Solar thermal power high-temperature long shaft molten salt pump

A technology of solar thermal power generation and molten salt pumps, which is applied to pumps, pump components, non-variable pumps, etc., can solve the problems of molten salt pump vibration failure, insufficient screw sealing effect, and potential safety hazards in smooth operation, and achieve low Cavitation, satisfies cavitation, improves hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

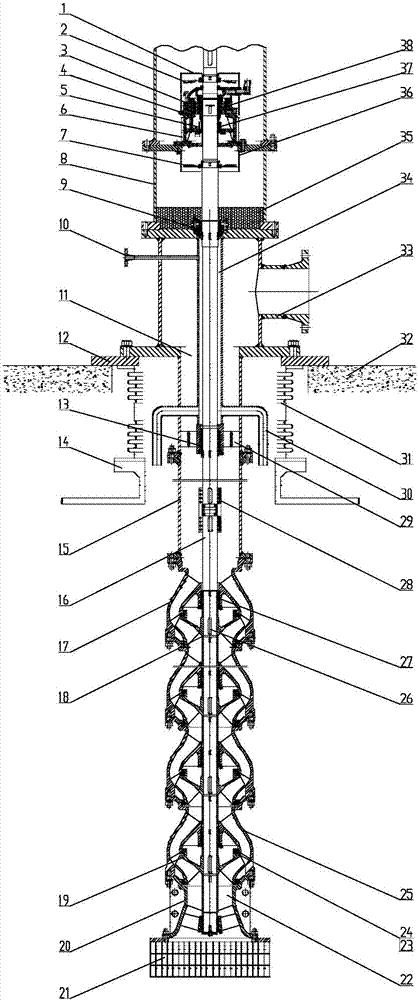

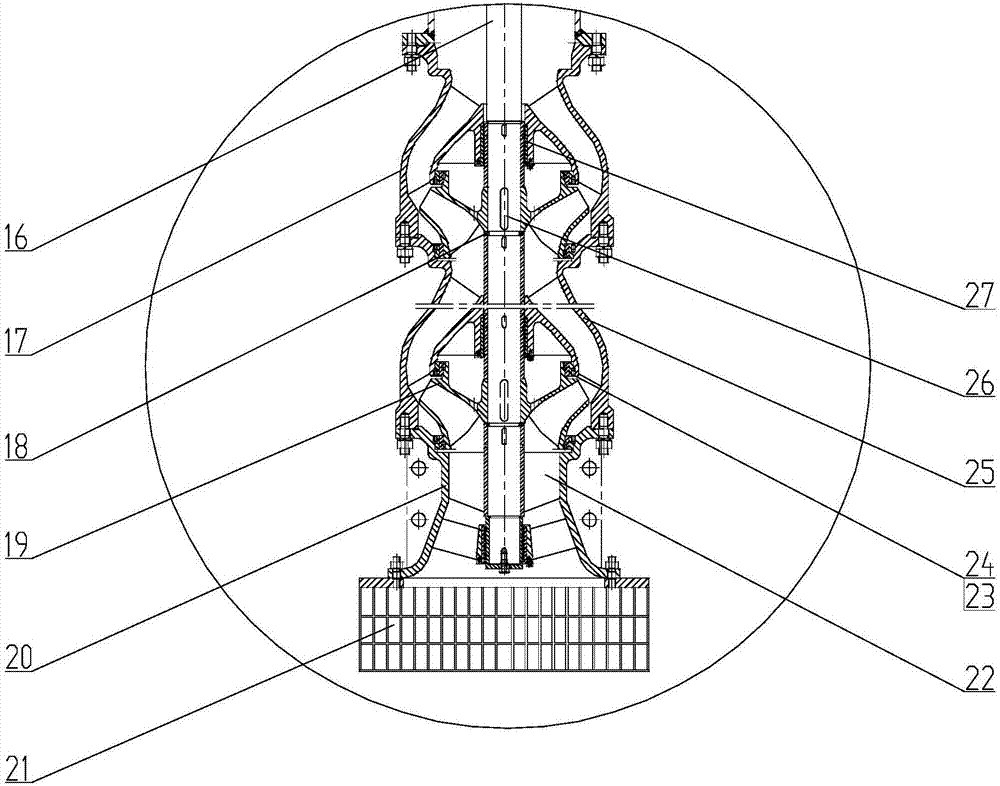

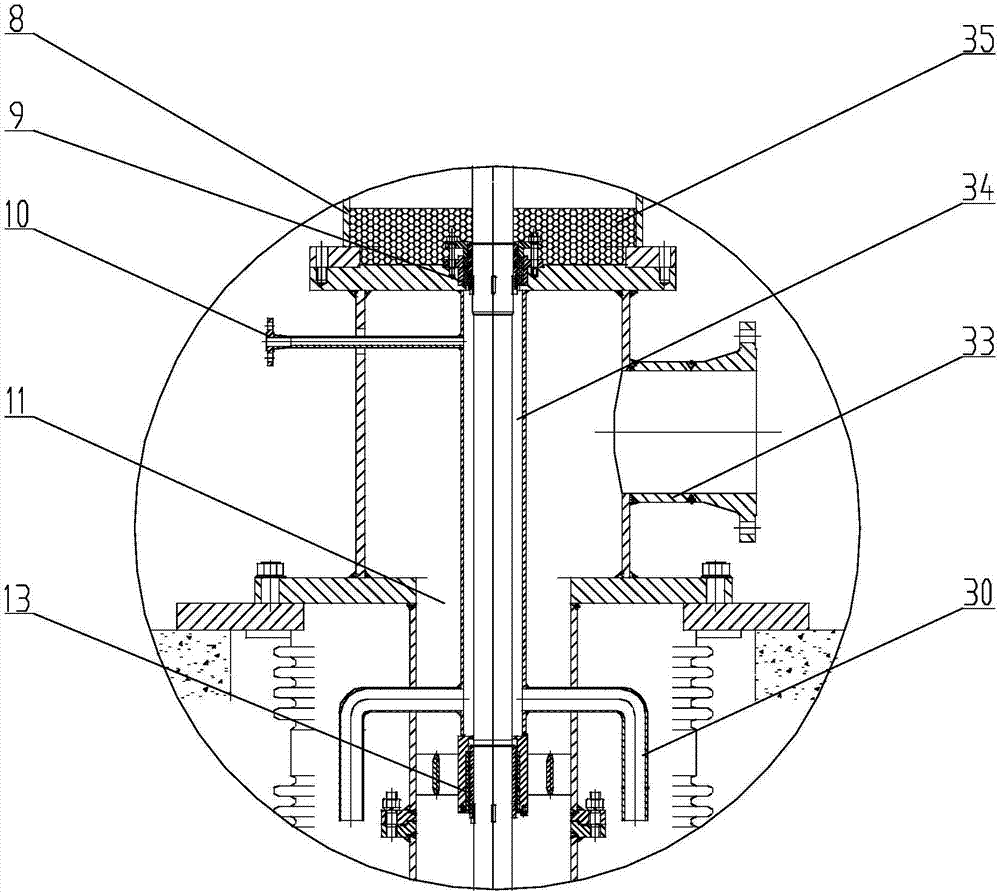

[0037] like Figure 1 to Figure 5As shown, a high-temperature long-axis molten salt pump for solar thermal power generation includes a pump shaft 16, and the pump shaft 16 is sequentially provided with hydraulic components, a support damping structure, a fluid sealing structure, and a bearing cooling device from bottom to top; The front end of the component is provided with a suction section 20, and the front end of the suction section 20 is provided with a cascade filter 21 to avoid backflow and eddy currents in the water at the entrance. The end of the hydraulic component is provided with a final diversion shell 17, and the end of the last stage diversion shell 17 is connected and fixed with the front end of the support tube 15 of the support vibration damping structure; the support tube 15 of the support vibration damping structure The end is connected and fixed with the bottom of the outlet section 33 of the fluid-tight structure through a flange plate, and the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com