Energy-saving spindle for magnetic suspension two-for-one twister

A double twisting machine and magnetic levitation technology, which is applied in spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of large rotation resistance of spindles, large load weight, etc., and reduce the unevenness of twist. , the effect of increasing production and improving product quality levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

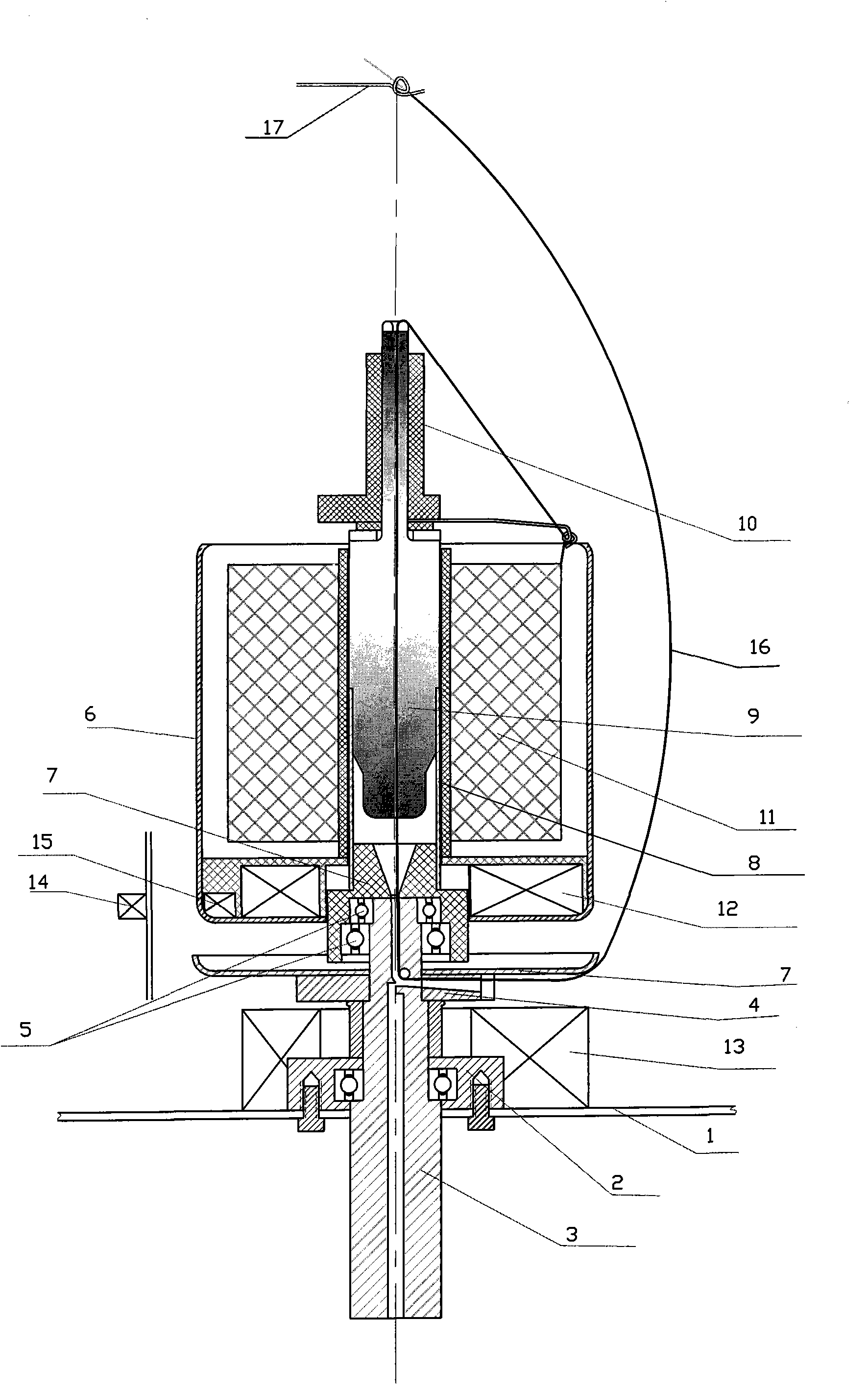

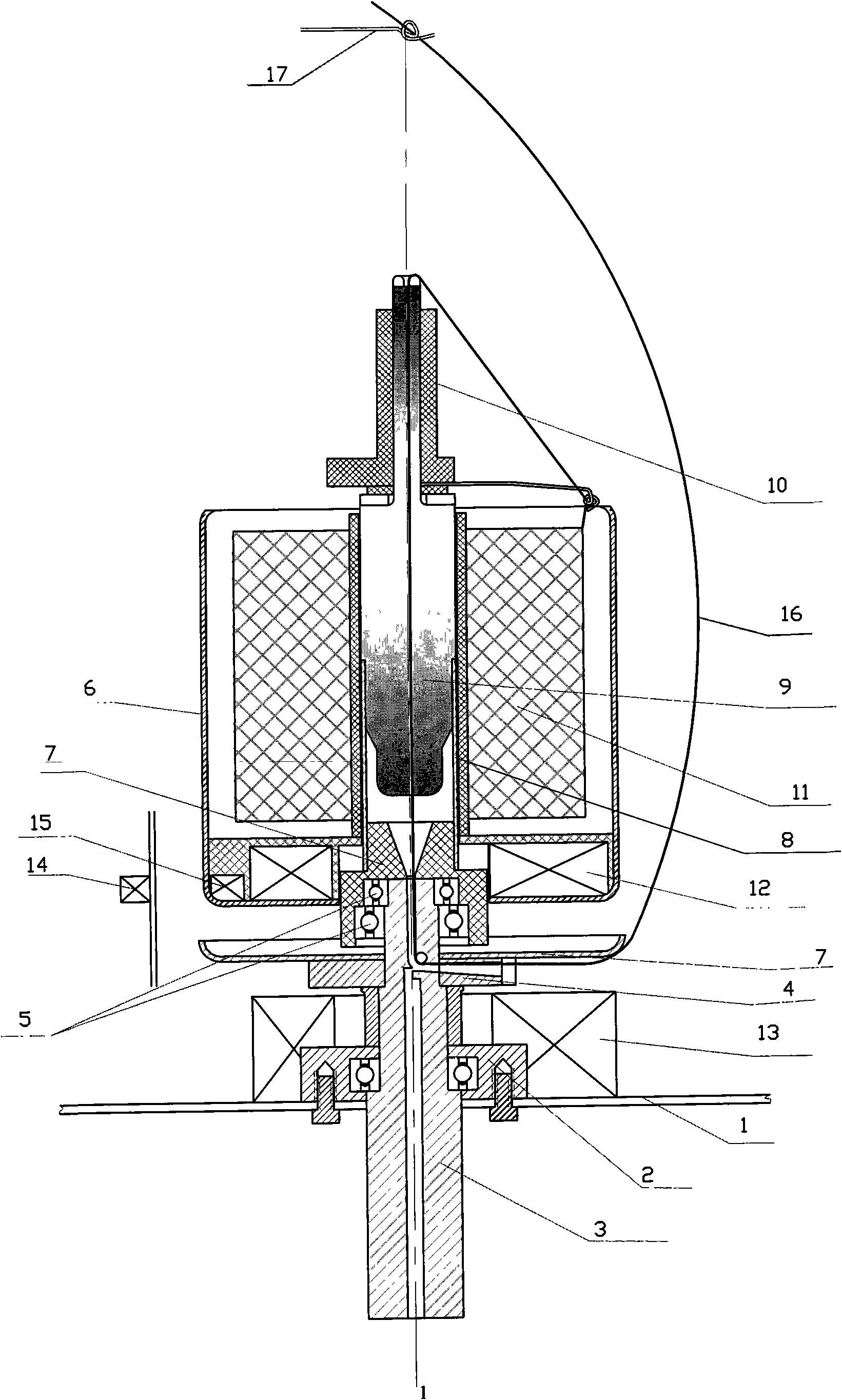

[0011] The embodiments of the present invention are described in detail below with reference to the drawings

[0012] As shown in the figure, the magnetic suspension two-for-one twisting energy-saving spindle of the present invention has a bottom plate 1, a bearing seat 2 installed on the bottom plate 2, a spindle 3 installed in the bearing seat 2, and a yarn storage on the spindle 3 respectively. Disk 4, double bearing 5, sleeve 7 tightly sleeved outside the double bearing, hollow tube 8 connected to sleeve 7, yarn tensioner 9, flyer 10, sleeved on sleeve 7 and hollow tube 8 A circular tank shell 6 that slides up and down and cannot rotate relatively. The circular tank shell 6 is equipped with a ring-shaped permanent magnet 12 and a ring-shaped permanent magnet 13 adsorbed on the floor (or ingot base). The built-in permanent magnet 15 and the external permanent magnet 14 have opposite poles opposite to each other. The yarn supply bobbin 11 installed in the circular tank shell 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com