A boiling dryer for pharmaceutical production

A boiling dryer and pharmaceutical production technology, which is applied in the direction of dryers, drying chambers/containers, and drying solid materials, etc., can solve the problems of troublesome cleaning inside the boiling dryer, incomplete drying, and low work efficiency, so as to save manpower The effect of material resources, simple structure, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

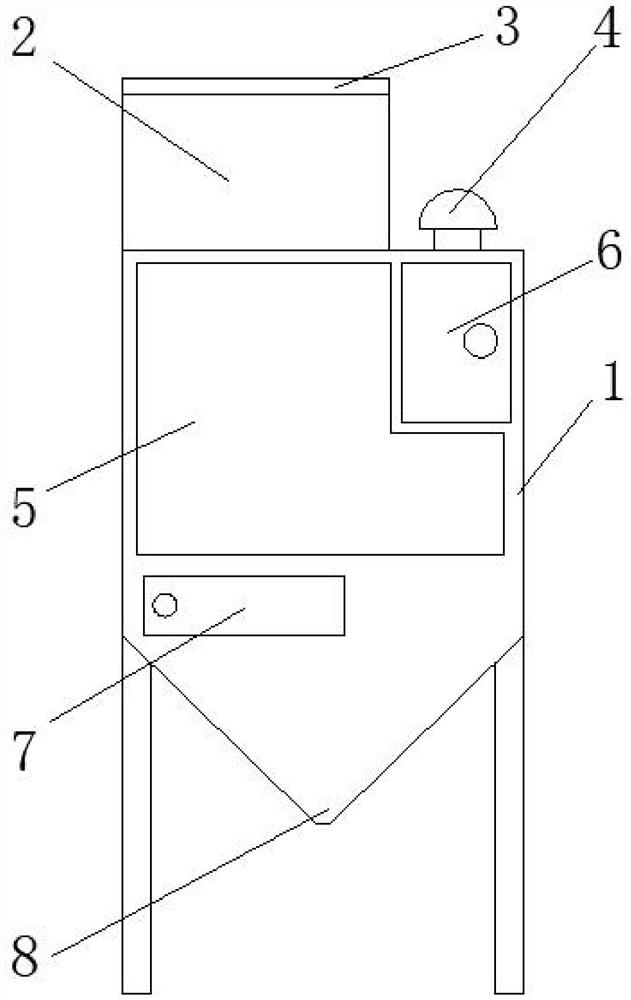

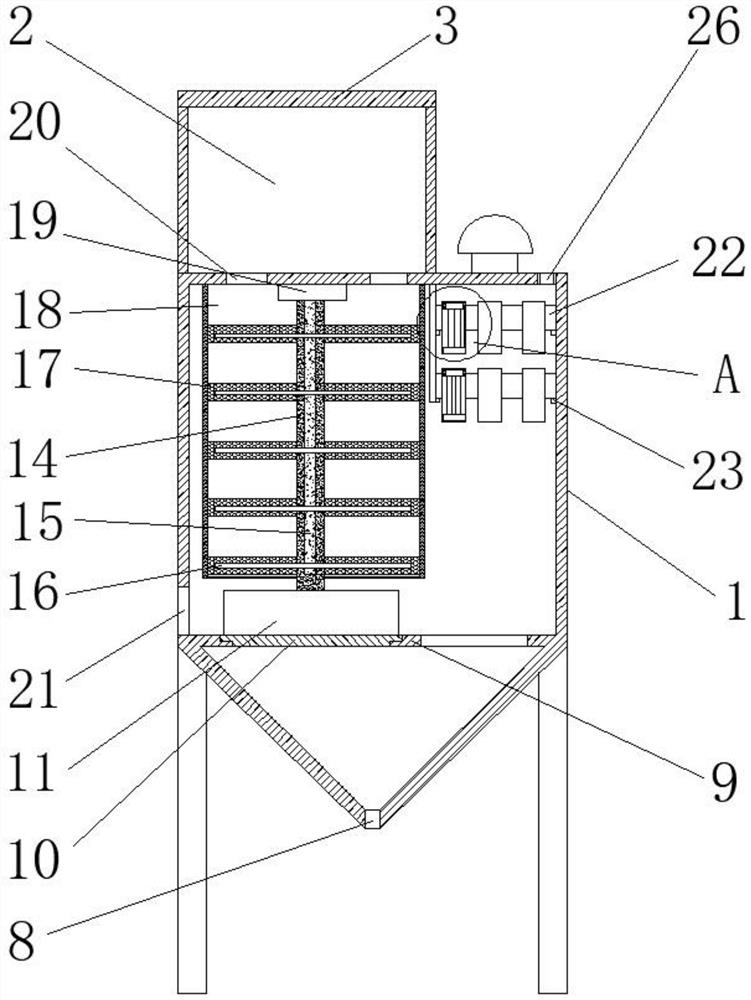

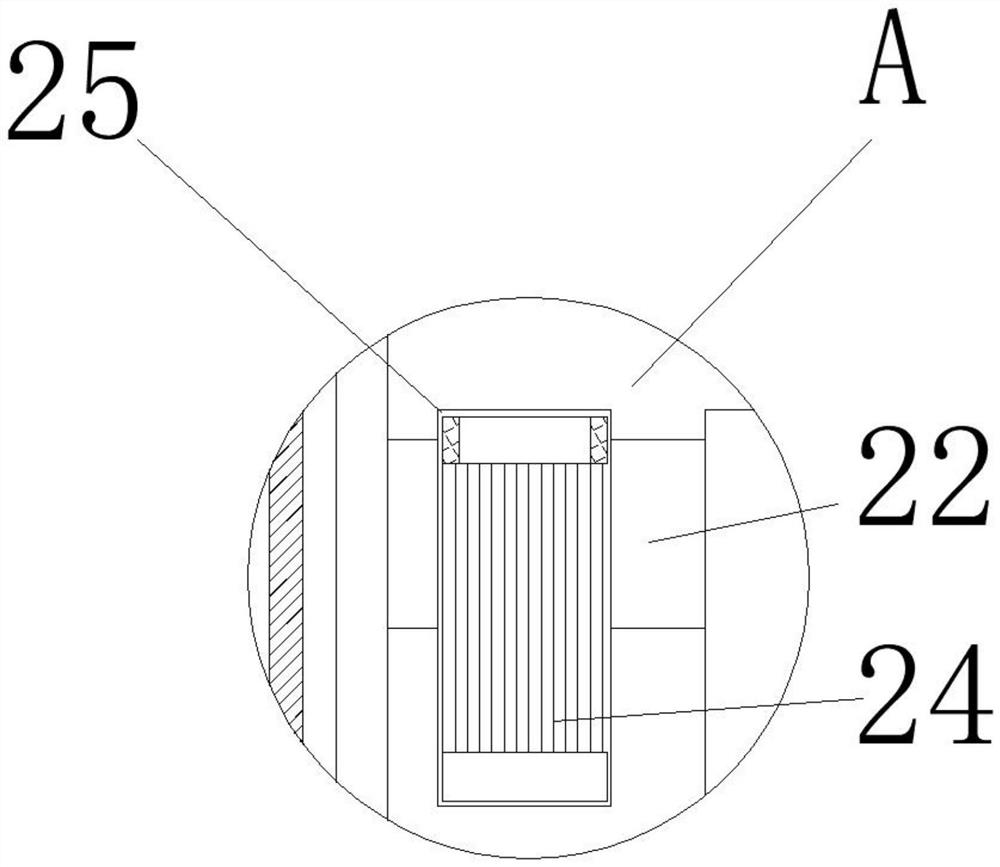

[0021] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a fluidized dryer for pharmaceutical production, comprising a fluidized dryer body 1, a discharge trough 2, a top cover 3, a pressure relief valve 4, a glass window 5, a cleaning door 6, a Door 7, discharge port 8, support plate 9, slide plate 10, motor 11, transmission shaft 12, fixing groove 13, rotating shaft 14, heater 15, fan blade 16, screen 17, screen box 18, fixing ring 19, Feeding port 20, blast port 21, support frame 22, support block 23, keel 24, cloth bag 25 and air outlet 26, a discharge trough 2 is installed on the top side of the main body 1 of the boiling dryer, and a top is provided on the top of the discharge chute 2. Cover 3, a pressure relief valve 4 is installed on the other side of the top of the main body 1 of the boiling dryer, a glass window 5 is installed in the middle of the front of the main body 1 of the boiling dryer, a cleaning door 6 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com