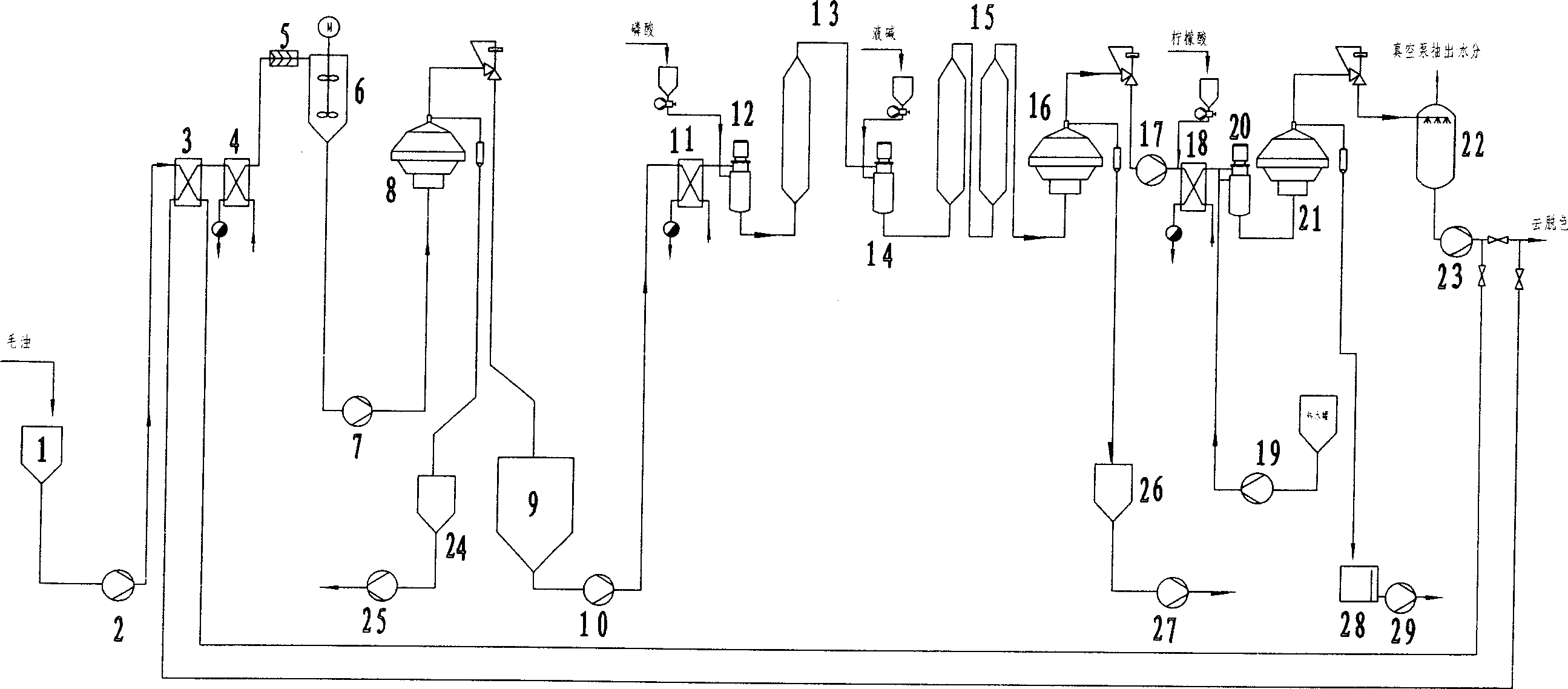

Continuous oil fat refining process

A technology of oil and process method, which is applied in the field of corn germ to produce refined corn oil, which can solve the problems of high tank body, increase of neutral oil, oil leakage, etc., and achieve the effect of intense molecular movement, accelerated reaction speed, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087]A production line with a daily processing capacity of 200 tons of crude corn oil

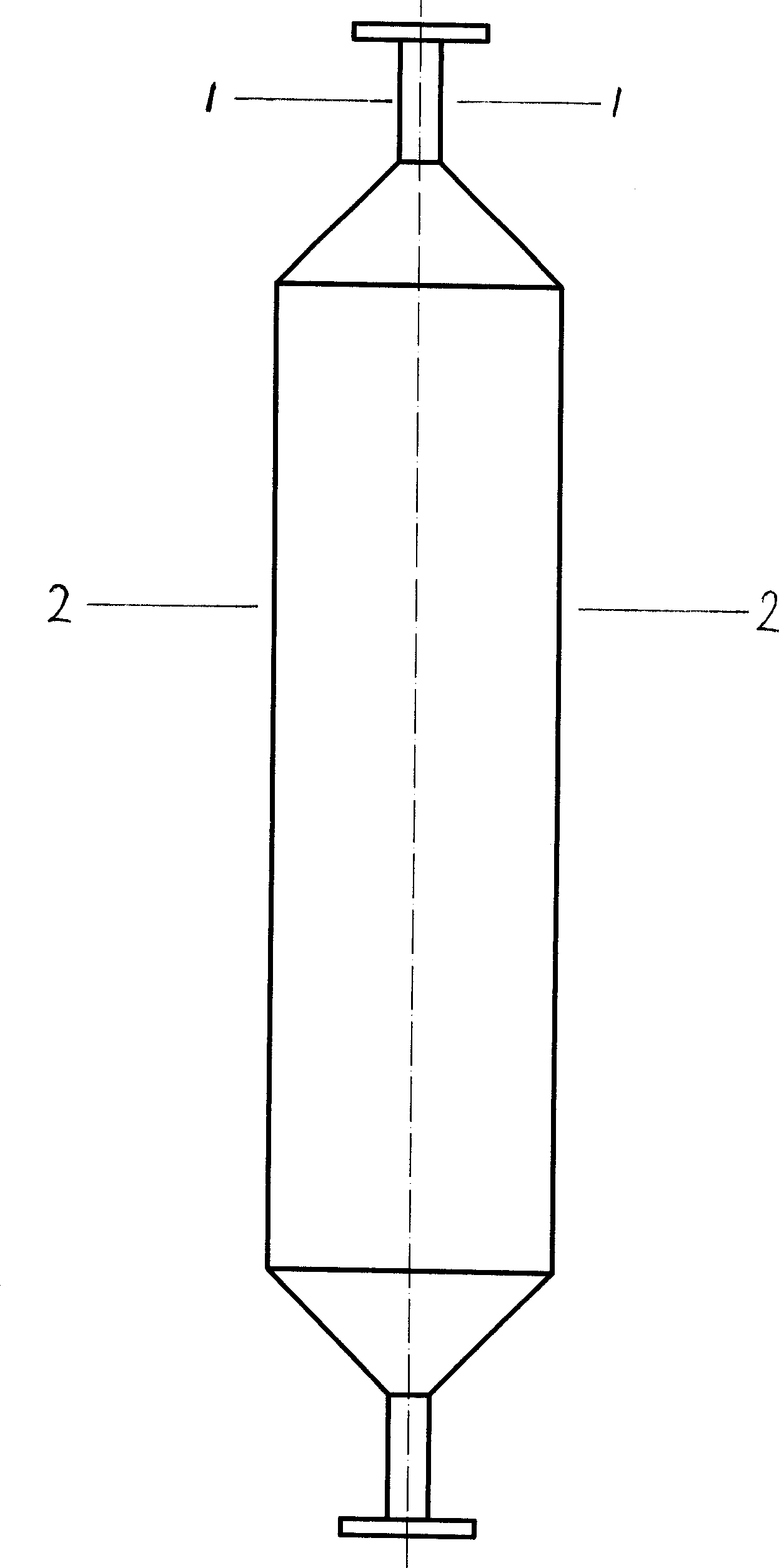

[0088] One acid continuous reactor: 350MM in diameter and 1400MM in length (cone at both ends).

[0089] The residence time of the material in the continuous reactor is 1.01 minutes

[0090] The alkali continuous reactor has a diameter of 350MM and a length of 3000MM (cones at both ends). 2 in series. The residence time of the material in the continuous reactor is 4.32 minutes

[0091] The former known soybean oil refining process has only a stirring type alkali delay tank. In the present invention, one acid continuous reactor is newly added, and two alkali continuous reactors are added to replace the stirring type alkali delay tank.

[0092] The set of reactors fully meet the technological requirements.

[0093] The product quality comparison with the traditional craft is as follows:

[0094] Degumming FFA%, the present invention can reach 0.05%, the traditional process is generally...

Embodiment 2

[0097] A production line with a daily processing capacity of 1,000 tons of crude corn oil

[0098] The continuous reactor can be enlarged in the same proportion, and the above-mentioned indicators can be achieved.

[0099] That is: the diameter d of section 1-1 1 = 100mm, d 2 =600mm, the flow rate is Q 1 =42(m 3 / Hr),

[0100] 42m 3 / Hr / 60=0.7M 3 / Minute,

[0101] By Q=UA, then

[0102] u 1 =Q 1 / A 1 =0.7 / [3.14(0.1 / 2) 2 ]=89.2M / min,

[0103] And Q 1 =Q 2 ,

[0104] u 2 =Q 2 / A 2 =0.7 / [3.14(0.6 / 2) 2 ]=2.48M / min

[0105] a. When the diameter d of section 2-2 2 =600mm, when the length is 2800mm, the time for the fluid to flow through this section is

[0106] 2.8M / 2.48M / min=1.129(min) for acid refining continuous reactor

[0107] b. When the diameter d of section 2-2 2 =600mm, when the length is 5000mm, the time for the fluid to flow through this section is

[0108] 5M / 2.48M / min=2.02(min) is used in the continuous reactor of alkali refining. 2 in series. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peroxide value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com