AALOO multipoint water feeding synchronization denitrification and dephosphorization process, operation method thereof, and used biological reaction tank

A technology of synchronous denitrification and phosphorus removal and multi-point water inflow, which is applied in the field of environmental engineering, can solve the problems of complex process process, increase process operation management and operation difficulty, ensure the treatment effect, improve the guarantee rate of effluent compliance, and solve the problem of Inconsistent Effects of Slime Age Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

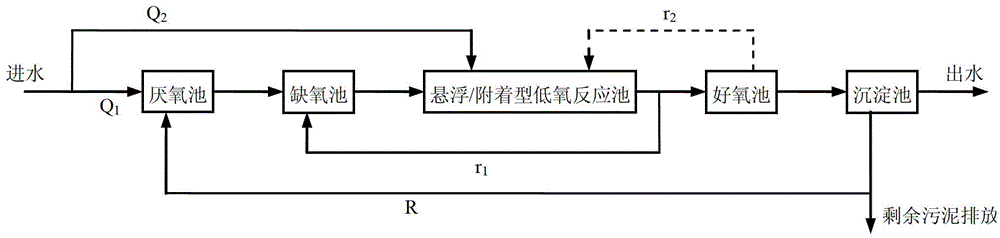

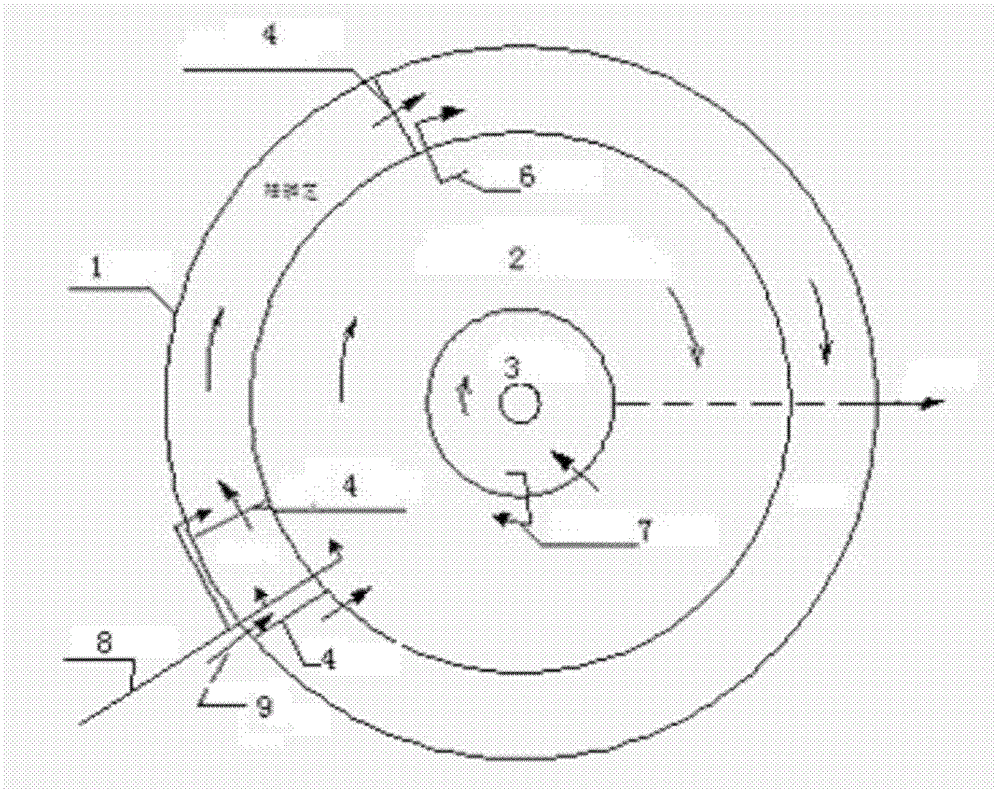

[0023] Such as figure 1 Shown: an AALOO multi-point influent synchronous nitrogen and phosphorus removal process, characterized in that all or part of the pretreated sewage enters the anaerobic tank, and then flows through the anoxic tank, hypoxic tank, and short-term good Oxygen tanks and sedimentation tanks flow out, and part of the sewage can also directly enter the low-oxygen tanks to provide carbon sources for denitrification and denitrification and improve denitrification efficiency. Part of the settled sludge is returned to the anaerobic tank, and part of it is discharged as residual sludge. There is a mixed liquor backflow from the hypoxic tank to the anoxic tank to provide the NO required for denitrification and phosphorus removal 3 - , From the short-term aerobic pool to the hypoxic pool, there is also a mixed liquid reflux to strengthen the nitrification, and the reflux ratio depends on the need. A small grid is separated from the front end of the anaerobic tank,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com