Flowmeter

A flowmeter and counter technology, applied in the field of volumetric flow metering instruments, can solve problems such as decreased measurement accuracy, reduced liquid pressure, and easy wear of parts, and achieve stable liquid flow, small pressure loss, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

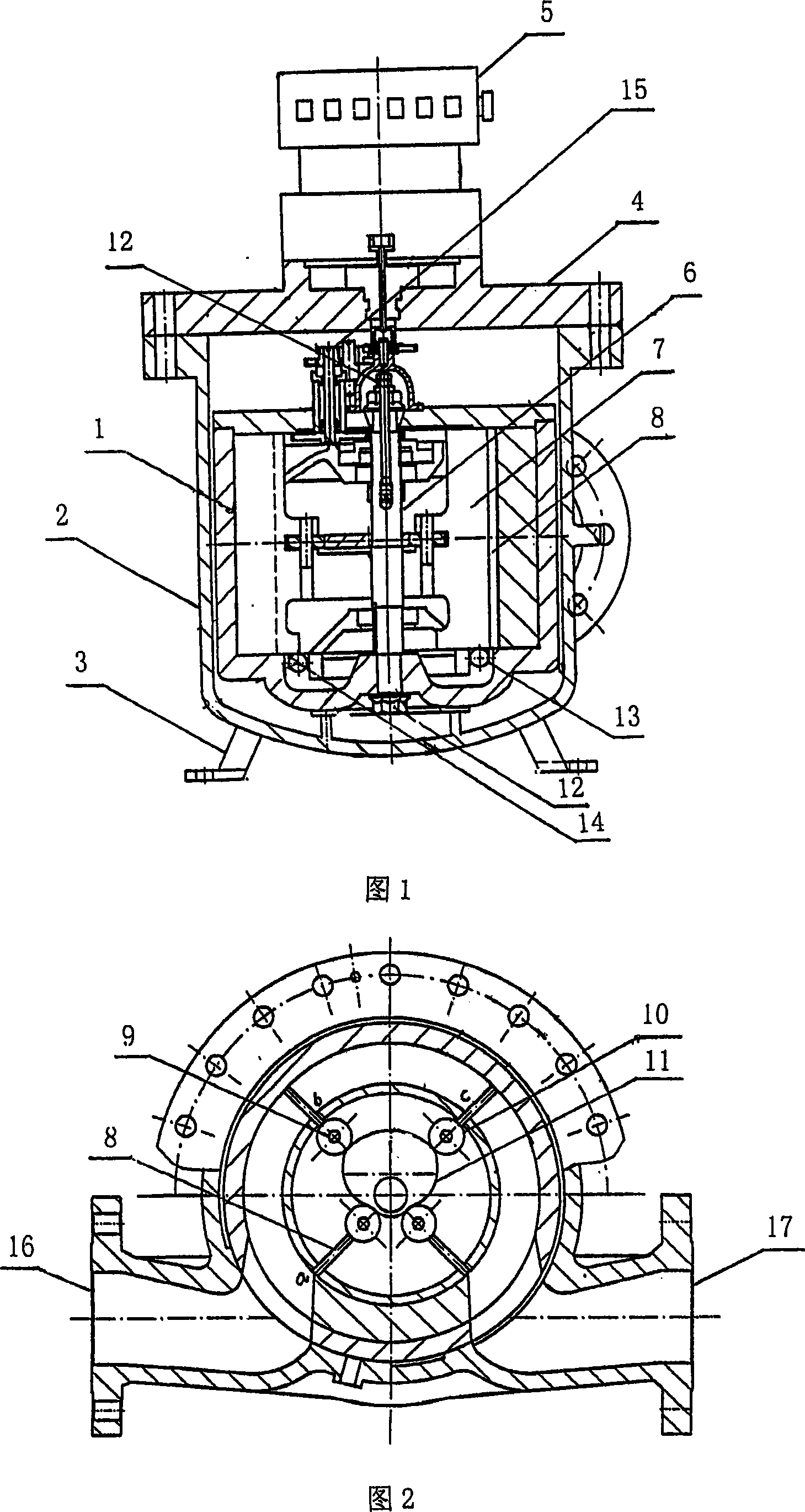

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0012] As shown in Figures 1 and 2, the flowmeter includes a metering body 1, a housing 2, a support 3, an upper cover 4 and a large character wheel counter 5, and is characterized in that: the metering body 1 is provided with two pairs symmetrical to the main shaft 6 Distributed and connected scrapers 7, and a cylindrical rotor 8 with the main shaft 6 as the center, the outer end of the scraper 7 runs through the grooves left on the wall of the rotor 8 and can stretch back and forth radially, the scraper 7 The inner end of the rotor is in contact with the cam 11 fixed on the main shaft 6 through the roller 10 with the roller bearing 9, and the two ends of the rotor 8 are connected with the bearings 12 at the two ends of the main shaft.

[0013] When the liquid flows in from the inlet 16 and the scraper 7 rotates from position a to position b, the closed cavity betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com