Catalytic oxidation treatment method of reverse-osmosis strong brine

A treatment method and catalytic oxidation technology, applied in the directions of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of poor catalytic effect of ozone oxidation catalysts, and achieve the effect of improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

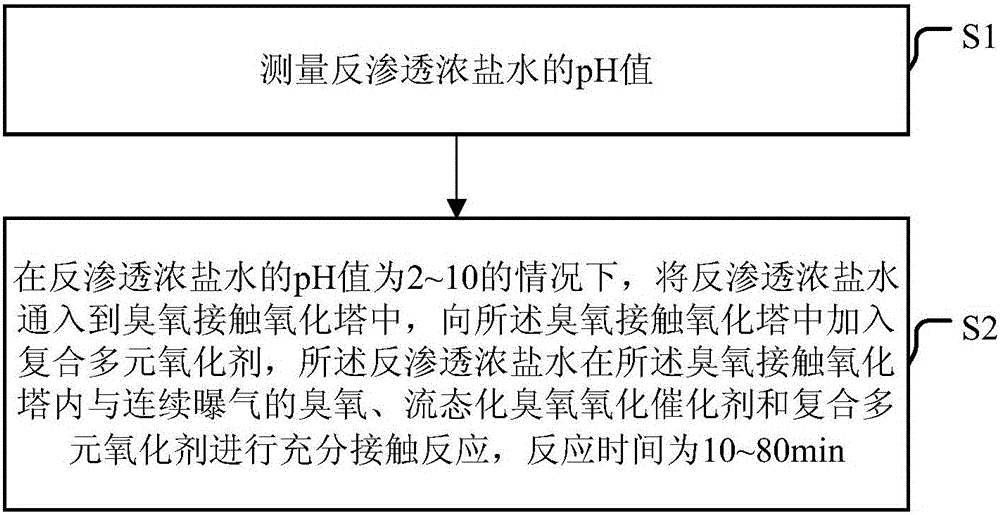

Method used

Image

Examples

Embodiment 1

[0039] The waste water comes from the reverse osmosis concentrated brine of a refinery project of Poten Environment Group Co., Ltd. Wastewater initial water quality index: COD Cr (Using potassium dichromate (K 2 Cr 2 o 7 ) measured as an oxidizing agent (ChemicalOxygenDemand)) is 303.7mg / L, the chromaticity is 64 times, and the turbidity is 1.285NTU.

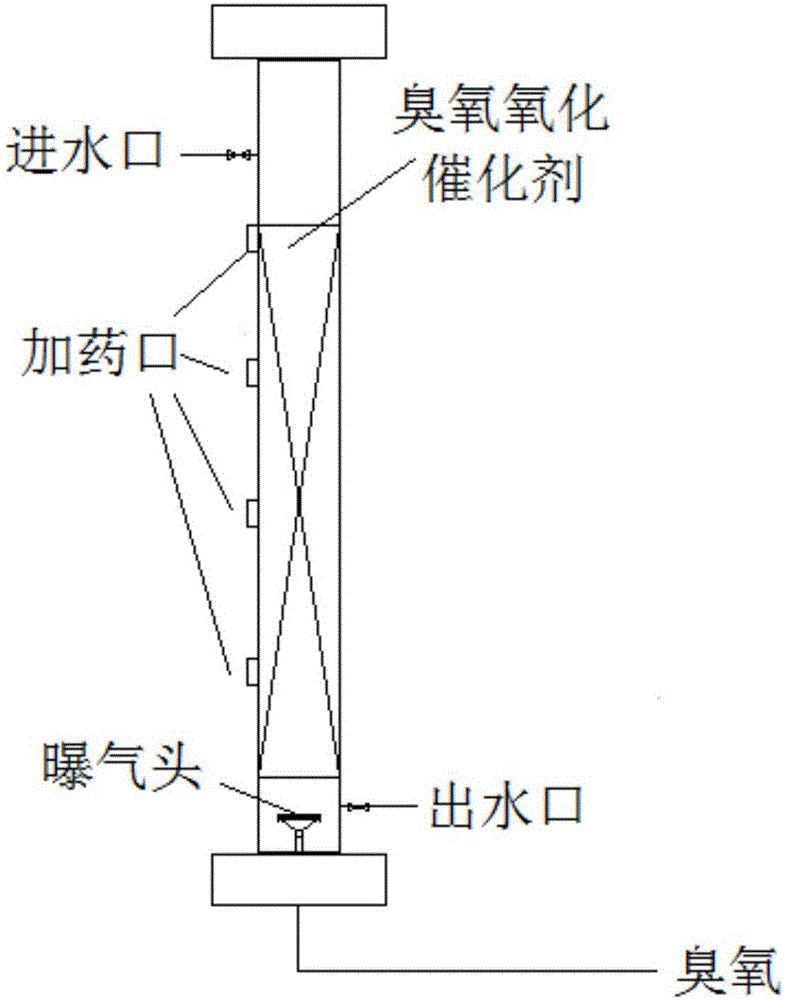

[0040] Take 1L of waste water, measure the pH value of the waste water, the pH value is 7.4. In the ozone contact oxidation tower, add 0.3g of granular fruit shell activated carbon with a particle size of 0.3mm, which is loaded with manganese and nickel ozone oxidation catalysts. Ozone is introduced into the bottom of the ozone contact oxidation tower for continuous aeration. The ozone flow rate is 0.80L / min, the dosage is 360mg, in this case, the ozone oxidation catalyst presents a stable flow state. 100mg of hydrogen peroxide is divided into four equal parts, and evenly dosed at the same time in the four dosing ports wher...

Embodiment 2

[0043] The waste water comes from the reverse osmosis concentrated brine of a refinery project of Poten Environment Group Co., Ltd. Wastewater initial water quality index: COD Cr It is 298.4mg / L, the color is 64 times, and the turbidity is 1.296NTU.

[0044] Take 2L of waste water, measure the pH value of the waste water, and the pH value is 6.5. In the ozone contact oxidation tower, add 1g of ozone oxidation catalyst with a particle size of 0.5mm on the granular porous ceramics loaded with iron, nickel, and copper, and pass ozone into the bottom of the ozone contact oxidation tower for continuous aeration, and the ozone flow rate is 1.20 L / min, the dosage is 474mg, in this case, the ozone oxidation catalyst presents a stable flow state. 400mg of sodium hypochlorite is divided into four equal parts, and is uniformly added to the four dosing ports on the outer wall of the ozone contact oxidation tower at the same time. for 45min.

[0045] After the reaction, collect the eff...

Embodiment 3

[0047] The waste water comes from the reverse osmosis concentrated brine of a refinery project of Poten Environment Group Co., Ltd. Wastewater initial water quality index: COD Cr It is 289.4mg / L, the color is 64 times, and the turbidity is 1.289NTU.

[0048] Take 1L of waste water, measure the pH value of the waste water, the pH value is 8.8. In the ozone contact oxidation tower, 0.9g of coal-based columnar activated carbon with a particle size of 0.4mm is loaded with an ozone oxidation catalyst of iron, cerium, cobalt, and copper, and ozone is continuously aerated at the bottom of the ozone contact oxidation tower. The flow rate is 1.30L / min, and the dosage is 200mg. In this case, the ozone oxidation catalyst presents a stable flow state. 260mg of sodium hypochlorite is divided into four equal parts, and is uniformly added to the four dosing ports on the outer wall of the ozone contact oxidation tower at the same time. It is 55min.

[0049] After the reaction, collect the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com