Drying cylinder condensate water draining device

A discharge device and condensed water technology, applied in the direction of textiles and papermaking, paper machines, dryers, etc., can solve the state of unstable vapor-liquid two-phase flow, without improving the drainage pipe of the drying cylinder, the effect cannot meet industrial production, etc. problems, to achieve the effect of ensuring the discharge drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

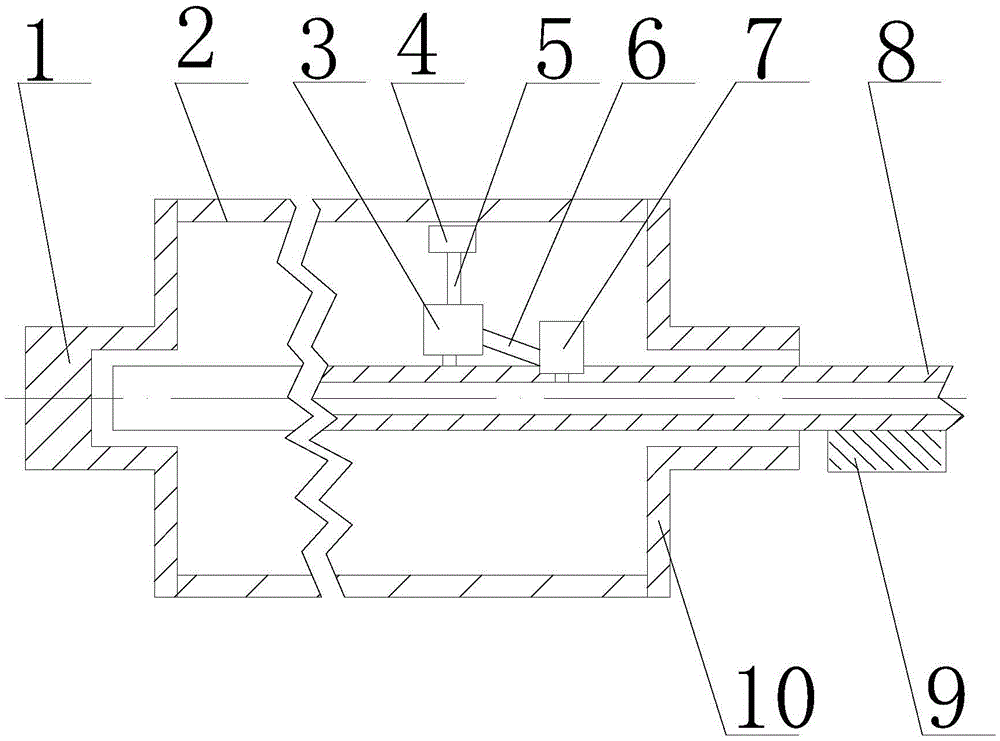

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] see figure 1 , the drying cylinder of the present invention comprises cylinder body 2, and the left end cap 1 that is installed on cylinder body 2 two ends and right end cap 10, the center of left end cap 1 is provided with blind hole, and the center of right end cap 10 is provided with through hole; Rigid drainage pipe 8 The left end of the drain pipe 8 is radially fixed to the central blind hole of the left end cover 1 of the drying cylinder through a bearing, and the right end of the drain pipe 8 passes through the central through hole of the right end cover 10 of the drying cylinder and is sealed and assembled with the through hole before being fixed on the frame 9; A group of separators 3 are rigidly fixed on the drain pipe 8 between the left end cover 1 and the right end cover 10 of the drying cylinder. The separators 3 all use steam-water separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com