Partial flow equivalently-dynamic diluting and sampling system for diesel engine exhaust particles and control method

A sampling system and diesel engine technology, applied in the field of dynamic dilution sampling system and control, can solve the problems of high price and difficult to meet domestic demand, and achieve the effect of convenient operation, low test and maintenance cost, and clear display.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

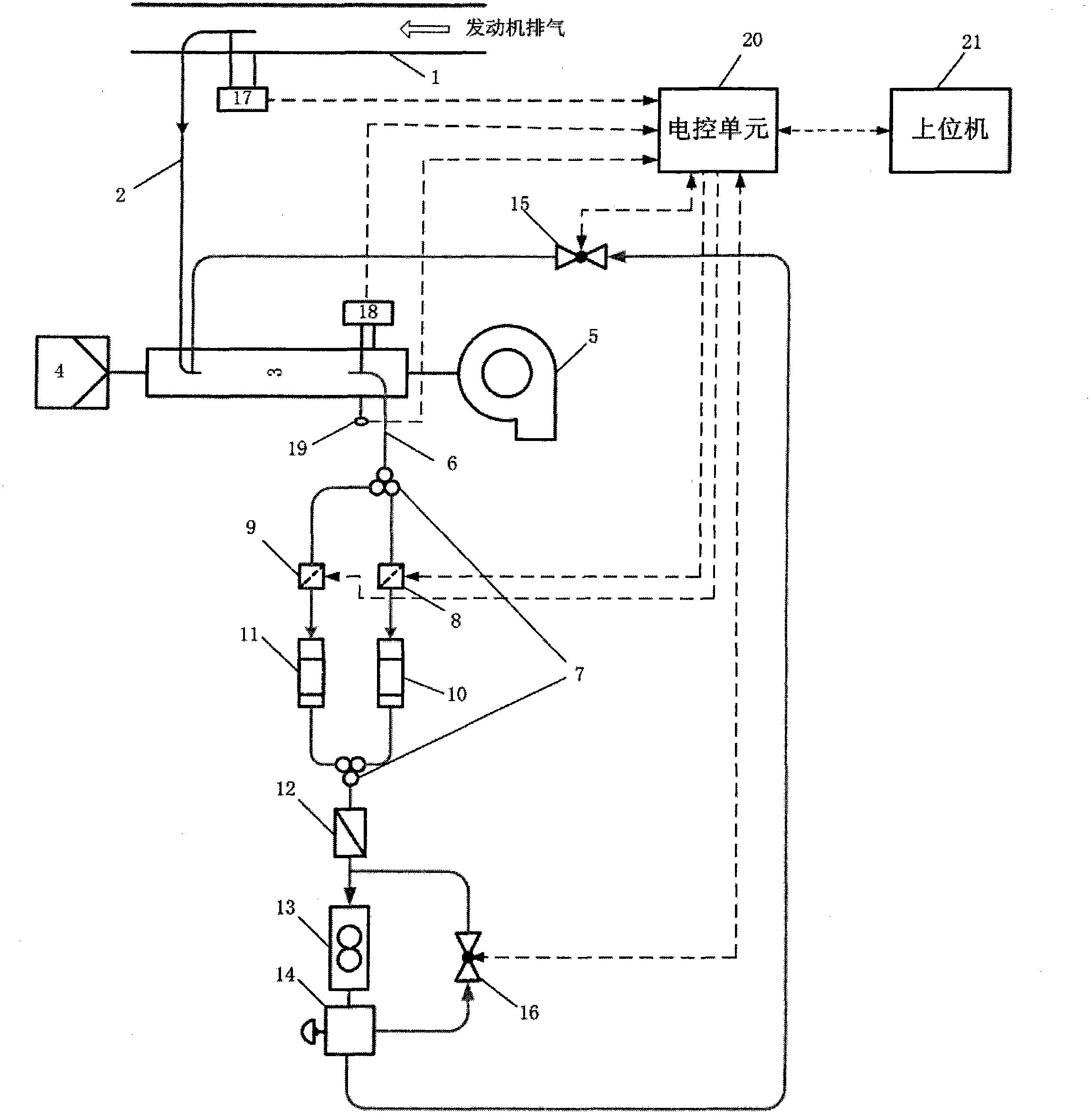

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] The working principle of the present invention is as follows:

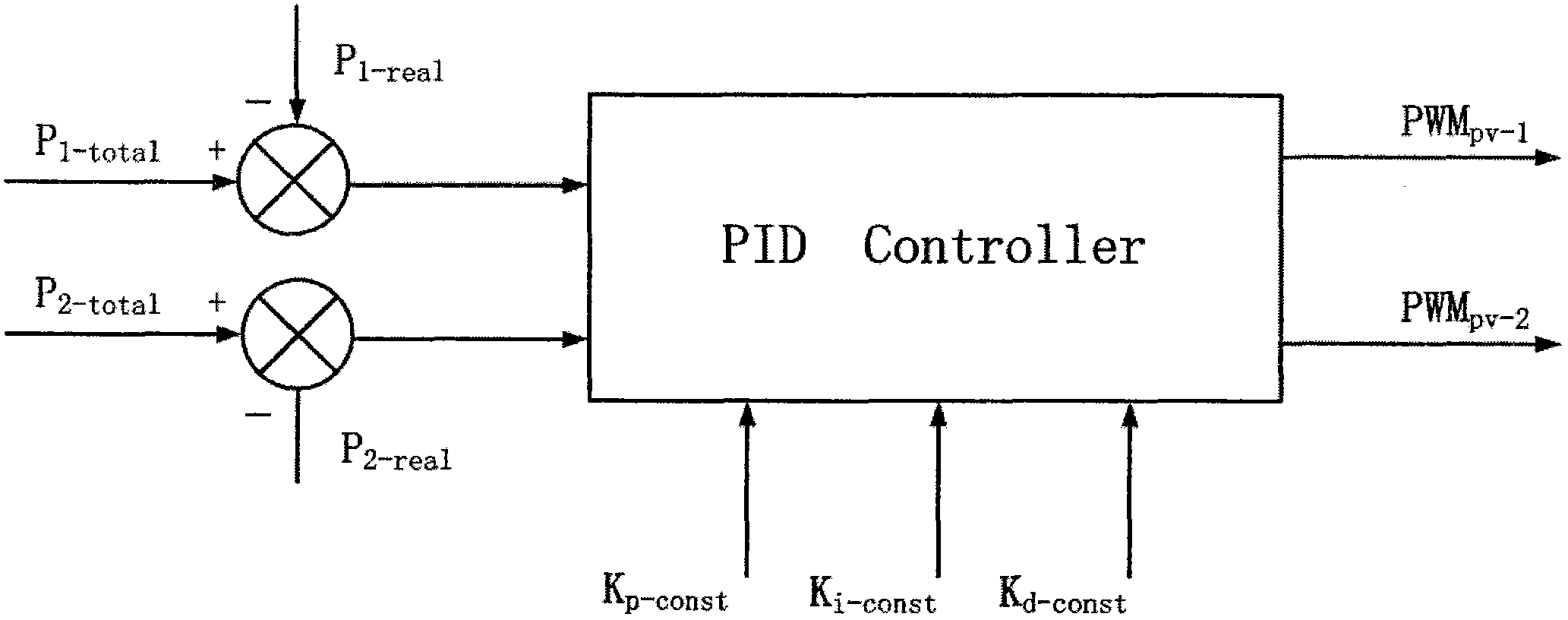

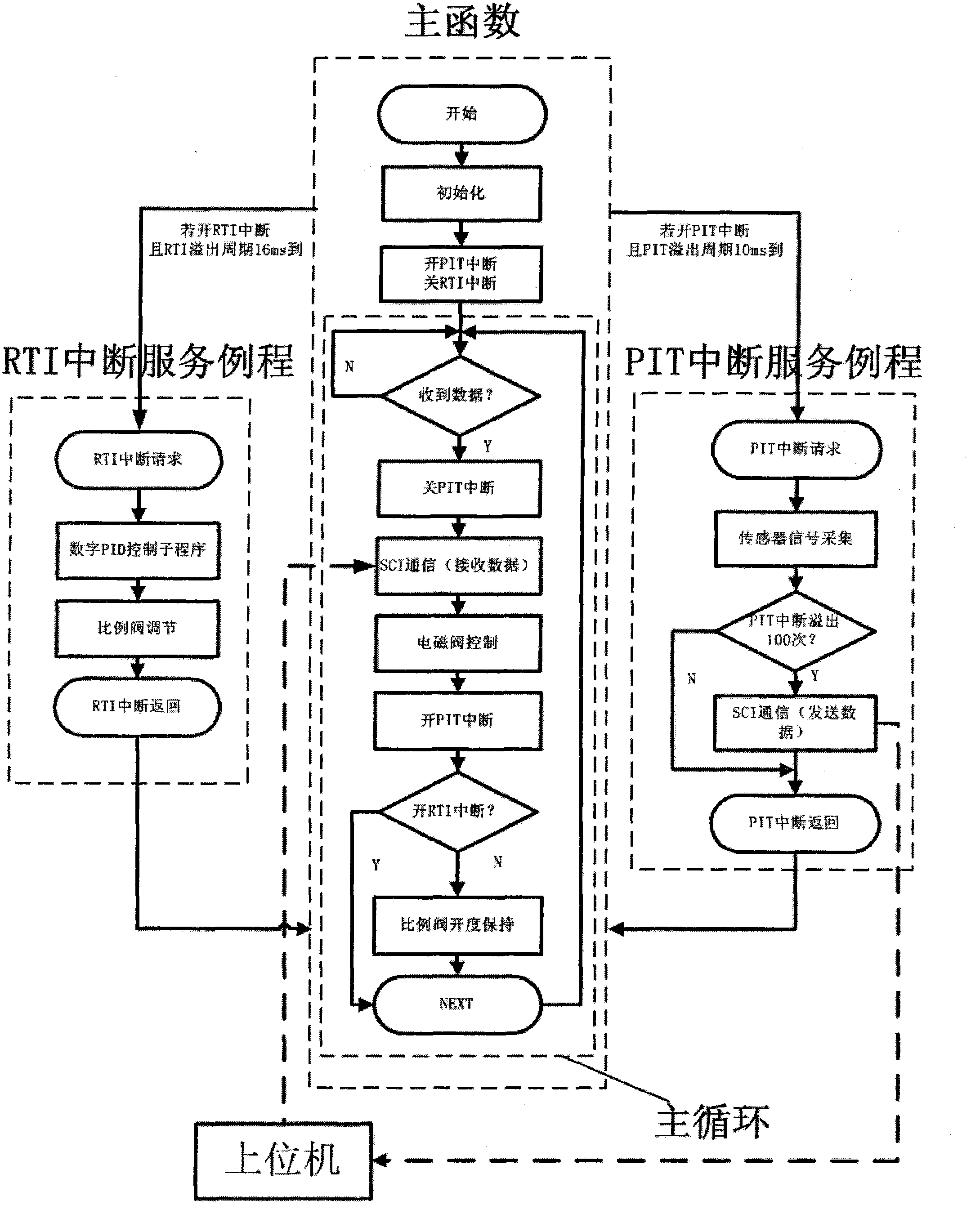

[0027] The electronic control unit 20 (lower computer) is powered on and starts to work, and after the serial port of the upper computer 21 is correctly configured, the upper and lower computers can realize bidirectional data transmission through the RS232 serial port communication protocol and a self-defined data format. The PIT interrupt service routine pre-stored in the electronic control unit 20 is responsible for collecting the signals of the temperature sensor 19, the opening degree of the proportional valve I15, the opening degree of the proportional valve II16, the micro-pressure difference sensor I17, and the micro-pressure difference sensor II18 every 10 ms. And transmit the collected data to the upper computer 21 every 1s for the user to monitor the state of the system. Simulta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com