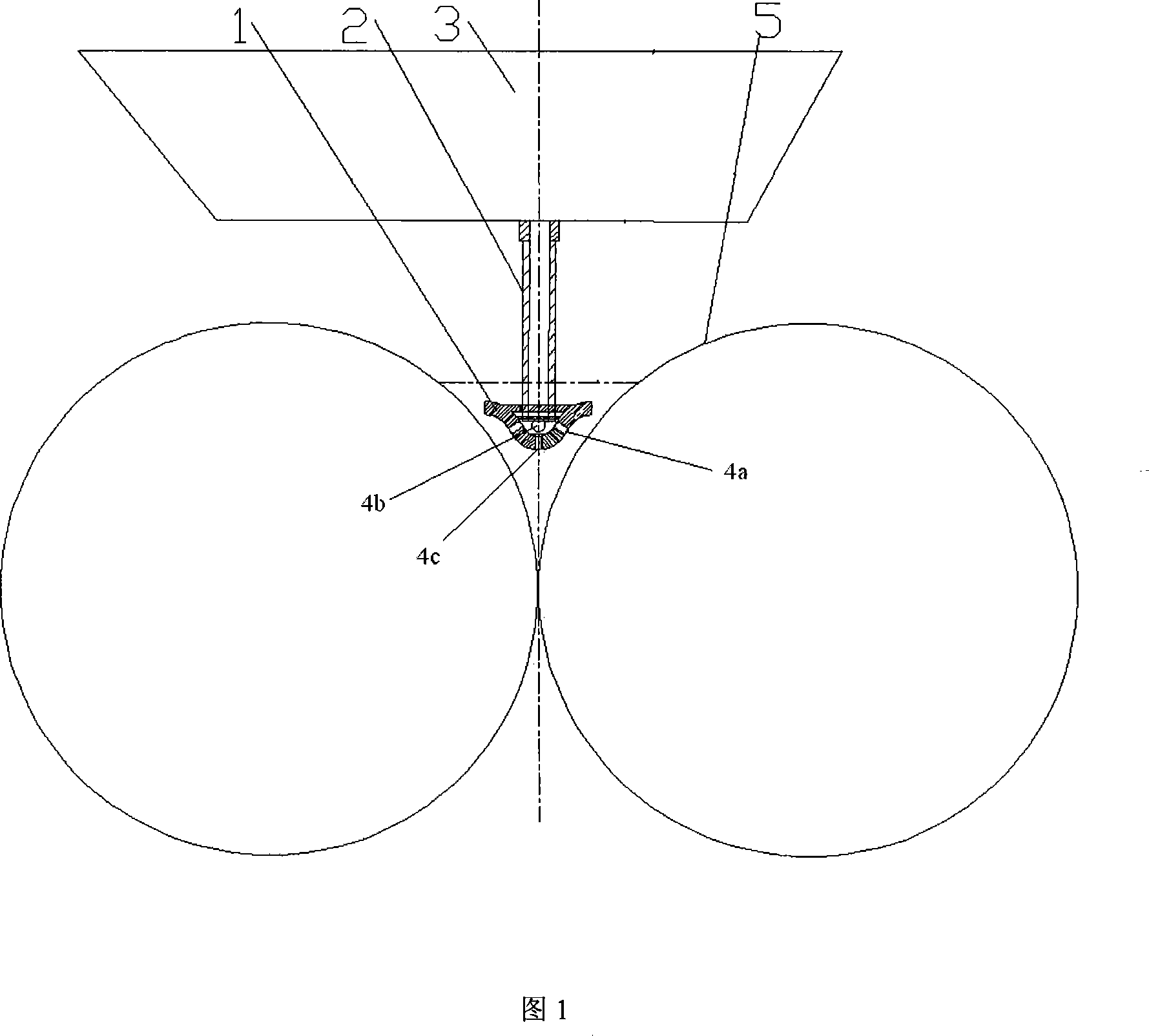

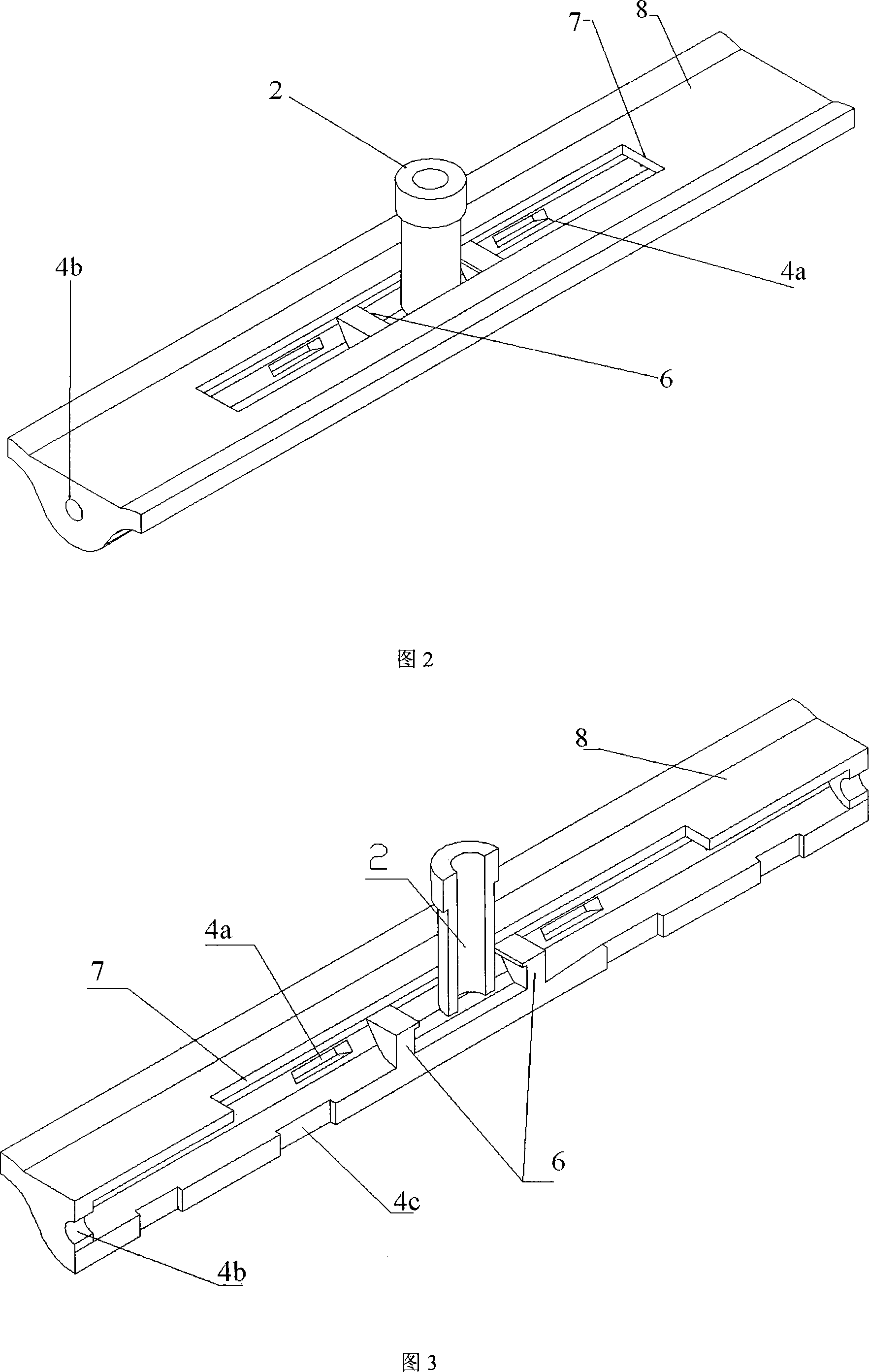

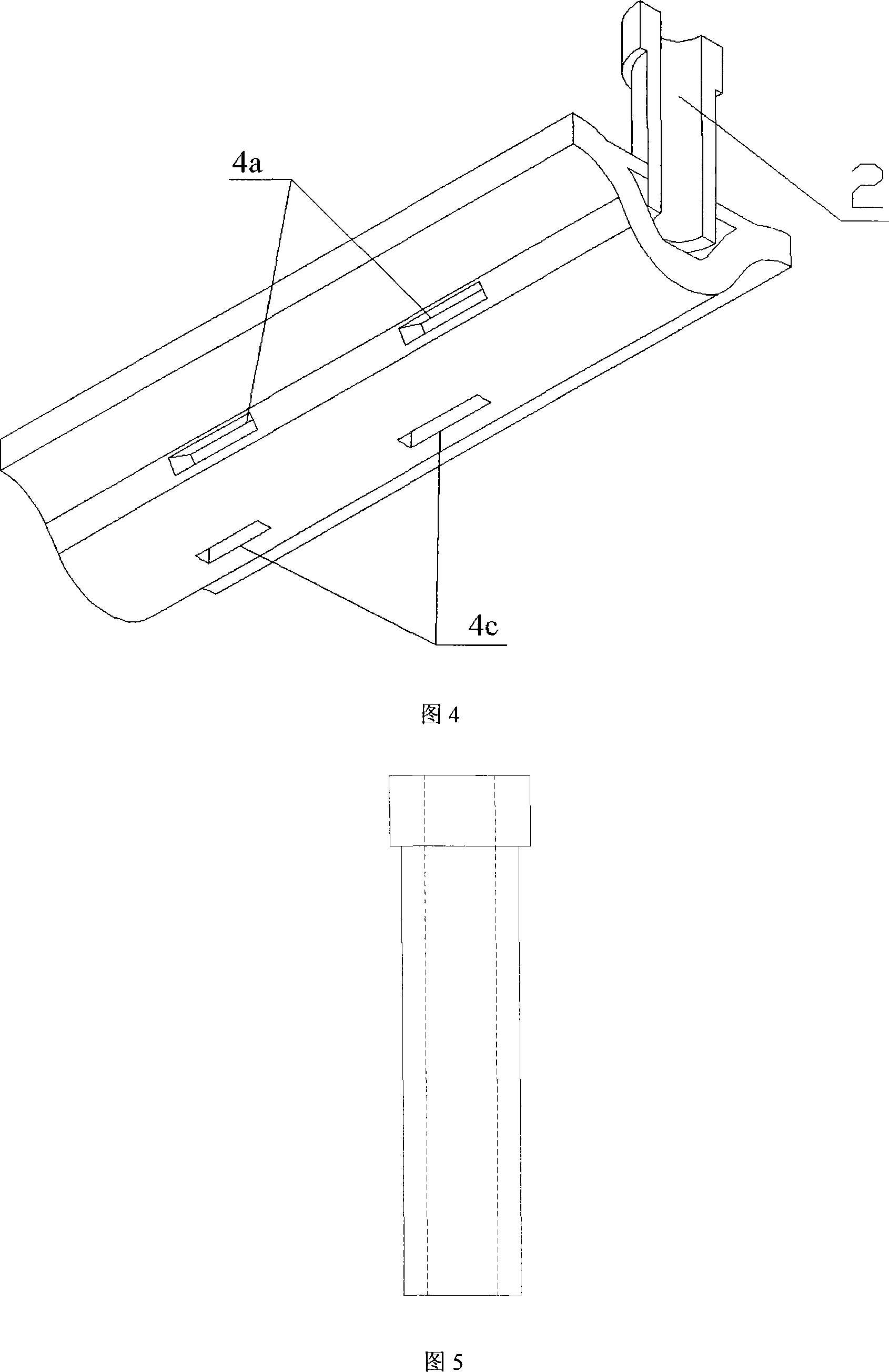

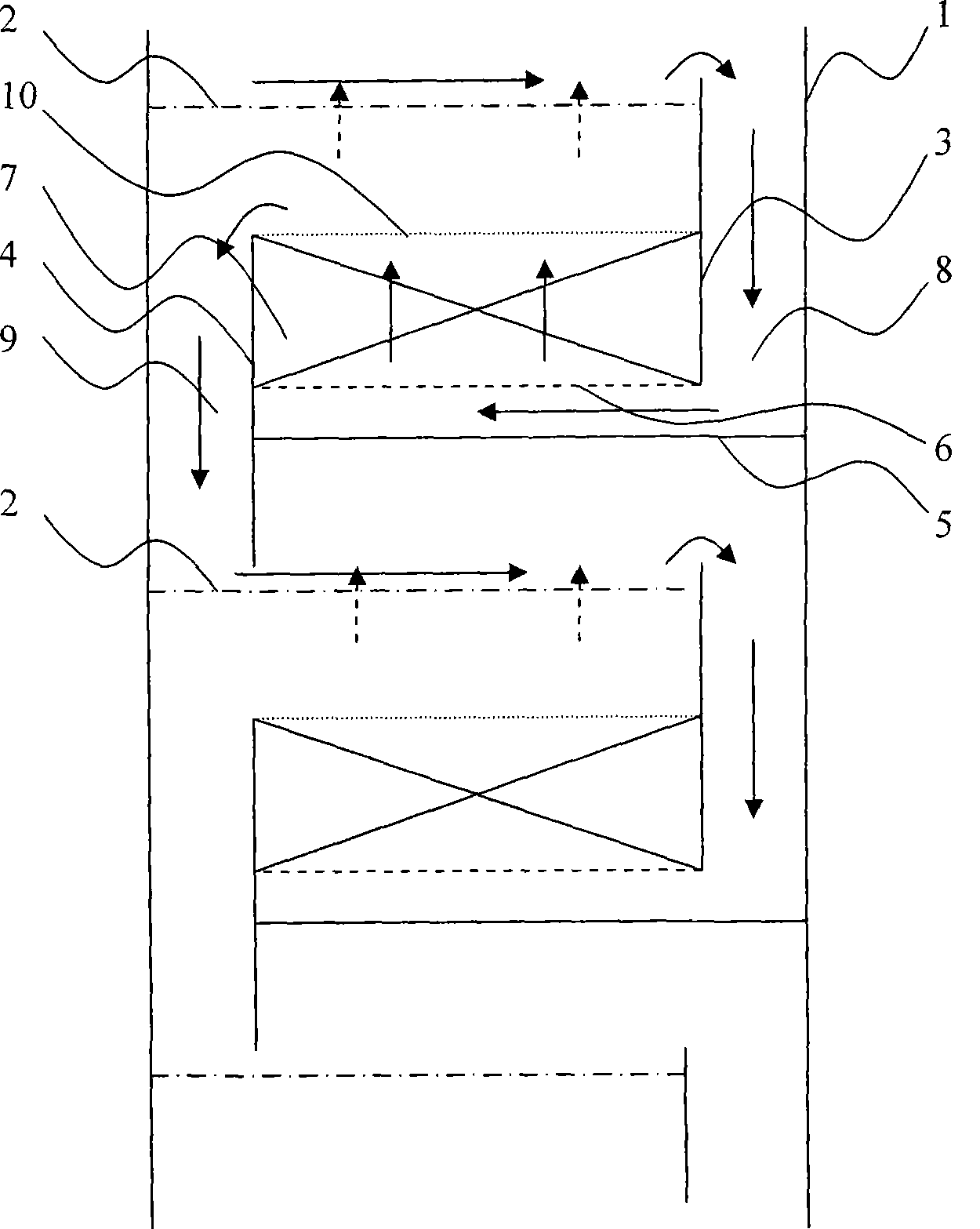

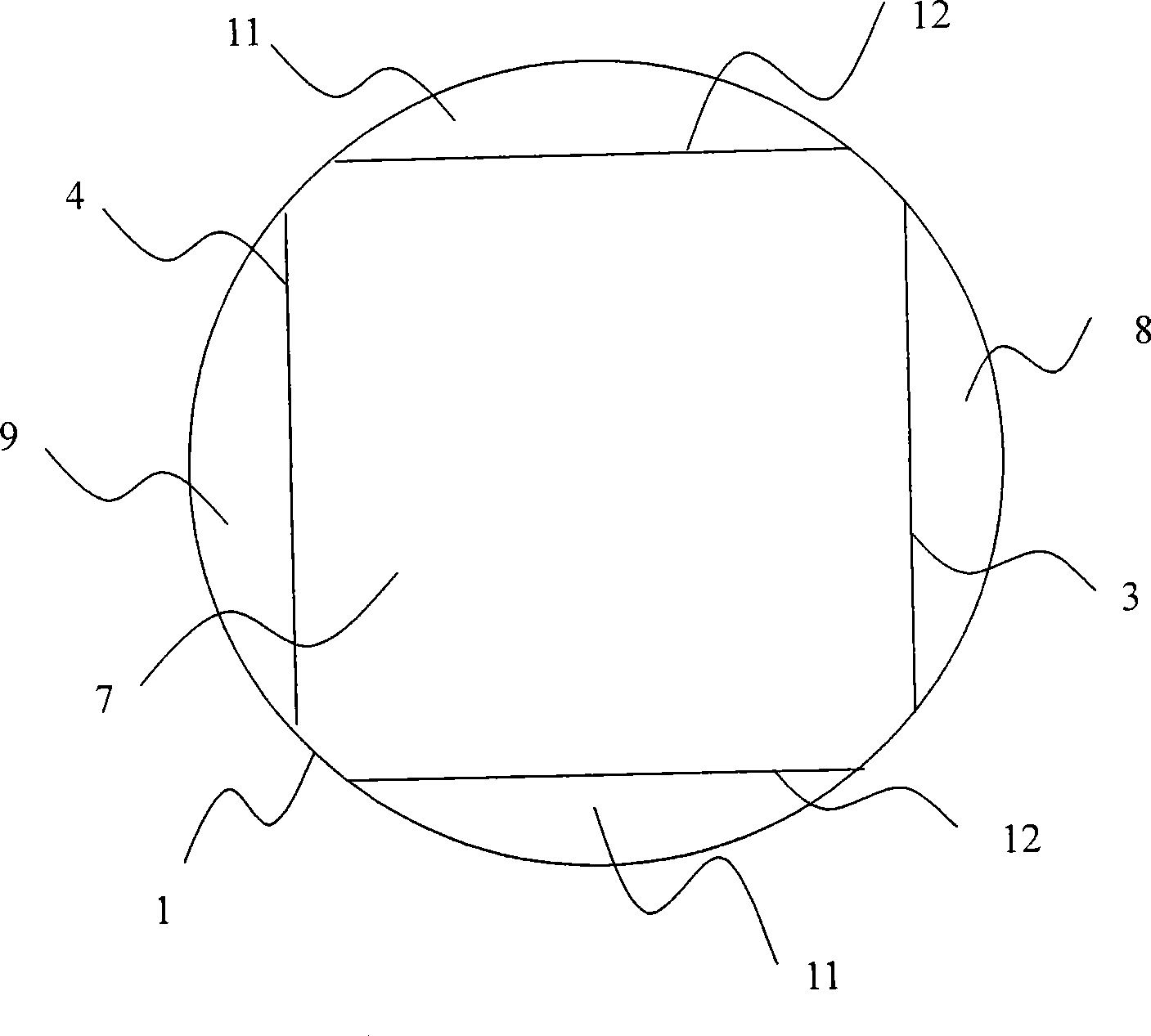

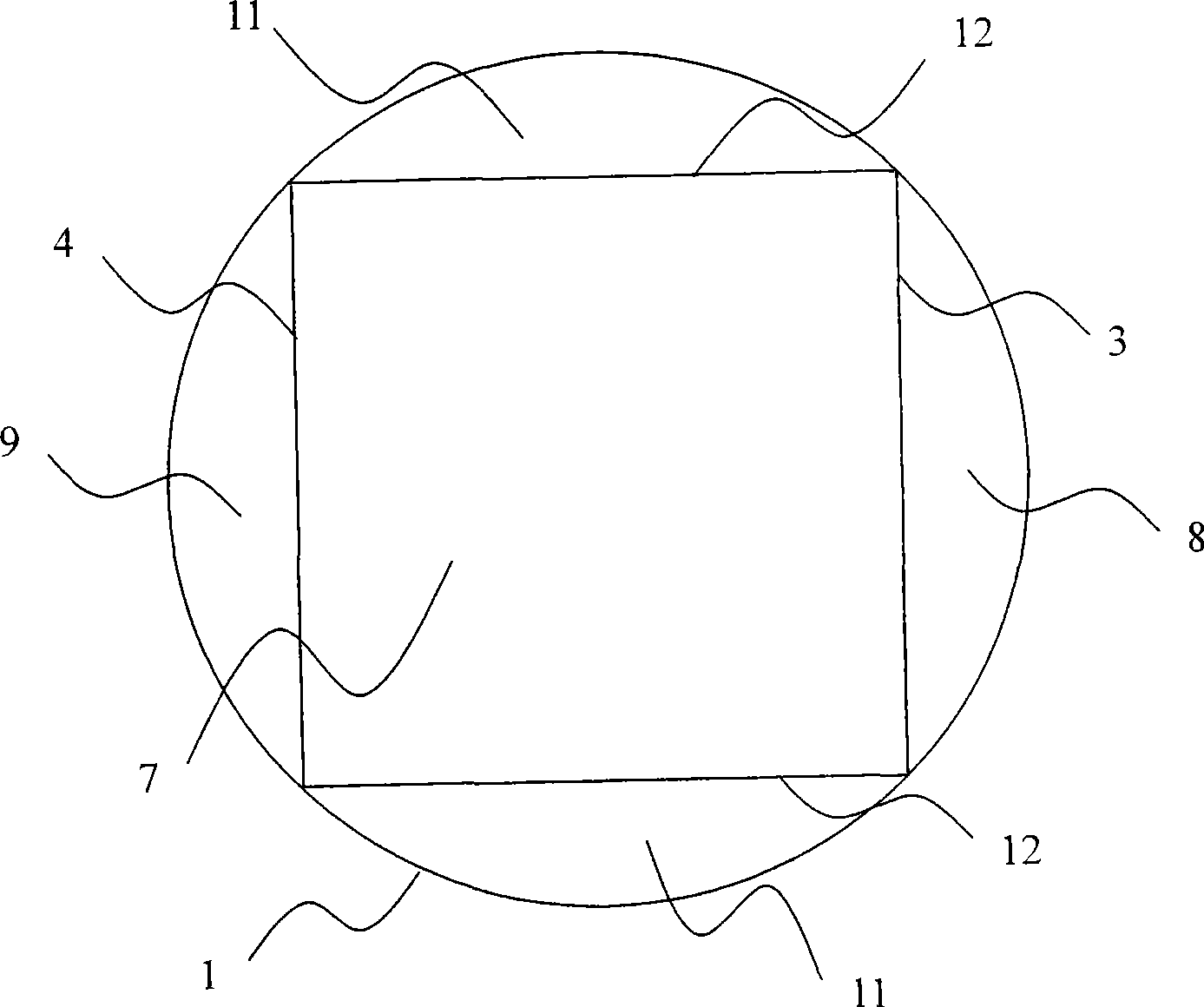

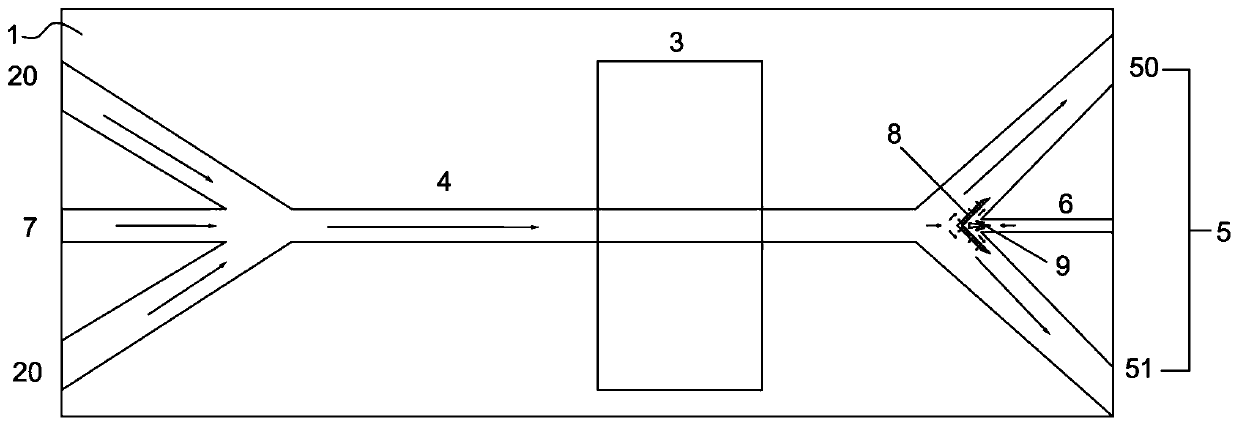

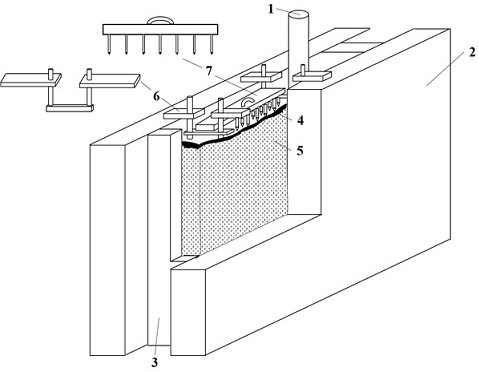

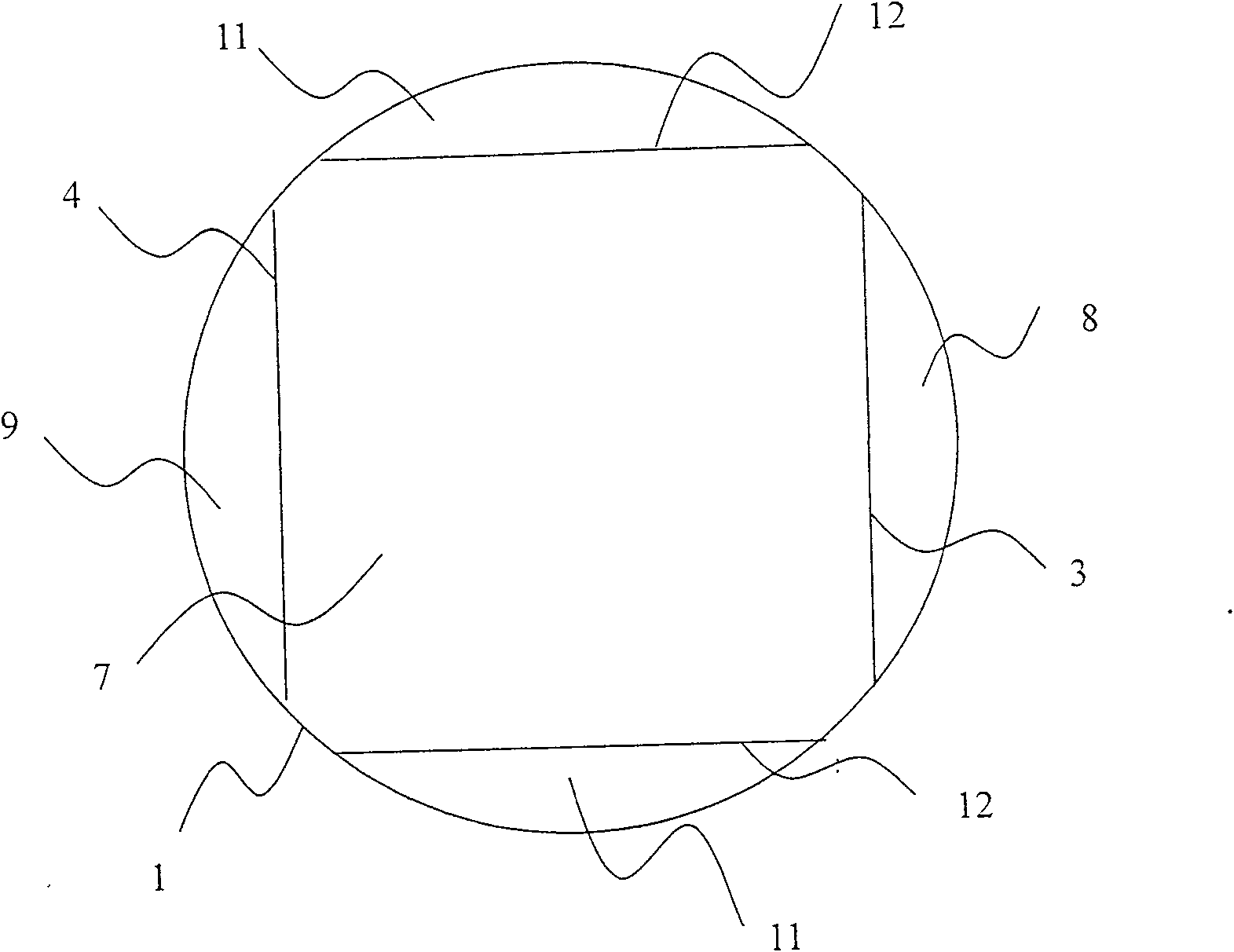

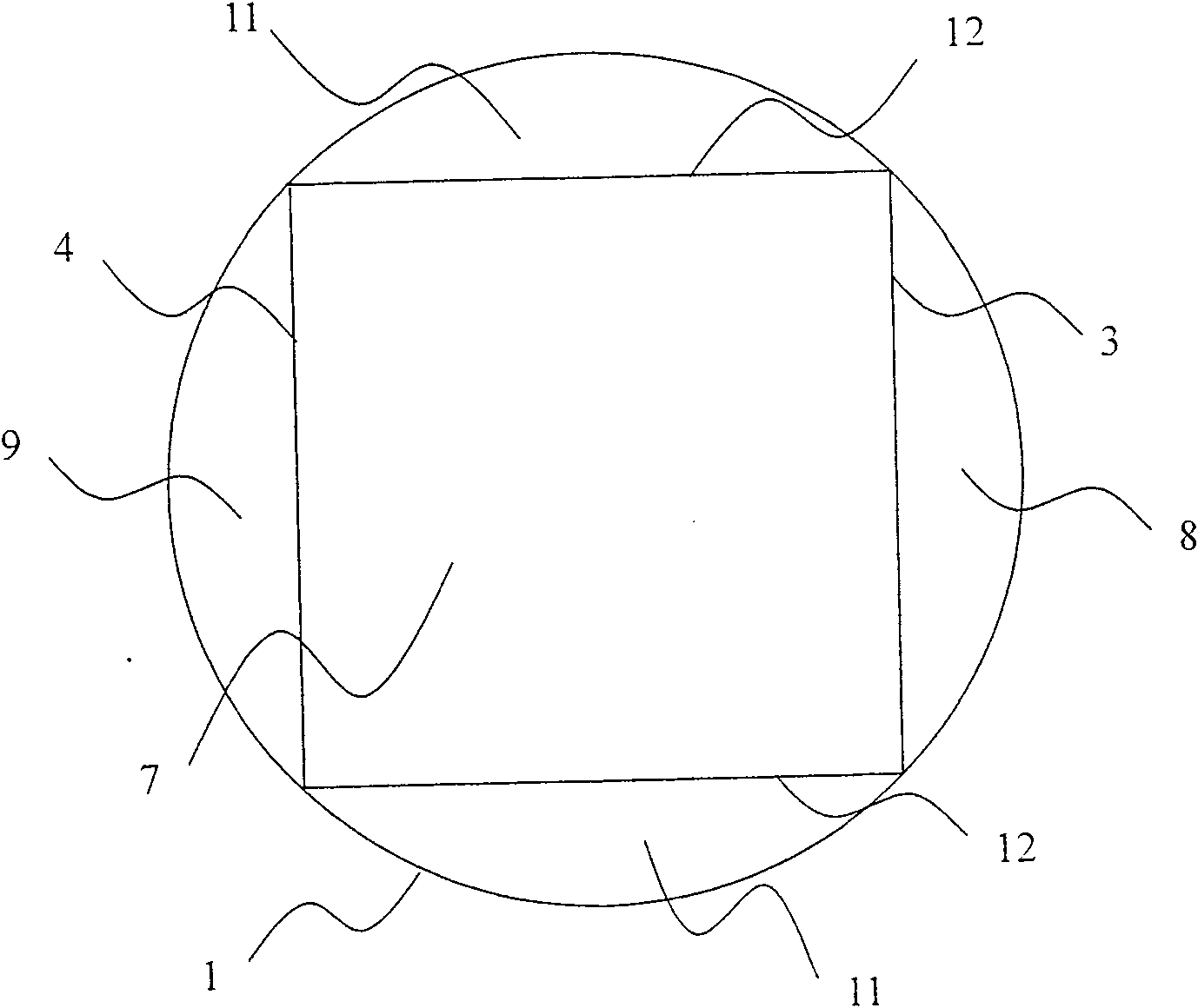

Steady flow distribution device for dual-roller thin band continuous casting

The invention relates to a steady-flow delivery device used in twin-roll strip continuous casting production process, which belongs to twin-roll strip continuous casting process technology field. The invention mainly comprises a delivery device with delivery holes and a submerged nozzle; the whole exterior shape of the delivery device is a scaphiform and the cross section is of ''V'' shape with the bottom being a arc. The delivery device is immerged in the steel water in the melting pool. The delivery device is provided with a plurality of delivery holes, including end delivery holes, side delivery holes and bottom delivery holes. A cavity is arranged inside the delivery device which is provided with a cover board on the top half, and a rectangular slot bore is arranged on the cover board, the middle of the delivery device is provided with two steady-flow chamber which is formed by two retaining walls to inhibit turbulent flow; the steel water flows out from the lower end of the submerged nozzle to the steady-flow chamber with retaining walls firstly and then flows out through the retaining walls of the chamber to the cavity space on the both sides and then flows out through a plurality of delivery holes to the melting pool between the twin-roll. The device can stabilize the turbulent flow and the liquid surface, thus leading to the even temperature of the steel liquid in the melting pool and facilitating operation.

Owner:SHANGHAI UNIV

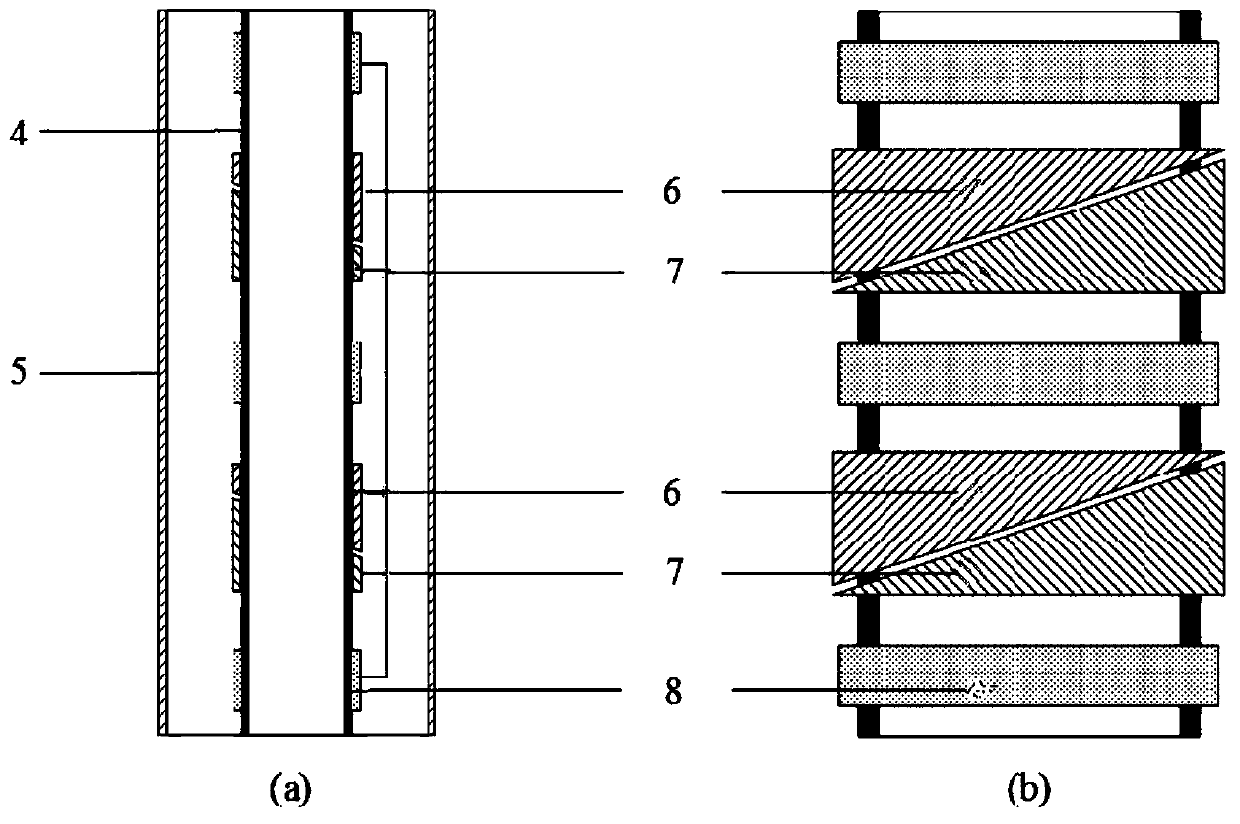

Reaction segment structure of catalytic distillation tower

InactiveCN101391150AAvoid problems with greater resistance to flowFlow state is stableChemical/physical processesFractional distillationReaction zoneCatalytic distillation

Disclosed is a catalytic distillation tower reaction zone structure, and a reaction zone consists of a catalyst tray and a separation tower tray in alternating arrangement, and the catalyst tray is partitioned into down-flow zones, a catalyst filling zone and a vapor phase channel by a plurality of vertical baffles; and the catalyst filling zone is composed of a horizontal baffle positioned at the bottom part, a horizontal support plate on the horizontal baffle at the bottom part, and a semi-enclosed space between the plurality of vertical baffles and part of tower walls; the two down-flow zones are formed between part of vertical baffles and near tower walls, and the vapor phase channel is formed between the rest part of vertical baffles and near tower walls or between the vertical baffles. The catalyst is filled in the semi-enclosed space enclosed by the vertical baffles, part of tower walls and the support plate, the space between the baffle at the bottom part and the support plate is communicated with the separation tower tray on a catalyst bed through the down-flow zones, and is communicated with the catalyst bed through an opening or a gap of the support plate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

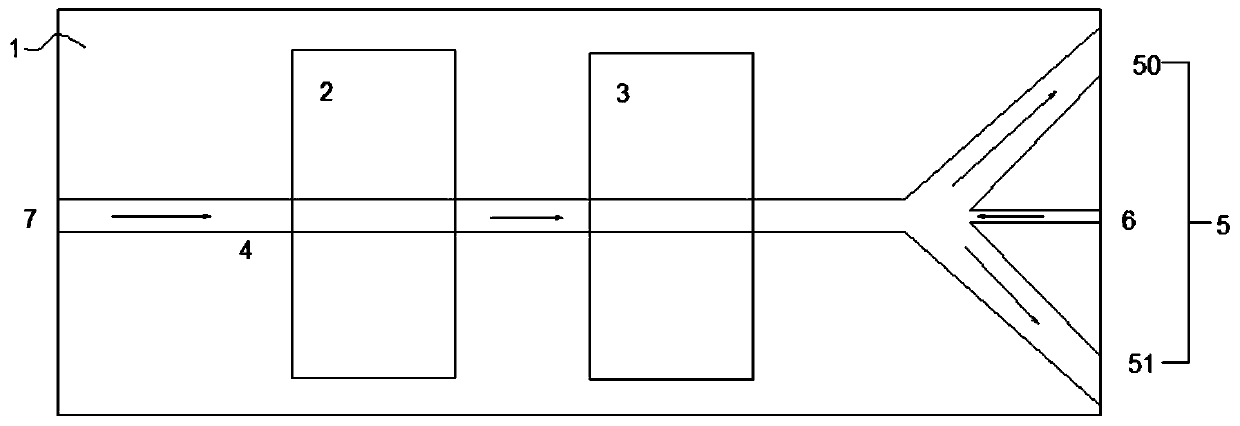

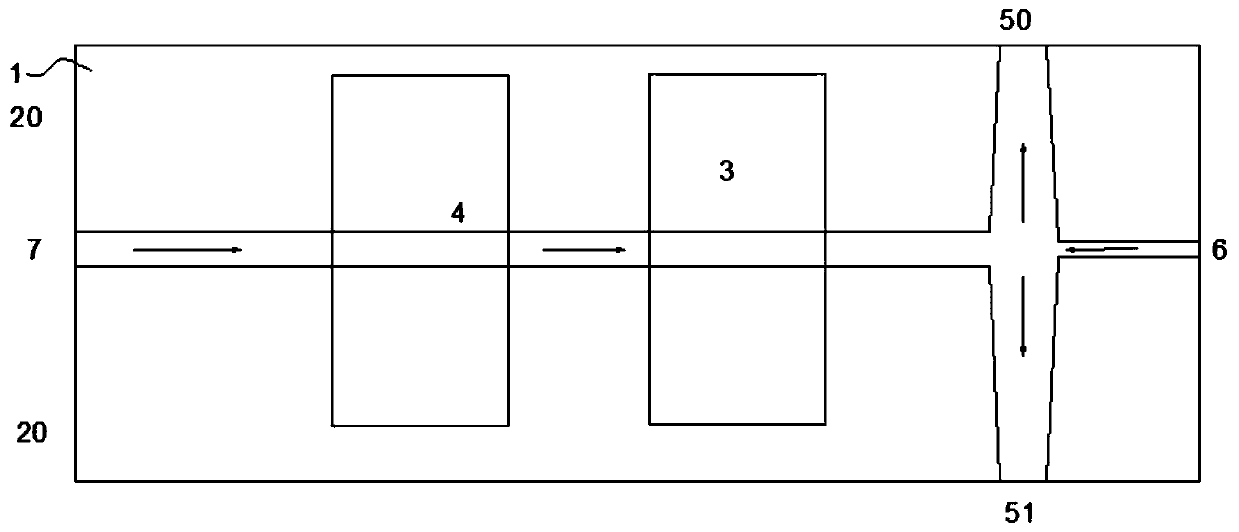

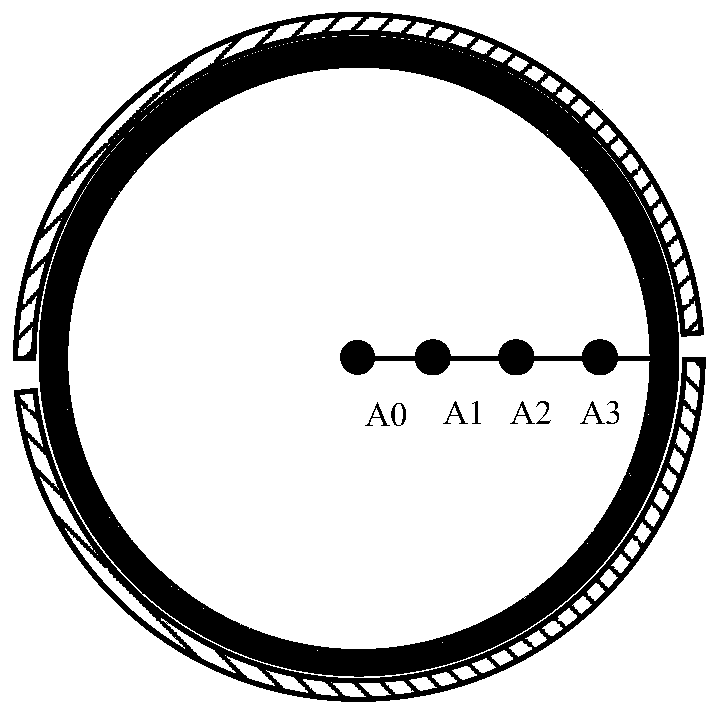

Microfluidic chip for preventing cell occlusion by using sheath fluid countercurrent

PendingCN110343603APrevent flow channel from cloggingImprove analysis or sorting accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsMicrofluidic chipEngineering

The invention discloses a microfluidic chip for preventing cell occlusion by using sheath fluid countercurrent. The microfluidic chip comprises a microfluidic chip main body, which has a focusing module, a sorting module and a main flow channel. The main flow channel is bifurcated at an outlet end of the microfluidic chip main body to form two liquid flow channels, a countercurrent sheath liquid flow path communicating with the main flow channel is disposed between the two flow channels, and the countercurrent sheath liquid flow path is provided with countercurrent sheath liquid opposite to the flow direction of the main flow channel. The microfluidic chip can solve the problem that the cells or particles adhere to a V-shaped wall surface in the prior art, which can prevent the flow channel from being blocked, improves the analysis or sorting precision, avoids the repeated removal and washing of the chip, and reduces the cost. The countercurrent sheath fluid of the present invention cooperates with the sheath fluid in the main flow channel to refocus a sample, and the cells stably flow out of the chip can be ensured.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI +1

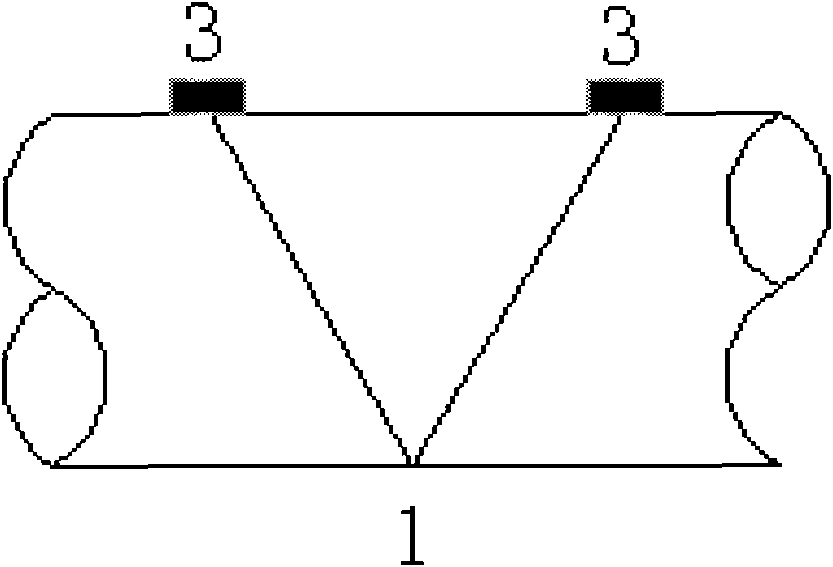

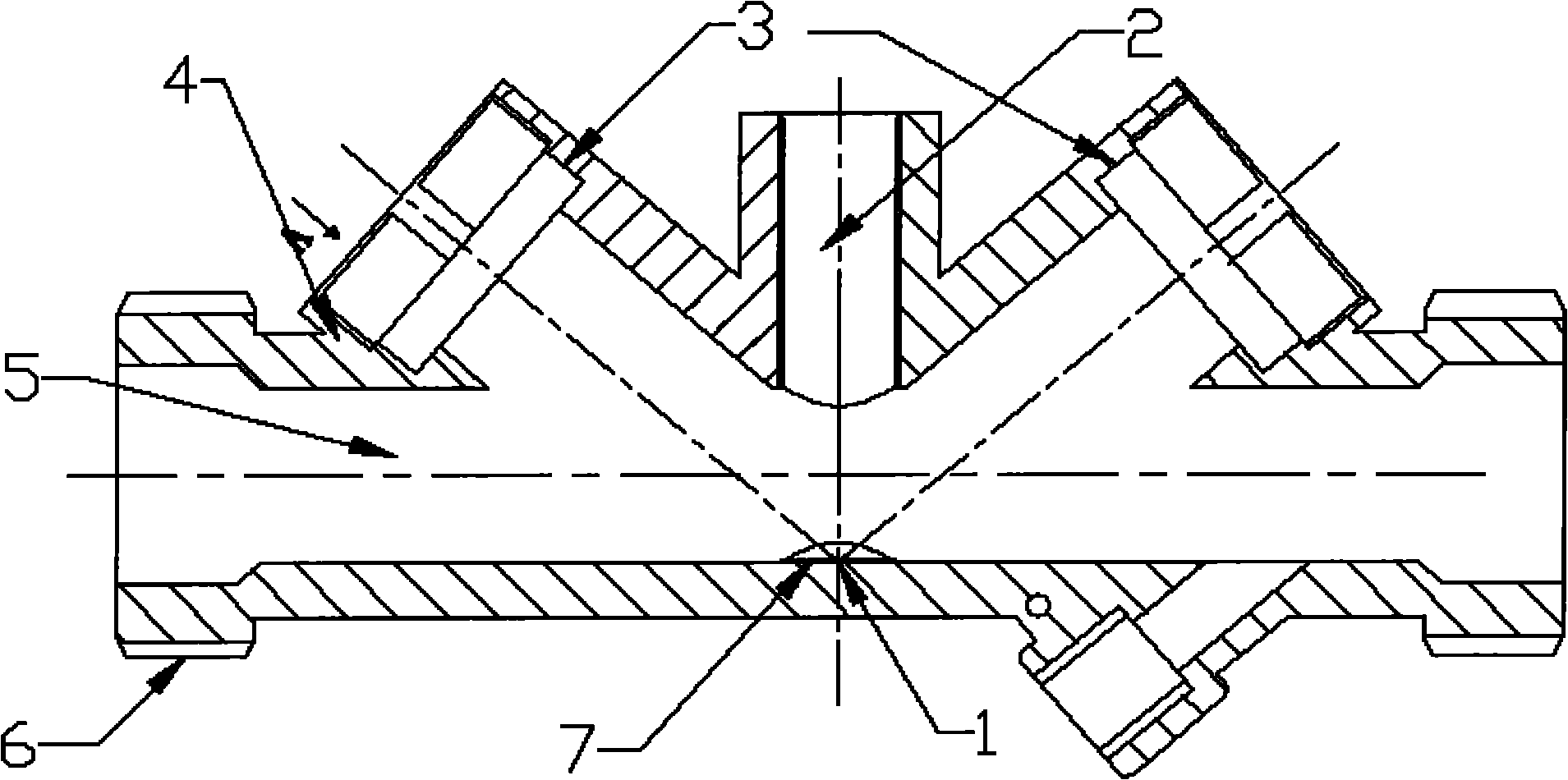

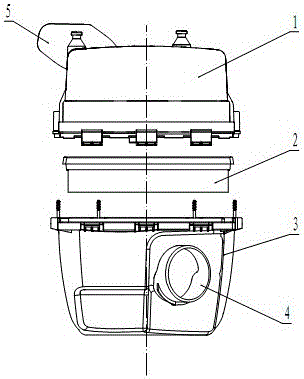

Straight-through reflecting type ultrasonic water meter and heat meter flow sensor

InactiveCN101839735ASimple structureAccurate measurementVolume/mass flow measurementCalorimeterEnergy converterUltrasound

The invention belongs to the technical field of metering appliances, and particularly discloses a straight-through reflecting type ultrasonic water meter and a heat meter flow sensor. The flow sensor comprises a sensor shell and is characterized in that the middle of the inner wall of the sensor shell is provided with a reflector platform; two ultrasonic energy converters are arranged on the inner wall of the sensor shell opposite to the reflector platform up and down; and a central perpendicular line of the reflector platform and central perpendicular lines of reflecting surfaces of the two ultrasonic energy converters are at the same plane. The straight-through reflecting type ultrasonic water meter and the heat meter flow sensor have the advantages of simple structure, safety, stability, accurate measurement, stable fluid flow state and small pressure loss.

Owner:邓鲁坚

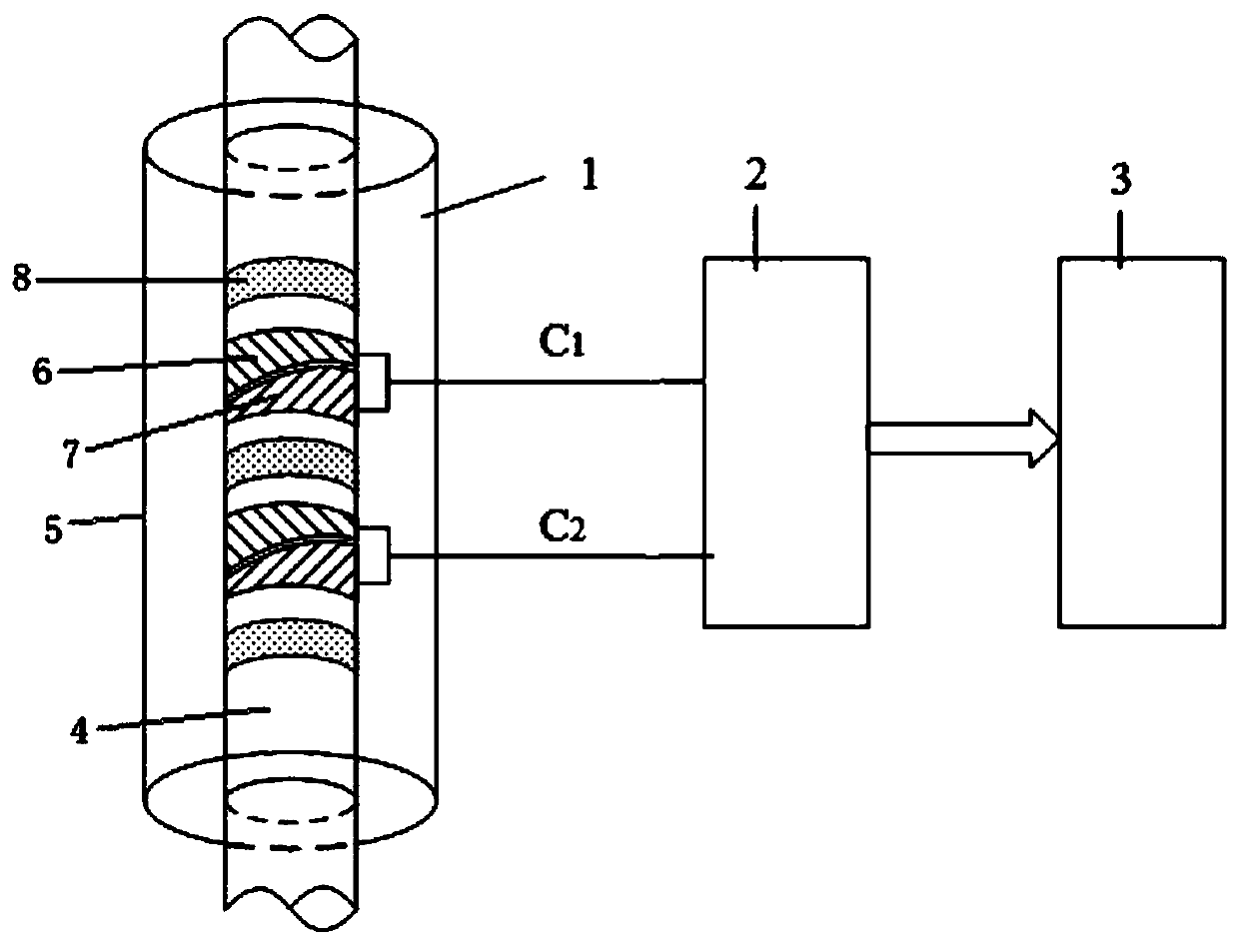

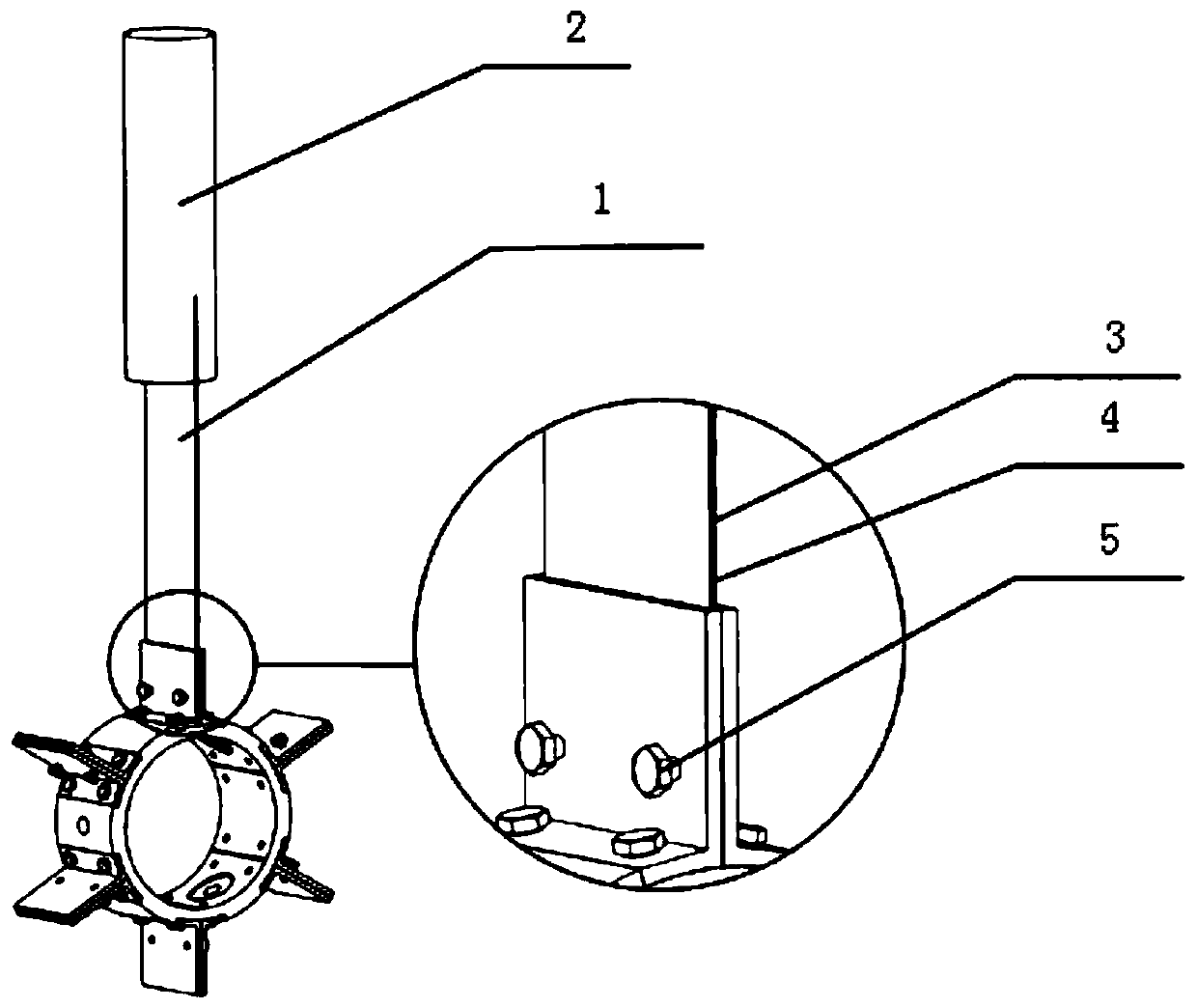

Metal particle flow velocity measuring device and method based on triangular electrode capacitance sensor

ActiveCN110579622AUniform sensitive fieldSimple structureFluid speed measurementMeasurement deviceMetal particle

The invention discloses a metal particle flow velocity measuring device based on a triangular electrode capacitance sensor. The device comprises a triangular electrode differential capacitance sensorfor detection, a signal acquisition circuit and a computer which are electrically connected in sequence. The triangular electrode differential capacitance sensor comprises an insulating pipeline whichis provided with an upstream electrode pair and a downstream electrode pair. Shielding electrodes are arranged above the upstream electrode pair, between the upstream electrode pair and the downstream electrode pair and below the downstream electrode pair respectively. The outside of the insulating pipeline is sleeved with a metal shielding cover. The invention further discloses a metal particleflow velocity measuring method based on a triangular electrode capacitance sensor. The computer calculates the velocity of metal particles by analyzing output signals of the sensor. The sensor devicedisclosed by the invention has the advantages of more uniform sensitive field, simple structure, low cost, quick response, high flexibility and high sensitivity, and improves the measurement accuracyof the flow velocity of the metal particles in the pipeline.

Owner:XIAN UNIV OF TECH

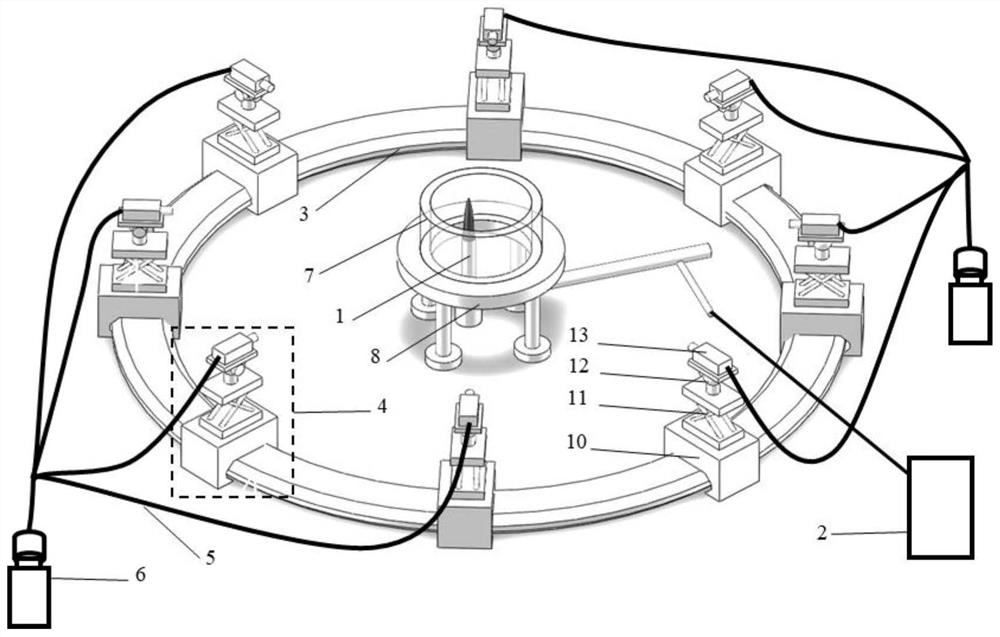

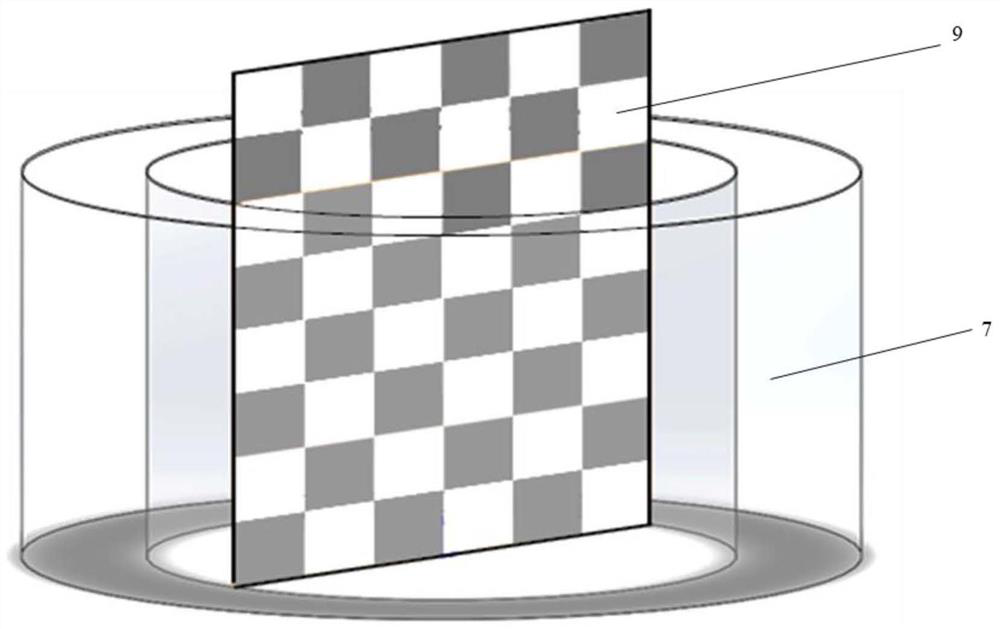

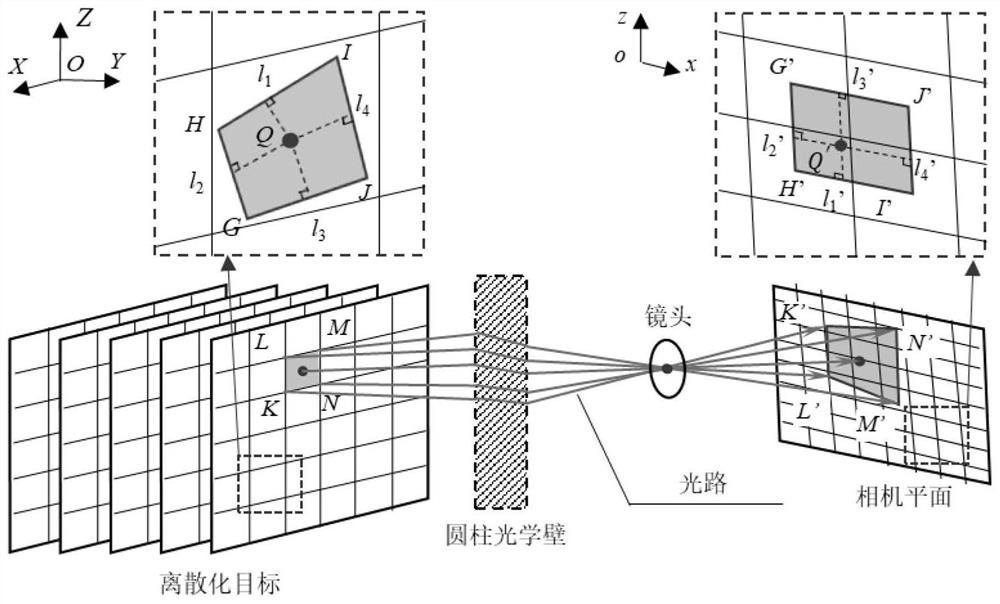

Three-dimensional cross-interface measurement system

ActiveCN113074946APlay a role in refractionWell mixedInternal-combustion engine testingAerodynamic testingSignal generatorMechanical engineering

The invention provides a three-dimensional cross-interface measurement system, which comprises a signal generator, a circular track, a transparent cylinder sleeve, a support and more than two imaging structural members, wherein each imaging structural member comprises a camera and a plurality of lens assemblies. Cross-interface propagation of optical signals such as flame signals is realized by arranging a transparent cylinder sleeve outside an optical signal generator, a plurality of lens assemblies are arranged on a circular track, and the optical signals are propagated to a camera from the lens assemblies, so that two-dimensional projections of the optical signals in different observation directions are obtained. Therefore, a transparent window of the optical engine is replaced by the transparent cylinder sleeve, an internal optical signal is refracted, an optical path propagation path of the optical signal in the optical engine can be simulated, and then the refraction condition of the internal signal of the optical engine when the internal signal passes through the inner wall and the outer wall of the transparent window in the outward transmission process can be simulated; and an experimental method is provided for solving the cross-interface measurement problem.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

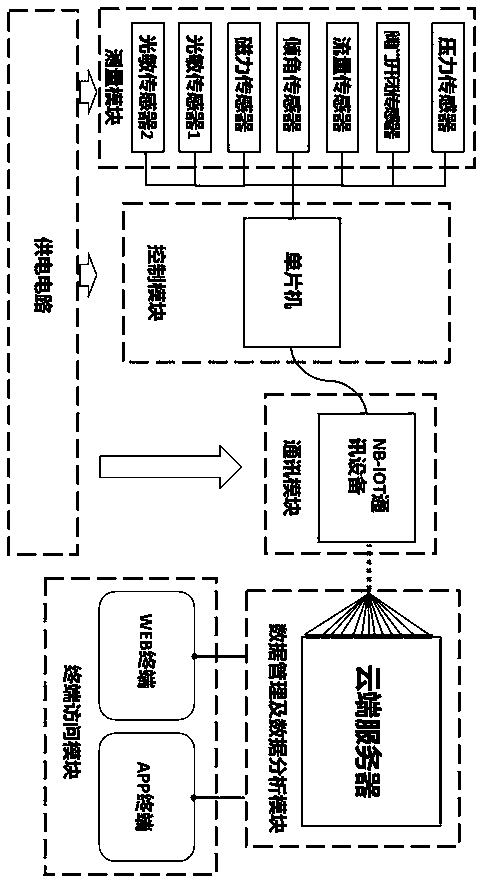

Outdoor fire hydrant monitoring system and detection method thereof

ActiveCN110989453AAvoid Water DelaysRapid and effective improvement of precisionProgramme controlComputer controlFeature (machine learning)Data analysis

The invention discloses an outdoor fire hydrant monitoring system and a detection method thereof. The system comprises a measurement module, a control module, a communication module, a power supply module, a data management and data analysis module and a terminal access module. The measurement module adopts a plurality of high-precision sensors to jointly measure, particularly adopts a micro turbine flowmeter, and realizes the function of a large-size flowmeter at the cost of 20 yuan under the condition that the error precision is less than 1%. And the adopted valve opening and closing sensornot only effectively provides water resource safety protection, but also can quickly respond to the water demand. The communication module effectively and uniformly distributes the number reporting time of the Internet of Things terminal equipment to the time period of the number reporting period, thereby avoiding possible network congestion. And the data management and data analysis module realizes visual feature interpretation, accurate anomaly detection and unified classification management of the fire hydrant data based on an anomaly detection algorithm and a clustering analysis algorithmof machine learning. Scientific management and comprehensive and timely monitoring of the fire hydrant are effectively realized, and the management difficulty is reduced.

Owner:应急管理部天津消防研究所

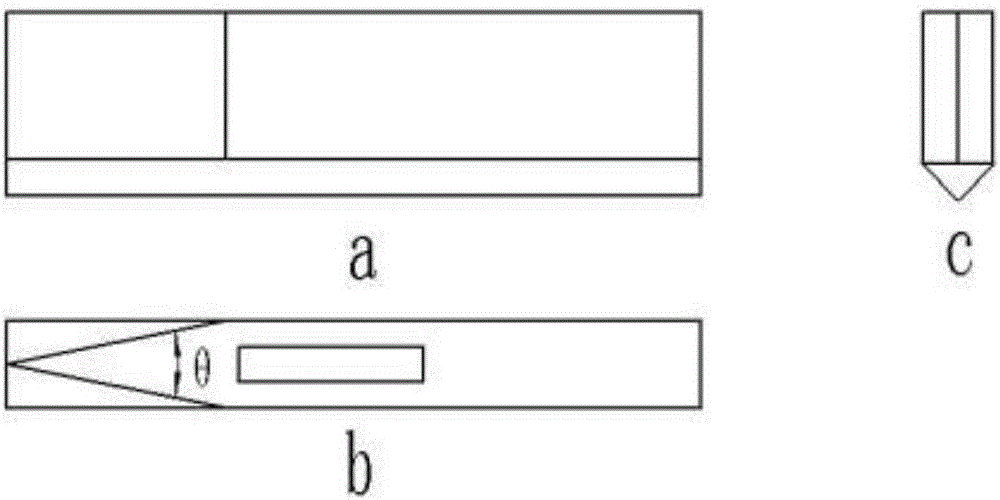

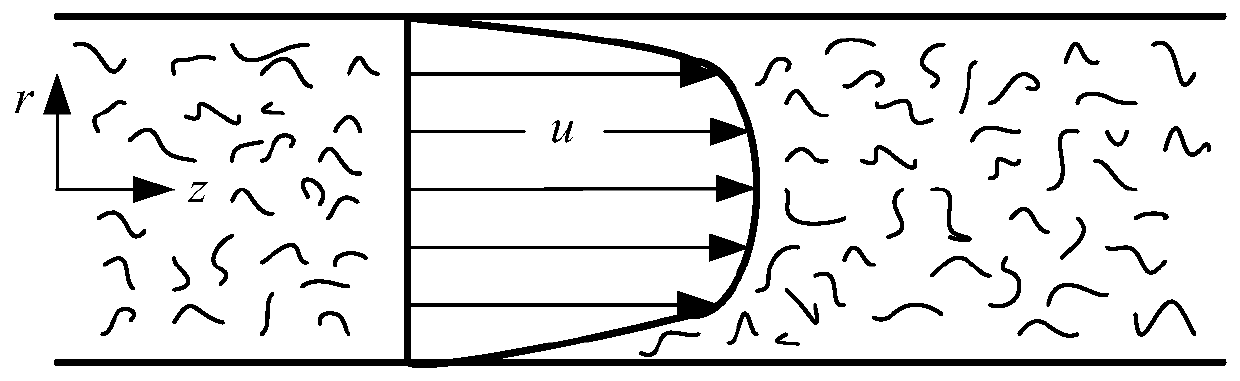

High-efficiency gas and liquid mixer for gas and liquid two-phase flow experiment

ActiveCN106215734AEasy to moveIncrease contact areaFlow mixersTransportation and packagingGas phaseSpray nozzle

The invention relates to a gas and liquid mixer, in particular to a high-efficiency gas and liquid mixer for a gas and liquid two-phase flow experiment table. The high-efficiency gas and liquid mixer is characterized in that gas conveying separating plates are arranged in a main flow pipe, and are used for conveying gas phase, and an angle of attack at the front part of each gas conveying separating plate is favorable for the flowing of fluid, so as to reduce the resistance loss; a shrinkage type spray pipe is arranged at the tail part of each gas conveying separating plate, and the inlet cross section is designed, so that the air flow which flows out of each spray nozzle has the same outlet state; under the spraying action of spray pipes, the contact area of gas and liquid is increased, the mixing is uniform, and the stress produced by mixing is uniformly distributed when each gas conveying separating plate is arranged in an axis symmetric way; guide vanes which are symmetrically arranged in a sleeve cylinder are used for guiding flow, so that the impact loss of flowing is reduced; after calculating, the inlet length of each gas conveying separating plate, and the value range of the length of each guide vane are obtained, so that the impact loss of flowing is reduced, and the stable flowing state is furthest maintained.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH

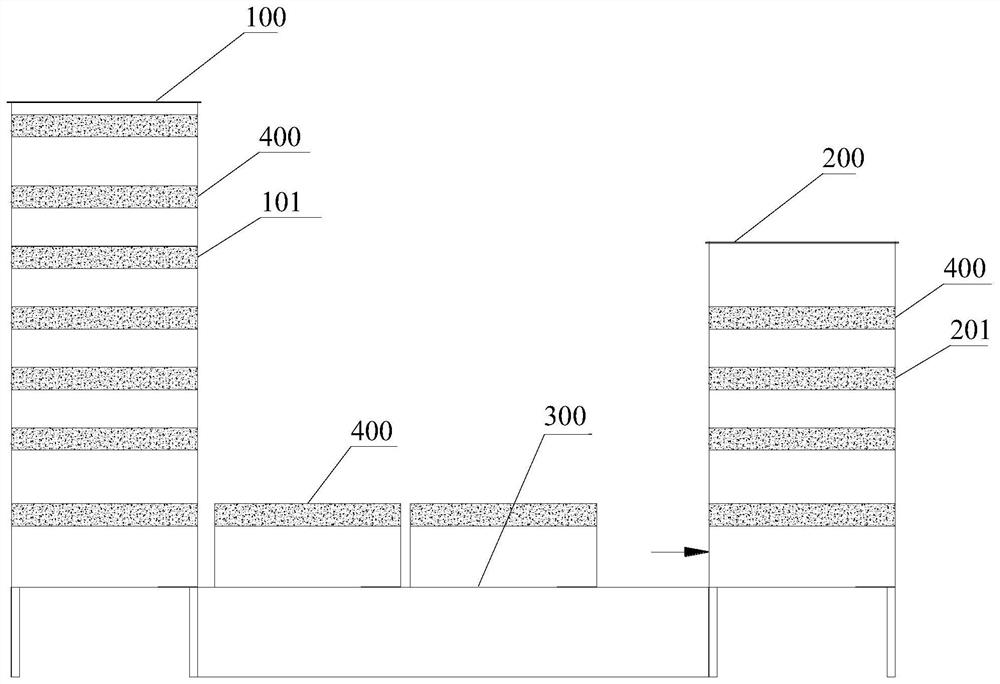

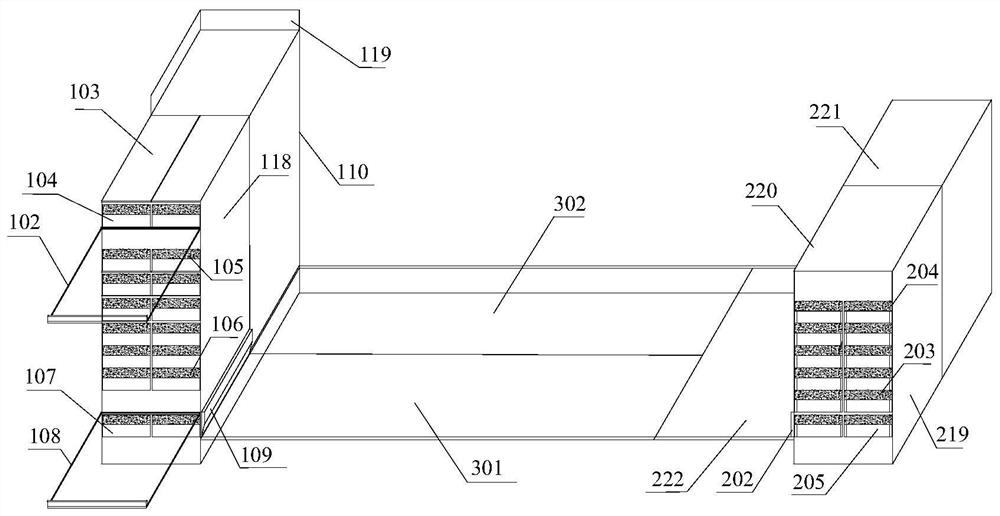

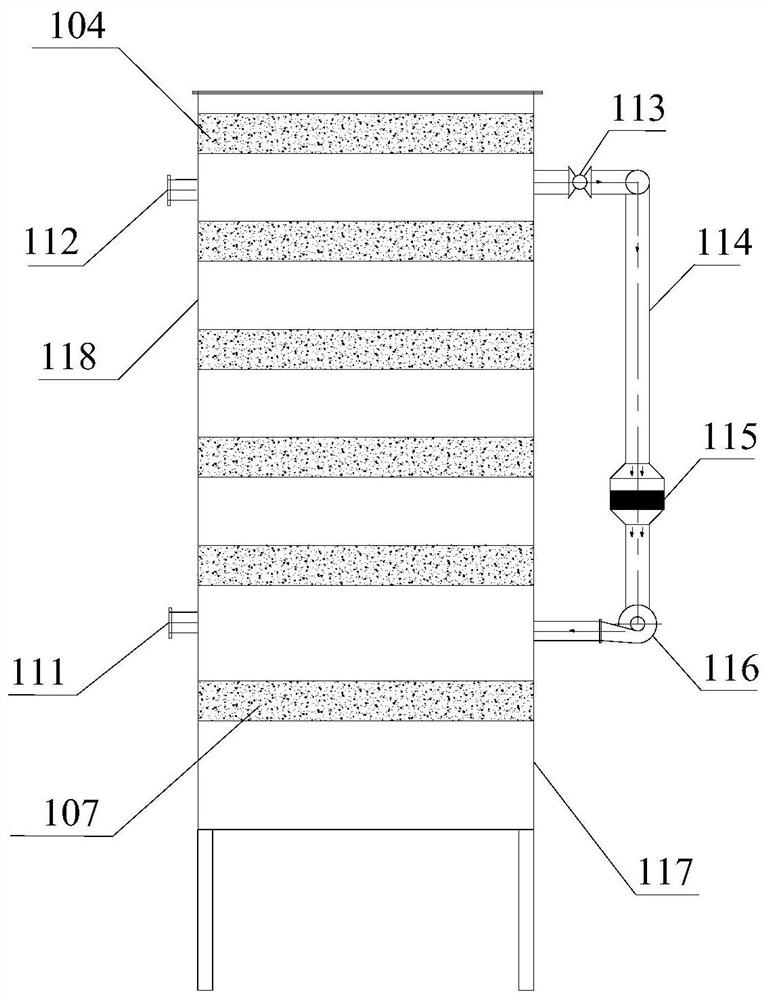

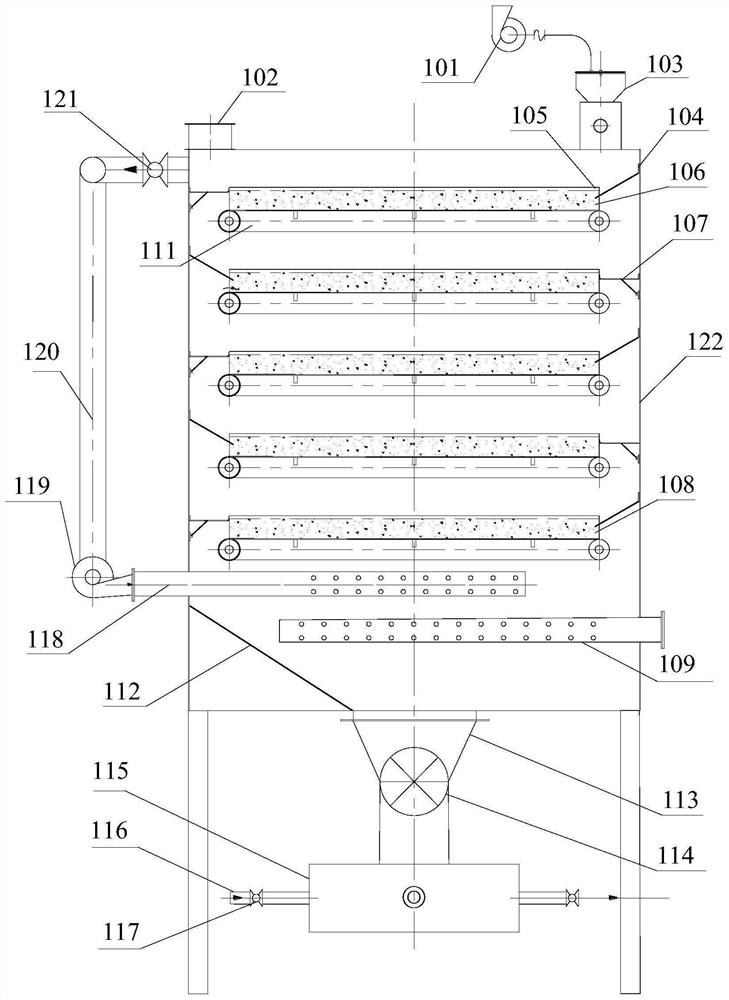

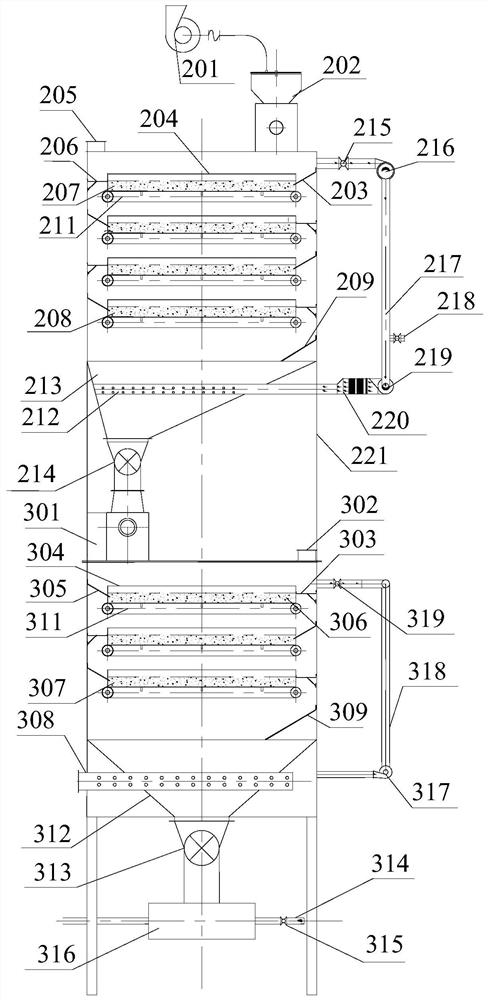

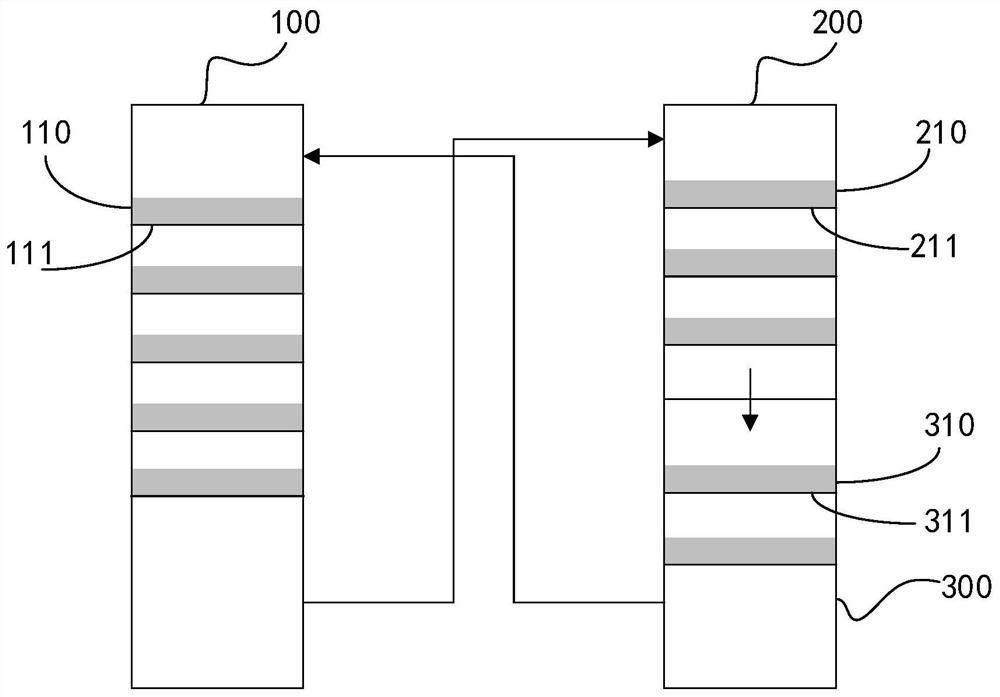

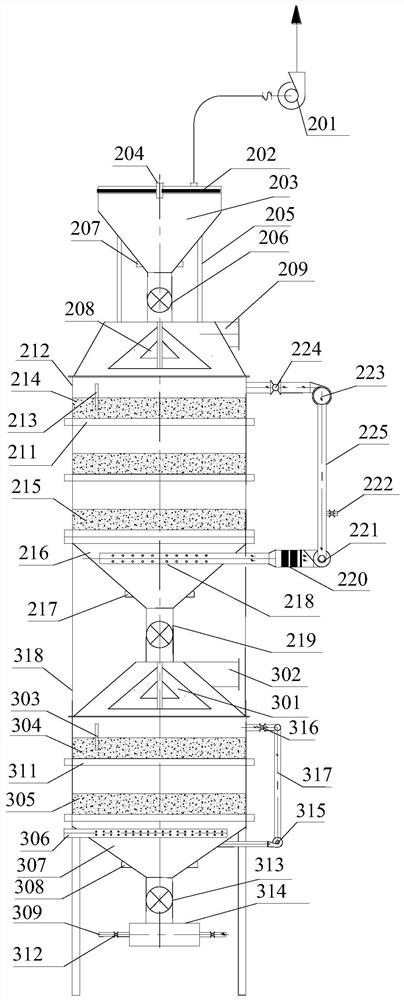

Box-type moving bed waste gas purification system

PendingCN113069885AGuaranteed tightnessPrevent leakageGas treatmentDispersed particle separationChemistryRegenerative cooling

The embodiment of the invention discloses a box-type moving bed waste gas purification system which comprises an adsorption purification unit and a regeneration cooling unit, the adsorption purification unit is provided with multiple adsorption layers, and the adsorption purification unit is used for moving a perforated filler box of the upper adsorption layer downwards to the relative position of the lower adsorption layer, feeding a perforated filler box of the bottom adsorption layer into a regeneration cooling unit, andpurifying organic waste gas flowing from bottom to top through each stage of adsorption layer; the regeneration cooling unit is provided with a plurality of desorption cooling layers and is used for heating the filler of each stage of desorption cooling layer through hot nitrogen or water vapor flowing from bottom to top and cooling the filler of each stage of desorption cooling layer through air flowing from bottom to top after desorption is finished; and after cooling is finished, the perforated stuffing box of the upper desorption cooling layer is moved downwards to the relative position of the lower desorption cooling layer, and the perforated stuffing box of the bottom desorption cooling layer is fed into the adsorption purification unit.

Owner:孙绍堂

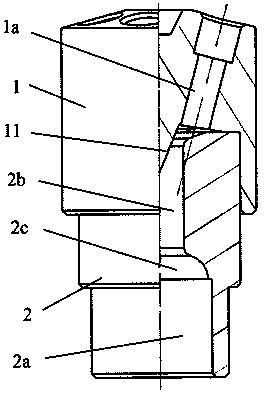

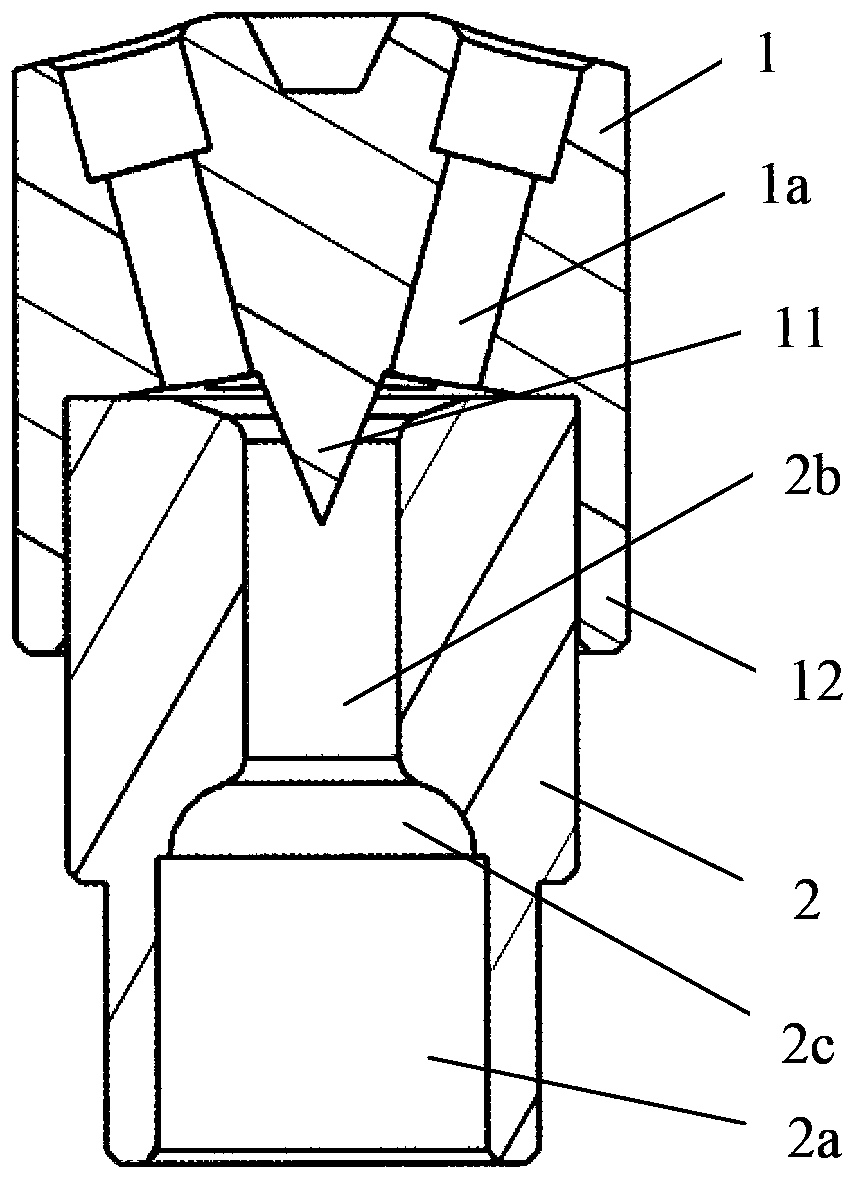

Liquid distributor and air conditioner equipped with liquid distributor

ActiveCN104061722AIncrease the lengthEvenly distributedFluid circulation arrangementEngineeringDistributor

The invention discloses a liquid distributor and an air conditioner equipped with the liquid distributor. The liquid distributor comprises a distributing part at the upper end and a liquid inlet part at the lower end, wherein a drainage port is formed in the inner side of the lower part of the liquid inlet part, a flow stabilizing hole communicated with the drainage port is formed in the drainage port, the diameter of an inlet of the flow stabilizing hole is smaller than that of the drainage port, the flow stabilizing port extends to the top end of the liquid inlet part, a plurality of distributing ports at equal intervals are formed in the upper end of the flow stabilizing hole, and the distributing part is provided with a plurality of distributing channels communicated with the distributing ports; and the air conditioner is equipped with the liquid distributor. Liquids entering the liquid distributor are uniformly distributed, non-uniform turbulent flow is prevented from being formed, noise produced when a liquid flows is reduced, and the refrigerating capacity of the air conditioner is effectively improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

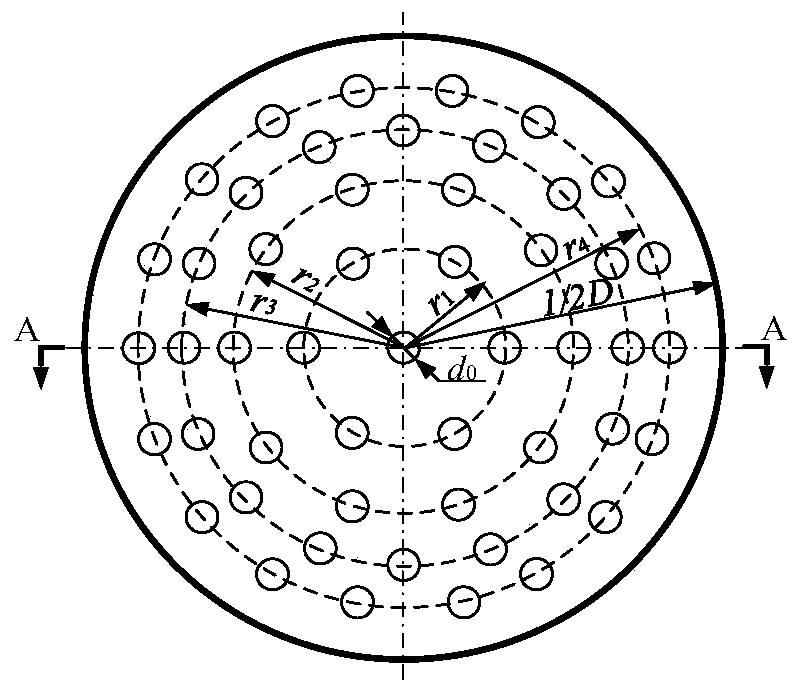

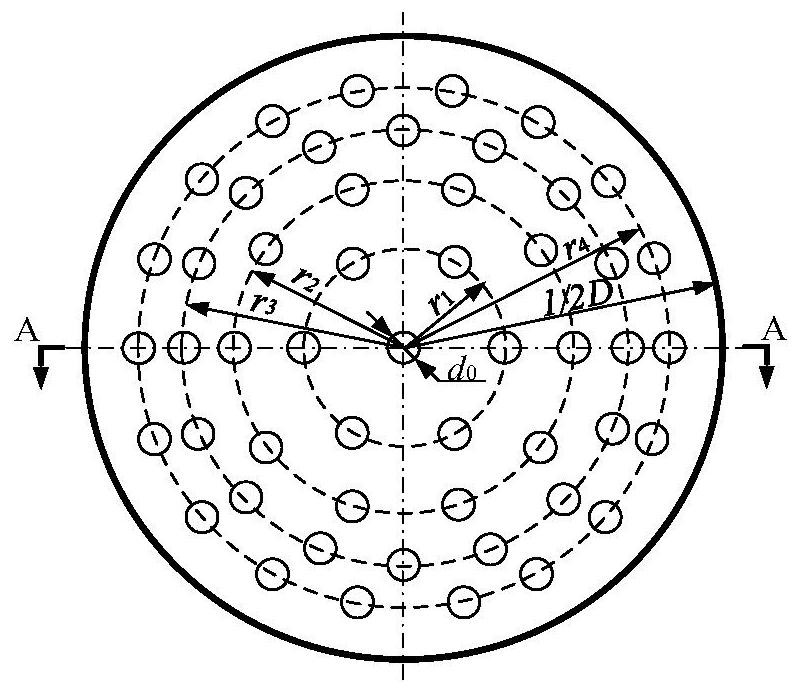

Porous flow-limiting noise-reducing orifice plate and flow-limiting noise reducer formed by same

ActiveCN111022813AExtreme value difference decreasesEvenly distributedPipe elementsPhysicsOrifice plate

The invention provides a porous flow-limiting noise-reducing orifice plate and a flow-limiting noise reducer formed by the same. According to the porous flow-limiting noise-reducing orifice plate, a flow-limiting orifice is arranged in the center of the orifice plate, other flow-limiting orifices are arranged in a group of concentric circles in an annular mode, the number of the flow-limiting orifices positioned on concentric circles with different radii gradually increases from inside to outside, the center distances of adjacent flow-limiting orifices positioned on the same concentric circlecircumference are the same, and the radius difference of adjacent concentric circles is arranged in an equal difference series from the center to the edge of the orifice plate. The flow-limiting noisereducer is composed of a pipe section and at least one porous flow-limiting noise-reducing orifice plate arranged in the pipe section, and connecting flanges are arranged at two ends of the pipe section. Compared with a conventional porous flow-limiting noise-reducing orifice plate, the noise-reducing capacity is improved, and the pressure loss is obviously reduced.

Owner:SICHUAN UNIV

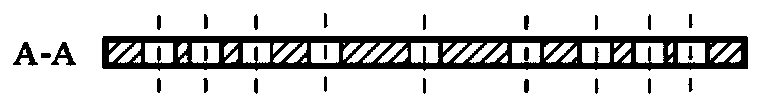

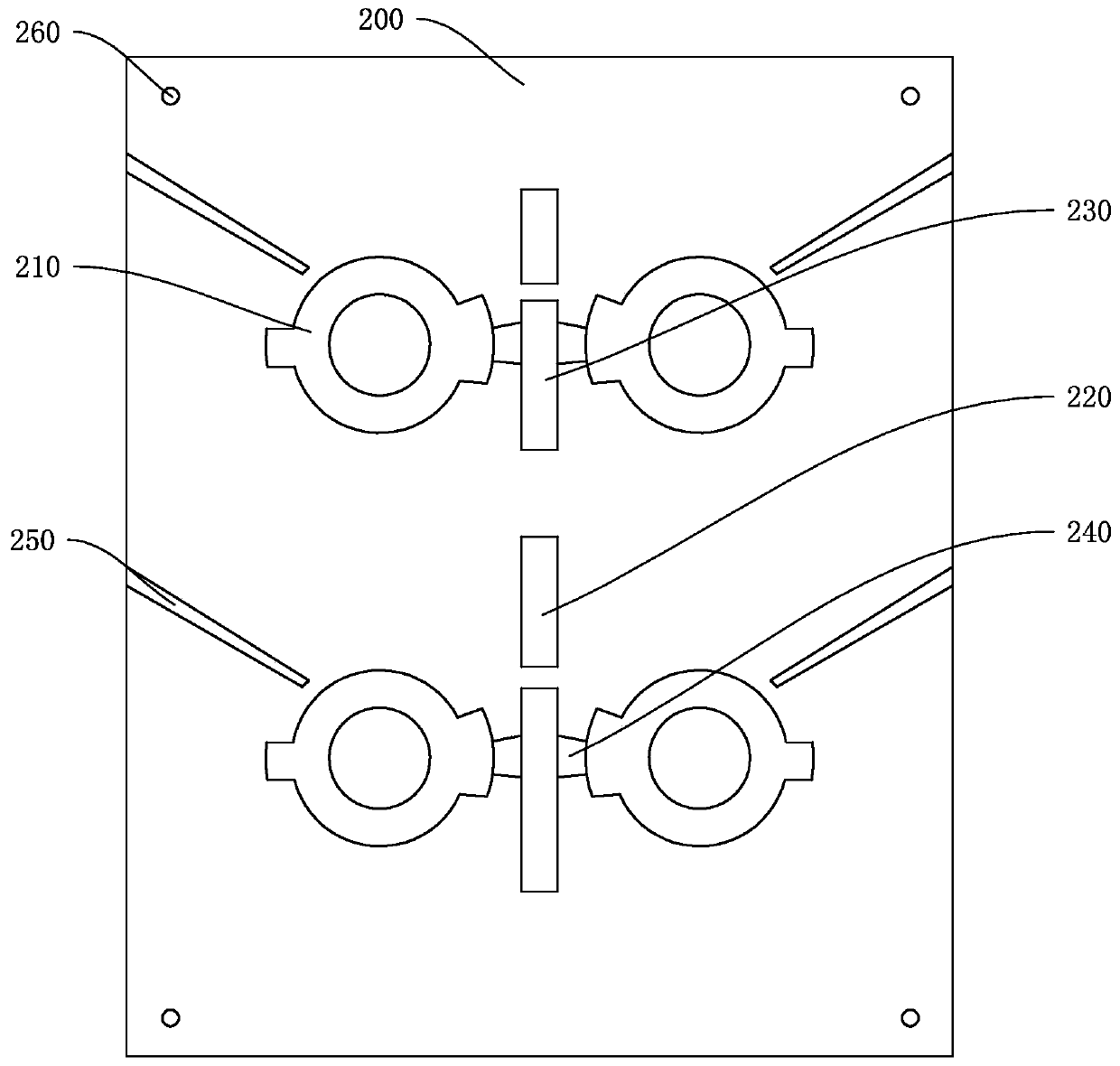

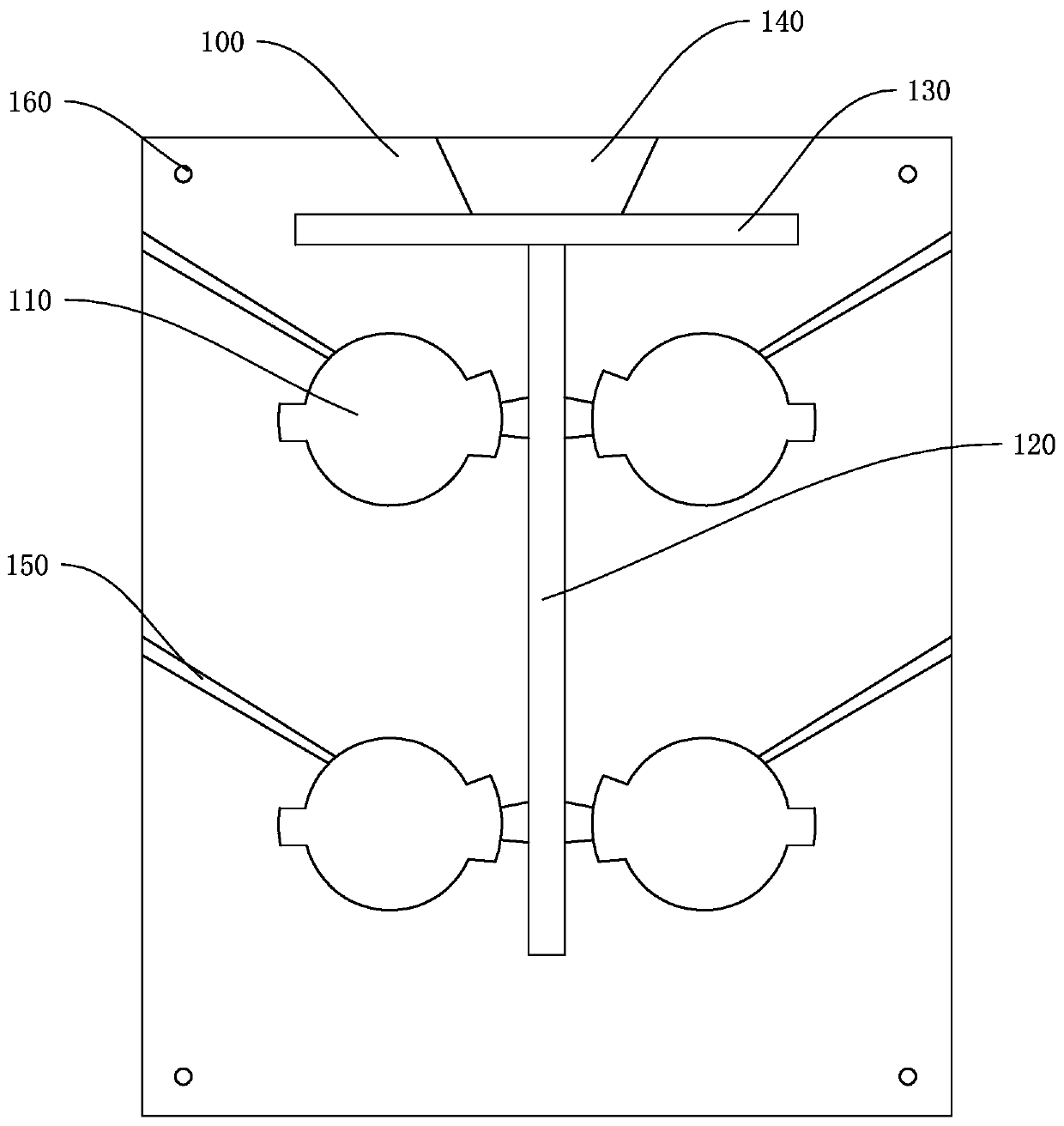

Pouring mold for reducing polishing water gaps of cylinder

PendingCN111036856ASlow down the flowImprove shipping efficiencyFoundry mouldsFoundry coresStructural engineeringCylinder block

The invention discloses a cylinder body capable of reducing polishing water gaps of a cylinder. The cylinder body comprises a positive pressing plate and a reverse pressing plate. The positive pressing plate is provided with a plurality of upper cavities and ingates communicated with all the upper cavities; the reverse pressing plate and the positive pressing plate are matched and combined, lowercavities corresponding to the upper cavities are formed in the reverse pressing plate, buffer channel grooves and pouring channel grooves corresponding to the ingates are formed between the lower cavities at intervals, and the pouring channel grooves are communicated with the lower cavities through flow gates. According to the cylinder body capable of reducing polishing water gaps of the cylinder,the pouring speed can be increased, it is guaranteed that a casting is not subjected to a polishing procedure after coming off a line, the delivery efficiency of the casting is greatly improved, andthe delivery bottleneck problem is reduced.

Owner:ZHUHAI NANTE METAL TECH

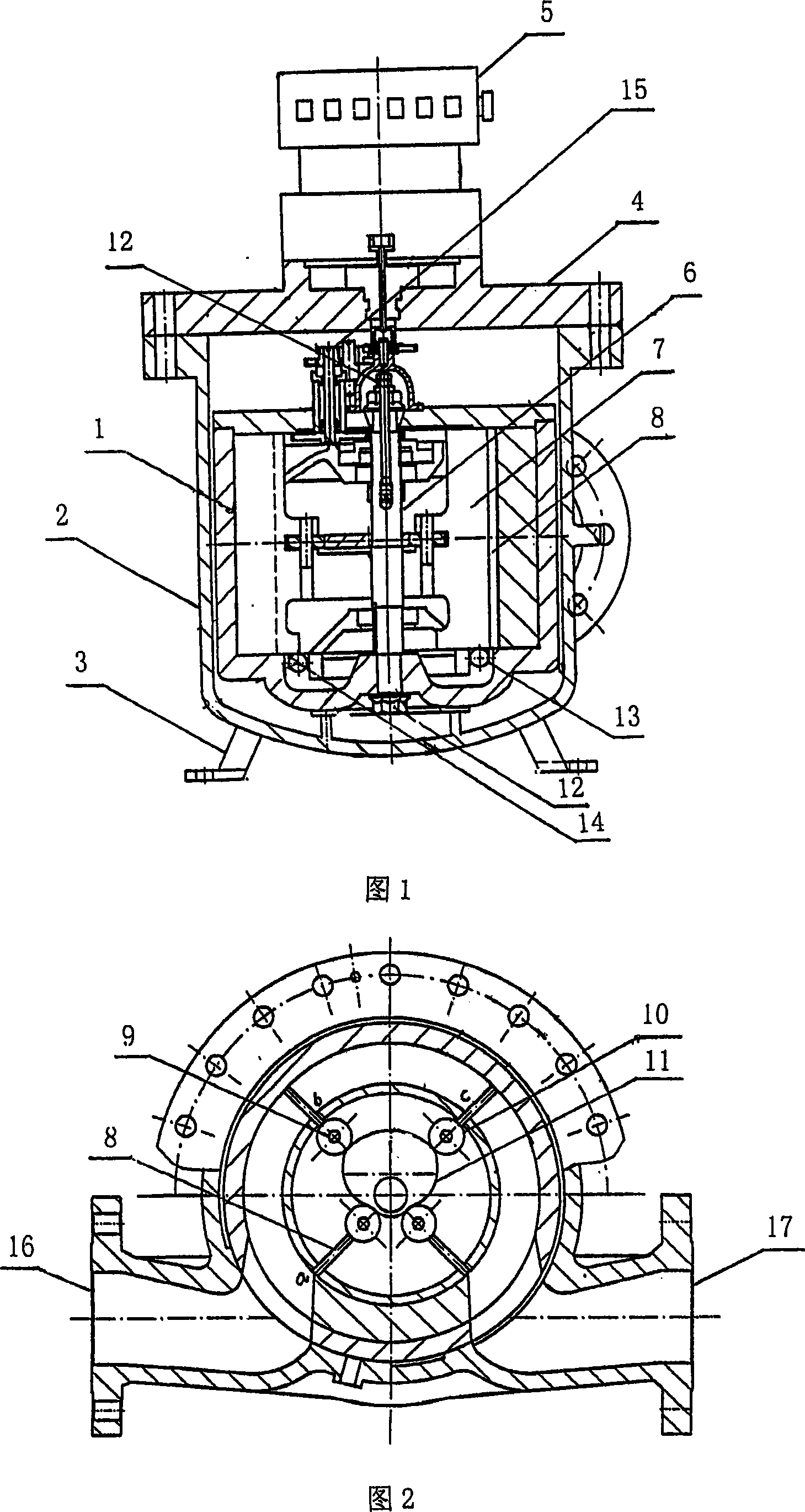

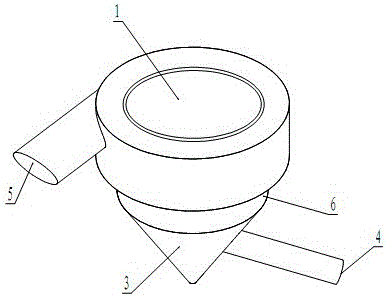

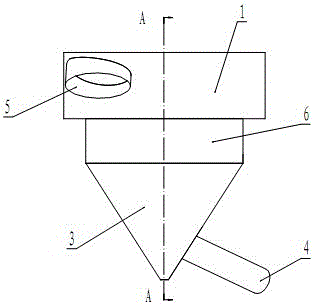

Flowmeter

InactiveCN101144734AFlow state is stableNot easy to wearStationary measuring chambersPetroleum productEngineering

The invention discloses a flow meter with smooth operation, high measuring precision and long service life, and the flow meter comprises a metering body, a casing, a supporting seat, an upper cover, and a large print wheel counter, wherein, a plurality of pairs of mutually connected scrapers which are symmetrically distributed with the chief axis as the center are arranged inside the metering body, a circular cylinder model rotor adopts the chief axis as the center is arranged inside the metering body, the outer ends of the scrapers penetrate a gutter bar reserved on the rotor wall and can be expanded backward and forward along the radial direction, the inner ends of the scrapers contact with a cam fixed on the chief axis through a roller with a bearing, and the two ends of the rotor is connected with the bearing arranged on the two ends of the chief axis with. The volumetric flow meter is a metering device for continuously measuring the volume flow of the liquid inside a sealed pipeline. The invention is suitable for the transportation of crude oil and varieties of petroleum products.

Owner:陈还喜

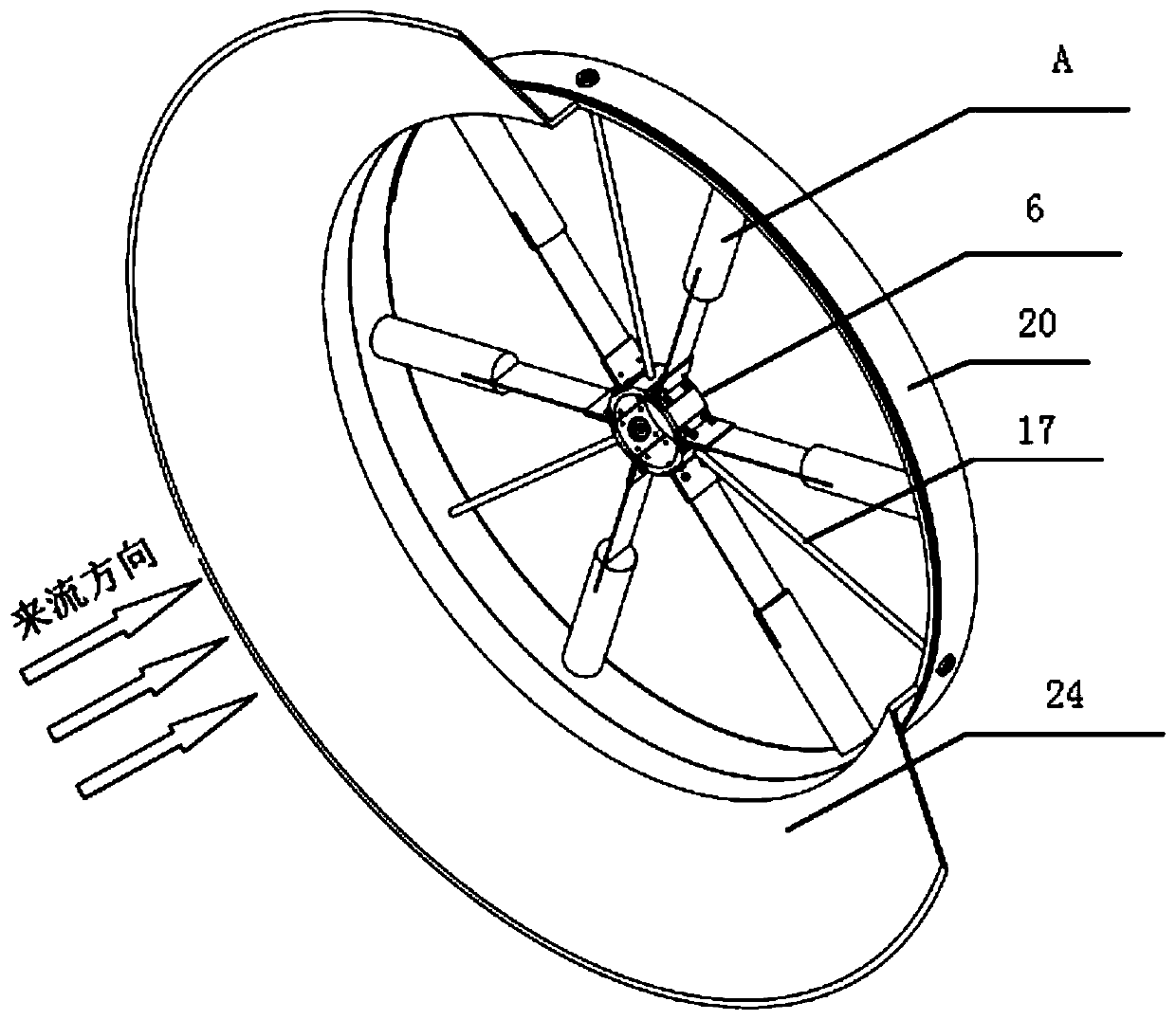

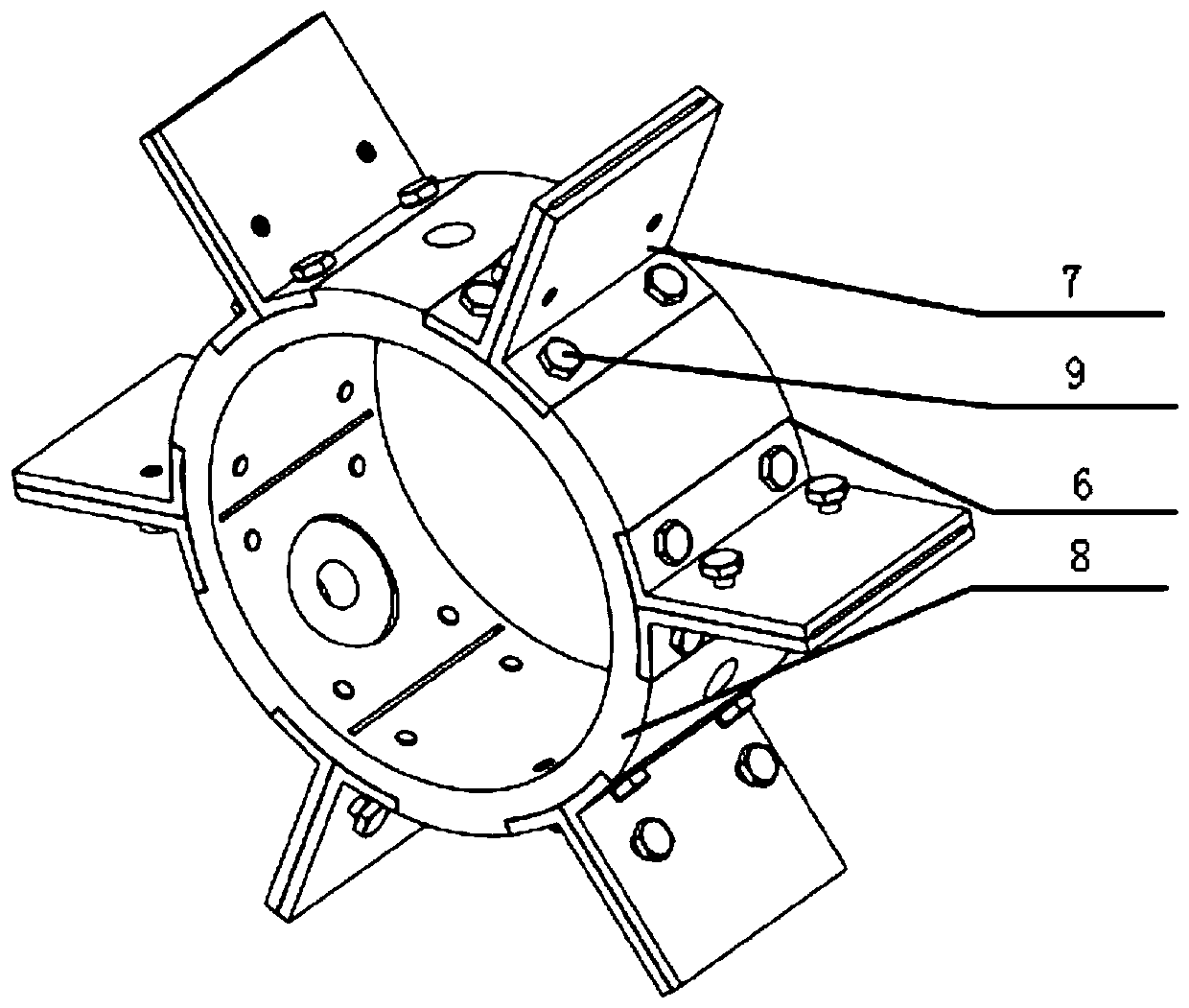

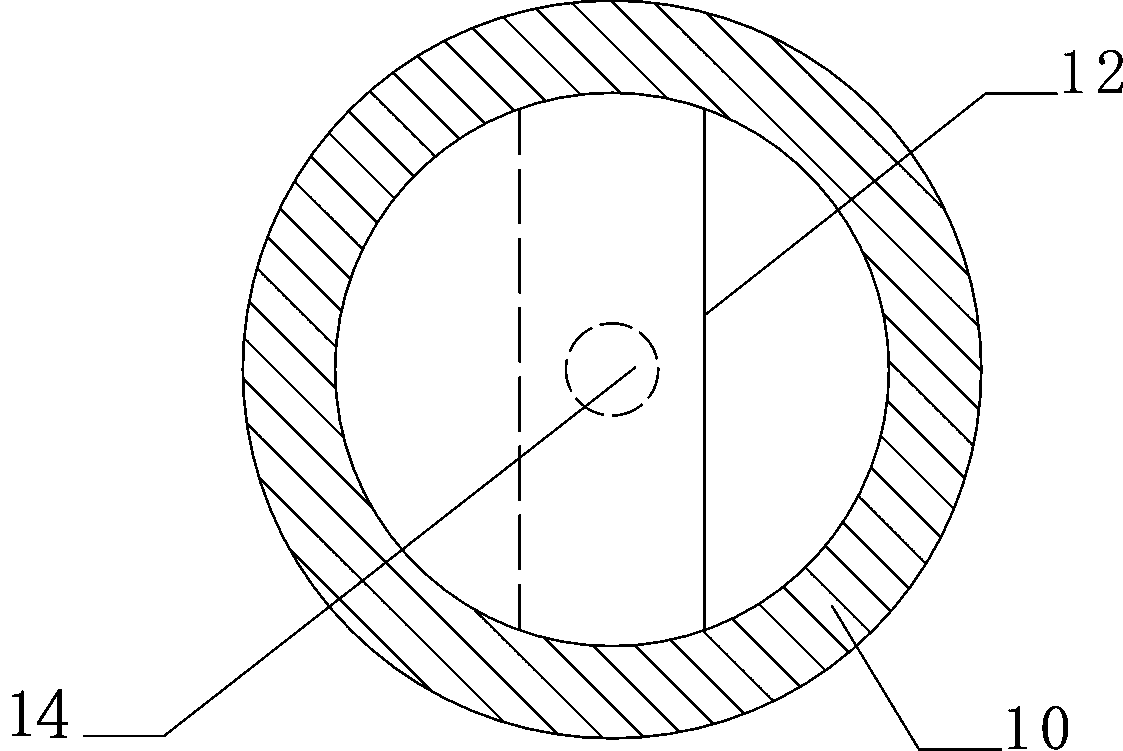

Modular directional flow pipeline type piezoelectric energy harvester arranged in a circumferential array

ActiveCN110380645AReduce distractionsReduces interference while reducing overall structural massPiezoelectric/electrostriction/magnetostriction machinesCurrent limitingPiezoelectric actuators

The invention relates to a modular directional flow pipeline type piezoelectric energy harvester arranged in a circumferential array, which belongs to the technical field of water flow and air flow induced vibration energy harvesting and solves the problems that energy harvesters in the existing flow-induced energy harvesting are mostly fixed, the mutual coupling relation is difficult to adjust and that the application limitation is large. The piezoelectric energy harvester comprises a flow-gathering and speed-accelerating coil and at least one piezoelectric module, the piezoelectric modules are connected in series when there are two or more piezoelectric modules, each piezoelectric module includes a plurality of piezoelectric vibrators, a central support, a current-limiting outer ring andconnecting screws; the central support and the current-limiting outer ring are coaxially arranged inside and outside and are connected through a plurality of connecting screws, and the plurality of piezoelectric vibrators are arranged in a circumferential array between the central support and the current-limiting outer ring; the flow-gathering and speed-accelerating ring is coaxially arranged onthe outer end face of the current-limiting outer ring on the incoming side; and a plurality of long holes are formed in the central support along the circumferential direction of the central support.The piezoelectric energy harvester can be widely applied to energy collection in the fields of stream pipelines, distillation pipelines, tap water pipelines, exhaust pipelines and the like.

Owner:HARBIN INST OF TECH

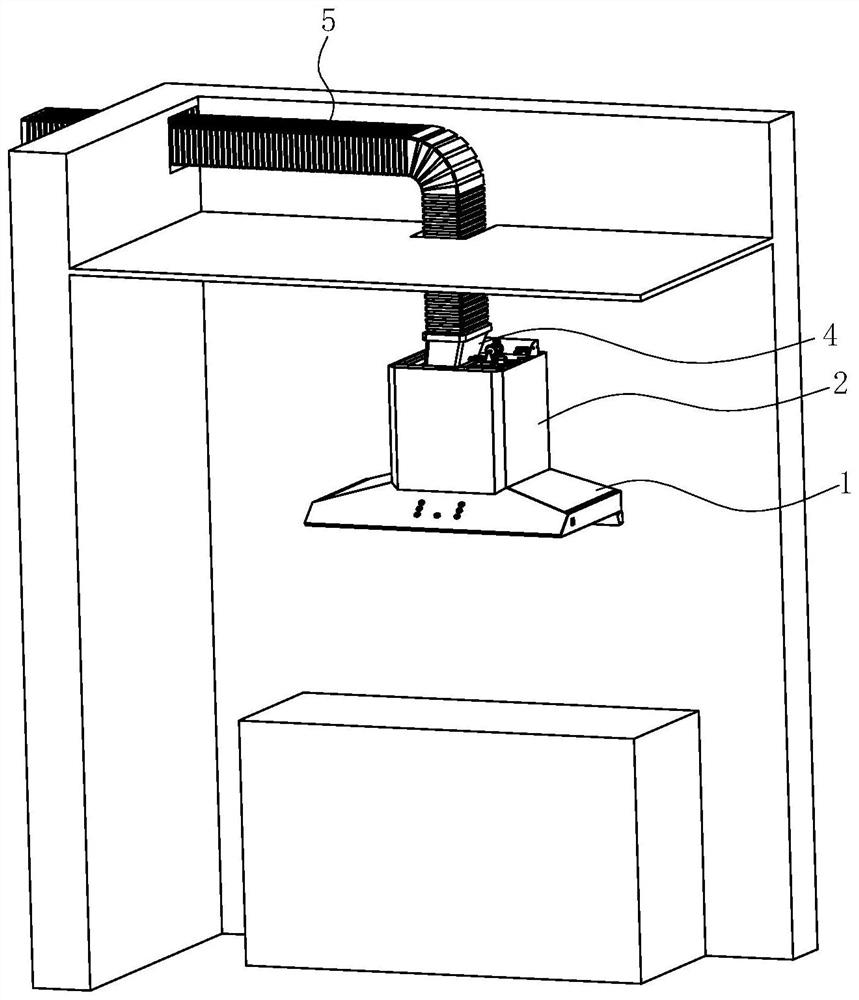

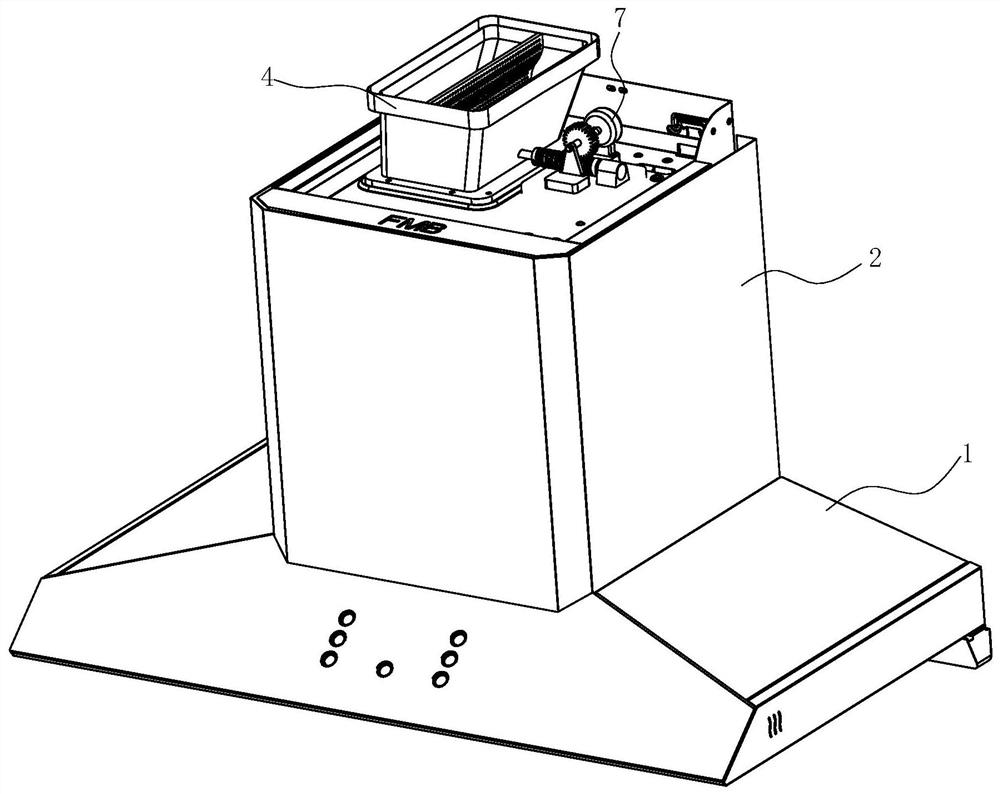

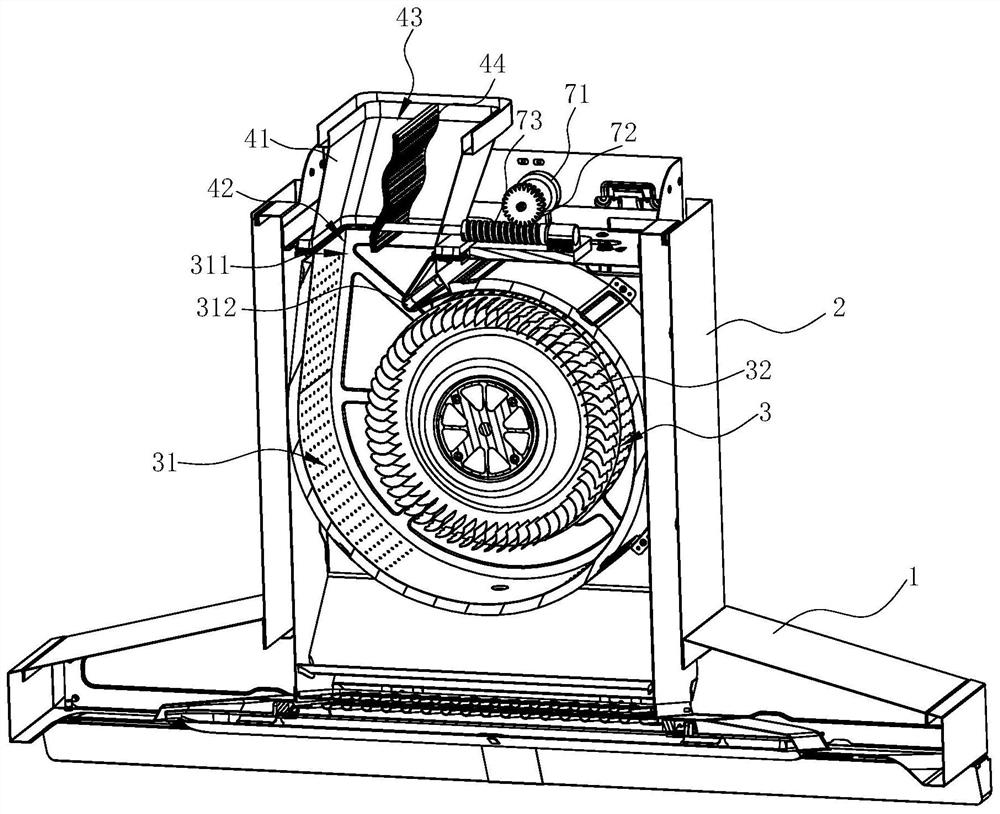

An air outlet hood, a range hood with the air outlet hood and its control method

ActiveCN111336558BReduce contactIncrease contactDomestic stoves or rangesLighting and heating apparatusNoiseEngineering

The invention discloses an air outlet cover, which comprises a hollow cover body and inlets and outlets respectively formed at both ends of the cover body, and is characterized in that: a deflector is arranged inside the cover, and the deflector extends from the inlet At the outlet, the deflector divides the space in the cover into independent first flow channels and second flow channels, and the two ends of each flow channel respectively pass through the inlet and outlet. Also disclosed are a range hood applied with the above-mentioned air outlet hood, a control method of the above-mentioned range hood, and a smoke exhaust pipe for connecting with the above-mentioned air outlet hood. By setting deflectors in the cover body of the air outlet hood, double air flow channels are formed inside the cover body, which can have good rectification and deceleration and boosting effects, reduce the contact times of sound waves with the outer wall of the cover, and reduce the radiation of the outer wall of the cover. noise.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

car engine air filter

ActiveCN103452712BLarge filter areaImprove work efficiencyMachines/enginesAir cleaners for fuelNoise, vibration, and harshnessAir filter

The invention discloses an air filter of an automobile engine, which is used for solving the problems that the volume of the air filter is large and the effective filtering area of a filtering core is small in the prior art. The air filter comprises an upper shell, a lower shell and the filtering core, wherein the outer side wall of the upper shell is provided with an air outlet of the air filter; the outer side wall of the lower shell is provided with an air inlet of the air filter. The air filter is characterized in that an airflow buffering belt is arranged between the upper shell and the lower shell; the filtering core is arranged in a cavity of the lower shell; the lower shell and the filtering core are respectively in a conical structure. The air filter disclosed by the invention has the advantages that not only can the filtering efficiency of the air filter be improved and can the NVH (Noise Vibration and Harshness) performances of a vehicle are improved, but also the distribution of an engine cabin of the vehicle is easy.

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

Method capable of realizing on-line prediction of crystallizer flow field flow state in actual production

The invention relates to a method capable of realizing on-line prediction of crystallizer flow field flow state in actual production, and belongs to the technical field of continuous casting processesof ferrous metallurgy steelmaking. According to the technical scheme, three rows of steel nail plates are manufactured according to the section sizes of a crystallizer and a water gap, penetrate through a stainless steel support placed near the water gap and a narrow face of the crystallizer to be vertically inserted into the liquid level of the crystallizer from the two sides of the water gap atthe same time under different casting parameter conditions, and are vertically lifted out after several seconds; and the diameter of metal blocks adhered to steel nails, the distance from the highestpoints and the lowest points of the metal blocks to the tail ends of the steel nails are measured correspondingly, and the height difference of the metal blocks at the highest points and the lowest points on two sides of the steel nails is calculated. The method capable of realizing on-line prediction of crystallizer flow field flow state in actual production has the beneficial effects that the advantages and disadvantages of the current continuous casting parameter conditions can be visually explained, a crystallizer flow field flow state transition diagram can be drawn based on a flow statemeasurement result, and casting parameters are optimized and adjusted in real time according to the field production rhythm, so that molten steel in the crystallizer is in a stable flowing state, andthe casting blank quality is improved.

Owner:HANDAN IRON & STEEL GROUP +3

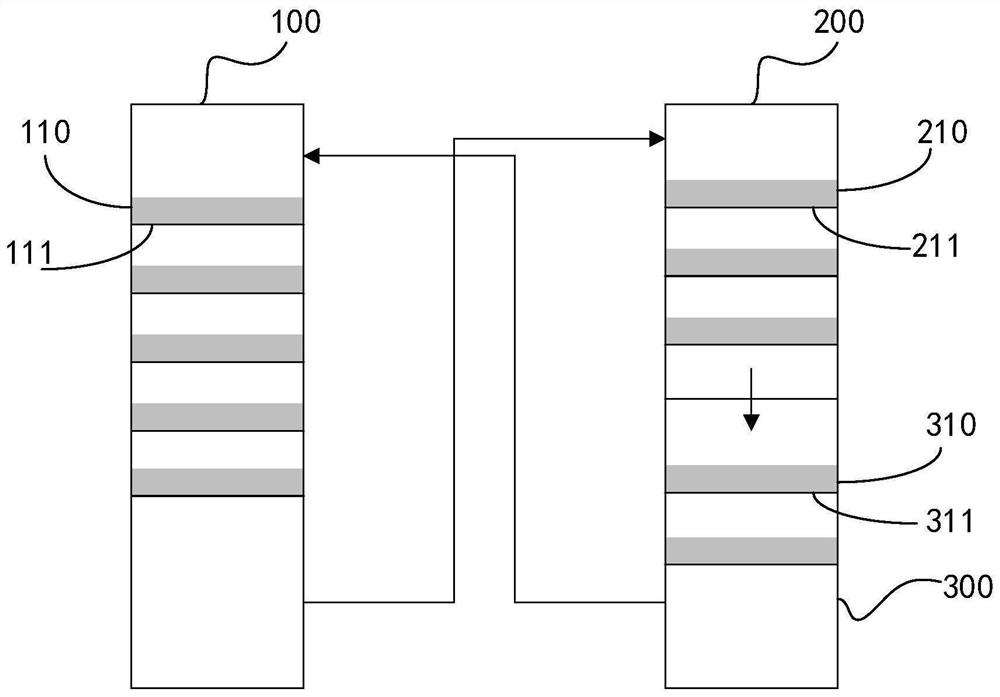

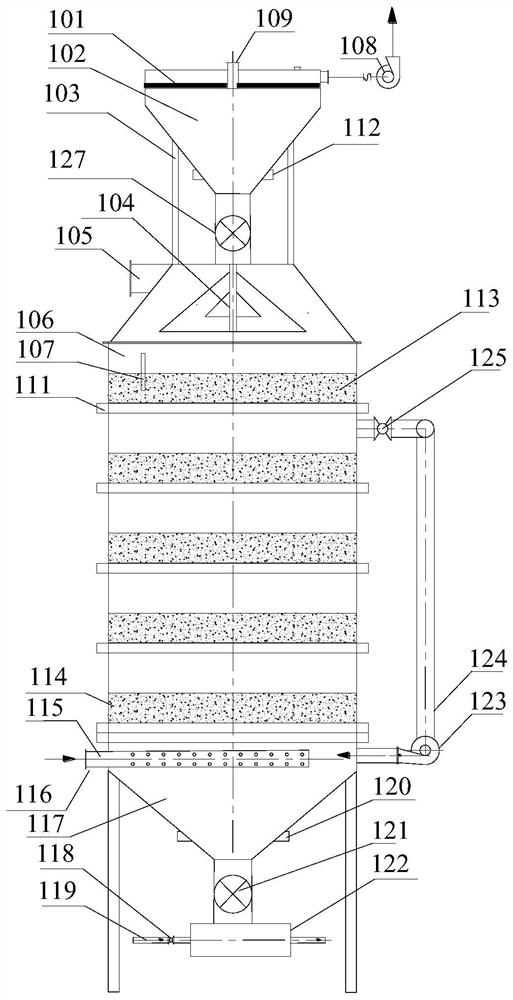

Multi-layer mesh moving bed waste gas purification system

PendingCN113069887AImprove purification efficiencyHigh control precisionGas treatmentDispersed particle separationWater vaporDesorption

The embodiment of the invention discloses a multi-layer mesh moving bed waste gas adsorption and purification system which comprises an adsorption and purification unit, a desorption and regeneration unit and a cooling unit, the adsorption and purification unit is used for uniformly discharging filler of an upper-stage adsorption layer to a lower-stage adsorption layer through a first conveying belt, feeding the saturated filler of the bottom adsorption layer into the desorption regeneration unit, and purifying organic waste gas flowing from bottom to top through each stage of adsorption layer; the desorption regeneration unit is used for uniformly discharging the filler of the upper-stage desorption layer to the lower-stage desorption layer through a second conveyor belt, feeding the filler of the bottom-stage desorption layer after high-temperature regeneration into the cooling unit, and heating the filler of each stage of desorption layer through hot nitrogen or water vapor flowing from bottom to top; and the cooling unit is used for uniformly discharging the filler of the upper-stage cooling layer to the lower-stage cooling layer through a third conveying belt, feeding the normal-temperature regenerated filler of the bottom-stage cooling layer into the adsorption purification unit, and cooling the filler of each stage of cooling layer through air flowing from bottom to top.

Owner:孙绍堂

Drying cylinder condensate water draining device

InactiveCN105648822AEnsure normal dischargeDischarge in timeDryer sectionDraining tubePulp and paper industry

The invention relates to a drying cylinder condensate water draining device. The drying cylinder condensate water draining device comprises a draining pipe installed in a drying cylinder, one end of the draining pipe extends out of the drying cylinder, multiple separators are installed on the draining pipe, an inlet of each separator is connected with a winnowing pan, and an outlet of each separator is communicated with the draining pipe. By means of the winnowing pans, condensate water in the drying cylinder carries part of steam to rush into the separators, the condensate water and the steam are separated through the separators, the steam returns into the drying cylinder, only the condensate water enters the draining pipe under the action of gravity, in this way, the stable flowing state in the draining pipe is kept, and the condensate water can be conveniently drained in time. The condensate water draining device is particularly suitable for draining condensate water in medium-and-high-speed paper making machines.

Owner:SHAANXI UNIV OF SCI & TECH

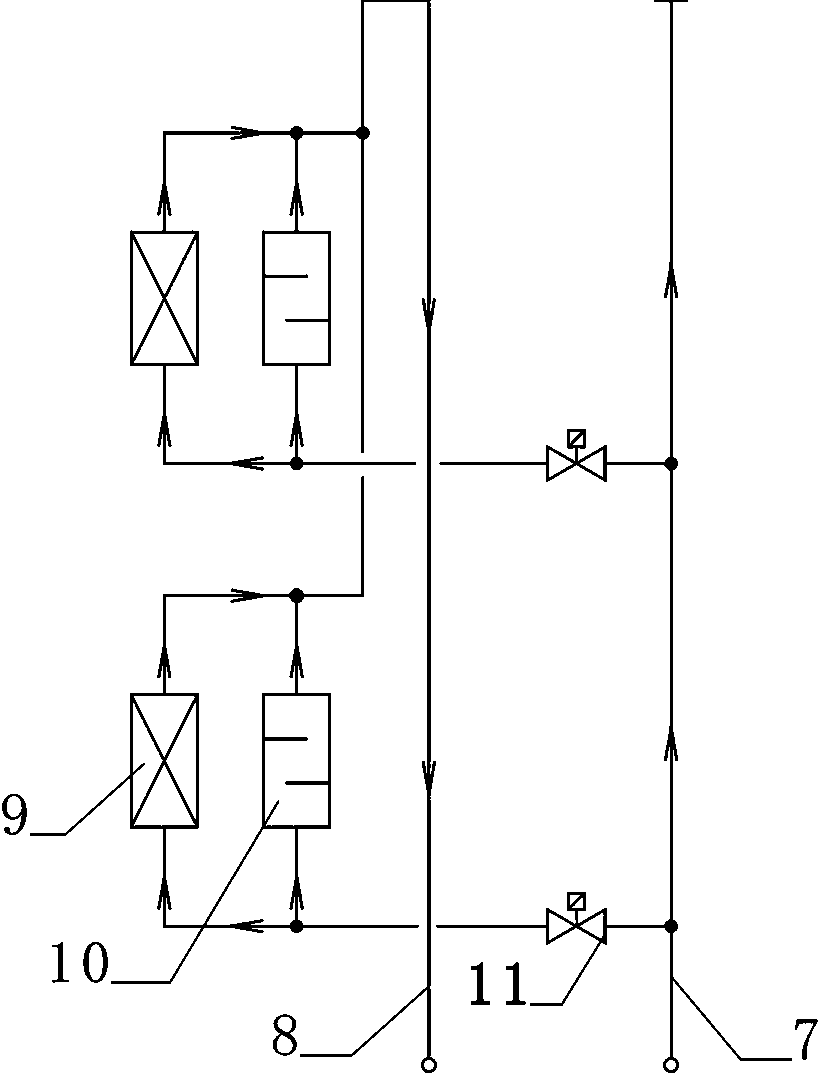

Fluoride pump cooling flow compatibility system for data center

PendingCN108055810AIncrease temperatureImprove cooling effectCooling/ventilation/heating modificationsData centerEngineering

The invention belongs to the technical field of refrigeration, and particularly discloses a fluoride pump cooling flow compatibility system for a data center. The fluoride pump cooling flow compatibility system for the data center comprises a condenser, a fluoride pump, a one-way valve, a heat-pipe heat exchanger, a control valve, a refrigerant liquid supply pipe, a refrigerant return pipe and a flow compatibility tube, wherein one end of the flow compatibility tube is connected with an outlet of the fluoride pump and the refrigerant liquid supply pipe and the other end is connected to an inlet of the condenser and the refrigerant return pipe; the outlet of the condenser is connected to the inlet of the fluoride pump; the flow compatibility tube is provided with the one-way valve for achieving the target that a refrigerant flows to the condenser from the fluoride pump; at least one heat-pipe heat exchanger is connected between the refrigerant liquid supply pipe and the refrigerant return pipe; and the control valve is arranged at the inlet of the heat-pipe heat exchanger. According to the fluoride pump cooling flow compatibility system for the data center, the problems that a liquid supply branch pipe close to the fluoride pump is over-high in refrigerant flow, the refrigerant in the heat-pipe heat exchanger is unstable in flow state and uneven in flow distribution, the refrigerant between different racks / cabinets is uneven in flow distribution, and the heat dissipation capacity is not up to standard when an existing fluoride pump cooling system is used by the data center can be solved.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

Organic waste gas adsorption and purification system of multi-layer fluid bed

PendingCN113069886AUniform feedingImprove purification efficiencyGas treatmentDispersed particle separationDesorptionExhaust fumes

The embodiment of the invention discloses a multi-layer fluid bed organic waste gas adsorption and purification system which comprises an adsorption and purification unit, a desorption and regeneration unit and a cooling unit, and the adsorption and purification unit is used for intermittently and uniformly discharging filler of an upper-stage adsorption layer to a lower-stage adsorption layer according to a set frequency; the saturated filler of the bottom adsorption layer is fed into a desorption regeneration unit, and organic waste gas flowing from bottom to top is purified through each stage of adsorption layer; the desorption regeneration unit is used for intermittently and uniformly feeding the filler of the upper desorption layer to the lower desorption layer according to a set frequency, feeding the high-temperature clean filler of the bottom desorption layer into the cooling unit, and heating the filler of each desorption layer through hot nitrogen or water vapor flowing from bottom to top; and the cooling unit is used for intermittently and uniformly discharging the filler of the upper-stage cooling layer to the lower-stage cooling layer according to a set frequency, feeding the normal-temperature clean filler of the bottom-stage cooling layer into the adsorption purification unit, and cooling the filler of each stage of cooling layer through air flowing from bottom to top.

Owner:孙绍堂

Catalytic distillation tower reaction segment structrue

InactiveCN100584420CAvoid problems with greater resistance to flowFlow state is stableChemical/physical processesFractional distillationEngineeringReaction zone

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Porous current-limiting and noise-reducing orifice plate and the current-limiting and noise-reducing device constituted thereof

The present invention provides a porous current-limiting and noise-reducing orifice plate and a current-limiting and noise-reducing device made of it. The structure of the multi-hole current-limiting and noise-reducing orifice plate is provided with a flow-limiting hole in the center of the orifice plate, and the rest of the flow-limiting holes are A group of concentric circles are arranged in a ring, and the number of restricting holes located on concentric circles with different radii gradually increases from the inside to the outside. The center to the edge of the orifice plate is arranged in an arithmetic progression. The current limiting and noise reducing device is composed of a pipe section and at least one porous current limiting and noise reducing orifice plate arranged in the pipe section, and connecting flanges are arranged at both ends of the pipe section. Compared with the conventional porous current-limiting and noise-reducing orifice plate, the present invention has improved noise-reducing capability and significantly reduced pressure loss.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com