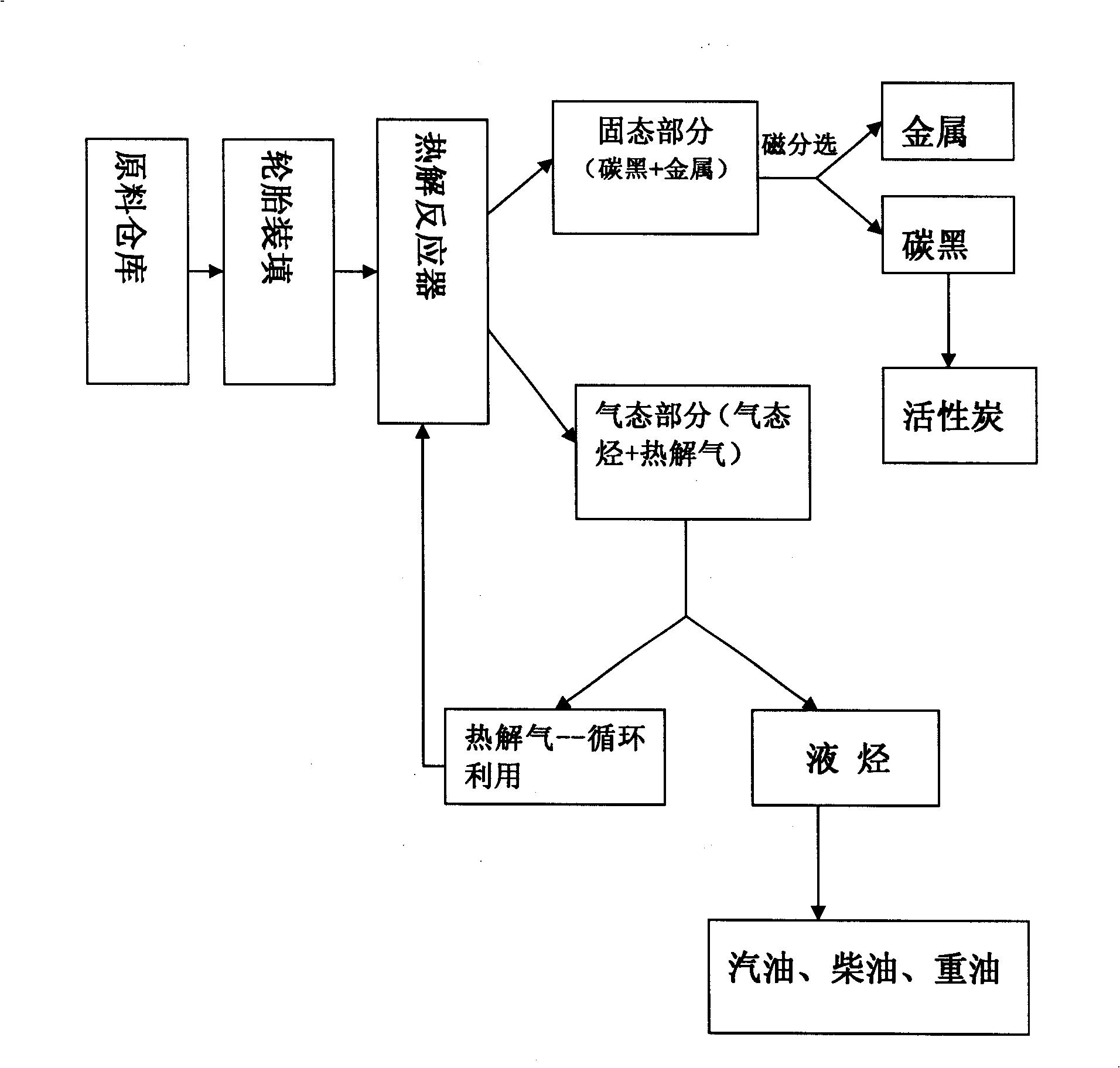

Apparatus for treating waste and old tyres

A technology of unloading device and conveying device, applied in the preparation of liquid hydrocarbon mixture, petroleum industry, plastic recycling, etc., can solve the problems of environmental pollution, difficulty in achieving continuous discharge, affecting the degree of process automation, and achieve good sealing effect. , cost reduction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

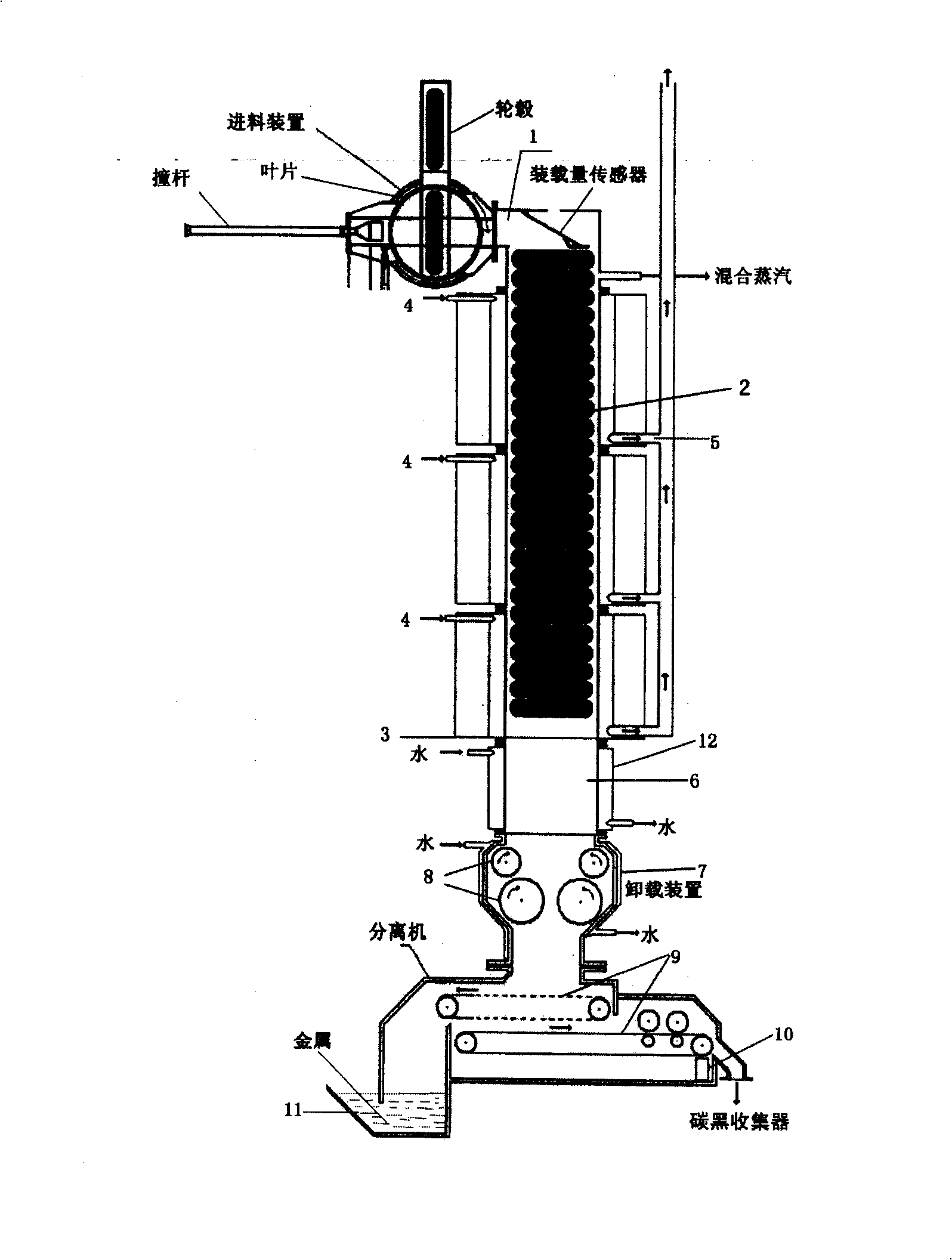

[0039] Further illustrate the present invention below in conjunction with accompanying drawing.

[0040] figure 2 It is a schematic diagram of the device of the present invention. Among them, 1 is the reactor inlet, 2 is the reactor body, 3 is the reactor outlet, 4 is the pyrolysis gas inlet, 5 is the pyrolysis steam outlet, 6 is the condenser, 7 is the shell, 8 is the Hub, 9 is a separator, 10 is a carbon black collector, 11 is a metal collector, and 12 is a water tank.

[0041]A device for processing waste tires includes a feeding device, a reactor, and a discharging device in sequence. The reactor includes a feed port, a shell, and a feed port in sequence; the feed port is connected to the feed device through an embedded sealing valve; the feed port is connected to the shell; the upper, middle, and lower parts of the shell are each There is a pyrolysis gas inlet, which divides the reactor into three heating areas. The shell is also provided with a mixed steam outlet, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com