Porous current-limiting and noise-reducing orifice plate and the current-limiting and noise-reducing device constituted thereof

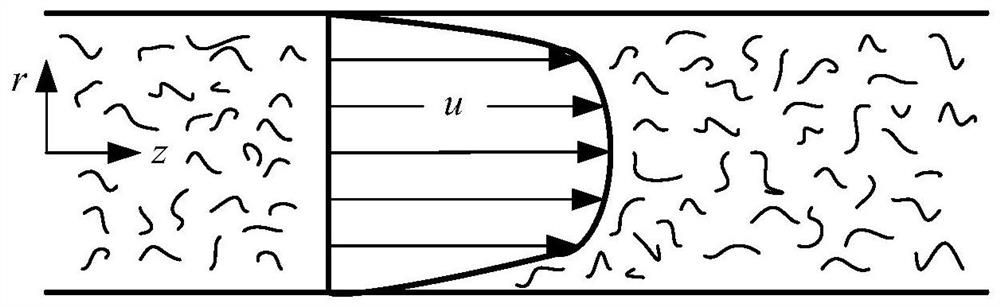

A technology of restricting orifices and noise-reducing holes, applied in the direction of pipe elements, mechanical equipment, pipes/pipe joints/fittings, etc. The effect of better current limiting and noise reduction, sufficient fluid development, and reduced extreme value difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

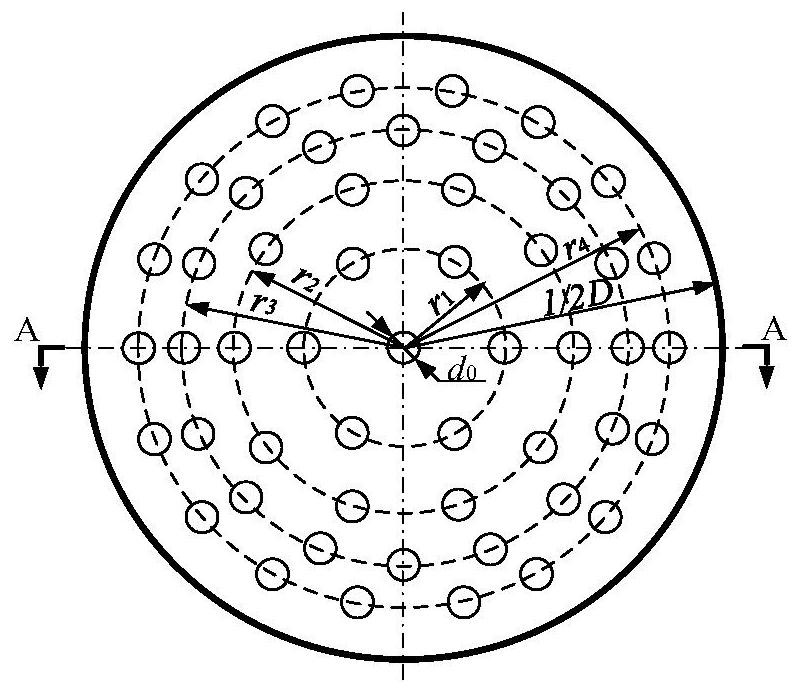

[0045] The porous current-limiting and noise-reducing orifice plate disclosed in this embodiment has a structure such as Figure 3A , the installation method is as follows Figure 9 shown. The porous current-limiting and noise-reducing orifice of this embodiment has a diameter of 203mm, a thickness of 12mm, a radius of 16mm, and a number of 25. The number of flow-limiting holes from the center of the orifice to the edge The order is: 1, 6, 8, 10, and the radius difference of the adjacent concentric circles where the flow limiting hole is located is: 34mm, 26mm, 18mm. The fluid medium used in the porous flow-limiting and noise-reducing orifice of this embodiment is water vapor with an inlet pressure of 1.56 MPa and a mass flow rate of 0.85 kg / s. The porous current-limiting and noise-reducing orifice plate is directly welded into the pipeline to achieve the effect of current-limiting and noise-reducing.

[0046] Comparative example is Figure 4A Compared with the multi-hole ...

Embodiment 2

[0048] The current limiting noise reducer disclosed in this embodiment has a structure such as Figure 10 As shown, its composition includes four porous current-limiting and noise-reducing orifice plates, two different-diameter pipes, a straight pipe section, and two flanges; the orifice plates at all levels adopt the concentric circle radius difference of the present invention in an arithmetic sequence arrangement , The interstage orifice plate is welded to the pipeline, and the two ends are connected to the inlet and outlet pipelines with flanges, forming a four-stage porous current limiting and noise reducer as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com