Pharmaceutical chemical wastewater treatment device and treatment method thereof

A technology for chemical wastewater and treatment devices, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. New environmental discharge standards, poor biodegradability of pharmaceutical and chemical wastewater, etc., to achieve the effects of easy equipment manufacturing industrialization, low process operating costs, and enhanced pretreatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

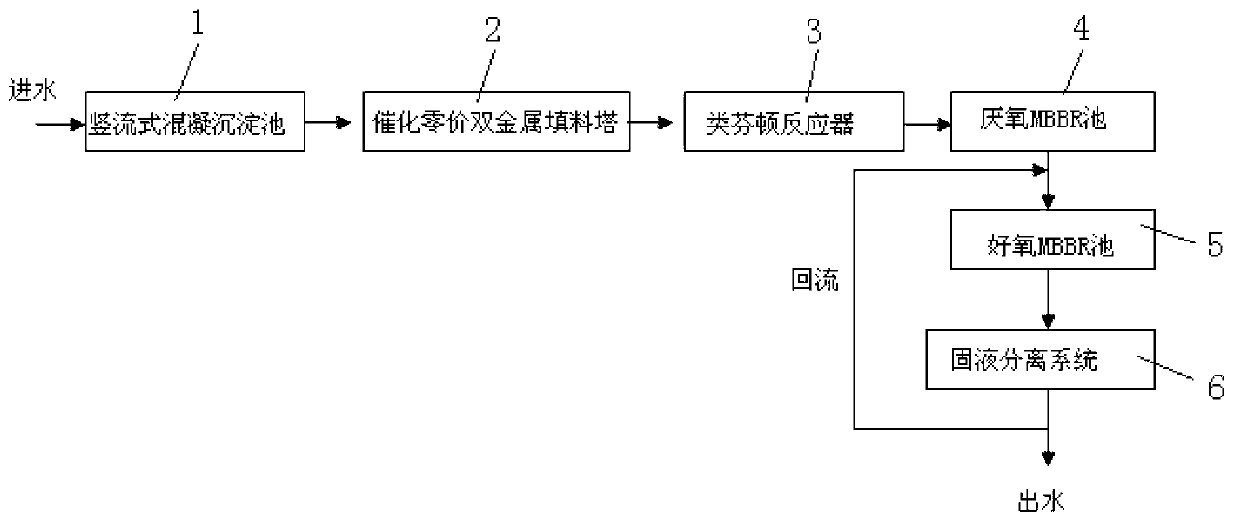

[0025] Such as figure 1 As shown, a pharmaceutical and chemical wastewater treatment device includes a vertical flow coagulation sedimentation tank 1, a catalytic zero-valent bimetallic packed tower 2, a Fenton-like reactor 3, an anaerobic MBBR tank 4, and an aerobic MBBR tank connected in sequence 5. The solid-liquid separation system 6, the water outlet of the solid-liquid separation system 6 communicates with the aerobic MBBR pool, so that the effluent of the solid-liquid separation system 6 can flow back to the aerobic MBBR pool through the water outlet of the solid-liquid separation system 6 ; The vertical flow coagulation sedimentation tank 1 includes a vertical flow sedimentation tank 1 and a coagulation dosing device, and the coagulation dosing device is located above the vertical flow sedimentation tank 1 .

[0026] Utilize above-mentioned device to process the method for medical and chemical industry waste water, the specific steps of this method are as follows:

[...

Embodiment 2

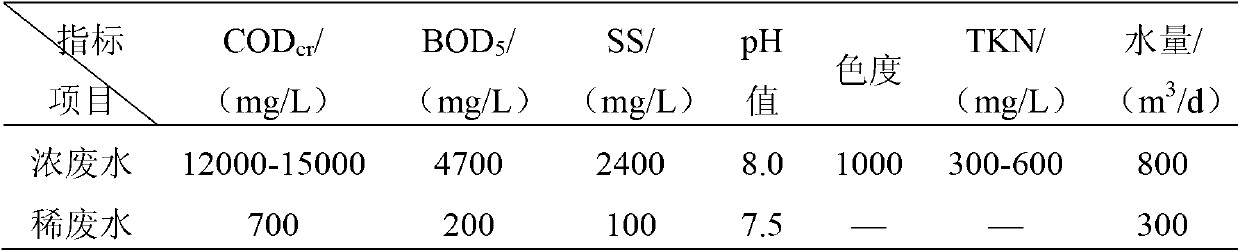

[0036] A pharmaceutical factory in Zhejiang mainly produces three raw materials and preparations of fluoroquinolones, vitamins, and antibiotics, and also produces feed additives, veterinary drugs, and chemical intermediates, with an annual output value of 1 billion yuan. Due to the expansion of production scale, the enterprise needs to construct the second phase of sewage treatment project. The wastewater treatment scale of the second phase project is 500m thick wastewater 3 / d, dilute wastewater 700m 3 / d, the quality of its wastewater is shown in Table 1.

[0037] Table 1 Wastewater quality and quantity

[0038]

[0039] The waste water is treated by quality separation. After the concentrated waste water passes through the fine grid and enters the adjustment tank, it is pumped into the flocculation vertical flow sedimentation tank of the present invention with a lift pump, and PAC and PAM are added to the water inlet pipeline through the coagulation dosing system for co...

Embodiment 3

[0041] Embodiment 3: basically the same as Embodiment 1, the difference is: the hydraulic retention time in the anaerobic MBBR tank in step 4 is controlled at 8h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com