Municipal solid waste pyrolysis and gasification process

A technology for municipal solid waste, pyrolysis and gasification, which is applied in the field of municipal solid waste pyrolysis and gasification technology, can solve problems such as troublesome pyrolysis treatment of municipal solid waste, reduce bulk density and moisture content, reduce energy loss, and improve looseness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

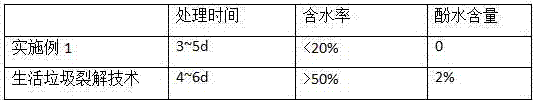

Embodiment 1

[0023] Embodiment 1: municipal solid waste pyrolysis gasification process, comprises the following steps:

[0024] a. Crushing: transport municipal solid waste to the double-shaft coarse crusher for coarse crushing, and the size of the crushed garbage is between 2 and 2.5cm;

[0025] b. Drying and dehydration: transport the crushed municipal solid waste to the biological drying bin for microbial dehydration, put the crushed waste into the biological drying bin from the feeding port, and the agitator can evenly stir the municipal solid waste , so that it is distributed on each stock plate, while stirring, add aerobic bacteria composed of Bacillus subtilis, Bacillus licheniformis, Bacillus macerans, Trichoderma reesei, Paenibacillus, Trichoderma konshii, white mold, The microbial agent composed of EM bacteria, nitrogen-fixing bacteria, phosphorus-solubilizing bacteria and potassium-solubilizing bacteria, after continuous stirring for 5~10 hours, stop stirring, continue to feed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com