Soil block crushing device for construction site

A pulverizing device, construction site technology, applied in grain processing and other directions, can solve problems such as difficulty in utilization and waste of clods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

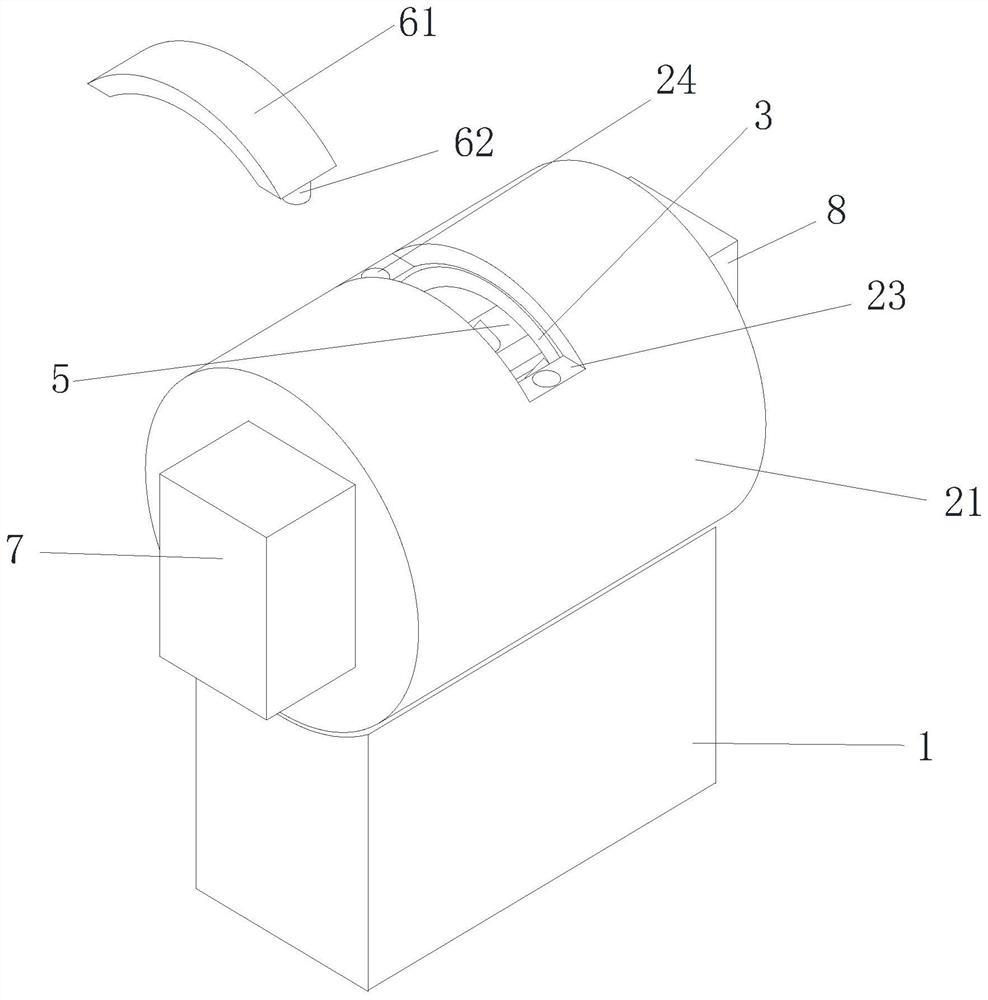

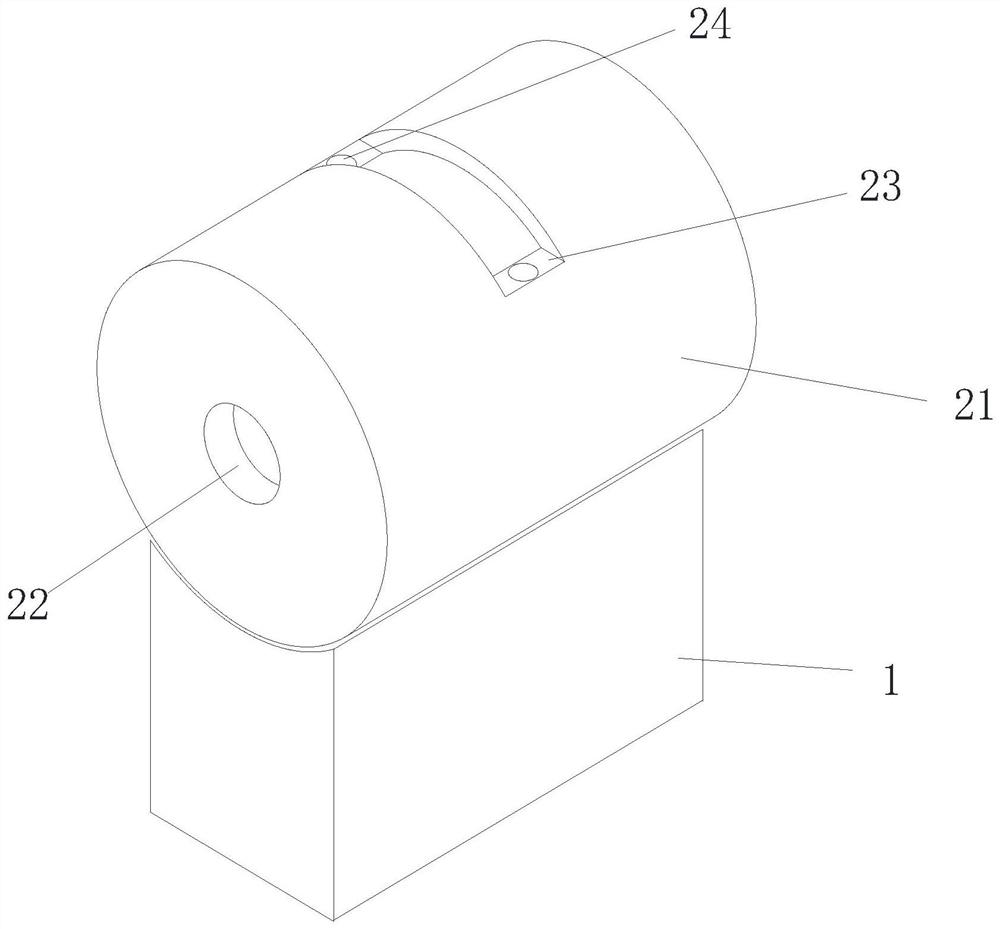

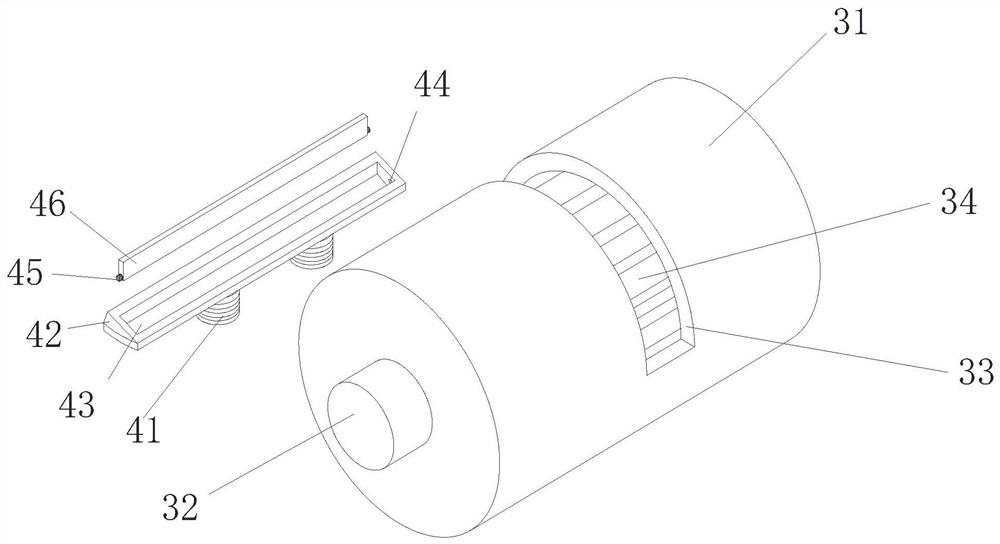

[0030] Embodiment: a kind of earth block crushing device for construction site, such as Figure 1-Figure 5 As shown, including a base 1, the base 1 is a rectangular block, the upper end of the base 1 is a concave arc surface, the upper end of the base 1 is provided with a fixing device 2, the fixing device 2 includes a fixing block 21, the fixing block 21 is a circular column with a hollow interior, and the fixed block 21 is movably installed on the upper end of the base 1. The interior of the fixed block 21 is provided with a rotating device 3, and the rotating device 3 includes a rotating block 31. The rotating block 31 is hollow inside. Circular column, the rotating block 31 is movably installed inside the fixed block 21, and the inner bottom side gap of the rotating block 31 is provided with a plurality of groups of movable grooves 34, and the inside of the movable groove 34 is provided with an extruding device 4. The right side of the rotating block 31 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com