High-efficiency gas and liquid mixer for gas and liquid two-phase flow experiment

A gas-liquid two-phase flow, gas-liquid mixer technology, applied in the direction of fluid mixer, mixer, mixing method, etc., can solve the flow state disorder of the produced gas-liquid mixture, increase the contact area of gas and liquid, and flow loss. Large and other problems, to achieve the effect of uniform stress distribution, reduction of impact loss, and reduction of resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

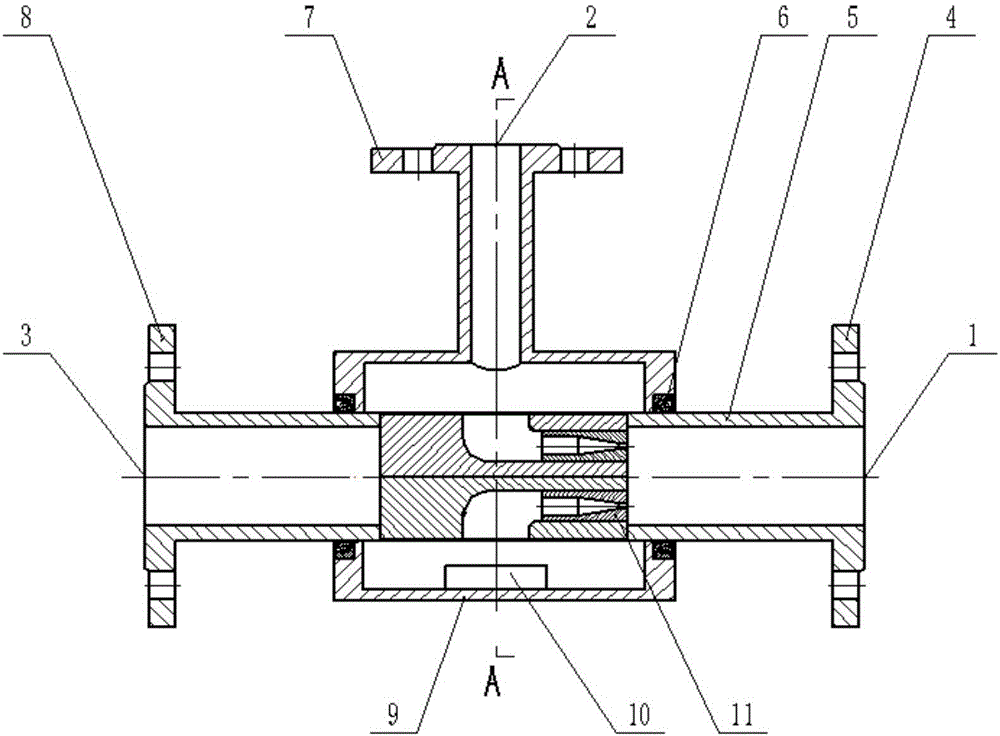

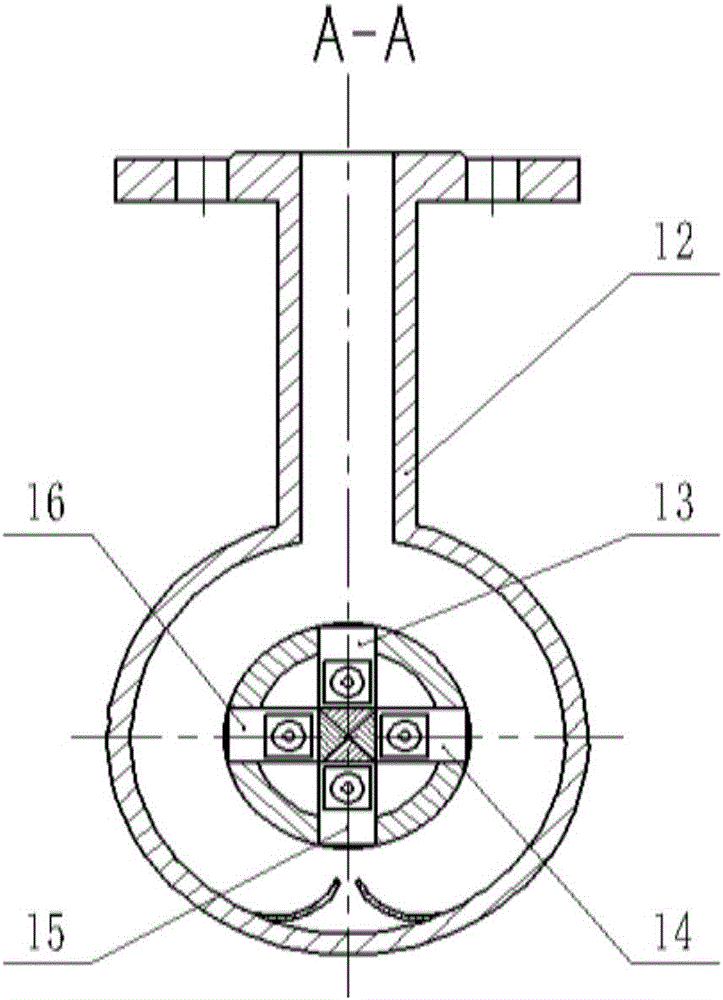

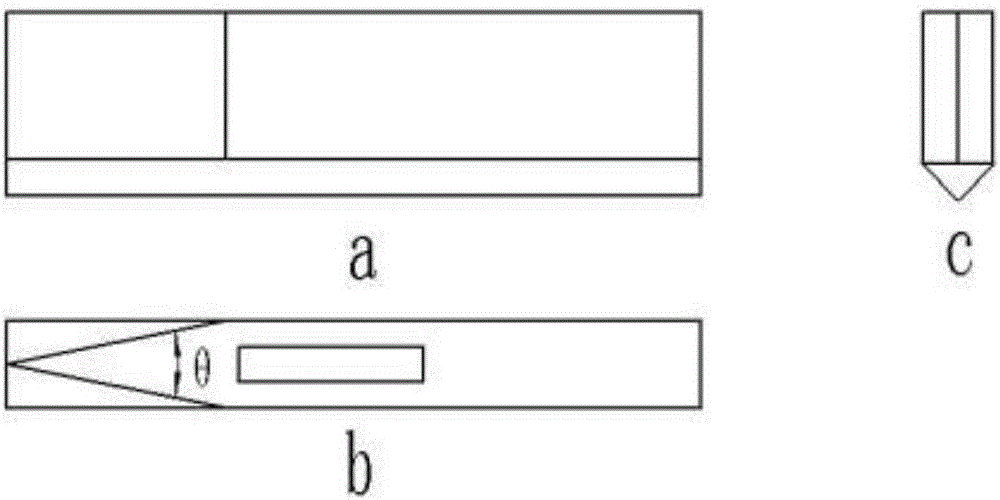

[0036] The specific implementation method of the present invention is now described in conjunction with the accompanying drawings: In order to meet the observation requirements of the test bench, an embodiment of the present invention is processed by using organic glass with good transparency and stable chemical properties. In order to realize the gas-liquid mixing function, the gas-water mixer adopts a horizontal three-way structure, and the three inlet and outlet ports are all equipped with flanges. The inlet flange 2 is connected to the sleeve 9 through the inlet pipe 12, the inlet flange 4 is connected to the outlet flange 8 through the main flow pipe 5, the sleeve 9 is coaxially sleeved outside the main flow pipe 5, and the inside of the sleeve 9 is far away from the inlet port. There are two guide vanes 10 arranged symmetrically, sealing grooves are opened at the left and right ends of the sleeve 9, and a skeleton oil seal 7 is used to seal the contact surface between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com