Modular directional flow pipeline type piezoelectric energy harvester arranged in a circumferential array

A technology of array arrangement and piezoelectric energy harvesting, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problem of large application limitations and difficult adjustment of coupling relationship and other problems, to achieve the effect of high space utilization, increased vibration amplitude, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

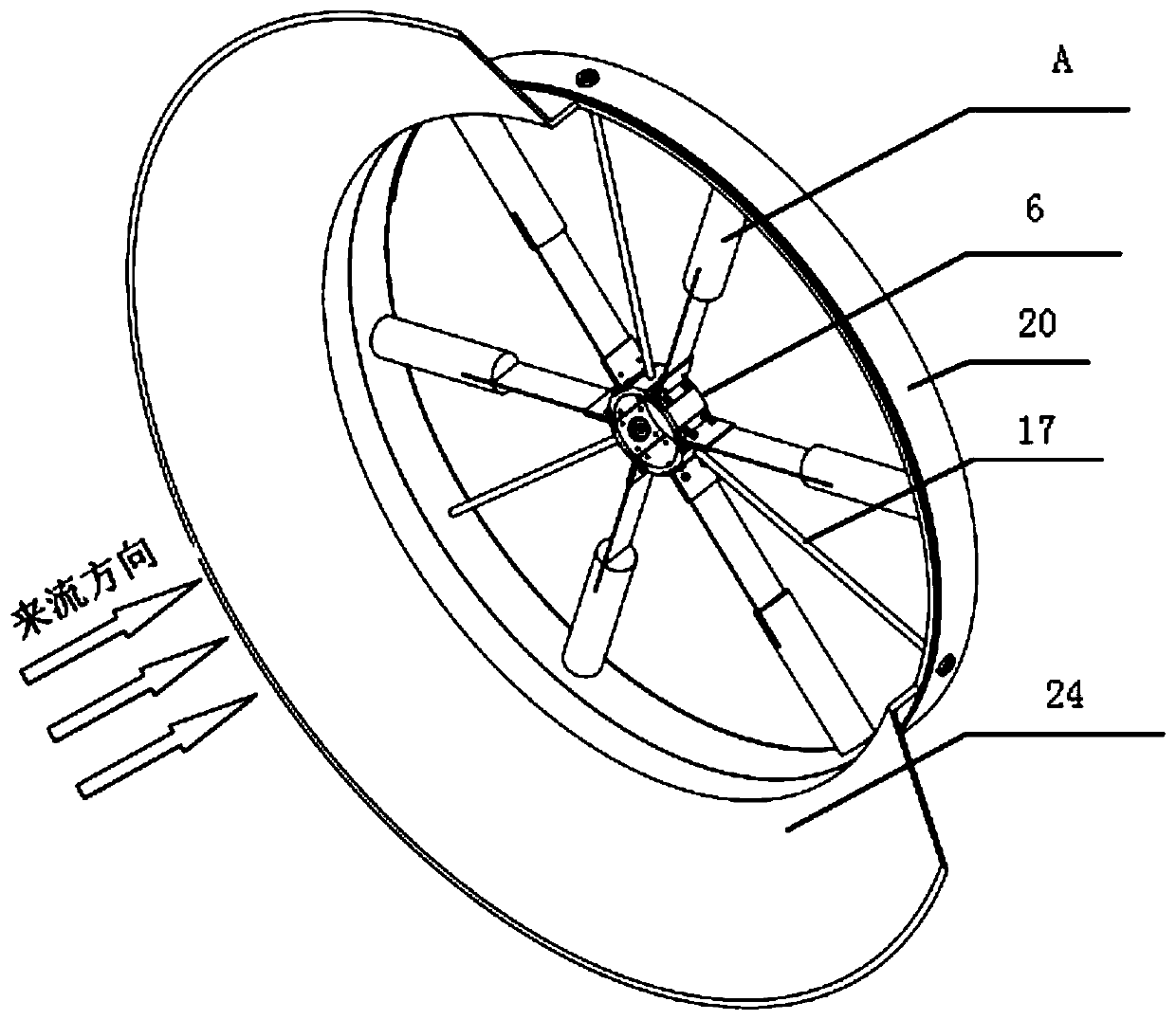

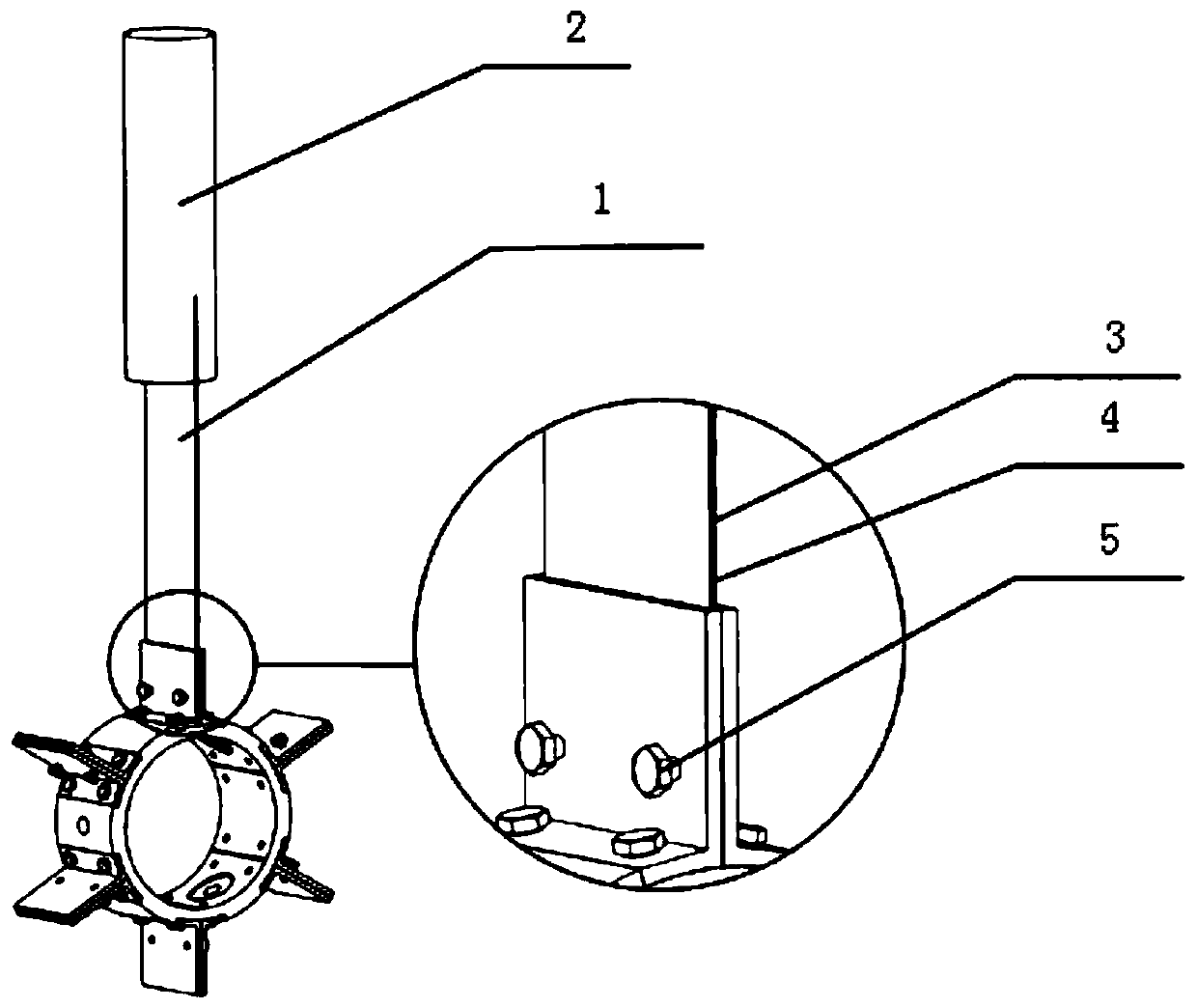

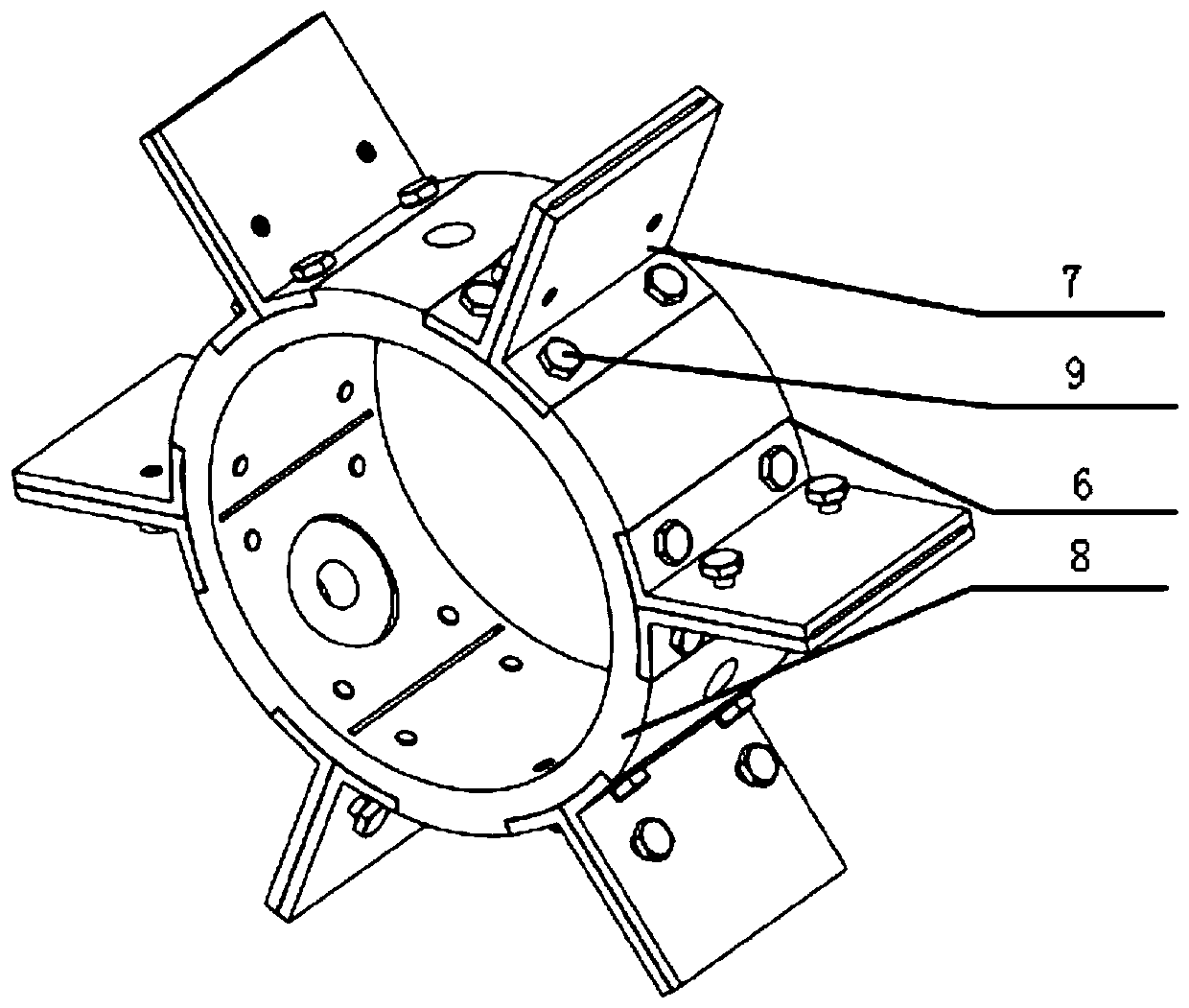

[0031] Such as Figure 1 to Figure 13 As shown, a piezoelectric energy harvester arranged in a modular directional flow pipe circumferential array described in this embodiment includes a piezoelectric vibrator, a central support, a current-limiting outer ring, a connecting screw, and a flow-concentrating speed increaser. ring; the piezoelectric vibrator includes a piezoelectric cantilever beam 1 and a spoiler column 2; the piezoelectric cantilever beam 1 is formed by attaching a piezoelectric material 3 to an elastic base 4, both of which have the same width, and are inserted into a central support 6 On the top, it is clamped by the clamping plates 7 on both sides, and fixed by pressing the compression bolts 5 through the threaded holes 10 on the side, and there are 6 pieces evenly distributed in the circumferential direction. The seat 8 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com