Patents

Literature

68results about How to "Constant level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combination sustained release-immediate release oral dosage forms with an opioid analgesic and a non-opioid analgesic

InactiveUS20030092724A1Long durationConstant plasma levels of opioid and non-opioid analgesicsBiocidePill deliveryImmediate releaseTherapeutic effect

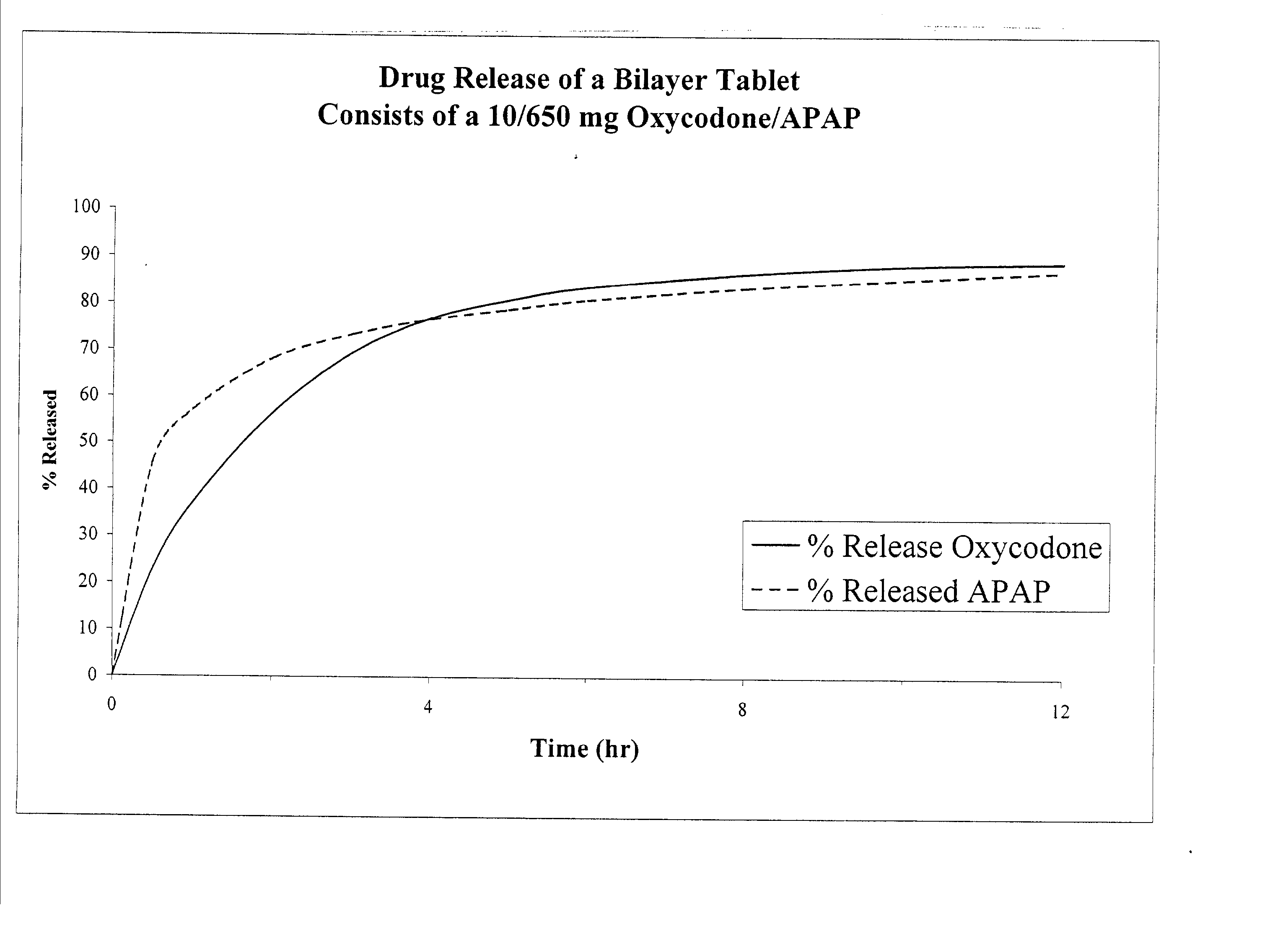

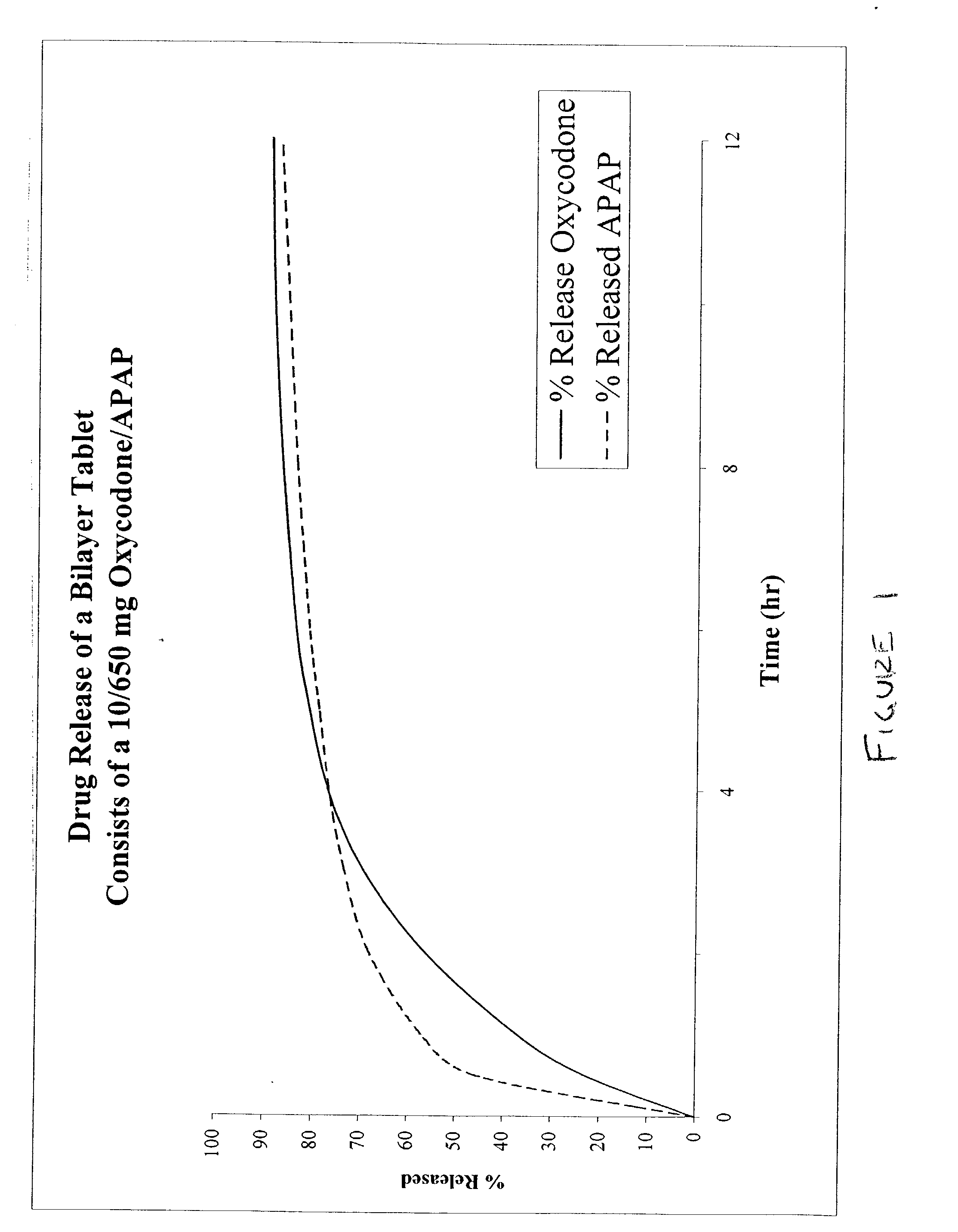

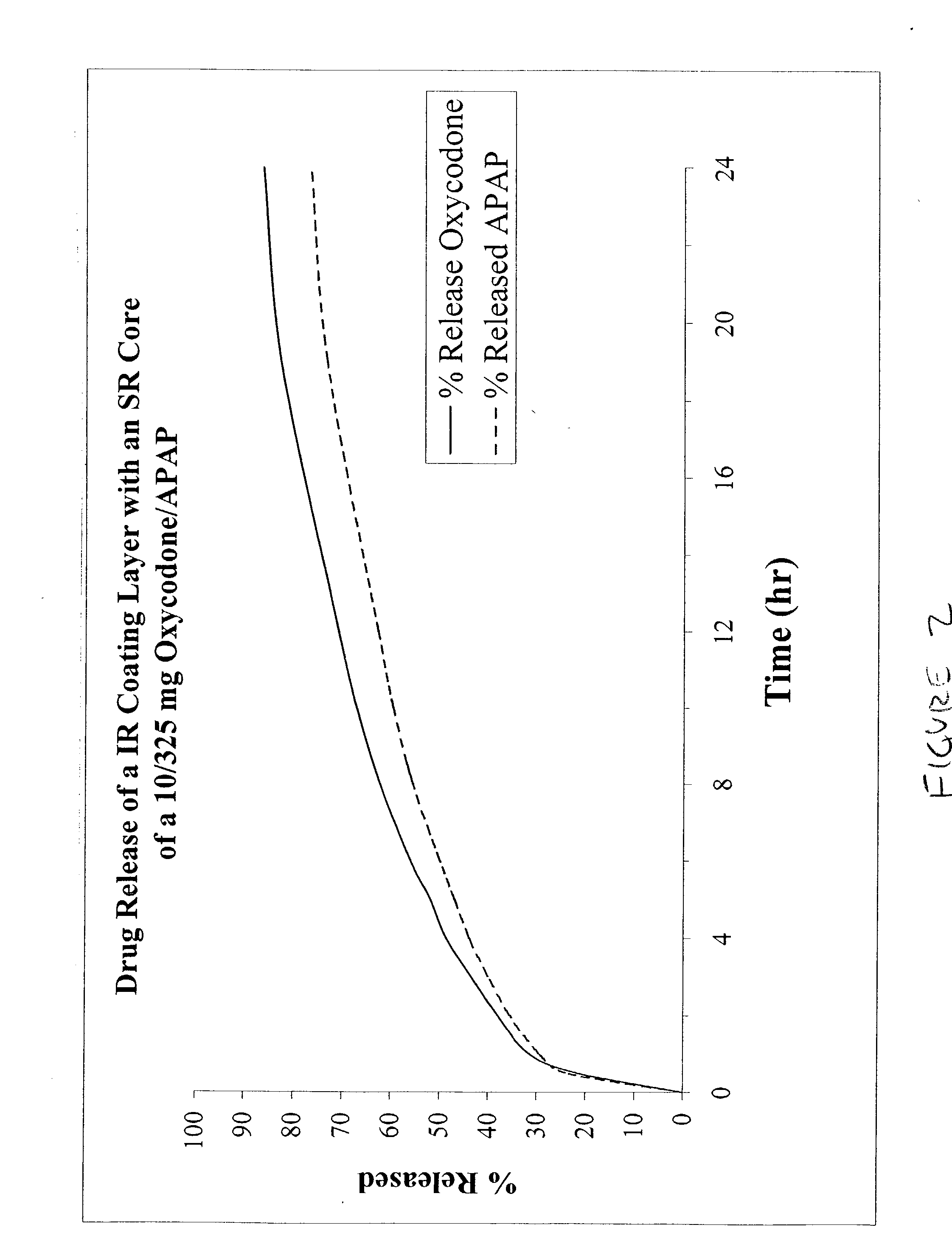

The present invention relates to new and useful oral tablet compositions which include an immediate release portion having an opioid analgesic and a non-opioid analgesic, providing for a rapid onset of therapeutic effect, and a sustained release portion of an opioid analgesic and a non-opioid analgesic, providing for a relatively longer duration of therapeutic effect. A multilayer oral dosage form containing a sustained release layer, which includes oxycodone and APAP, hydrocodone and APAP, or oxymorphone and APAP, and an immediate release layer containing the same active ingredients as the sustained release layer, is also disclosed. Also disclosed are oral tablet compositions, containing a sustained release core, which includes oxycodone and APAP, hydrocodone and APAP, or oxymorphone and APAP, and an immediate release coating containing the same active ingredients as the sustained release core, are also disclosed. In addition, methods of making and using such oral tablet compositions are disclosed.

Owner:ENDO PHARMA INC

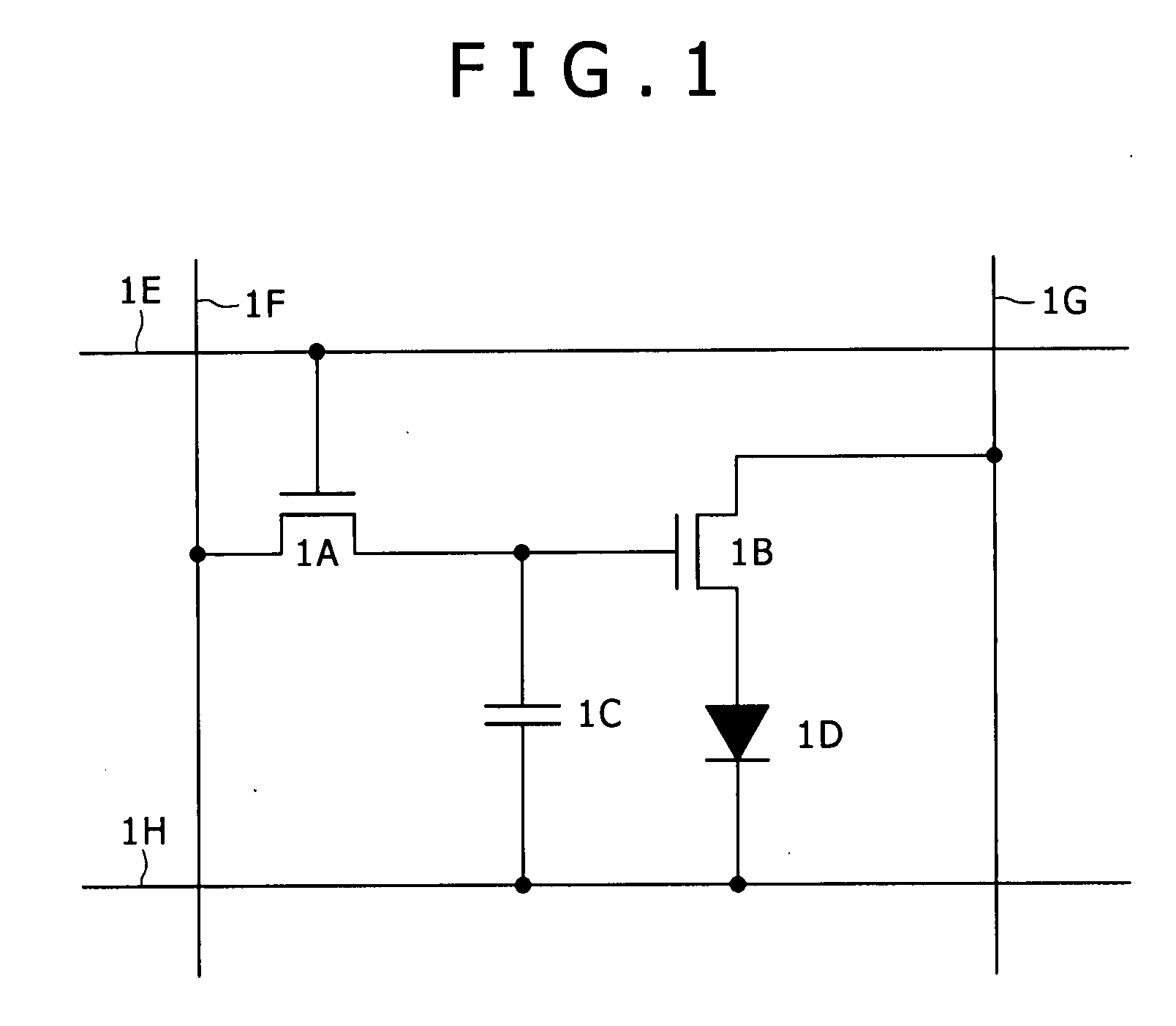

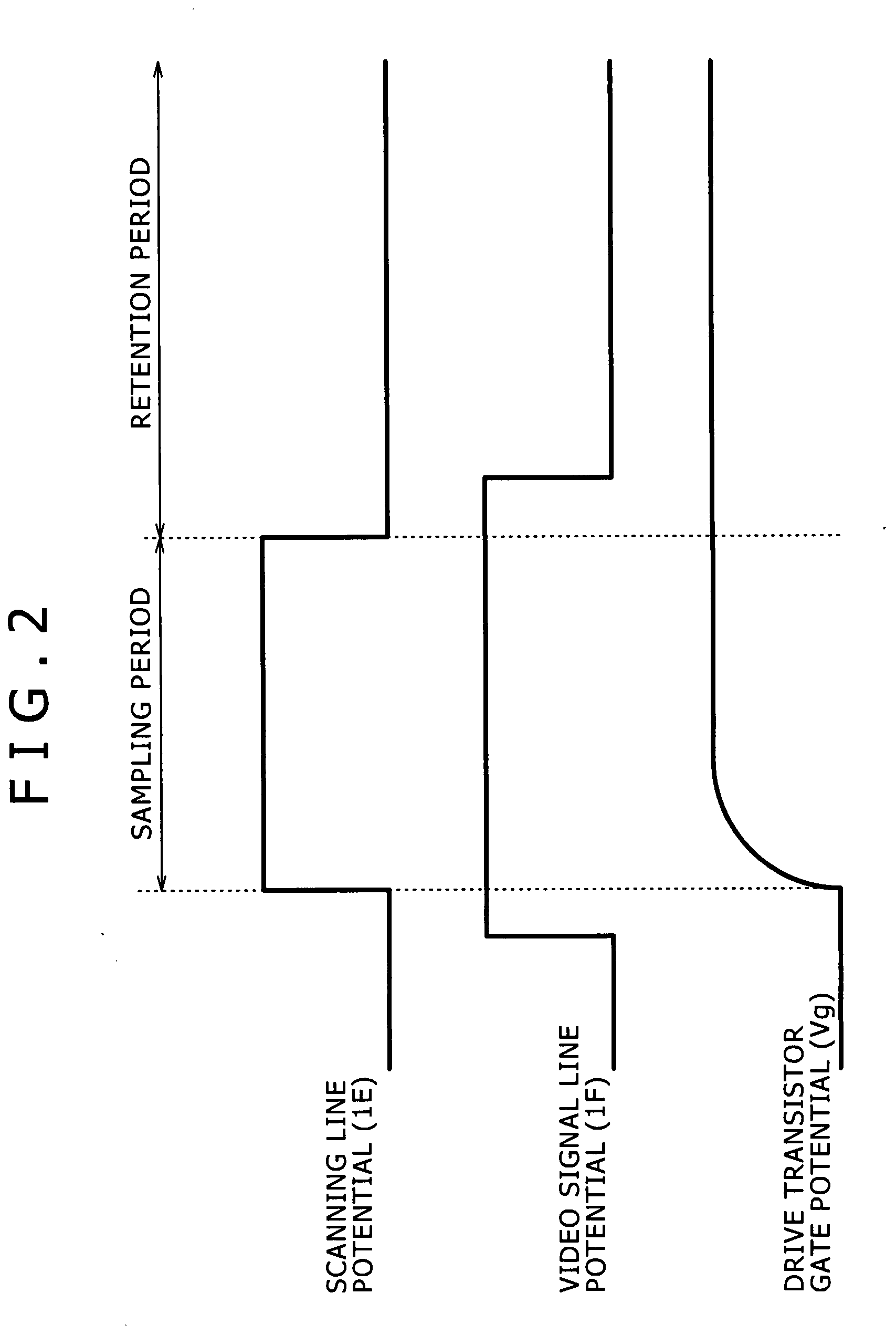

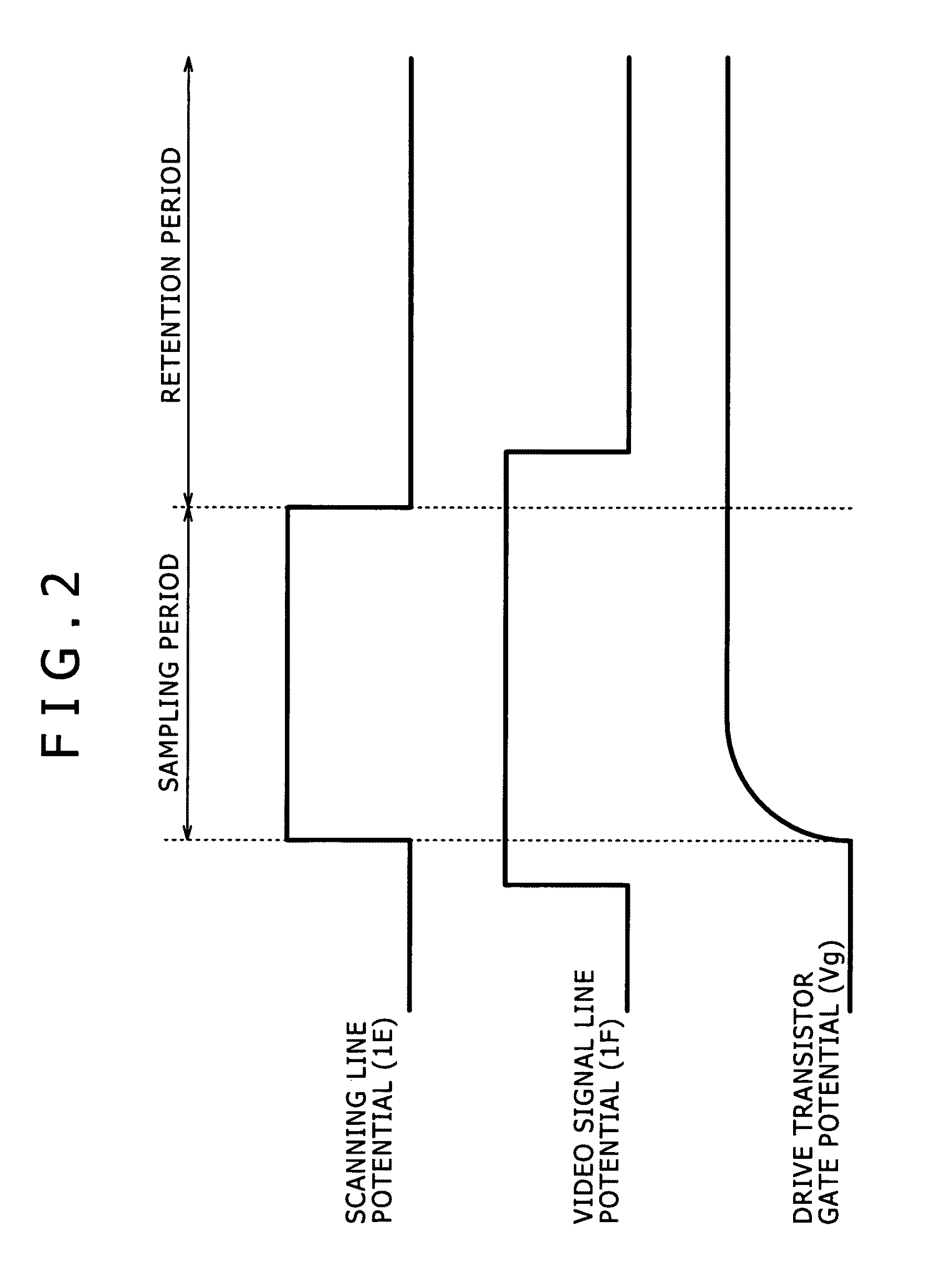

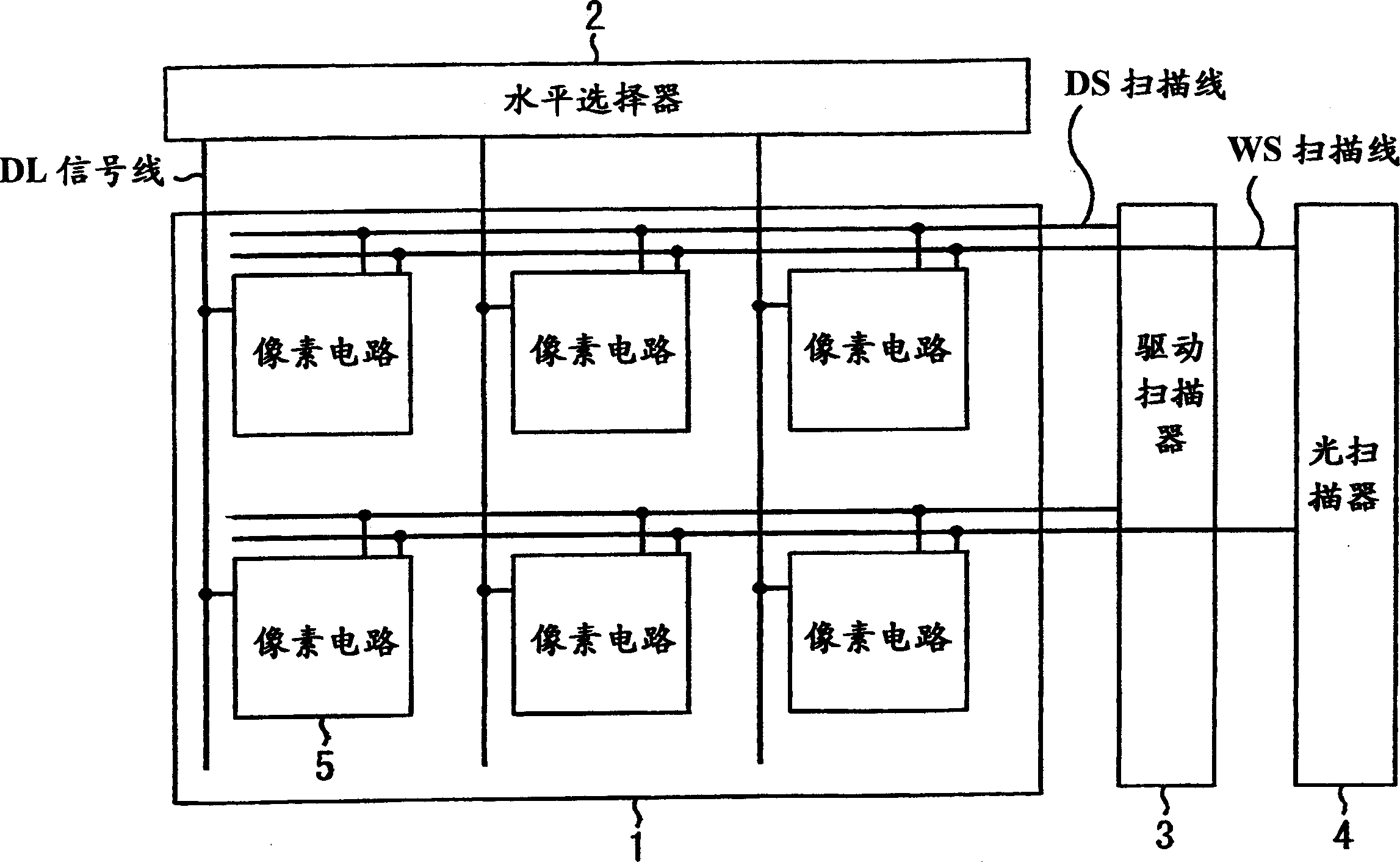

Display apparatus and method of driving same

ActiveUS20070268210A1Stay efficientConstant levelElectrical apparatusStatic indicating devicesControl signalPixel array

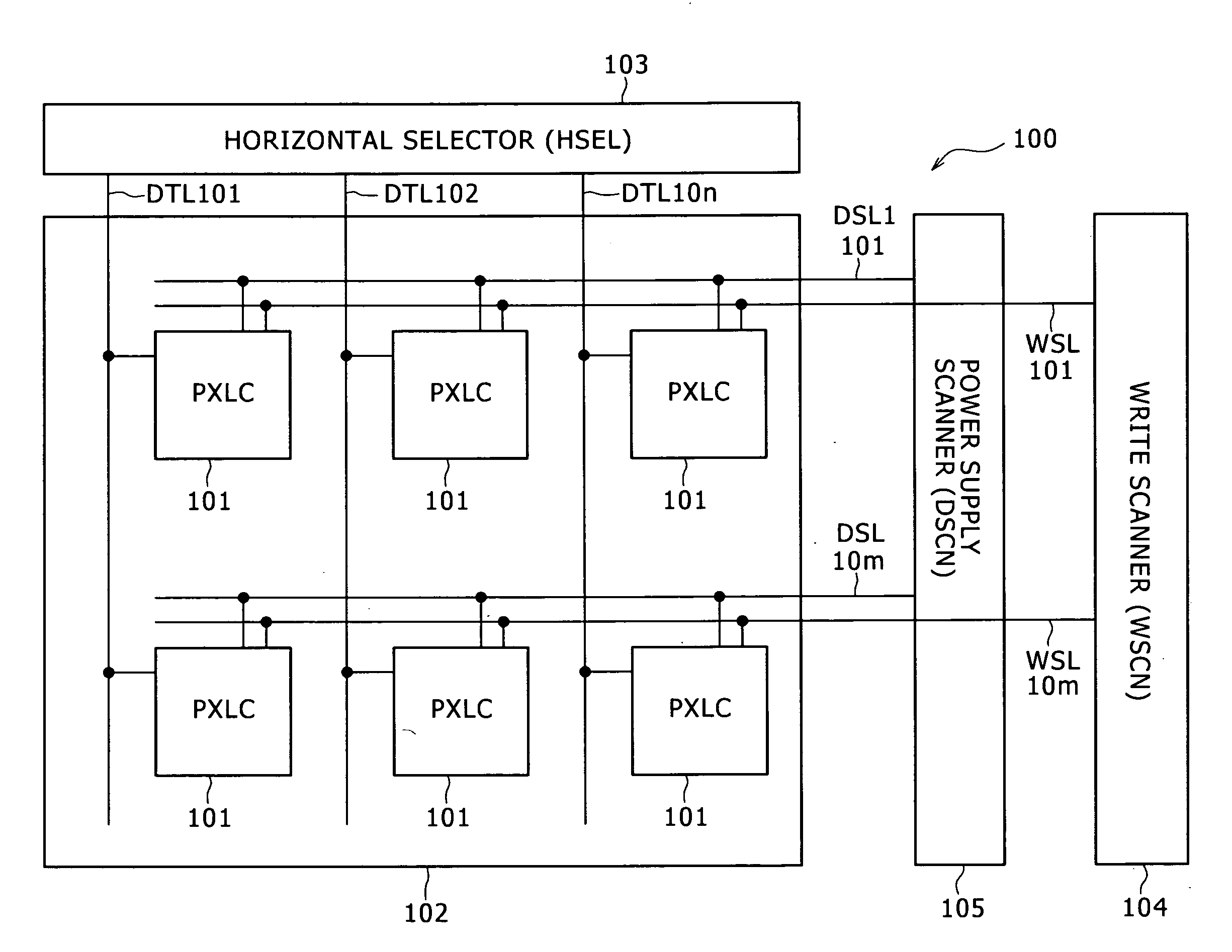

Disclosed herein is a display apparatus including a pixel array and a driver configured to drive the pixel array, the pixel array having scanning lines as rows, signal lines as columns, a matrix of pixels disposed at respective intersections of the scanning lines and the signal lines, and power supply lines disposed along respective rows of the pixels, the driver having a main scanner for successively supplying control signals to the scanning lines to perform line-sequential scanning on the rows of the pixels, a power supply scanner for supplying a power supply voltage, which selectively switches between a first potential and a second potential, to the power supply lines in synchronism with the line-sequential scanning, and a signal selector for supplying a signal potential, which serves as a video signal, and a reference potential to the signal lines as the columns in synchronism with the line-sequential scanning.

Owner:JOLED INC

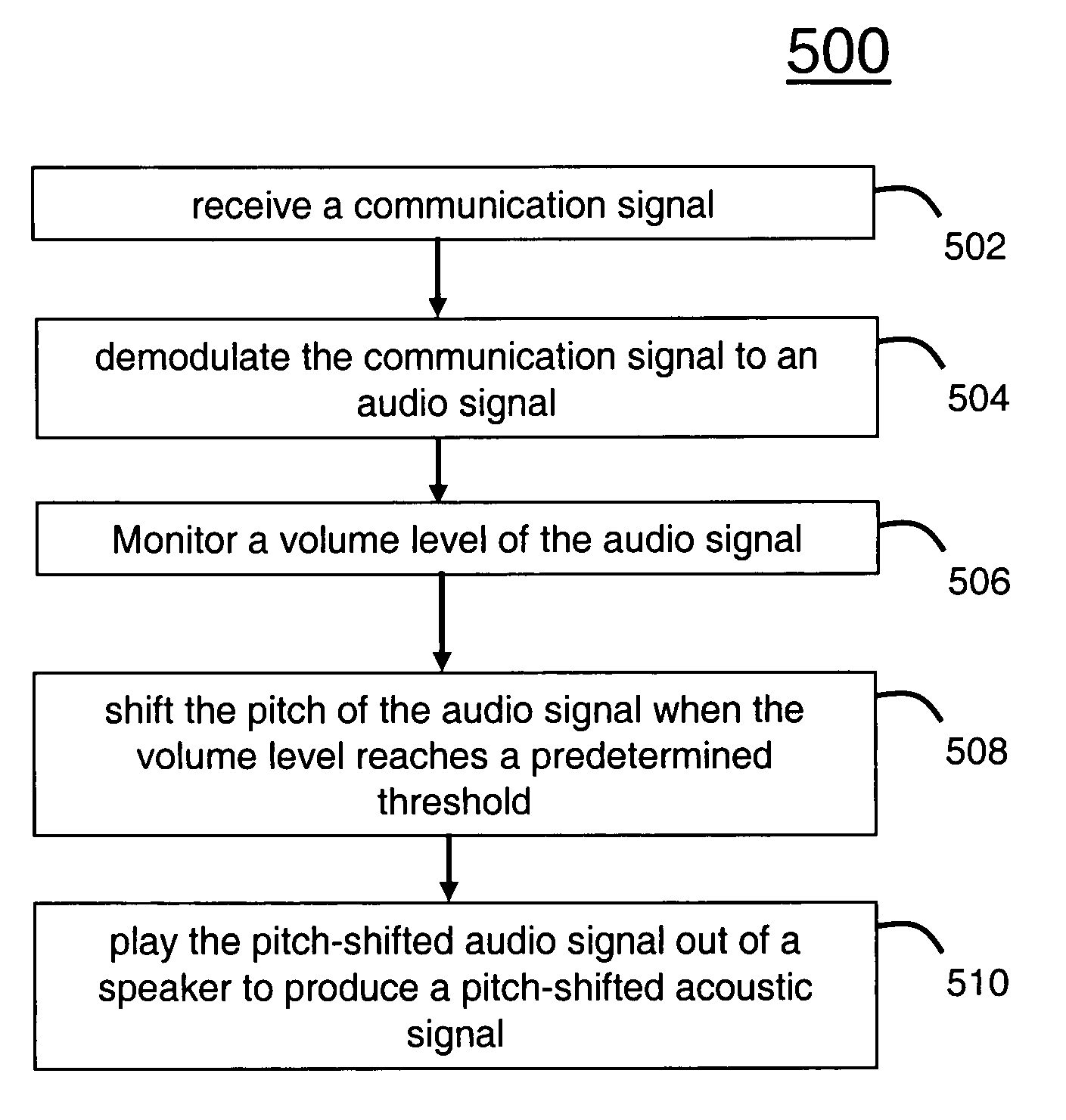

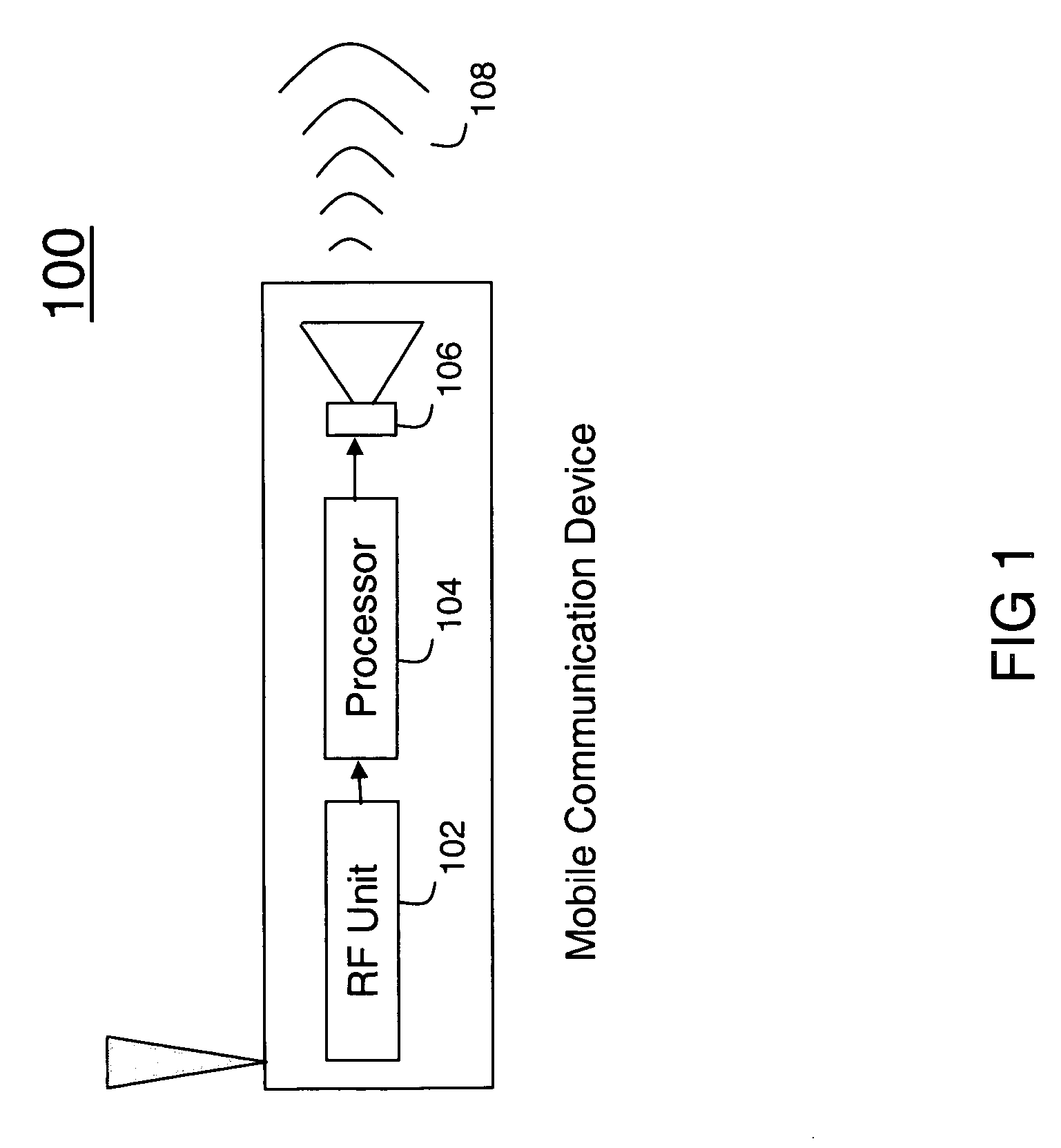

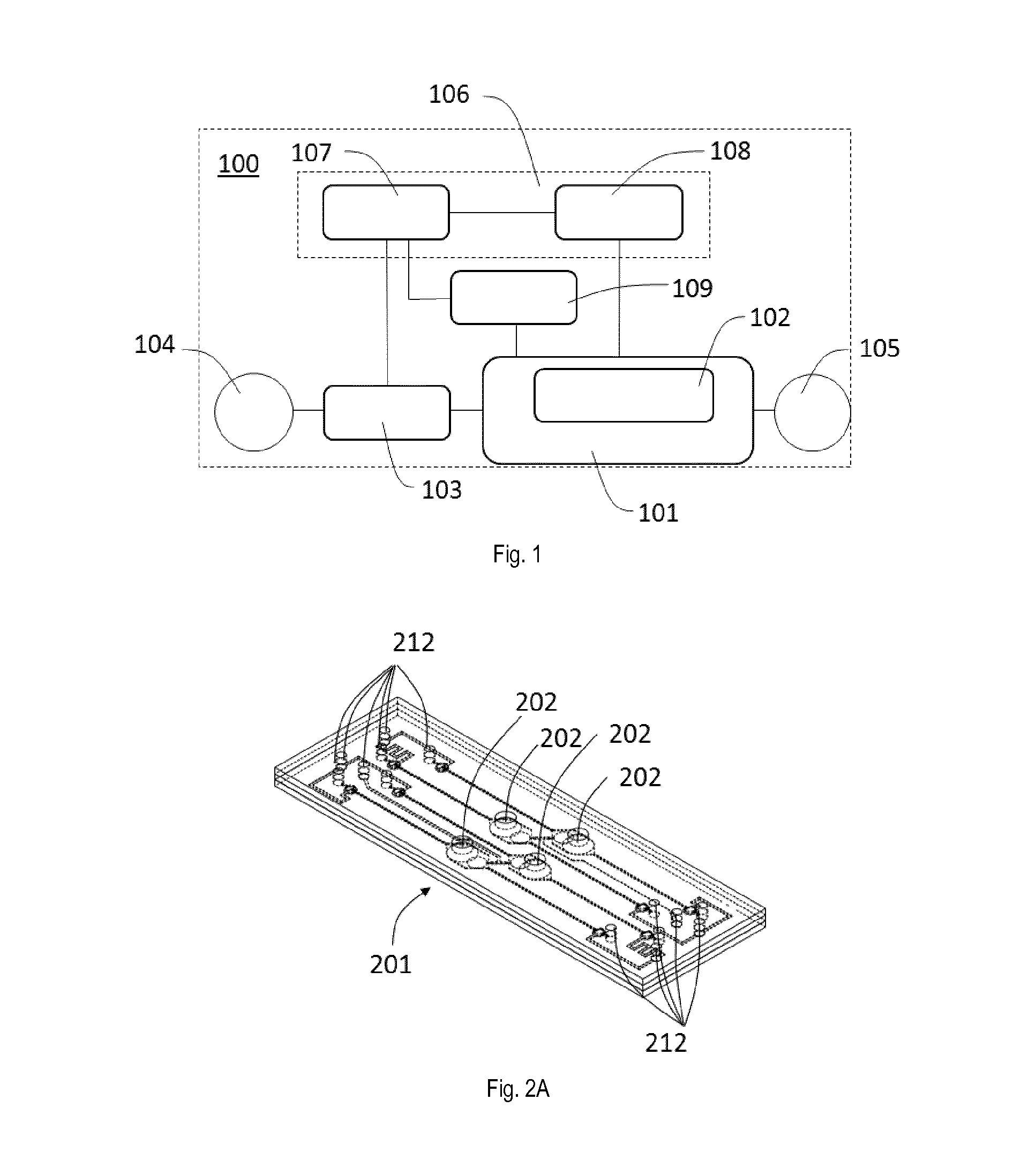

Method and system for suppressing receiver audio regeneration

ActiveUS7280958B2Suppression problemConstant levelSpeech analysisTransducer acoustic reaction preventionPitch shiftEngineering

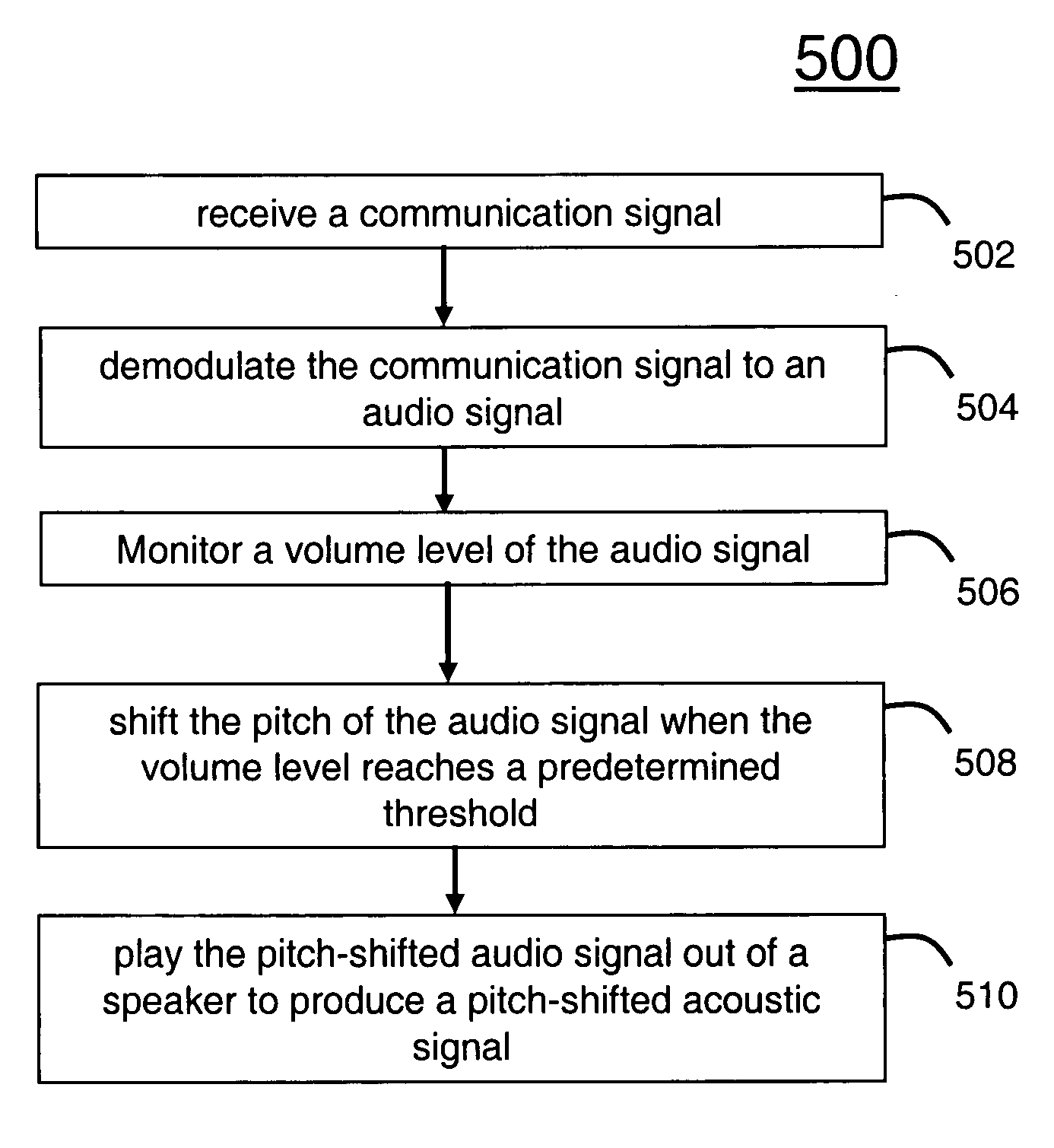

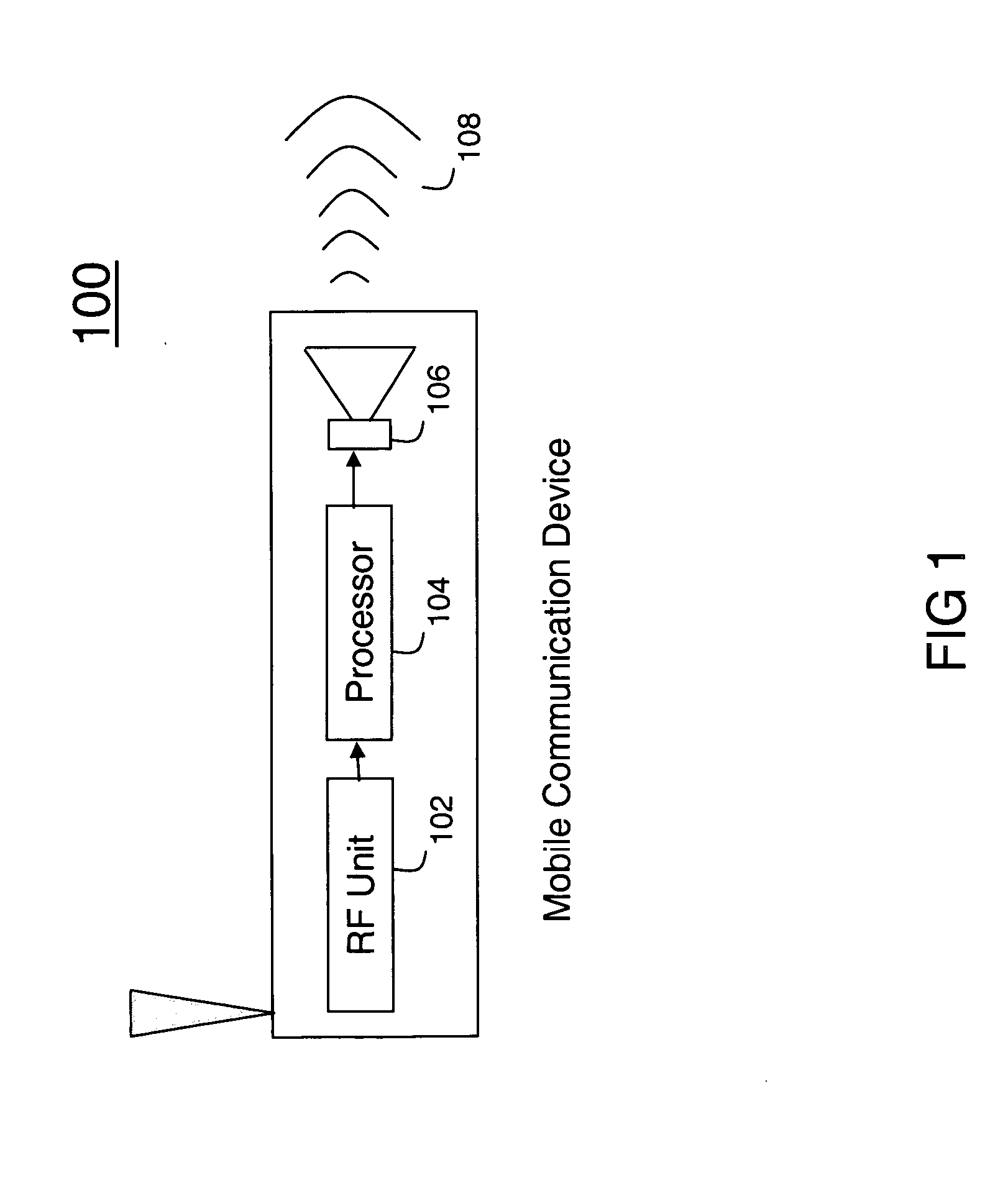

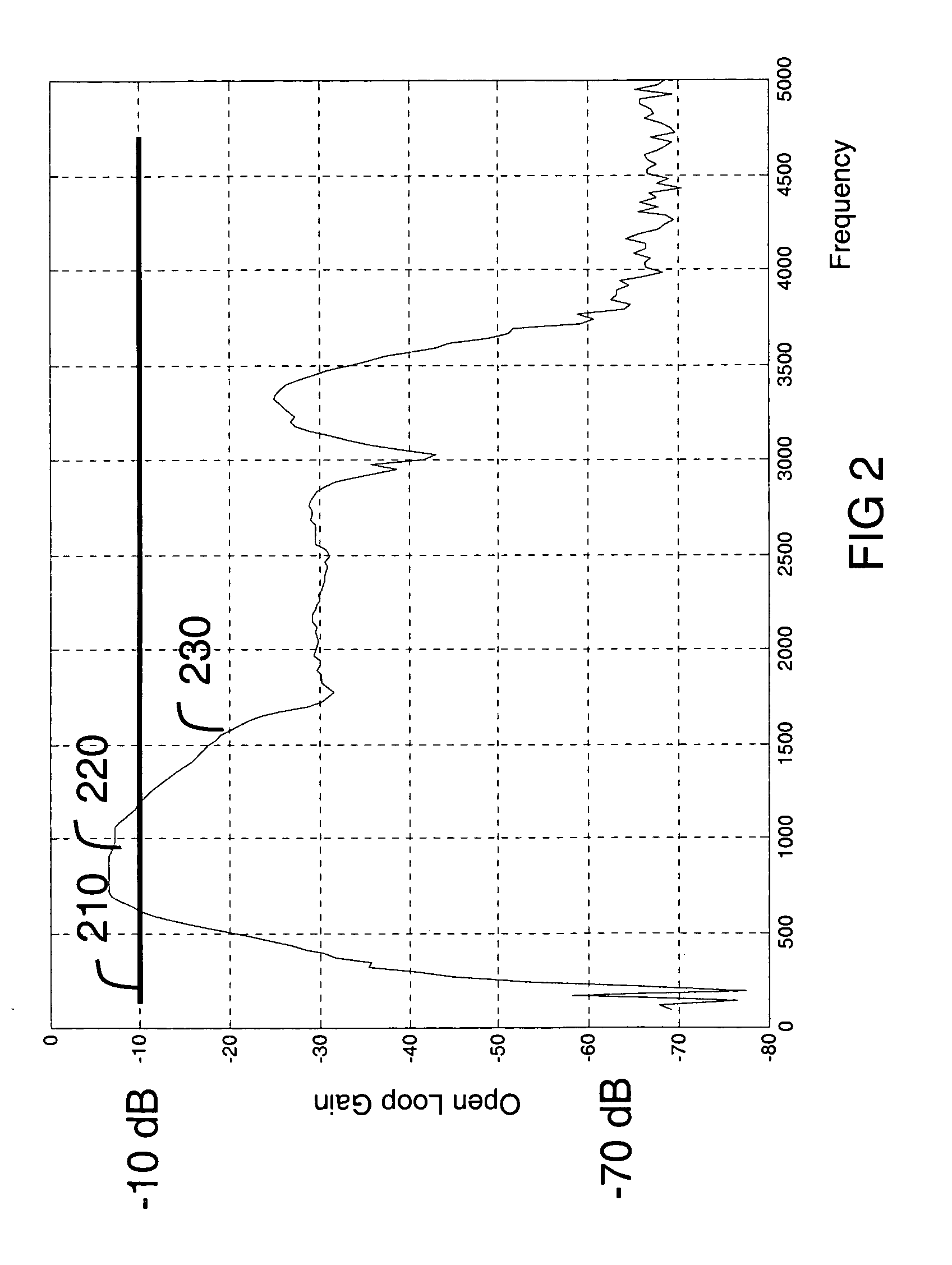

The invention concerns a method (500) and system (100) for suppressing receiver audio regeneration. The method (500) includes the steps of receiving a communication signal (502), at a Radio Frequency (RF) unit (102), demodulating the communication signal to an audio signal (504), monitoring a volume level of the audio signal (506), and shifting the pitch of the audio signal when the volume level reaches a predetermined threshold (508), and playing the pitch-shifted audio signal out of a speaker to produce a pitch-shifted acoustic signal (510). The method can shift the pitch of the audio signal to produce a pitch-shifted acoustic signal with signal properties suppressing regeneration of the acoustic signal onto the audio signal at the RF unit. The amount of pitch-shifting can be a function of the volume level.

Owner:MOTOROLA SOLUTIONS INC

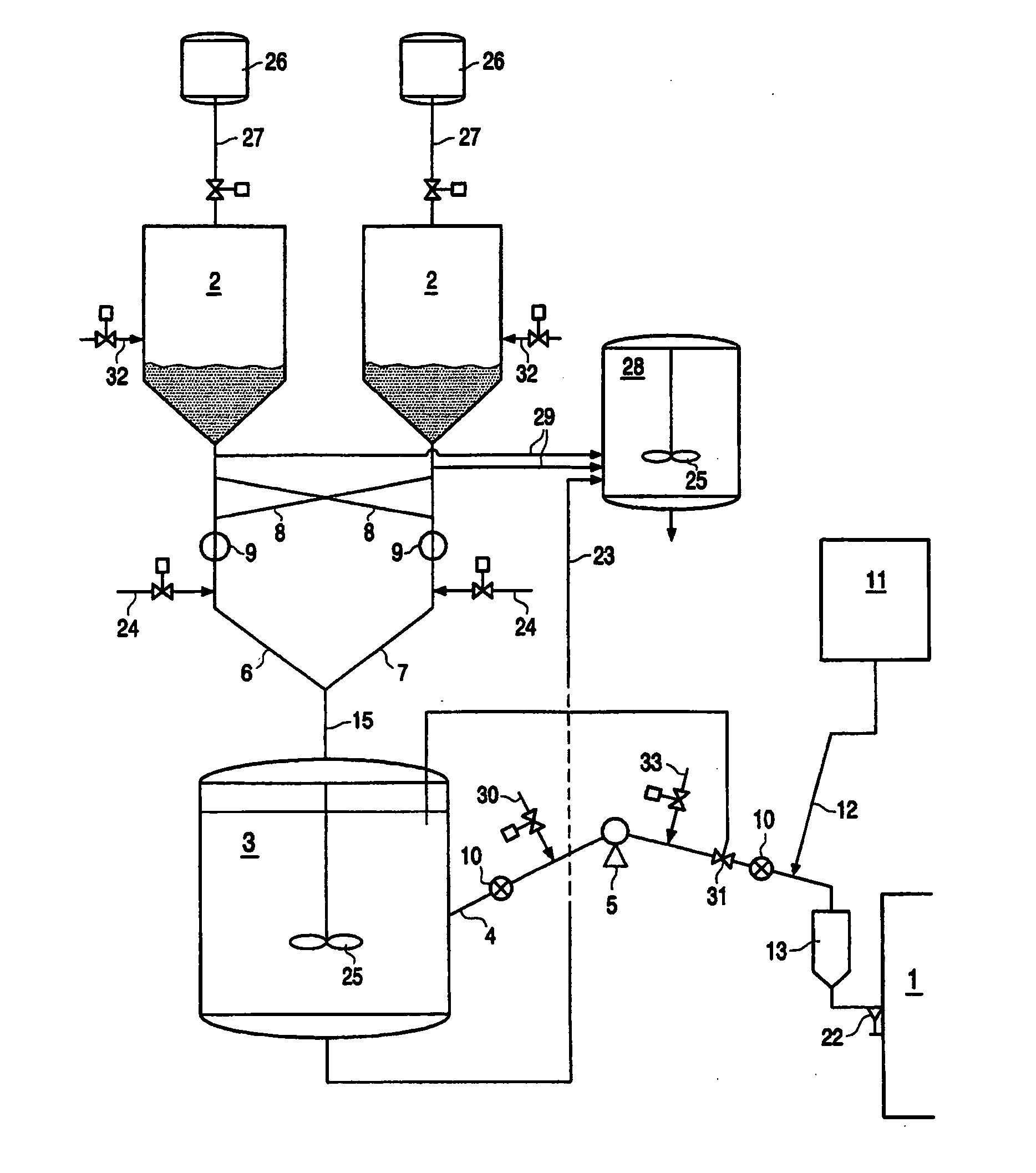

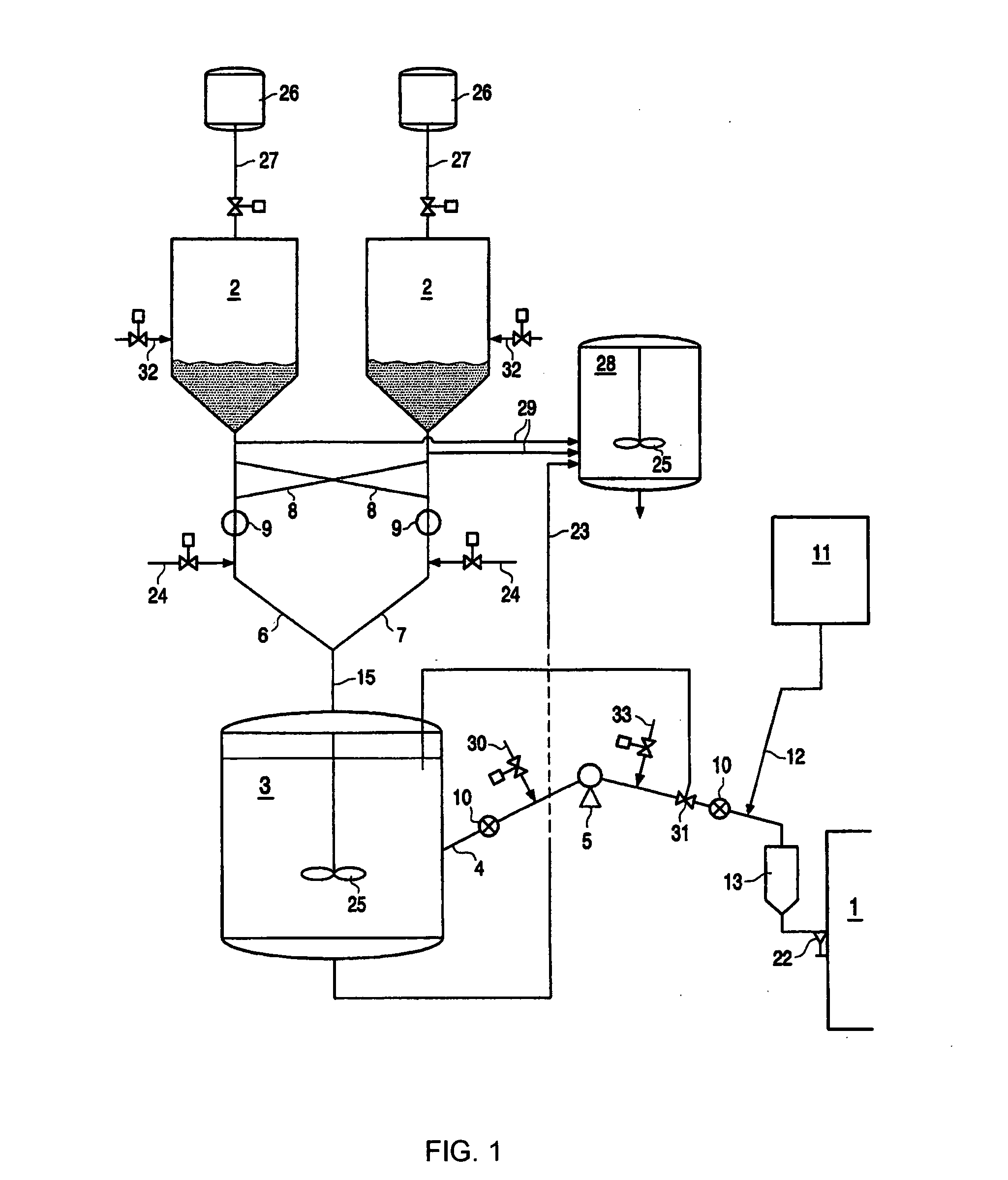

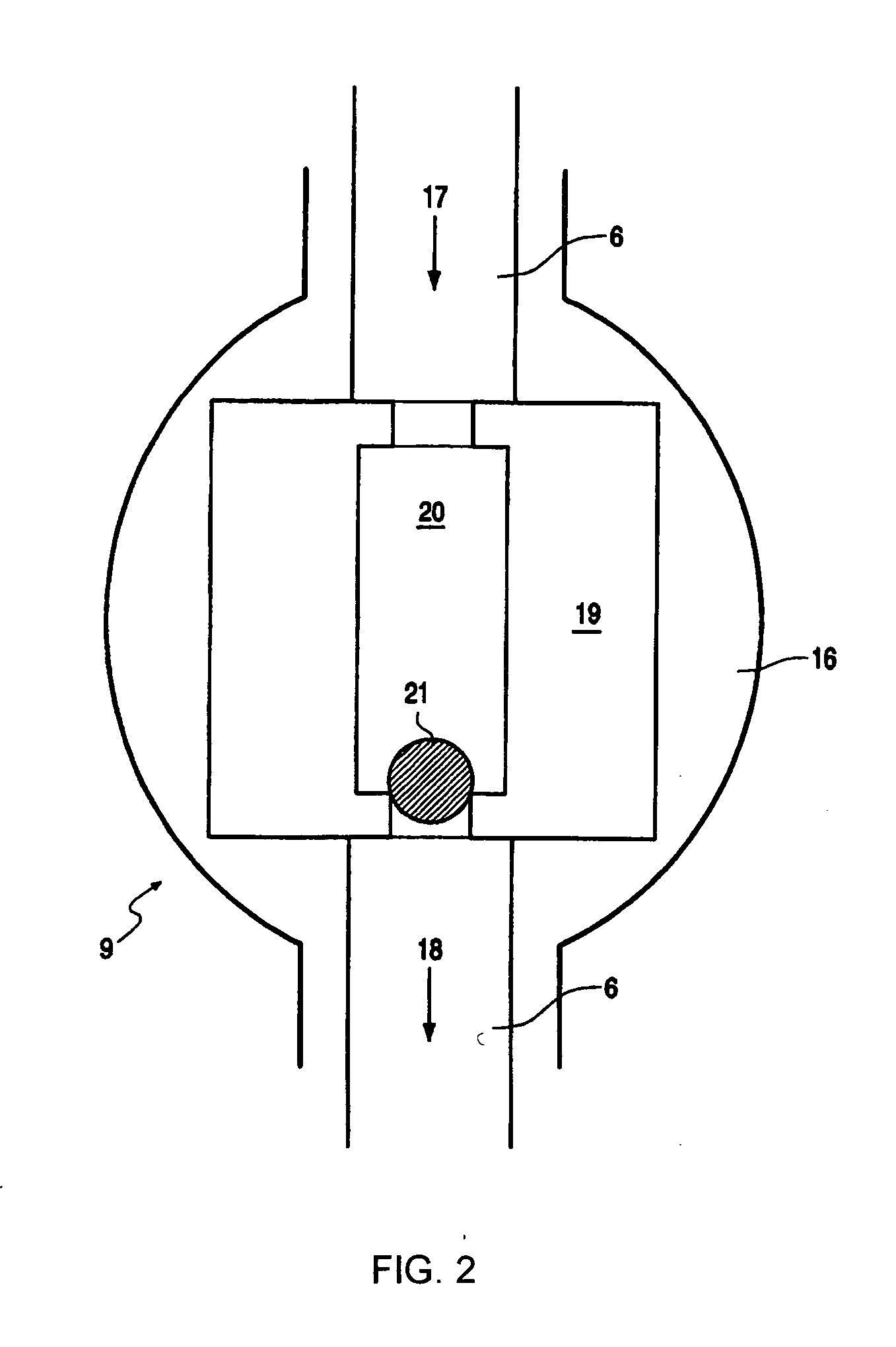

Double loop technology

InactiveUS20050272891A1Constant levelLimited wayControlling ratio of multiple fluid flowsExhaust apparatusPolymer sciencePolyolefin

The present invention relates to an apparatus and process for polymerizing olefins. One embodiment comprises polymerizing at least one monomer in a first loop reactor in the presence of a catalyst to produce a first polyolefin fraction. A portion of the first polyolefin fraction is transferred to a second loop reactor, connected in series with the first loop reactor. The process further comprises polymerizing in the second loop reactor at least one monomer in the presence of a catalyst to produce a second polyolefin fraction in addition to the first polyolefin fraction. The combination of the first and second polyolefin fractions can produce a polymer resin fluff having bimodal molecular weight distribution.

Owner:TOTAL RES & TECH FELUY

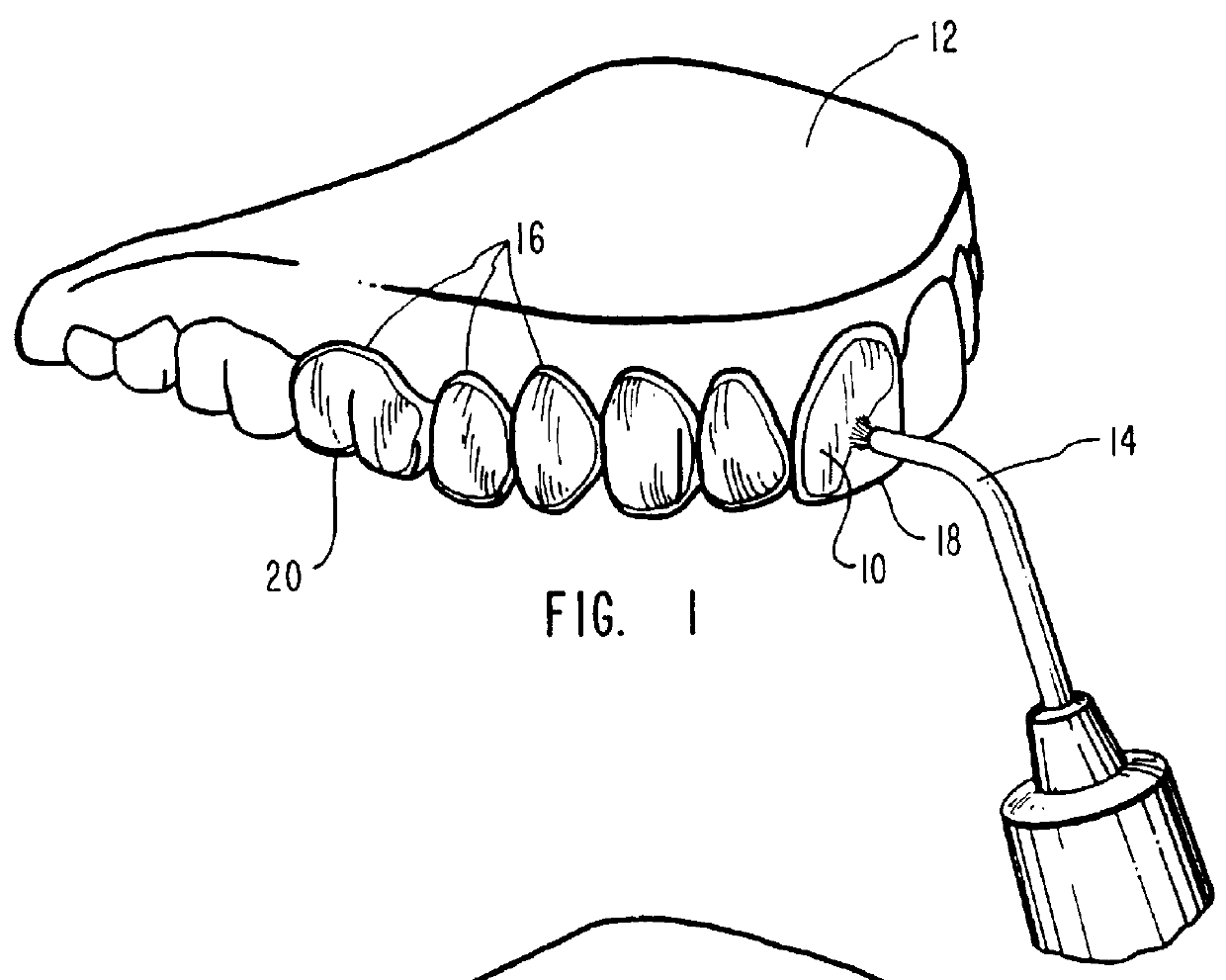

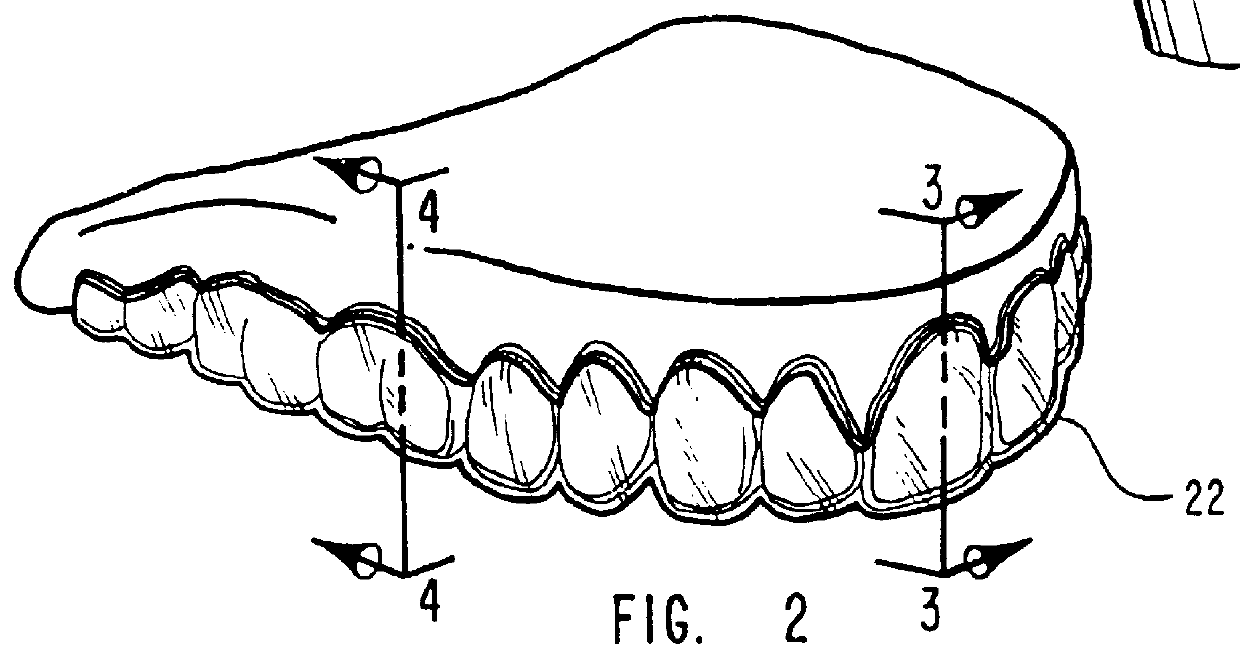

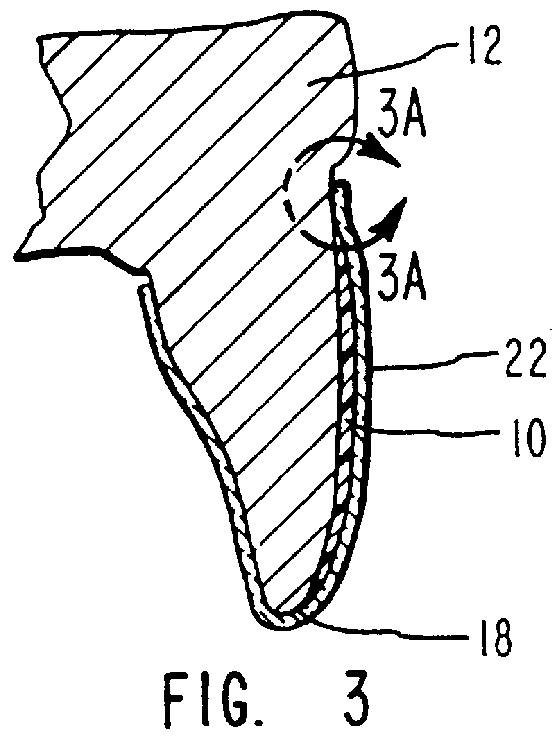

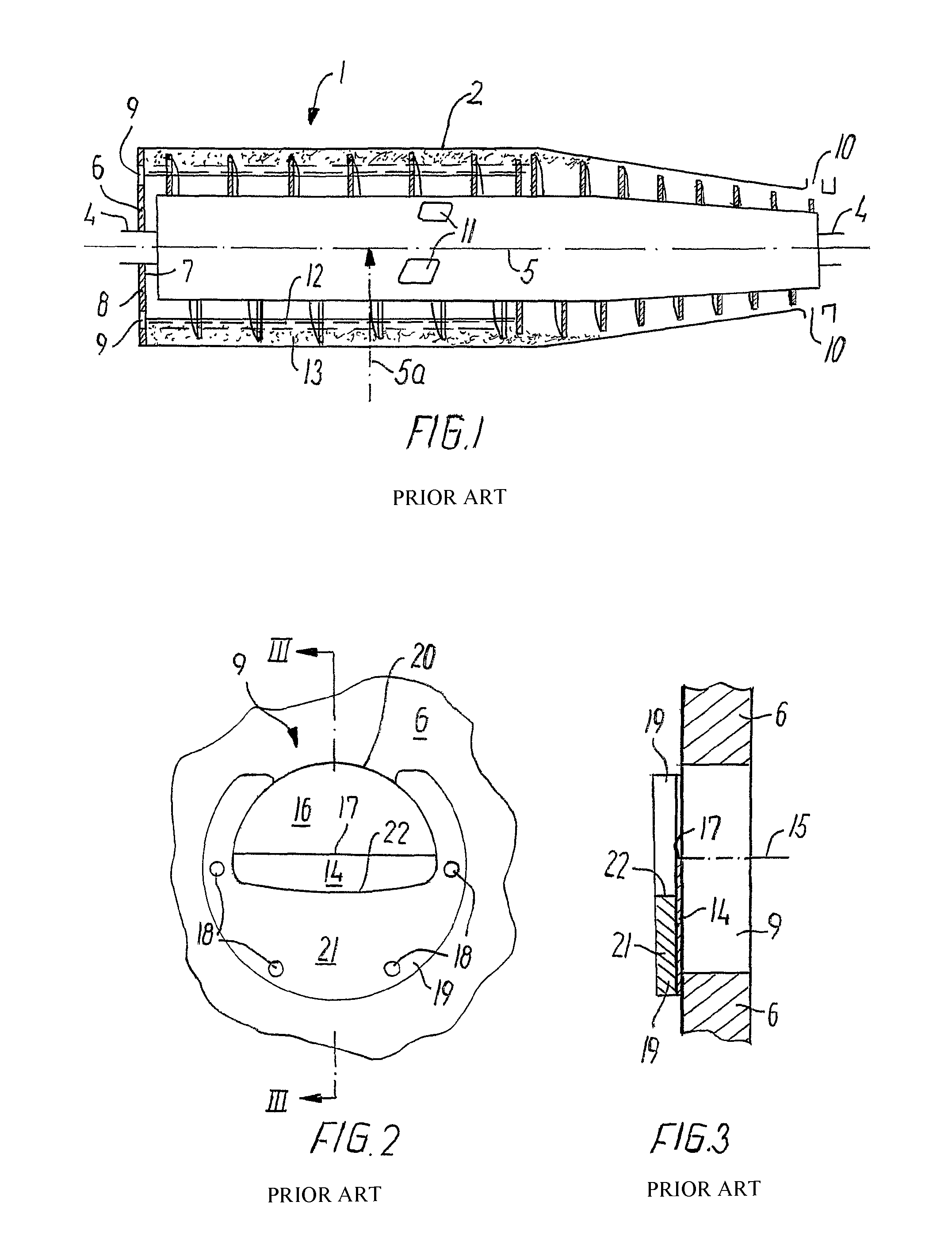

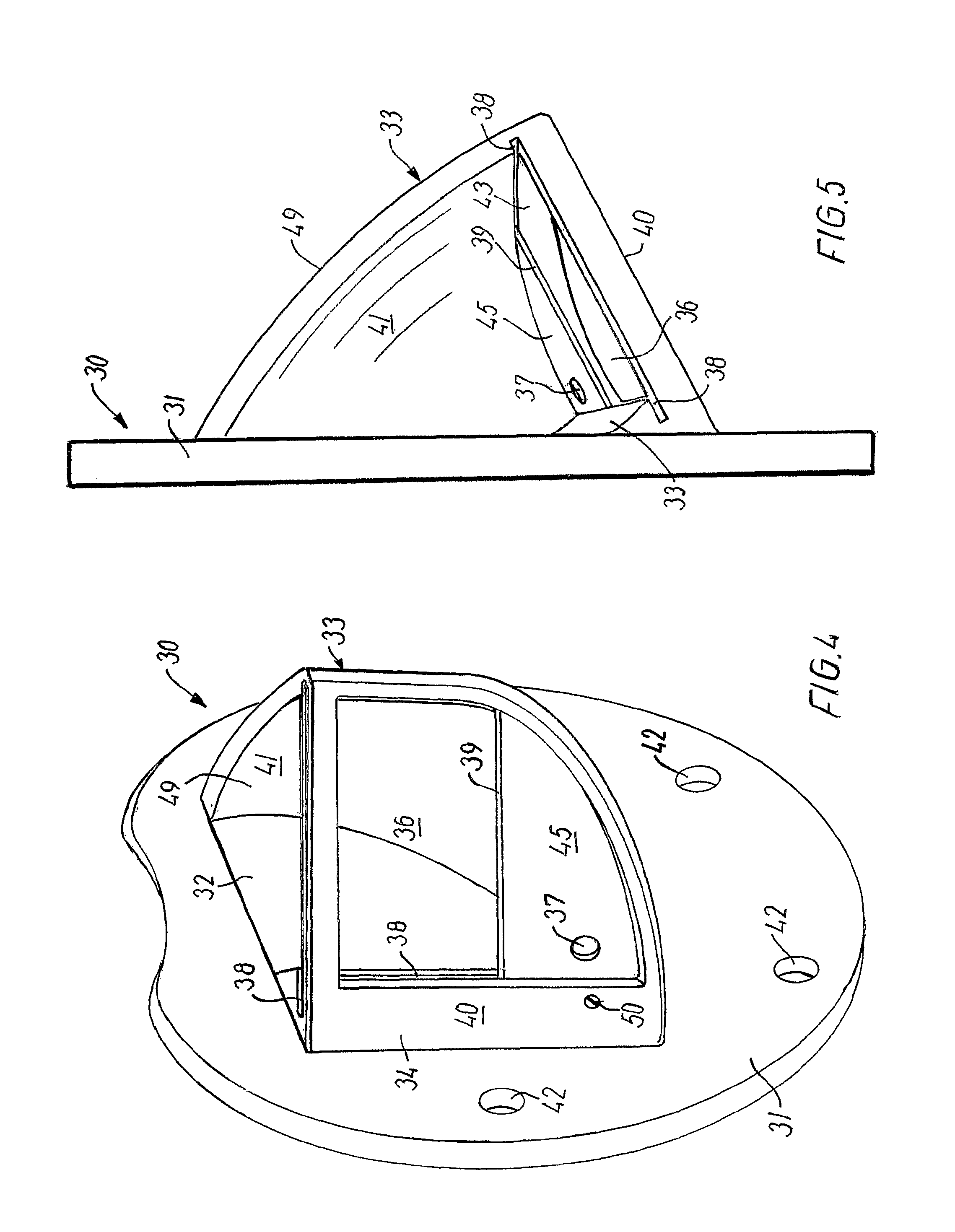

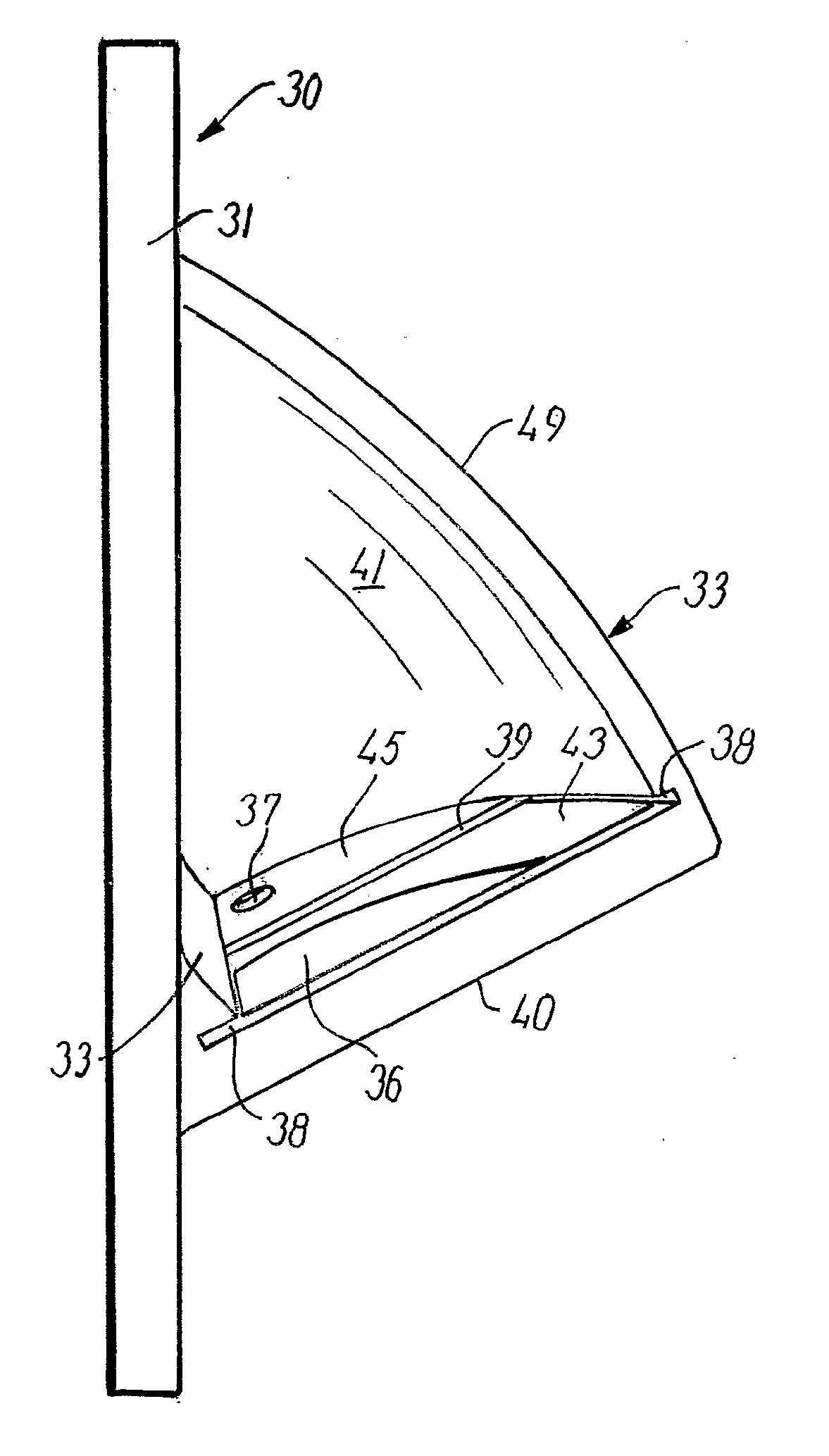

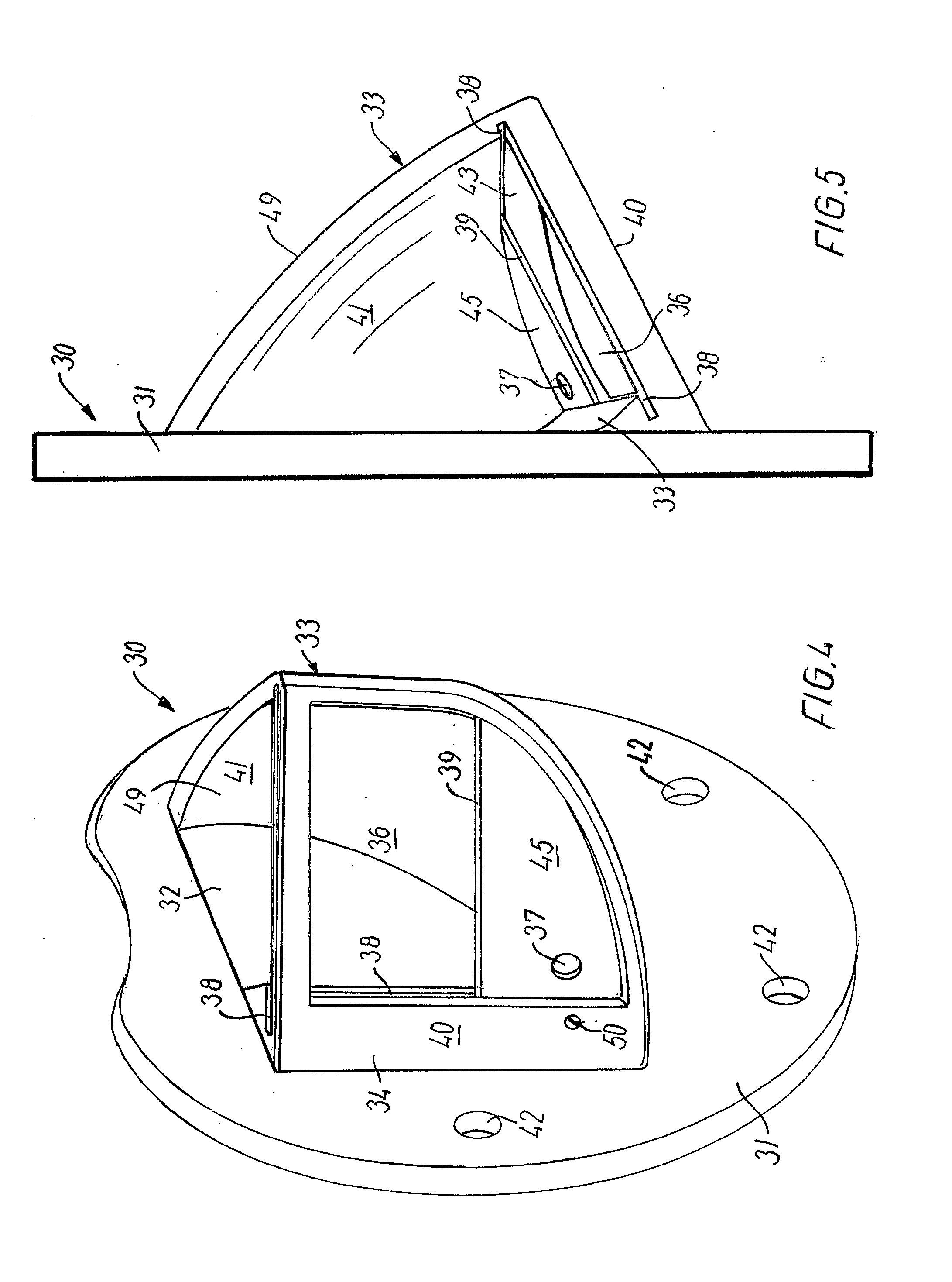

Methods for treating a person's teeth using sticky dental compositions in combination with passive-type dental trays

InactiveUS6036943ASufficiently stickyResistant to dilationCosmetic preparationsBiocideThin walledEtching

Sticky dental compositions which include a sticky, glue-like matrix material for treating a variety of tooth or gum ailments and methods for using such compositions. For maximum comfort, an improved dental tray that is thin-walled, flexible and lightweight is used to hold the sticky dental composition adjacent the desired tooth surfaces. The sticky dental compositions include a sticky matrix material into which is dispersed an appropriate dental agent, such as a bleaching agent, a desensitizing agent, and an anticariogenic agent, an antimicrobial agent. The matrix material preferably includes carboxypolymethylene that has been partially neutralized with a base to reduce etching of the enamel. The carboxypolymethylene adds a unique stickiness to the dental composition which helps to adhere and retain the soft tray material against the person's teeth.

Owner:ULTRADENT PROD INC

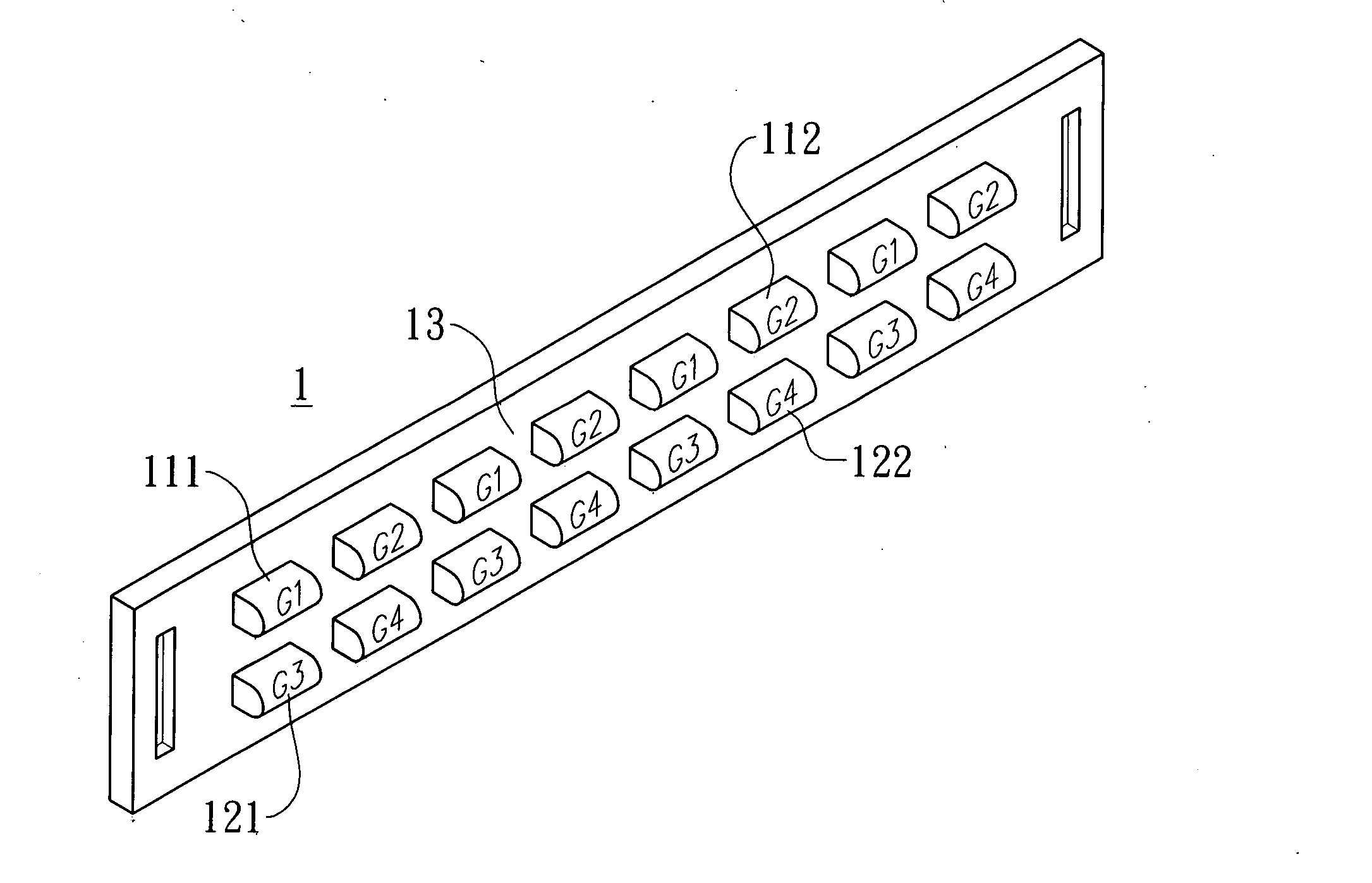

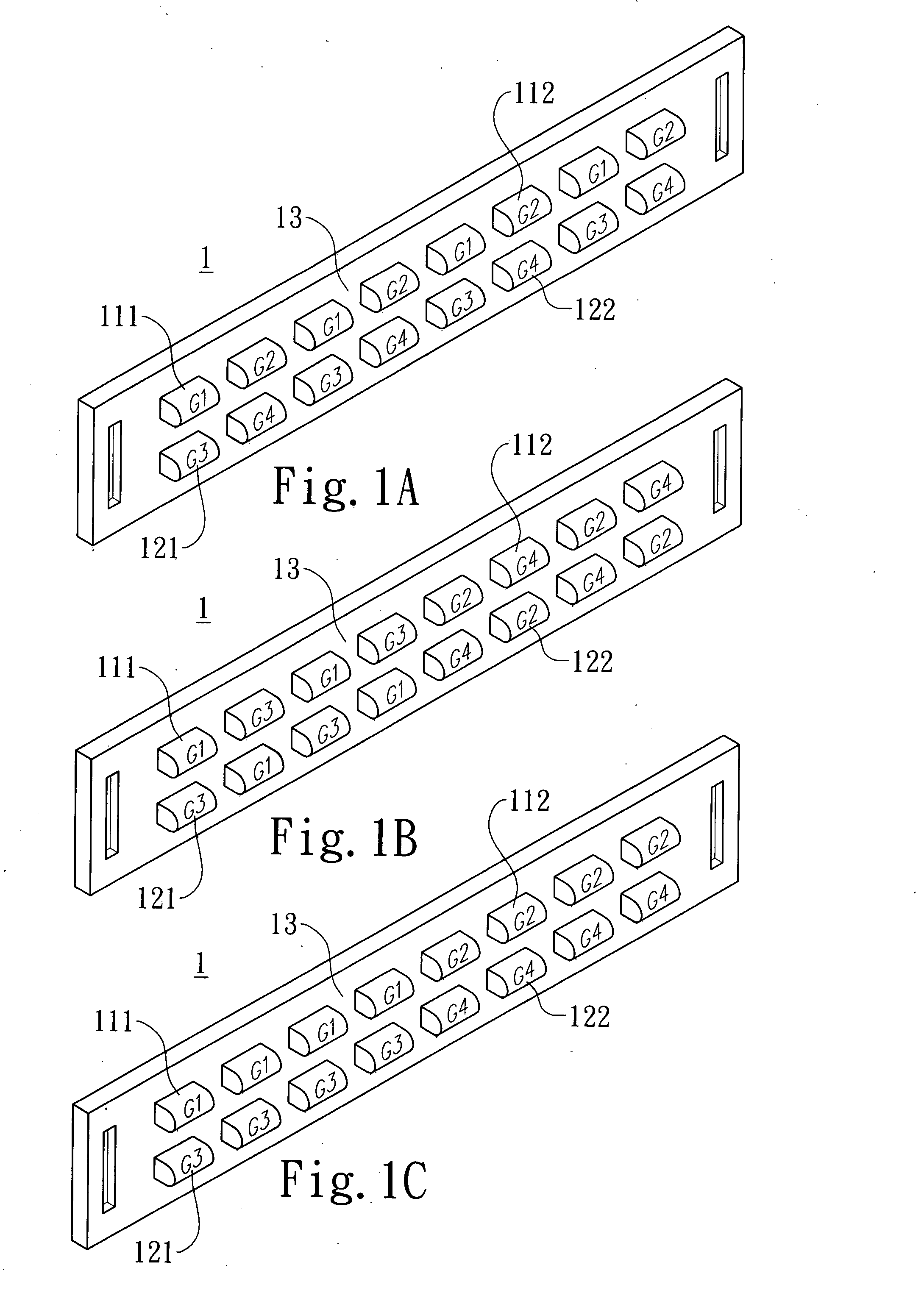

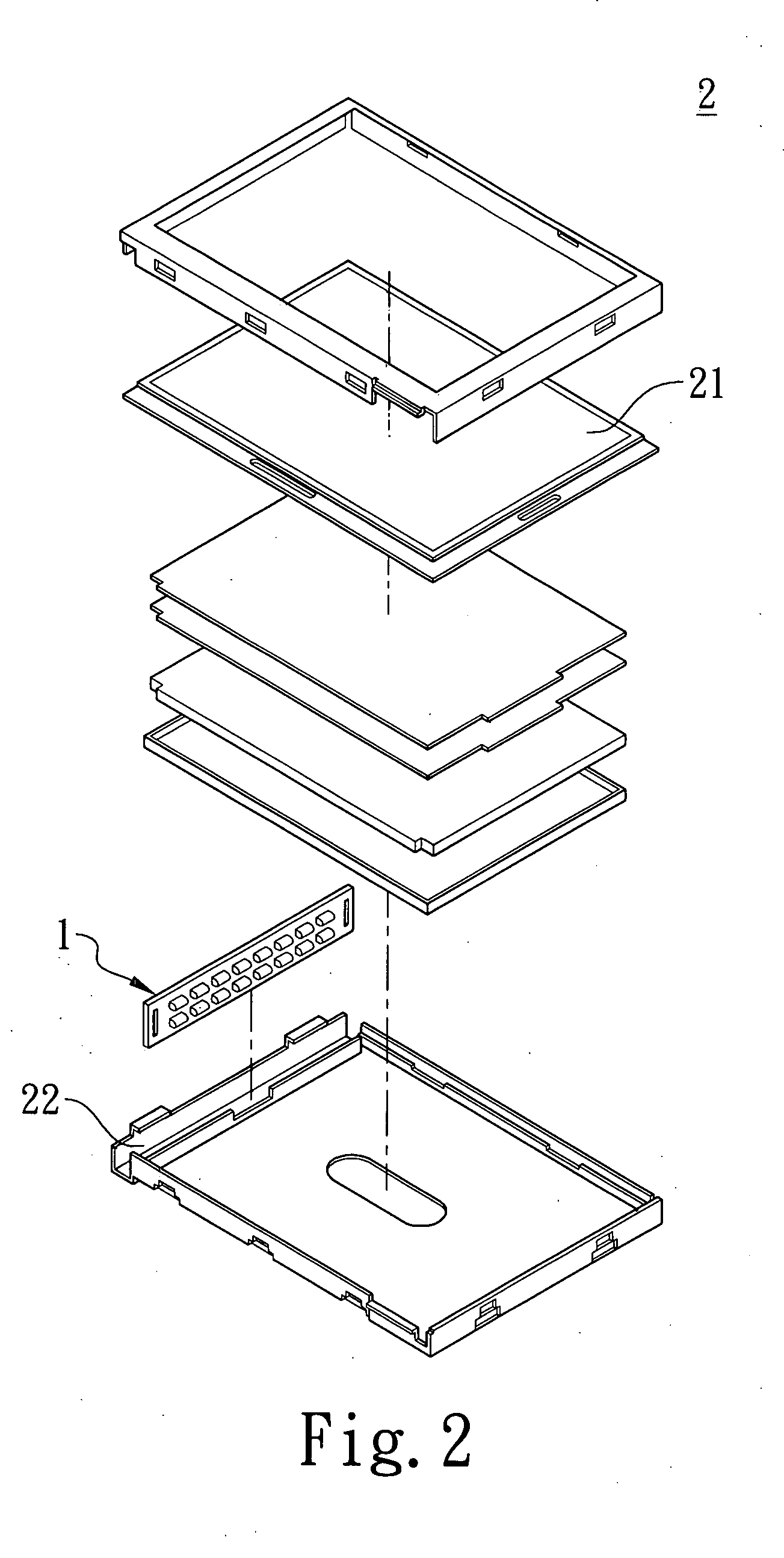

Light source of side-edge type LED backlight unit

InactiveUS20080231196A1Constant levelExtend your lifeElectrical apparatusElectroluminescent light sourcesLiquid-crystal displayLight source

A light source of side-edge type light-emitting diode (LED) backlight unit for using in a liquid crystal display (LCD) comprises a substantial LED bar, at least one primary LED set preset as the light source of the LCD, and at least one backup LED set. The primary LED set(s) and backup LED set(s) are composed of a plurality of LED and disposed at the LED bar, and a backup LED set will be enlightened and substituted for one primary LED set as the light source when the primary LED set is broken-down so that the light source for the LCD is maintained at constant levels.

Owner:PROMATE ELECTRONICS

Display apparatus and method of driving same

ActiveUS20100188384A1Constant levelImprove abilitiesElectrical apparatusElectroluminescent light sourcesControl signalSynchronism

A display apparatus including a pixel array and a driver configured to drive the pixel array, the pixel array having scanning lines as rows, signal lines as columns, a matrix of pixels disposed at respective intersections of the scanning lines and the signal lines, and power supply lines disposed along respective rows of the pixels, the driver having a main scanner for successively supplying control signals to the scanning lines to perform line-sequential scanning on the rows of the pixels, a power supply scanner for supplying a power supply voltage, which selectively switches between a first potential and a second potential, to the power supply lines in synchronism with the line-sequential scanning, and a signal selector for supplying a signal potential, which serves as a video signal, and a reference potential to the signal lines as the columns in synchronism with the line-sequential scanning.

Owner:JOLED INC

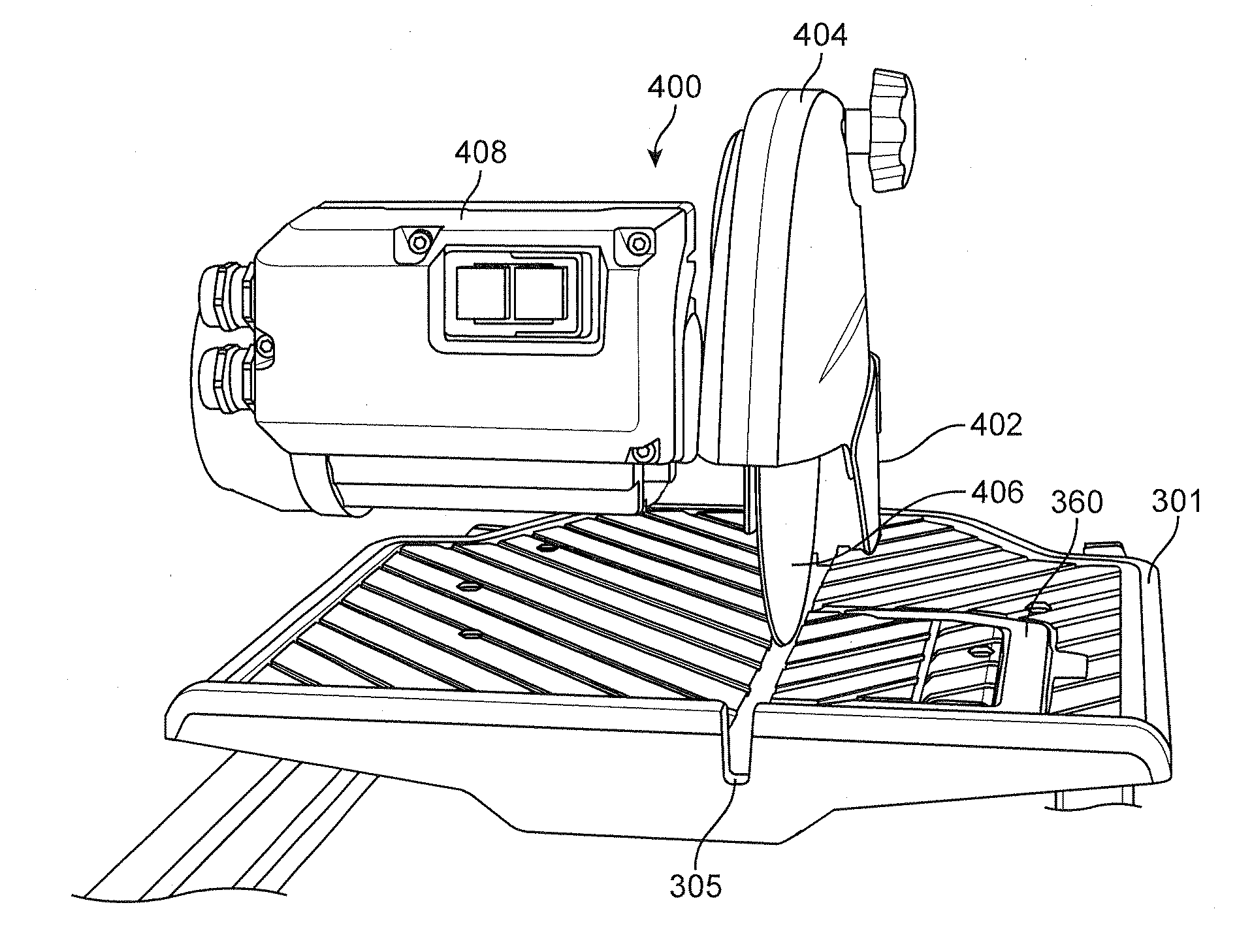

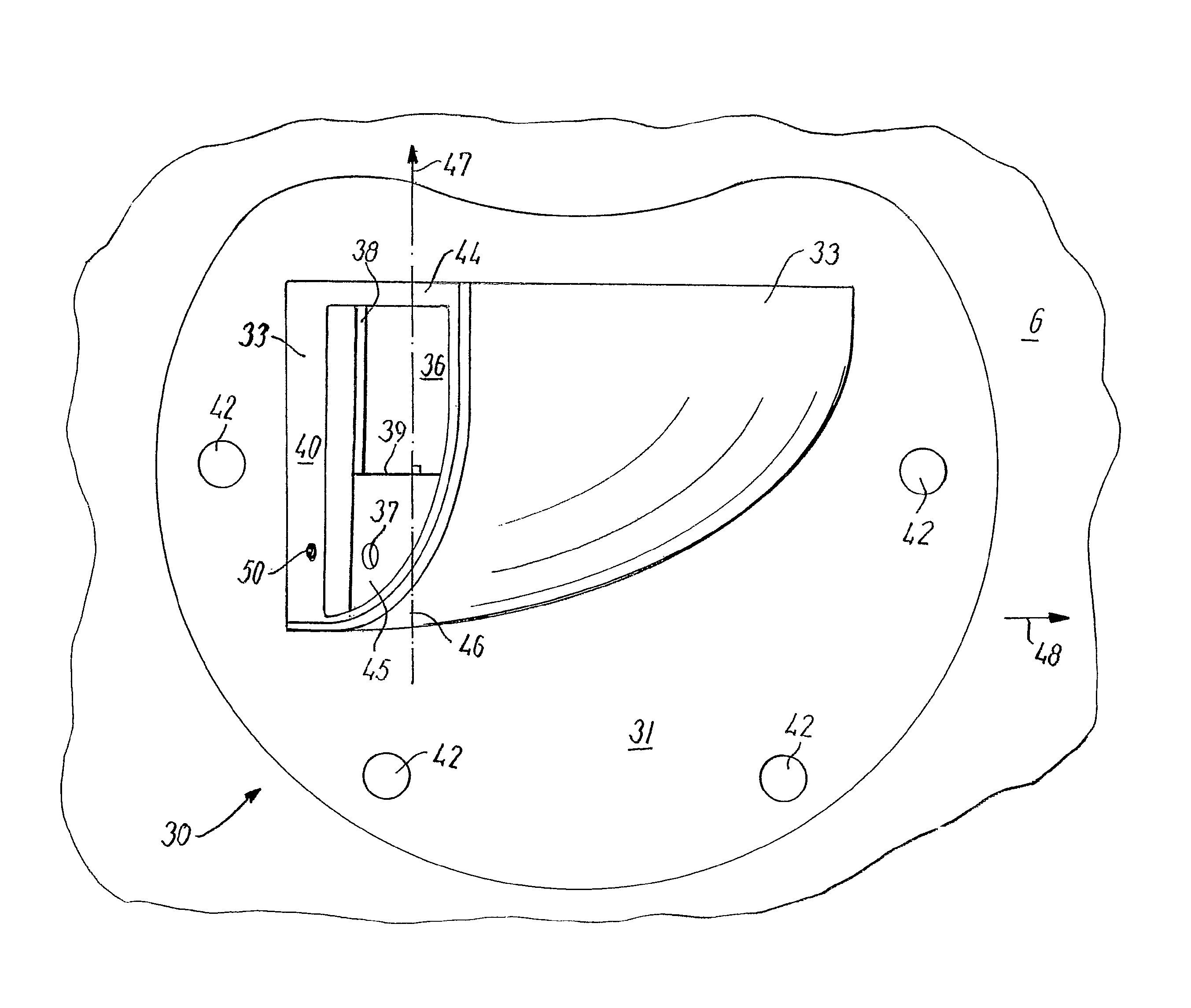

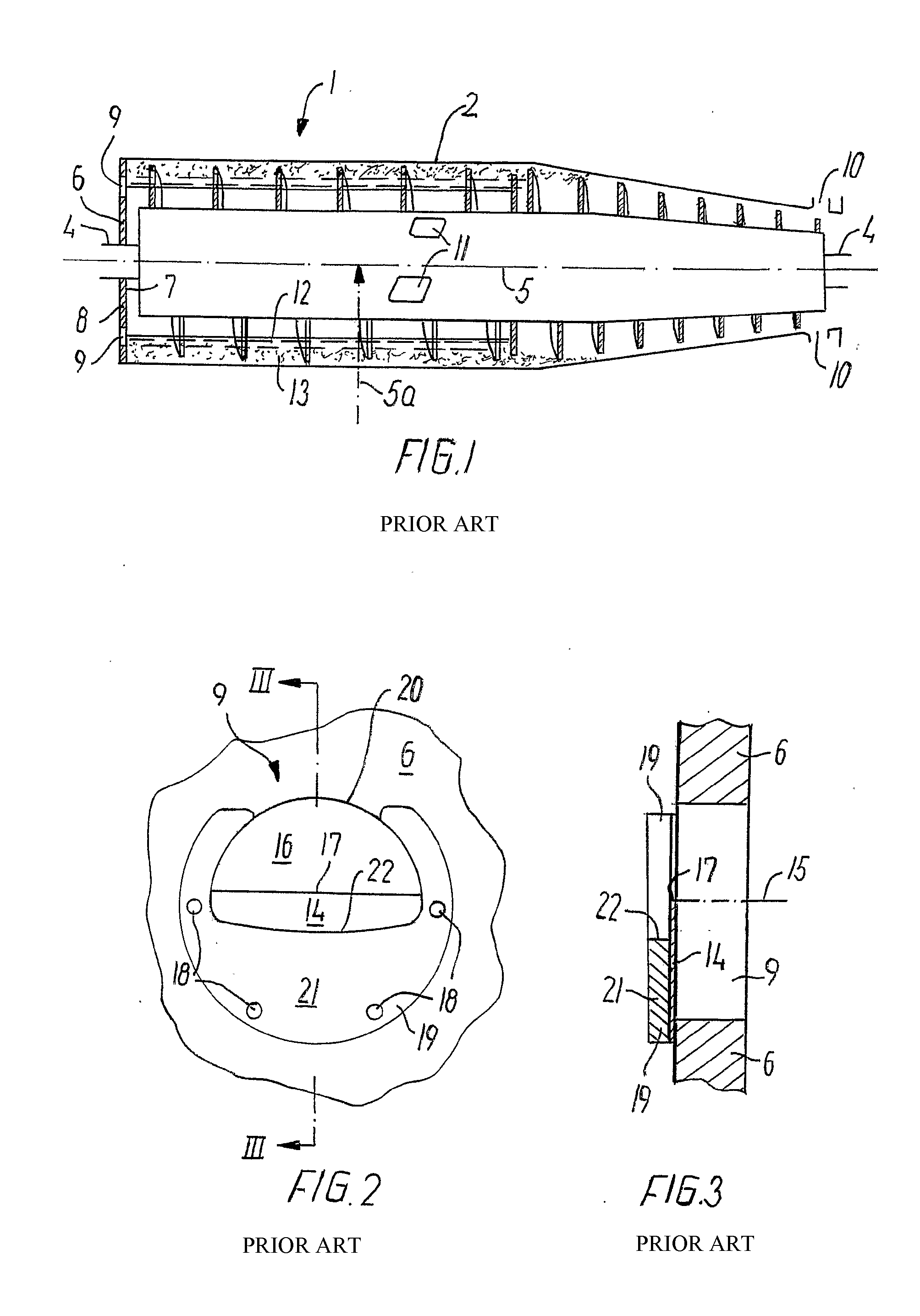

Cutting machine with a liquid lubrication delivery system having a controlled liquid level

ActiveUS20120118278A1Efficiently cool and lubricate and remove debrisImprove fluid flowMetal sawing devicesMetal sawing accessoriesMain channelEngineering

A cutting machine having a liquid lubrication delivery system. The machine includes a work-piece platform having an upper surface for supporting a work-piece thereupon. The work-piece platform can further include a main channel defining a recess in the upper surface. At least one liquid lubrication inlet for discharging liquid into the main channel can also be present on the work-piece platform. The at least one liquid lubrication inlet can be a plurality of liquid lubrication inlets.

Owner:HUSQVARNA AB

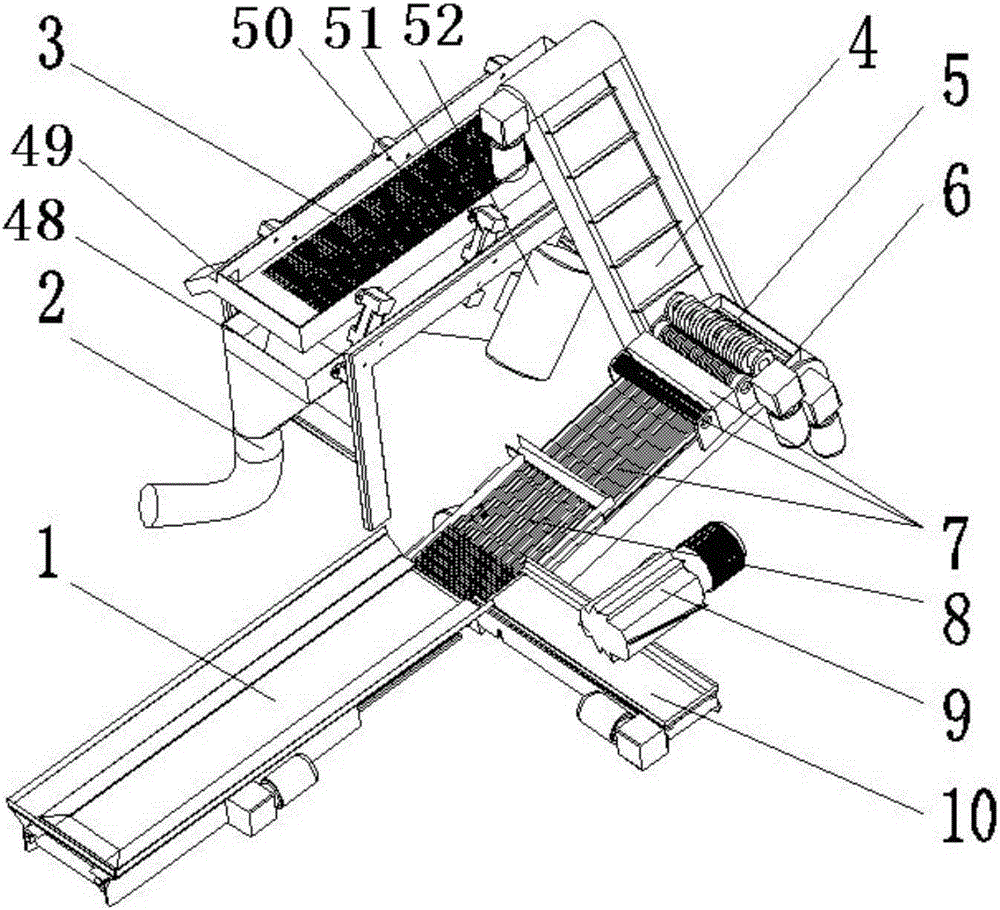

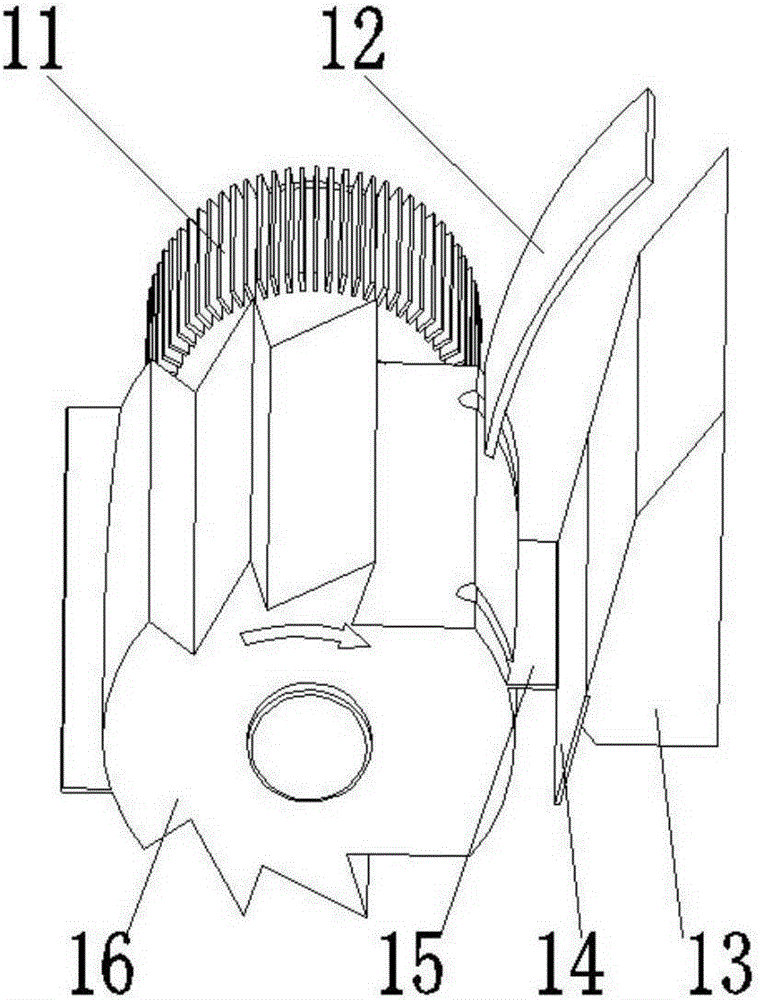

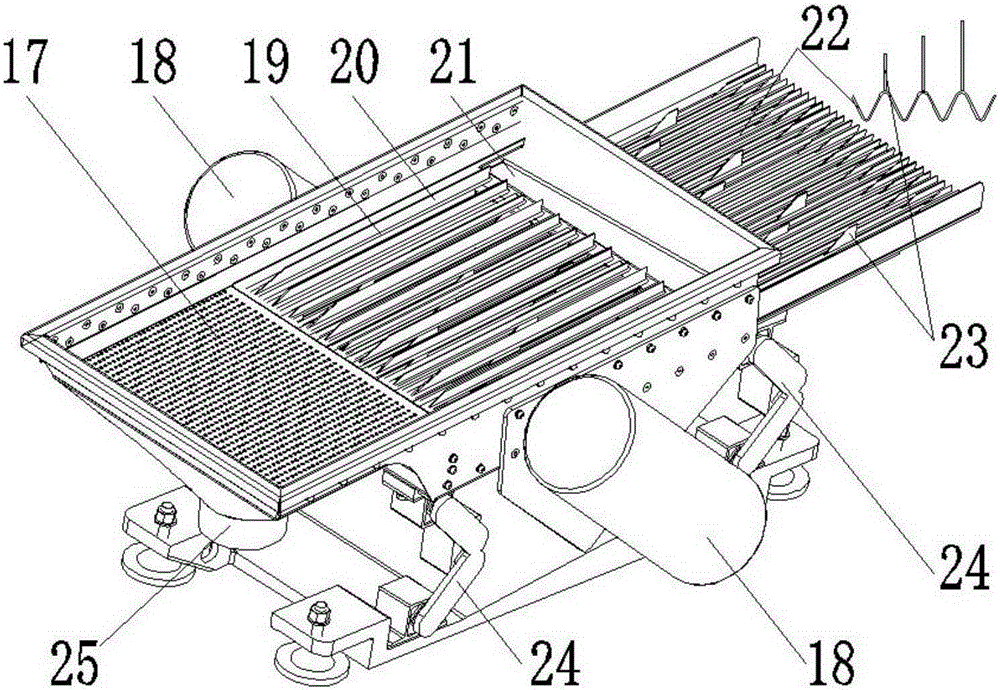

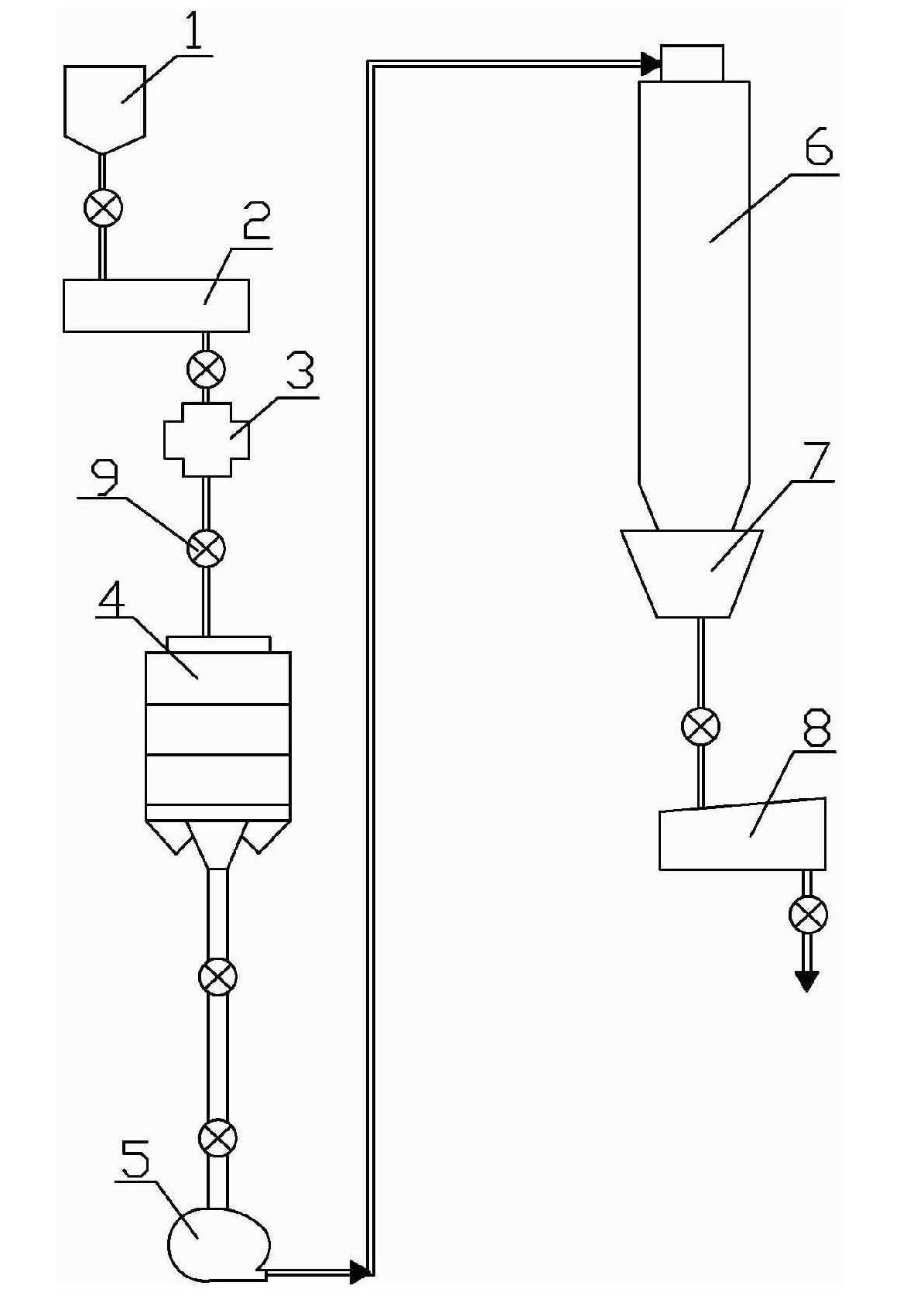

Online waste cigarette cut tobacco recovery system

The invention relates to an online waste cigarette cut tobacco recovery system. The system comprises an automatic break-out cigarette cutting device, a cigarette machine waste cigarette collecting device, an assembling machine waste cigarette collecting device, a waste cigarette screening and straightening device, a directional and quantitative waste cigarette arranging device, a waste cigarette slicing device, a waste cigarette loosening device, a waste cigarette lifting device, a waste cigarette vibrating and screening device and an online recovered cut tobacco adding device. According to the system, through automatic break-out cigarette cutting, automatic waste cigarette collection, straightening, directional and quantitative arrangement, slicing, loosening and screening, components and quality of recovered cut tobacco are unchanged, the class of the cut tobacco is unchanged, the cut tobacco is clean and sanitary, the recovery rate of the cut tobacco is high, the recovered cut tobacco is directly added to a cigarette machine for use through a cut tobacco feeding system, the loss of the cut tobacco is effectively decreased, and the production efficiency is improved. Problems that the cut tobacco is miscellaneous, the moisture of the cut tobacco is changed, the quality is declined and the like after scattered collection, centralized treatment and treatment of different classes of cigarettes by the aid of an offline waste cigarette cut tobacco recovery production line are solved.

Owner:BEIJING TIANSHEN ZHENGXIANG TECH

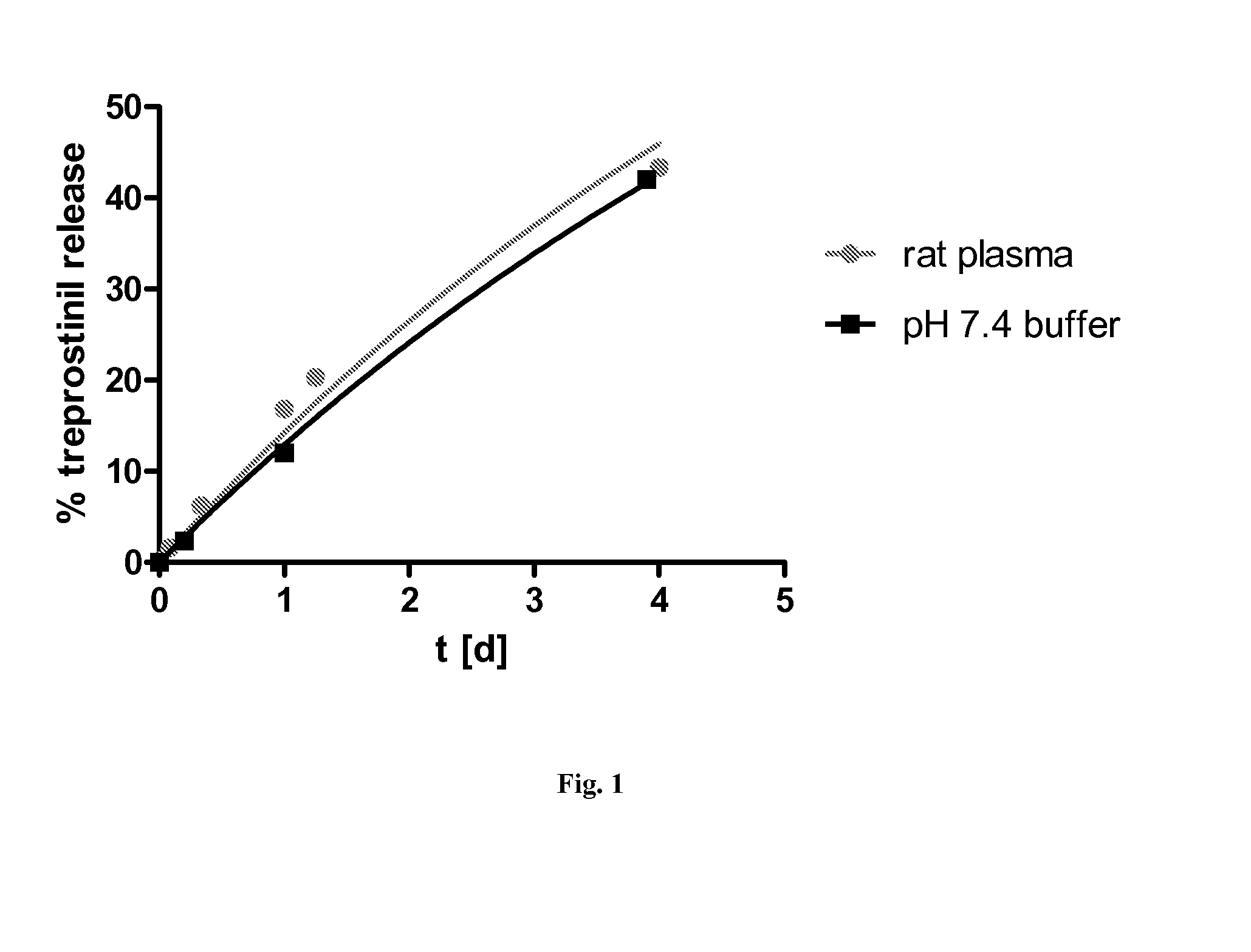

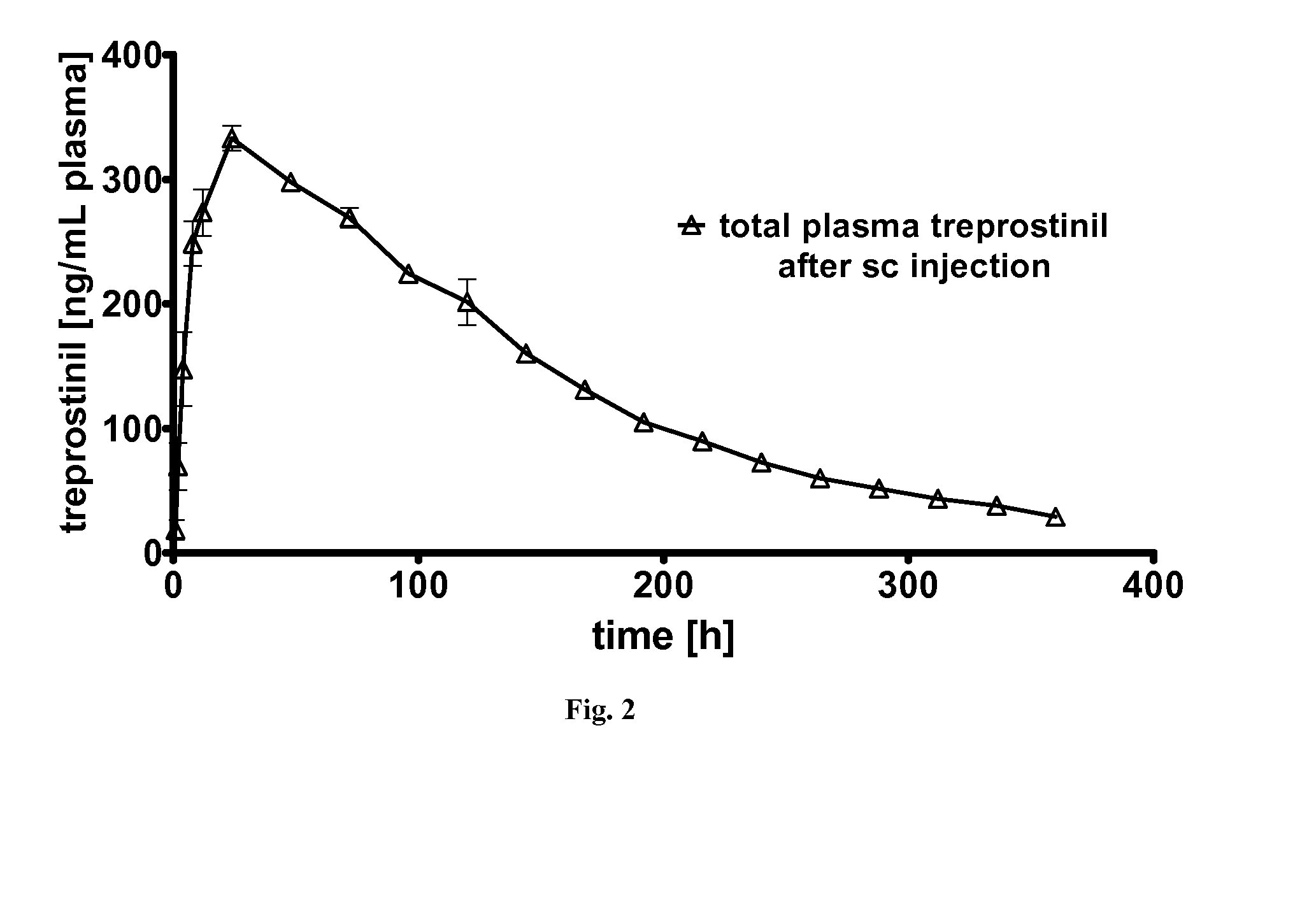

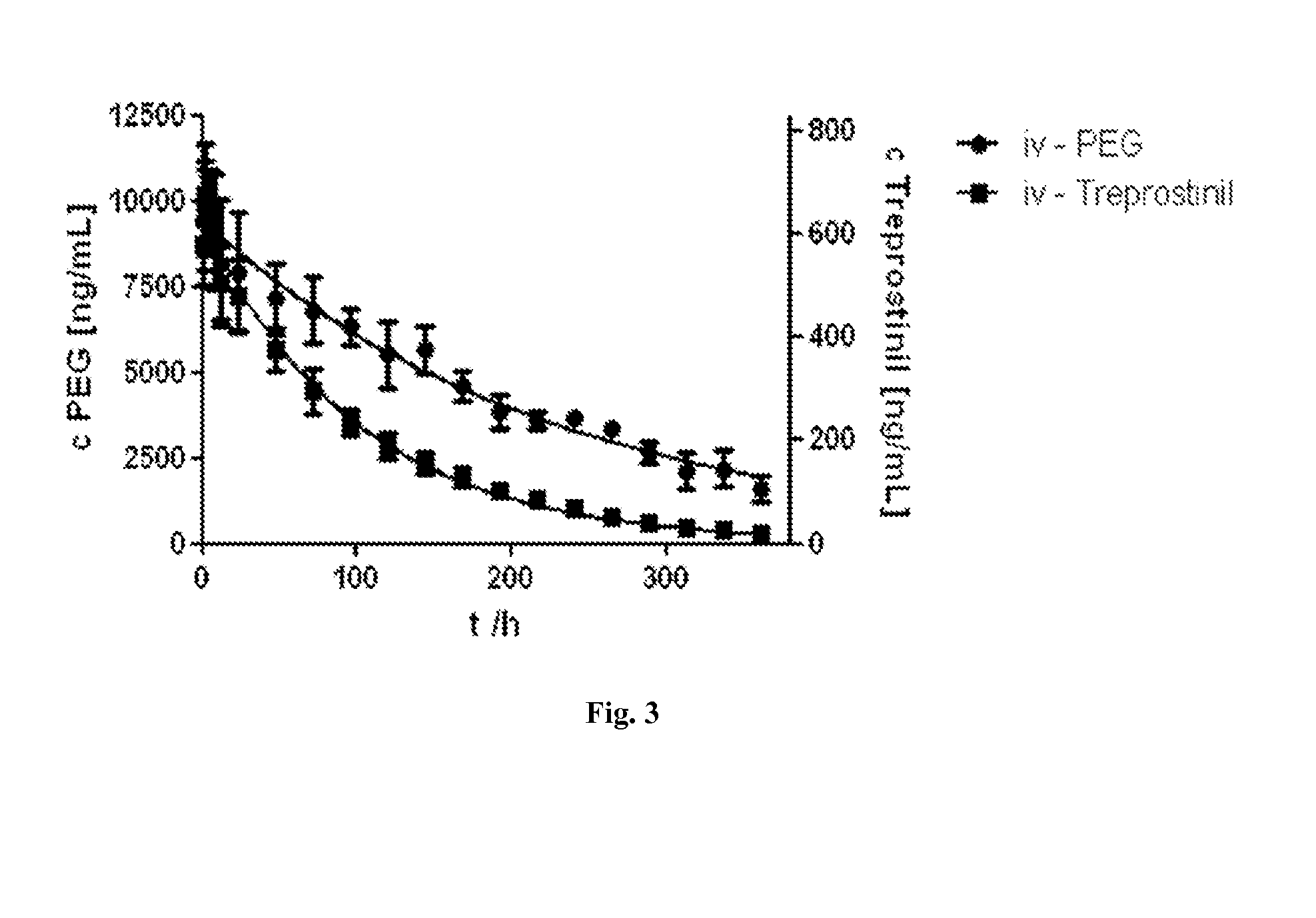

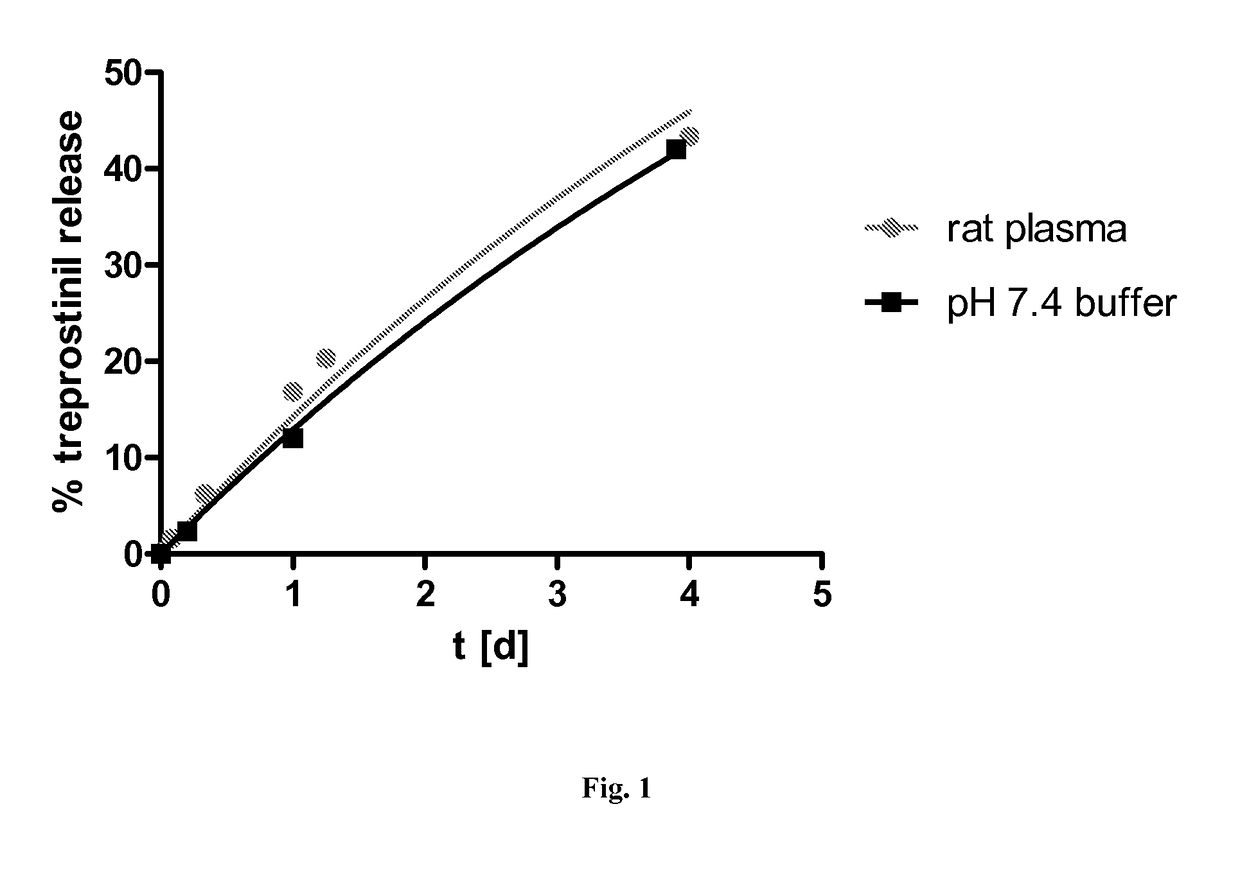

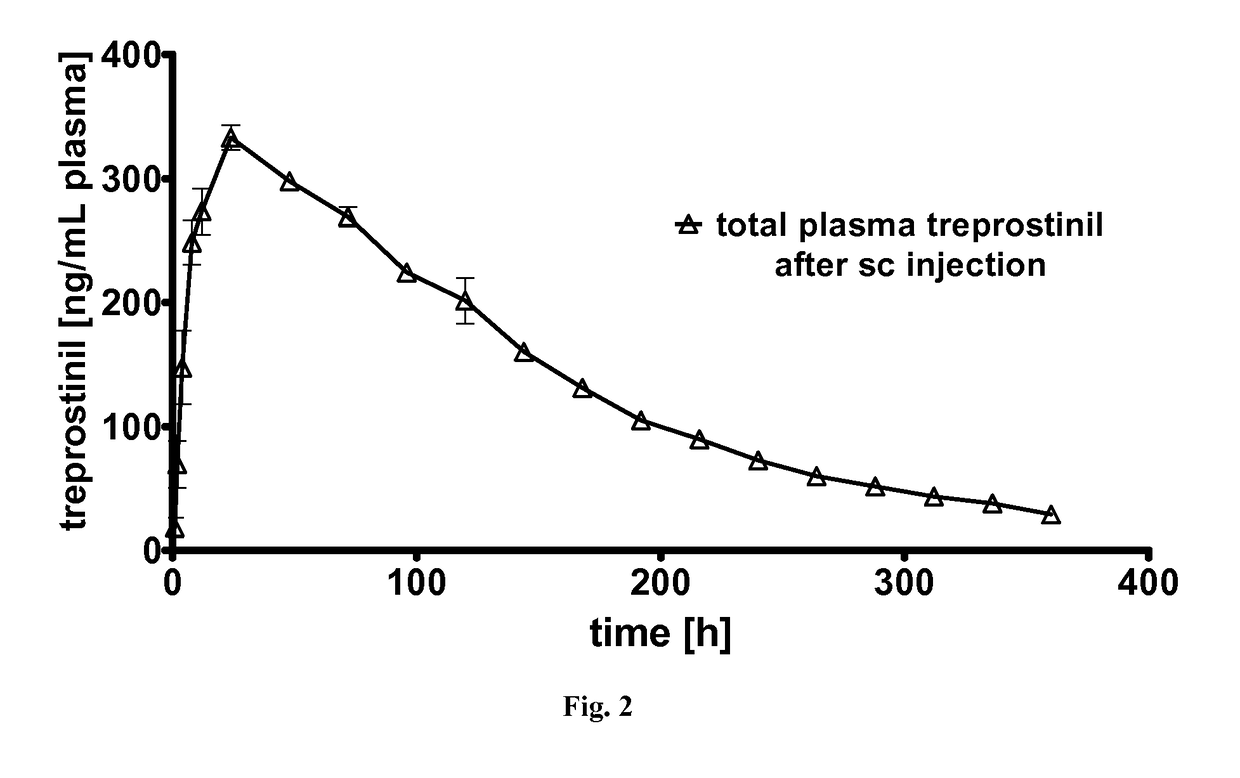

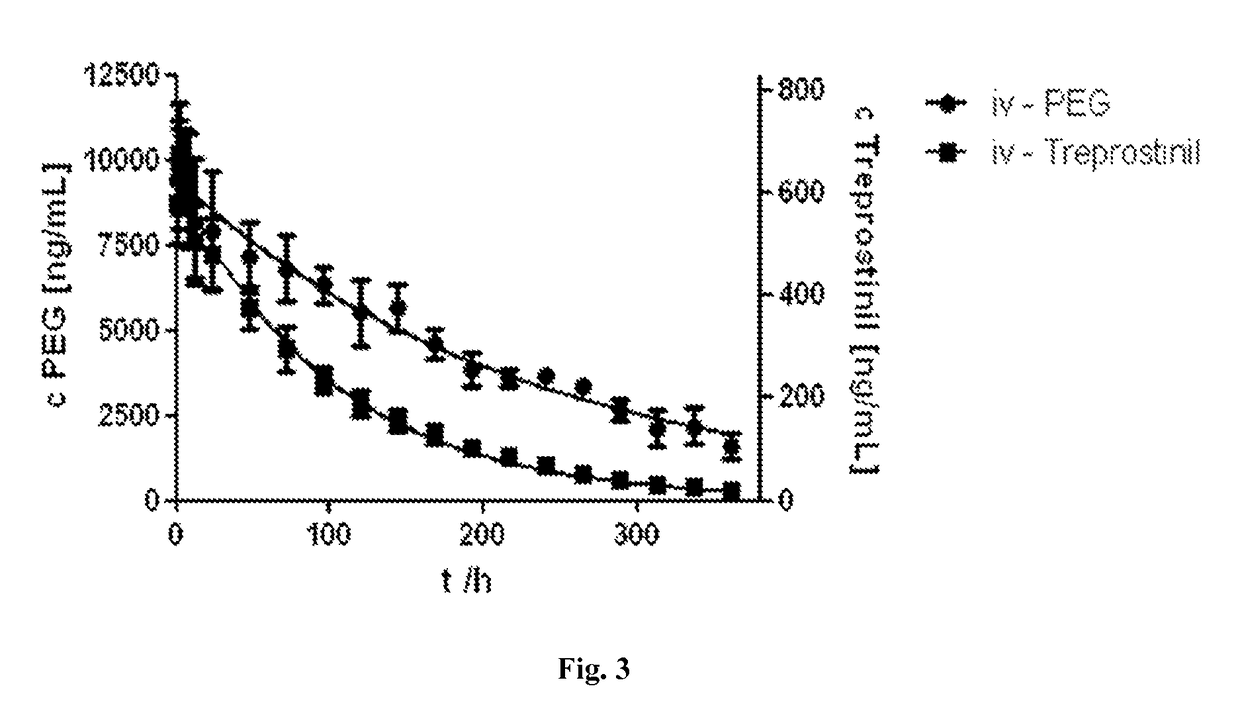

Sustained Release Composition of Prostacyclin

The present invention relates to sustained release compositions of prostacyclin, as well as uses thereof, in particular for the prevention and / or treatment of pulmonary arterial hypertension.

Owner:ASCENDIS PHARM AS

Linear motor-driven plunger pump

InactiveCN102305203AReduce in quantityImprove anti-pollution performancePumpsPositive-displacement liquid enginesPermanent magnet rotorReciprocating motion

The invention relates to a linear motor-driven plunger pump. The mechanical part of the plunger pump comprises a cylinder body I, a cylinder body II, flow distribution valves, an in-sucking communication pipe, out-pressing communication pipes, compacting flanges, plunger rods, linear motor stators, linear motor rotors and guide rails; and the electric part mainly consists of linear motors, a controller, drivers and a position feedback device. The linear motor-driven plunger pump is characterized in that a group of coil-type stators drive a permanent magnet rotor in a combinational way, thus realizing high thrust output of the linear motors. Each flat-type linear motor drives two plungers at the two ends of one plunger rod, and while the double-action plunger rod reciprocates, one end of the double-action plunger rod sucks water and at the same time the other end of the double-action plunger rod presses water. The two cylinders realizes the effective communication between the water sucking loop and water pressing loop of the plunger pump by means of the in-sucking communication pipe and the two out-pressing communication pipes. Each plunger hole is communicated with a flow distribution valve consisting of an in-sucking valve and an out-pressing valve. The electric part controls the out-of-phase movement of the linear motors, thus ensuring the stable combinational flow output of the pump. The linear motor-driven plunger pump disclosed by the invention has the advantages of less mechanical transmission links and high system efficiency and reliability.

Owner:BEIJING UNIV OF TECH

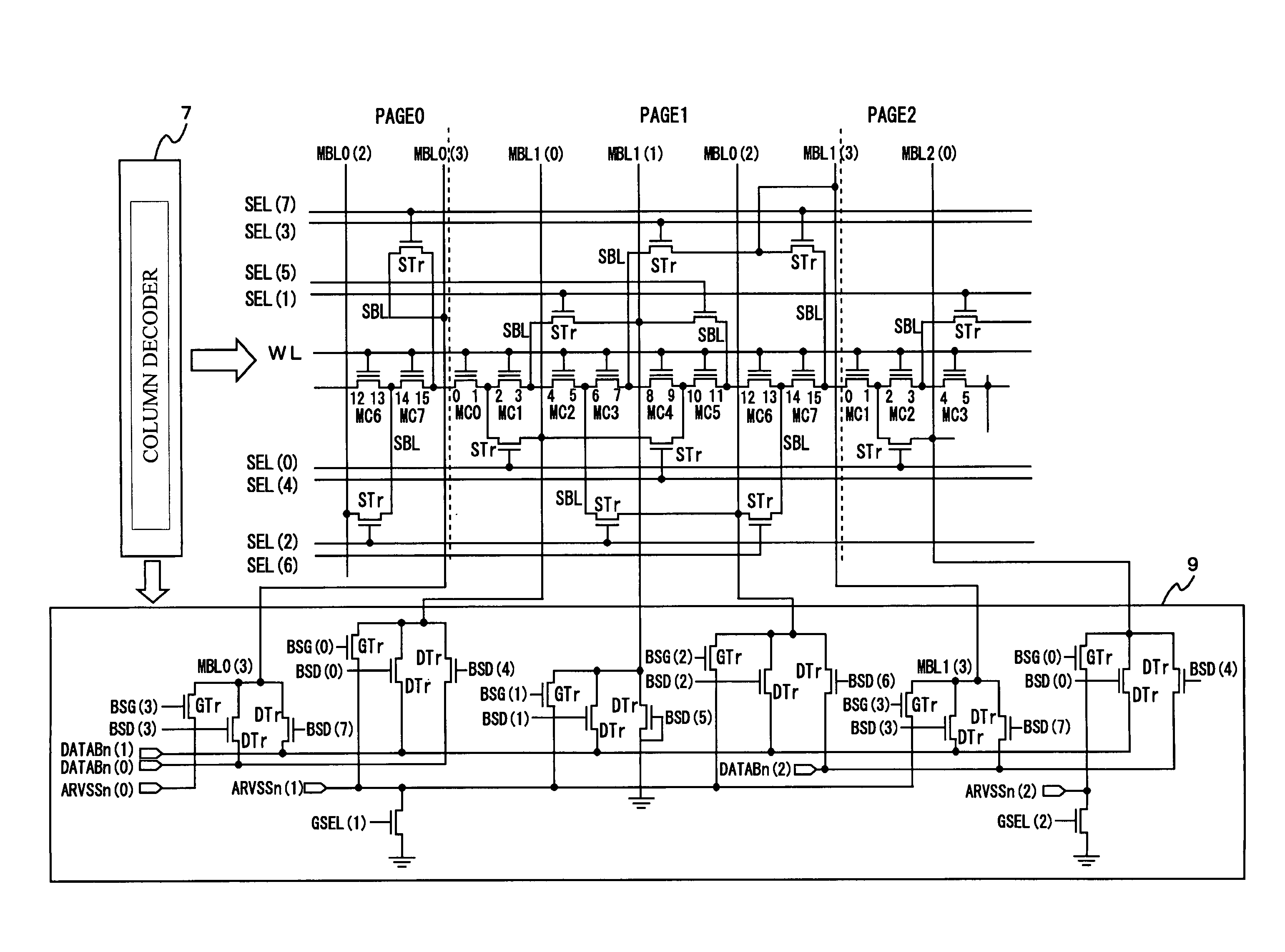

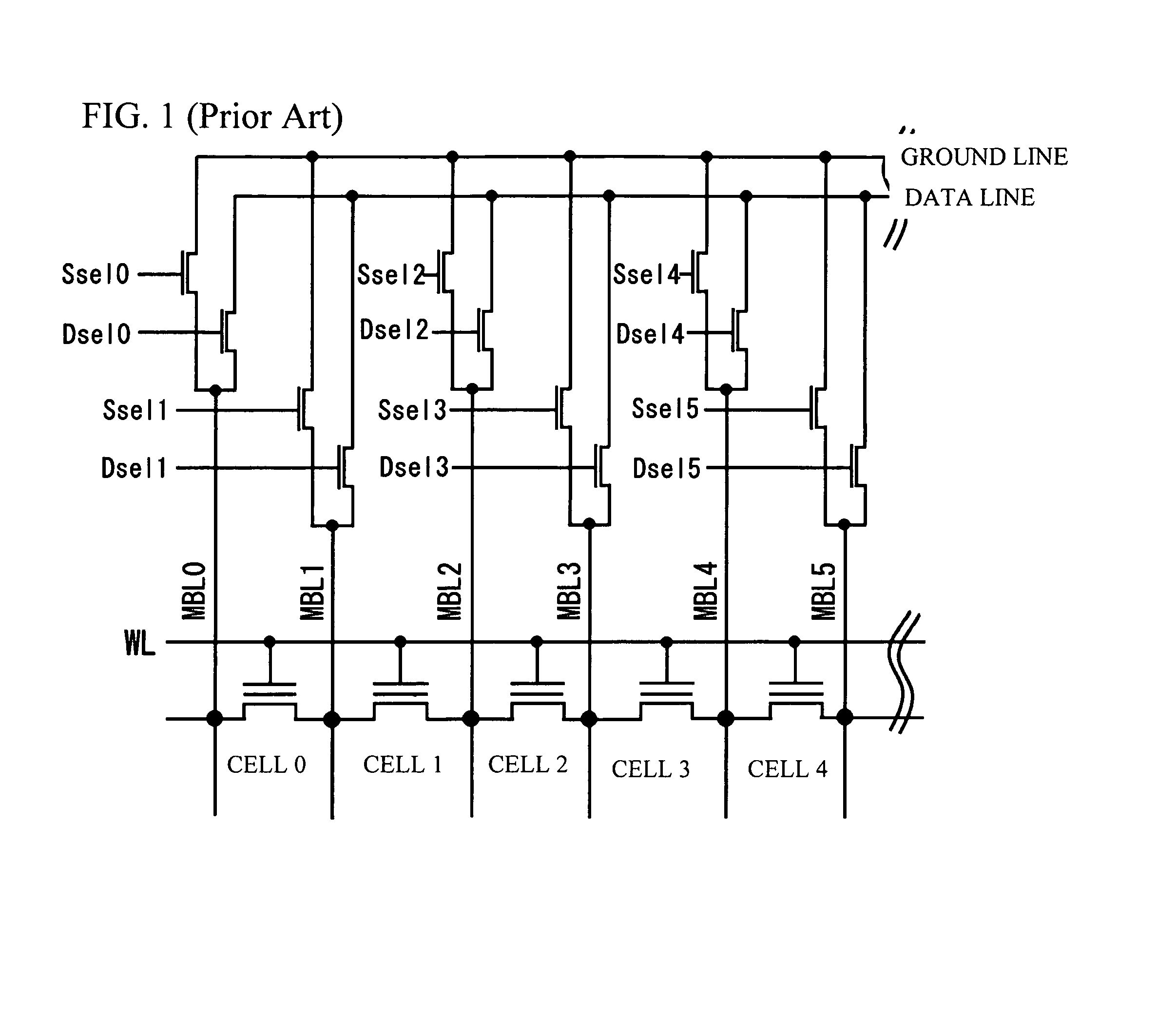

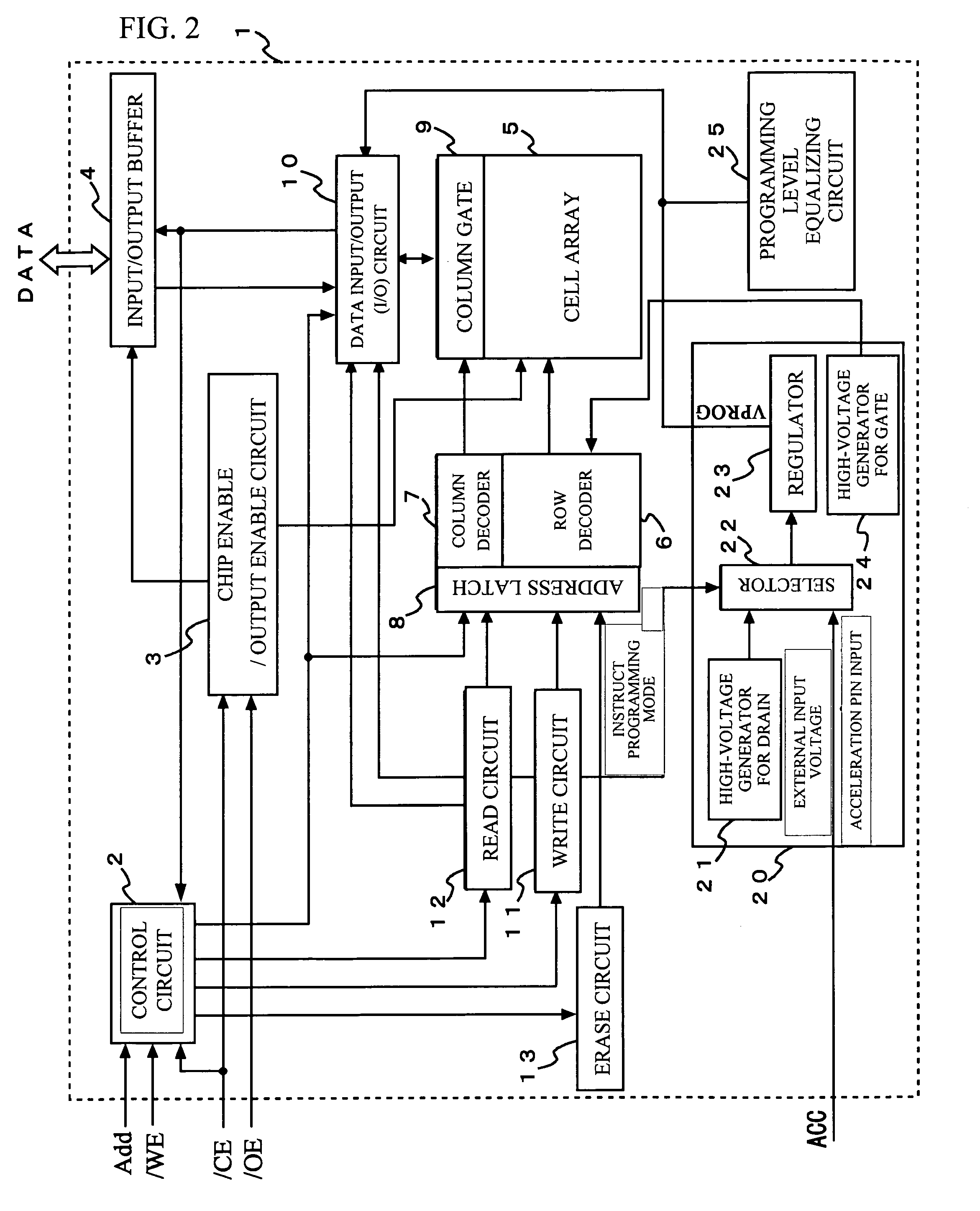

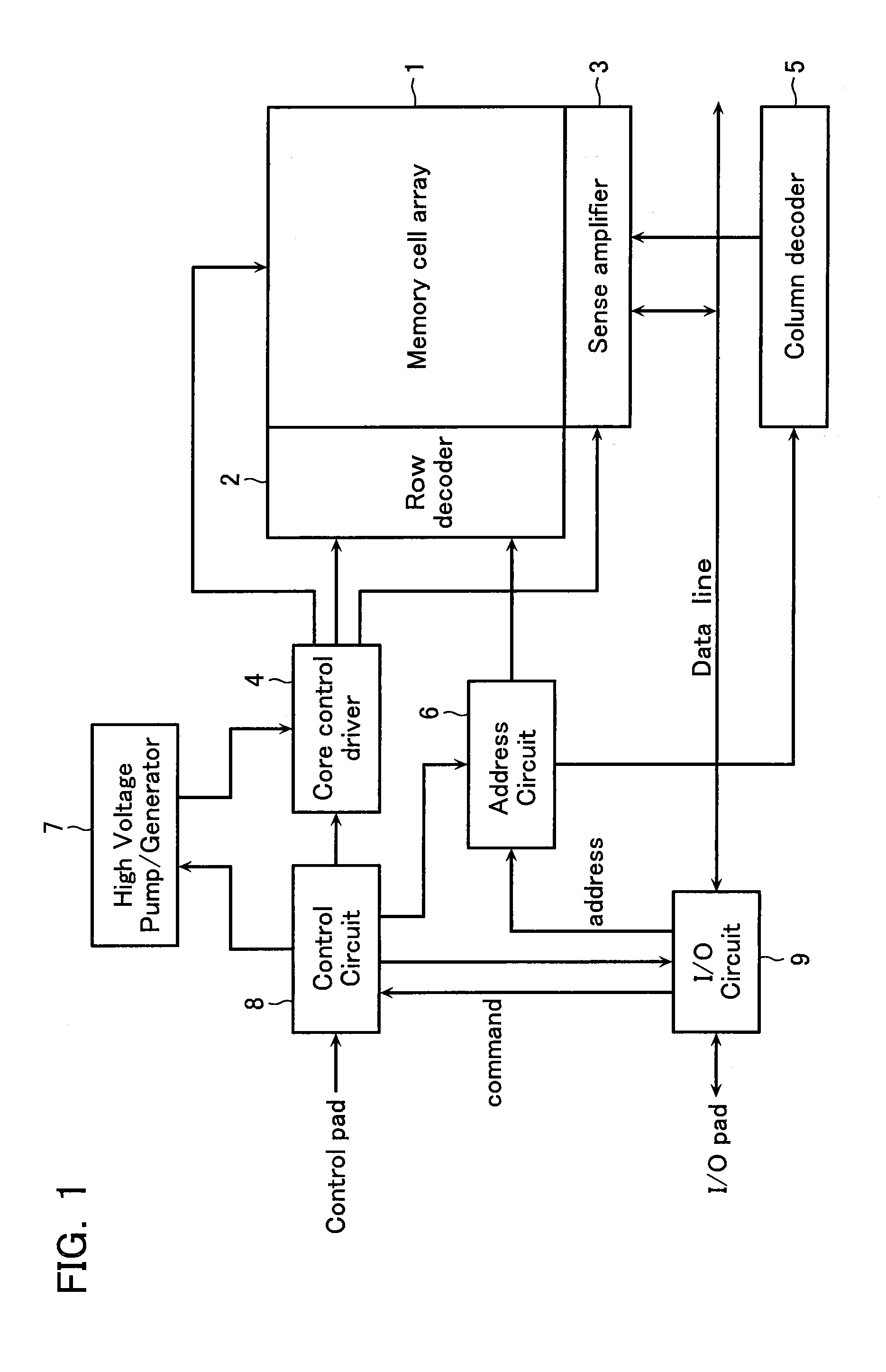

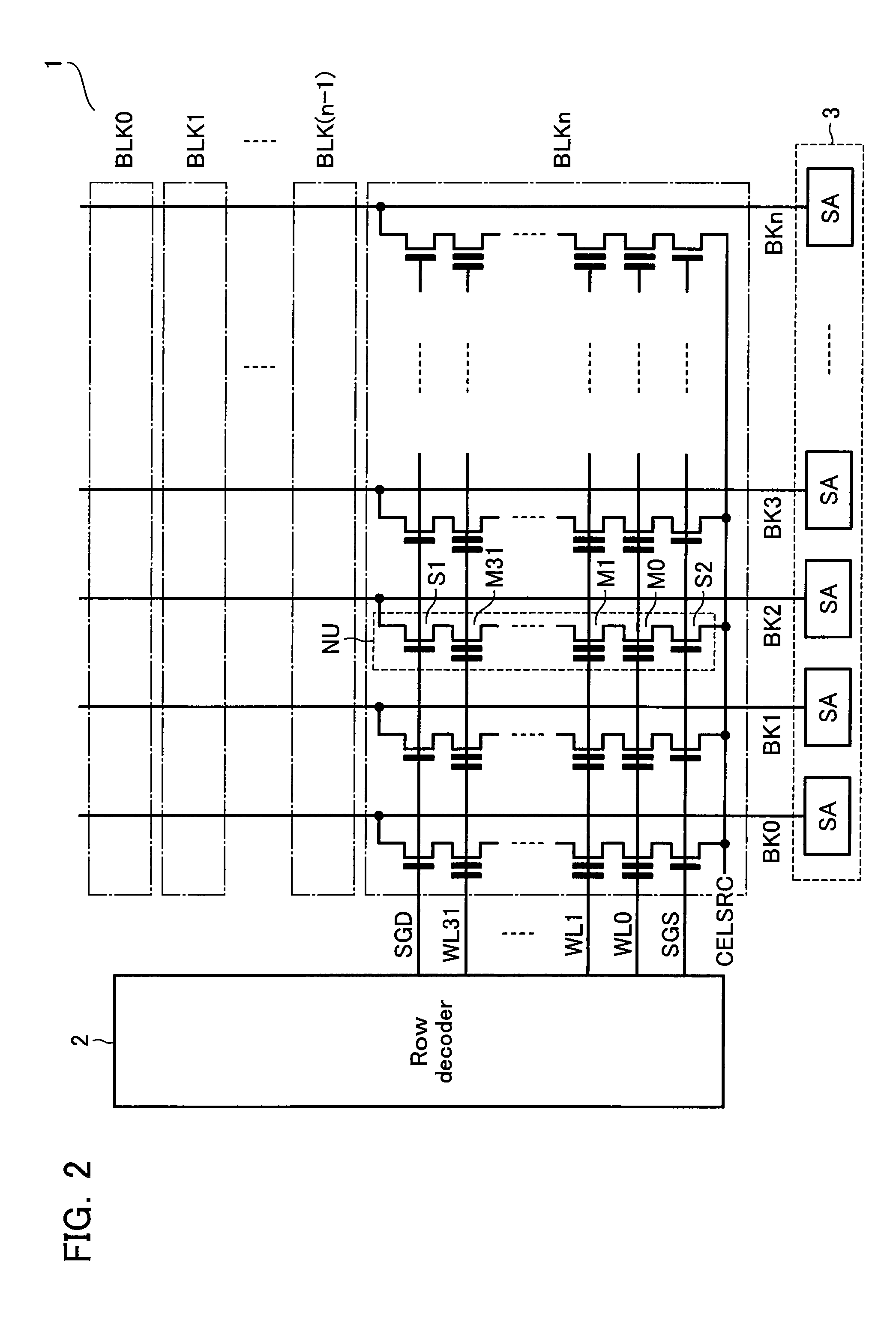

Semiconductor device and programming method

ActiveUS7221587B2Increase distanceAvoid flowRead-only memoriesDigital storageComputer scienceSemiconductor

The semiconductor device of the present invention includes a column decoder (select and write circuit), which selects multiple pages that are not located adjacently to each other so as to simultaneously program multiple bits in the memory cells of the selected page, when the multiple bits are programmed in the multiple pages. The page is a selection unit and is composed of a given number of the memory cells located on a same word line. An unnecessary stress of programming is not applied to the memory cells that are not to be programmed, by increasing the distance between the memory cells to be programmed simultaneously.

Owner:MONTEREY RES LLC

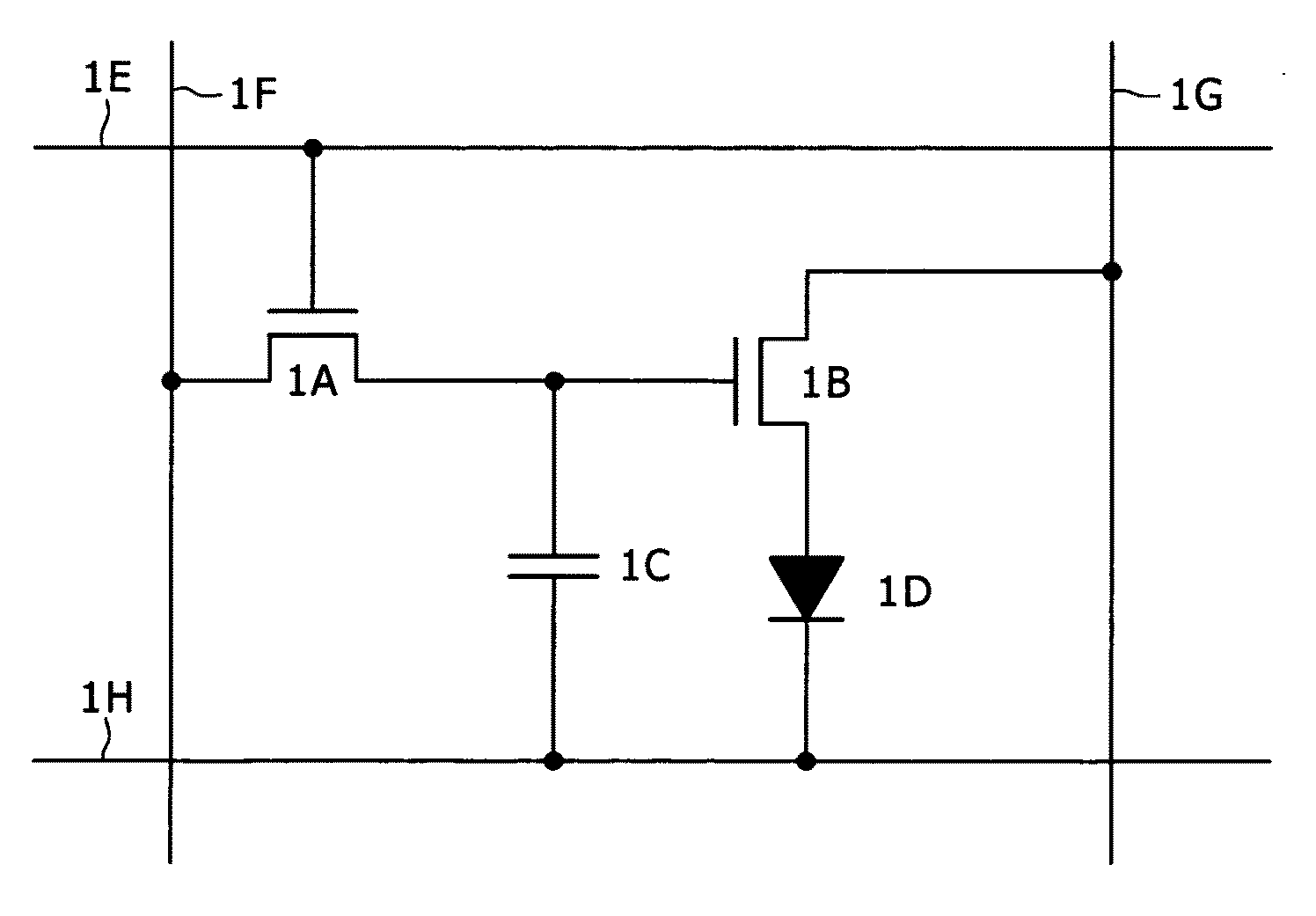

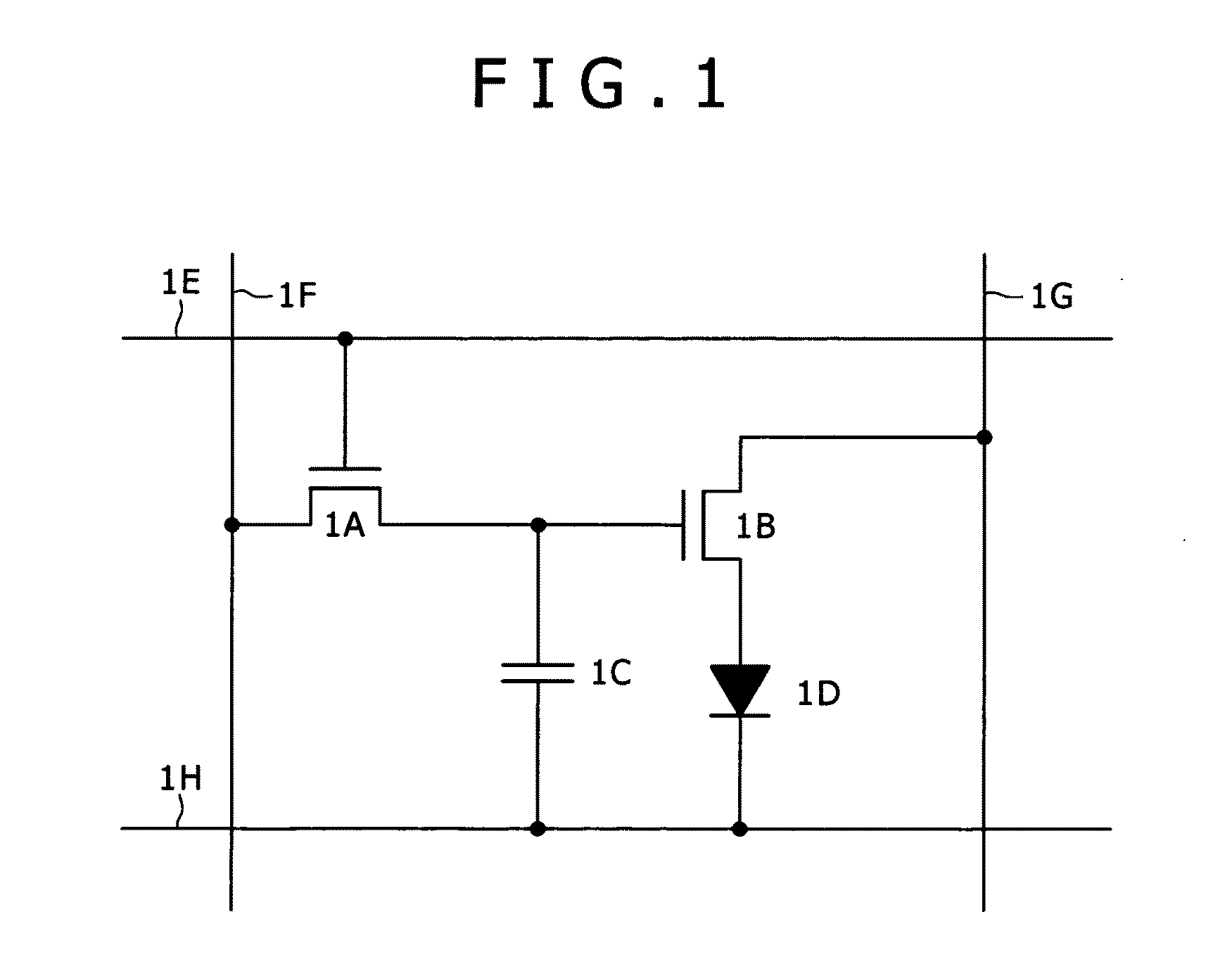

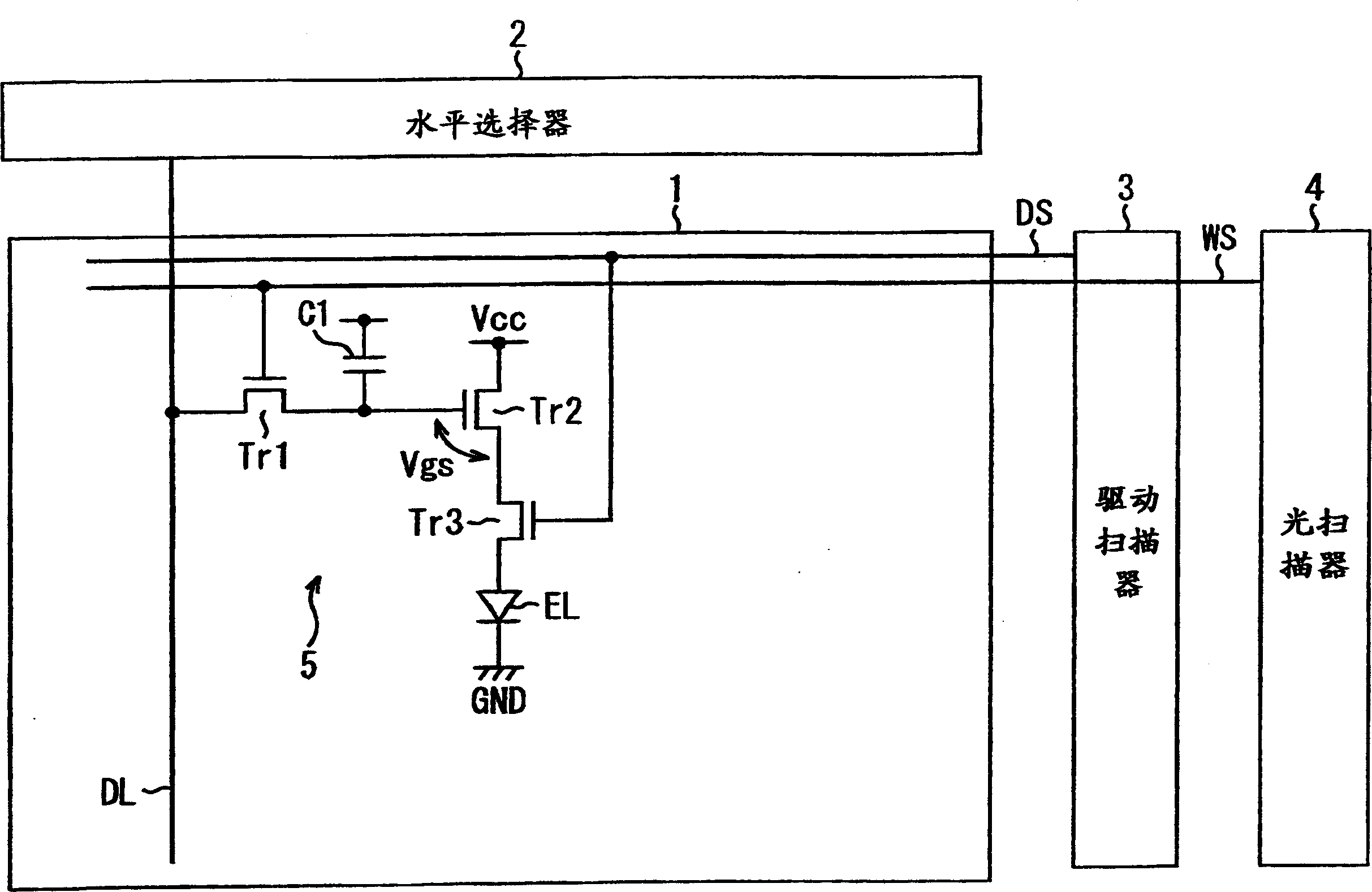

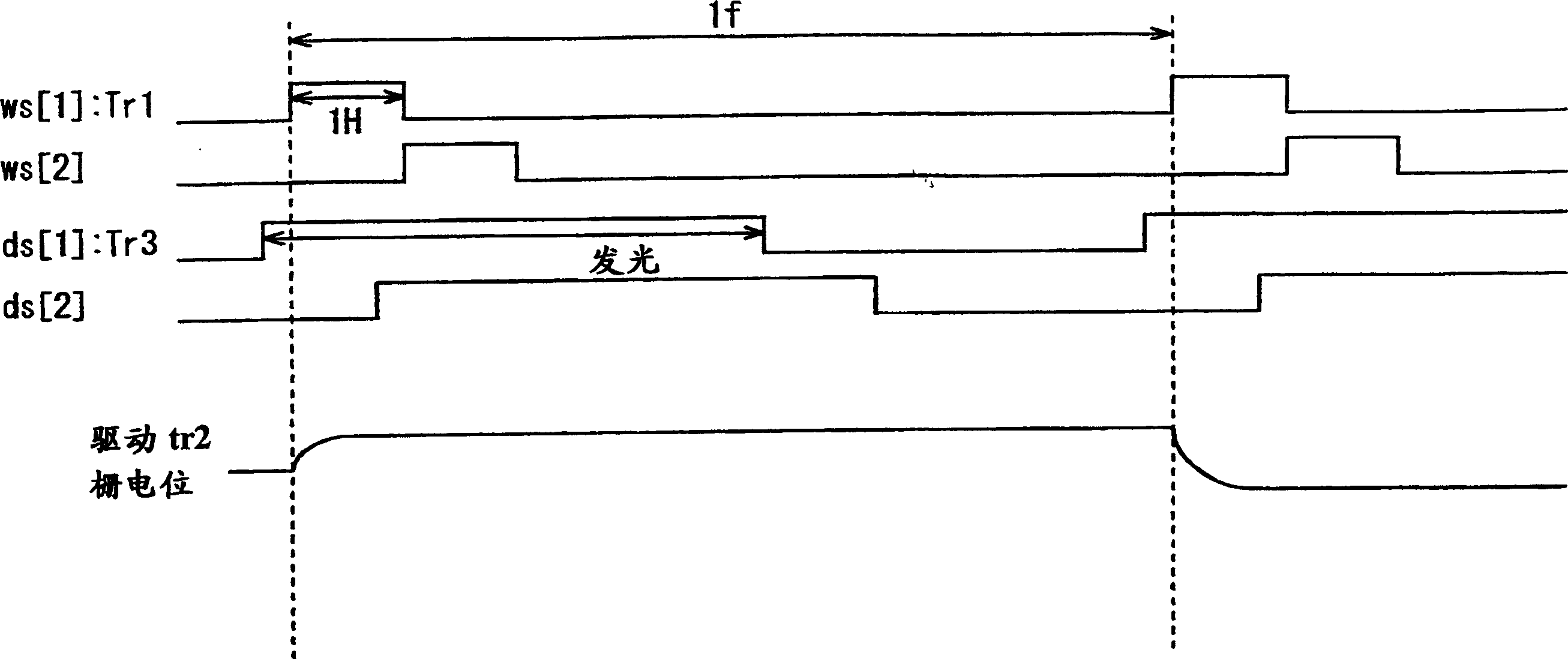

Pixel circuit, display device, driving method of pixel circuit, and driving method of display device

ActiveCN1722207APrevent brightness deteriorationGuaranteed uniformityElectrical apparatusStatic indicating devicesDriving currentCapacitance

PROBLEM TO BE SOLVED: To provide a pixel circuit which compensates change with time of a drain current in a drive transistor.SOLUTION: In a drive transistor Tr2, a gate G is connected to an input node A, a source S is connected to an output node B, and a drain is connected to a power supply voltage Vcc. A sampling transistor Tr1 is connected between the input node A and a signal line DL. A holding capacitance C1 is connected to the input node A. The sampling transistor Tr1 samples an input signal Vsig from the signal line DL and holds in the holding capacitance C1. The drive transistor Tr2 supplies a drive current Ids to a light emitting element EL in accordance with the signal voltage held by the holding capacitance C1. The pixel circuit is equipped with a compensation circuit 7 to compensate a decrease in the drive current Ids caused by changes in the drive transistor Tr2 with time. The compensation circuit 7 detects a decrease in the drive current Ids through the output node B side and feedbacks the detection result to the input node A side.

Owner:SONY CORP

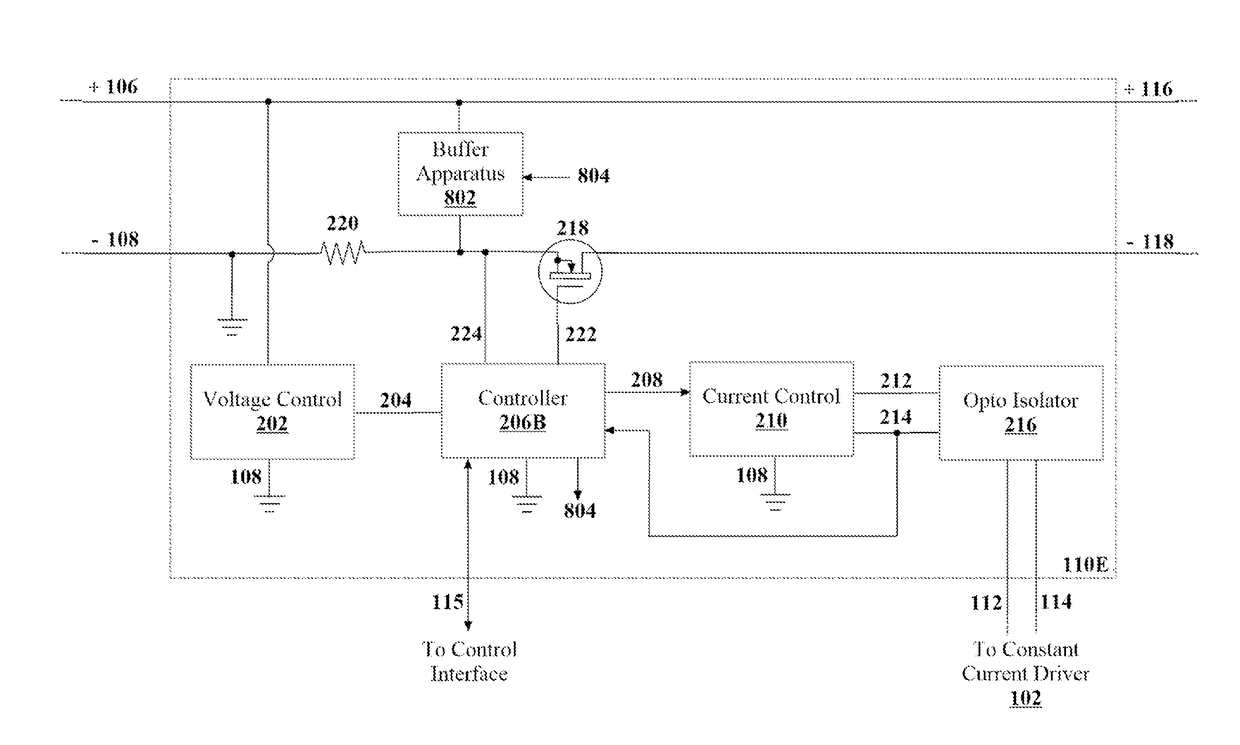

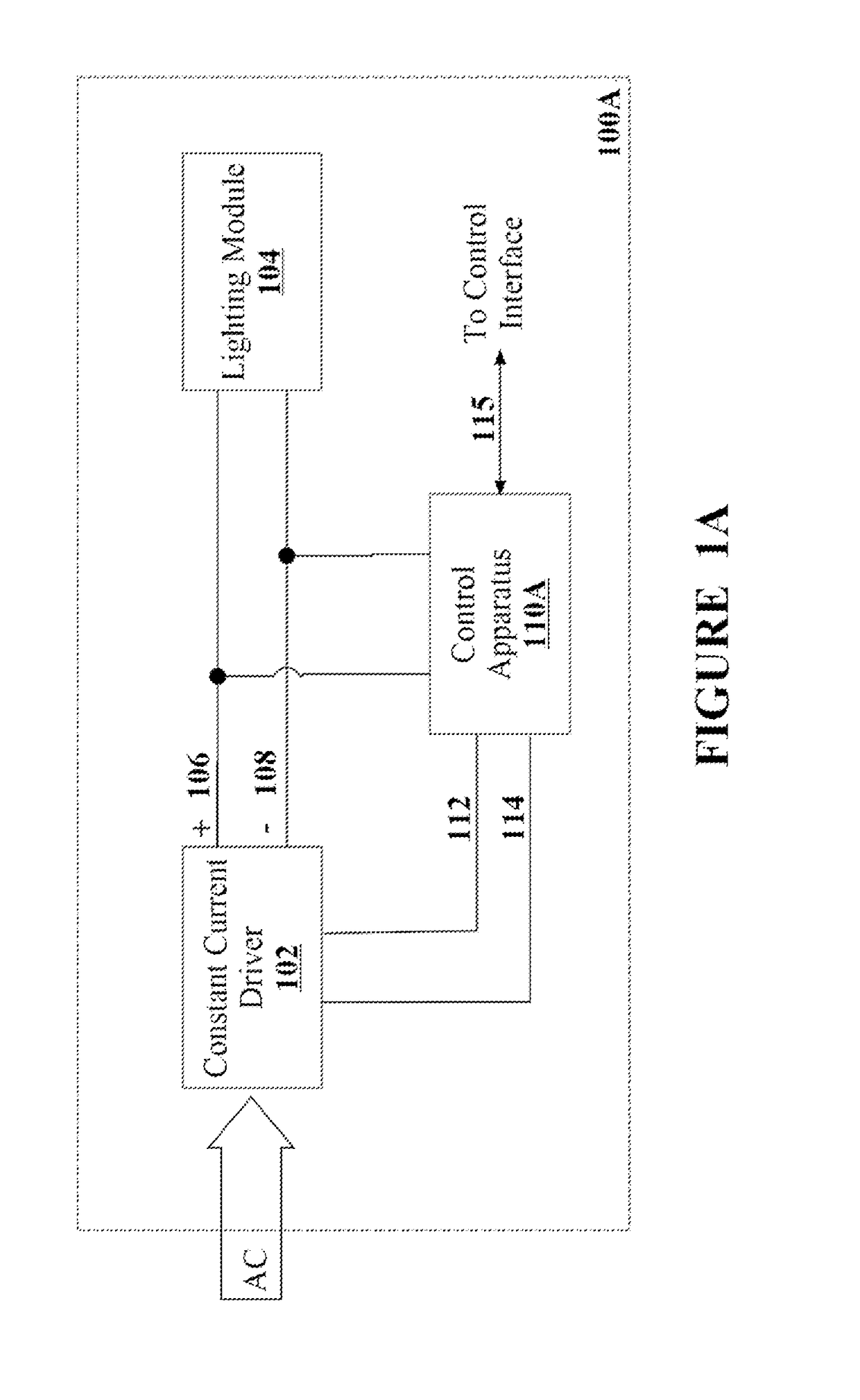

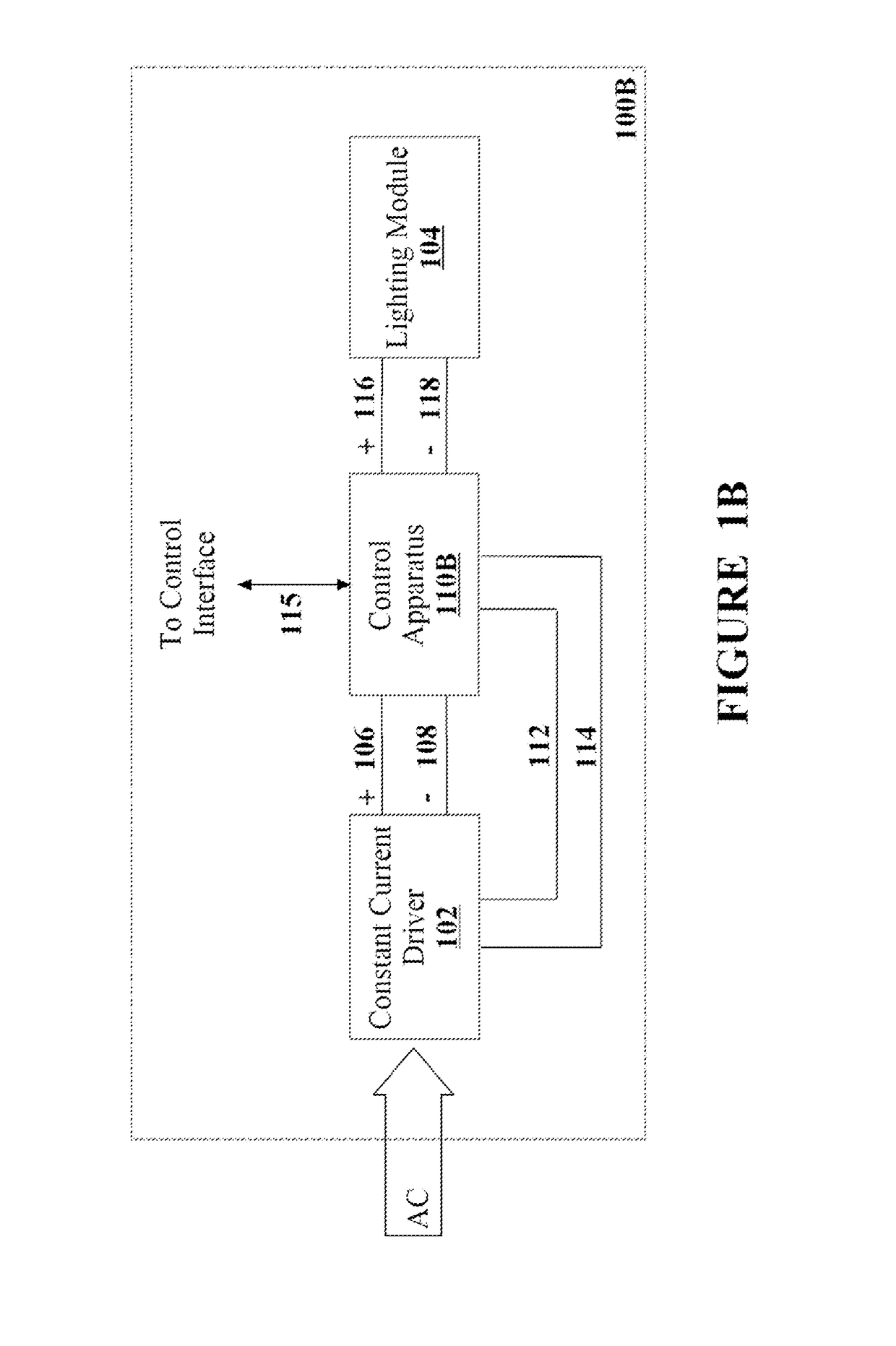

Method, system and apparatus for activating a lighting module using a buffer load module

ActiveUS20180070419A1Constant levelElectrical apparatusElectroluminescent light sourcesEffect lightEngineering

Control apparatus and system for controlling an output of a constant current driver are disclosed. A control apparatus is coupled between a constant current driver and a load, such as a lighting module, in order to add functionality to the overall system. The control apparatus is powered by the constant current driver and may control the dimming of the constant current driver by controlling the 0-10V dim input into the driver. The control apparatus may comprise one or more switching elements between the constant current driver and the load to allow for mixing of groups of LEDs of various colors or color temperatures. The control apparatus may include a buffer load to mitigate negative impacts of turning on the lighting module after a period of deactivation. The control apparatus can also be adapted to operate as a dim-to-warm module within a lighting apparatus.

Owner:ARKALUMEN

Centrifugal separator and a liquid phase discharge port member

A centrifugal separator comprises a bowl rotating in use around an axis of rotation. The axis of rotation extends in a longitudinal direction, and a radial direction extends perpendicular to the longitudinal direction. A base plate provided at one longitudinal end of the bowl, said base plate having an internal and external side, an outlet opening being provided in the base plate. A casing is projecting at the outlet opening on the external side of said base plate, said casing comprising a casing side, a normal to said casing side extending at an acute angle relative to a circumferential direction of the bowl at said casing and a discharge opening is provided in said casing side. The discharge opening is radially outwardly limited by a weir with an overflow edge and said discharge opening extending radially inwardly to a position above a highest intended level of liquid in the bowl.

Owner:ALFA LAVAL CORP AB

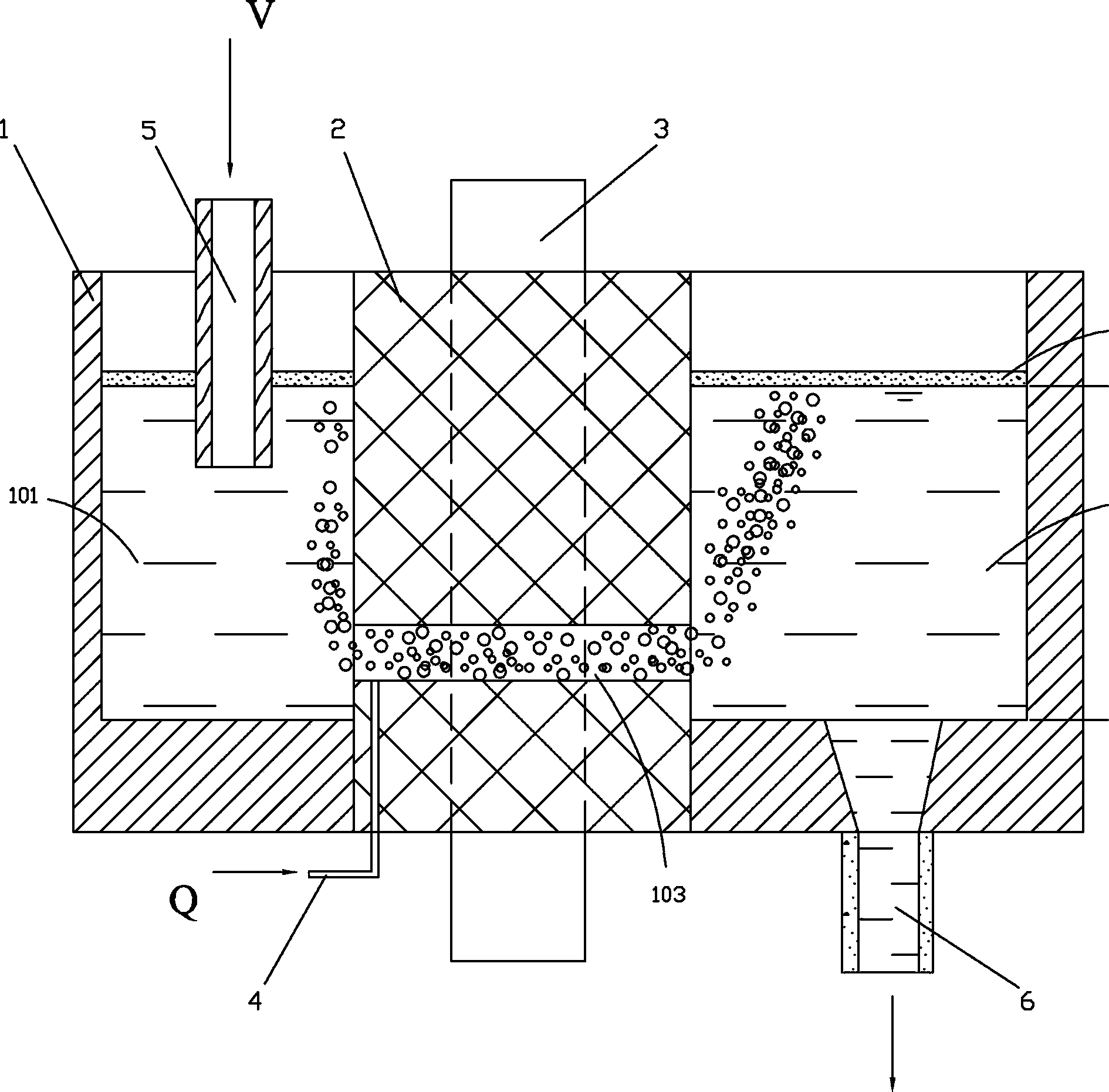

Channel type induction heating pouring basket and pouring method thereof

ActiveCN104249149APromote cohesion and buoyancyConstant levelMelt-holding vesselsMetallurgyInduction heater

The invention discloses a channel type induction heating pouring basket and a pouring method thereof. The channel type induction heating pouring basket comprises a pouring basket body, an induction heater and at least two air blowing pipes, wherein the inner part of the pouring basket body is separated into a molten steel containing cavity which is used for receiving large-basket molten steel and a molten steel pouring cavity which is used for pouring the molten steel by a refractory material, and at least two channels which are used for communicating the molten steel containing cavity with the molten steel pouring cavity are arranged in the lower part of the refractory material in parallel; the height of each channel is lower than 1 / 3 of the height of an inner cavity of the pouring basket body; an induction coil of the induction heater is arranged between the two channels in a penetrating way; the at least air blowing pipes are arranged in the refractory material of the pouring basket body, and outlets of the at least two air blowing pipes are correspondingly formed in inlet ends, which are positioned at the side of the molten steel cavity, of the channels. The channel type induction heating pouring basket disclosed by the invention can be applied to a continuous pouring whole process for removing impurities and enabling the temperature of the molten steel to be uniform.

Owner:BAOSHAN IRON & STEEL CO LTD

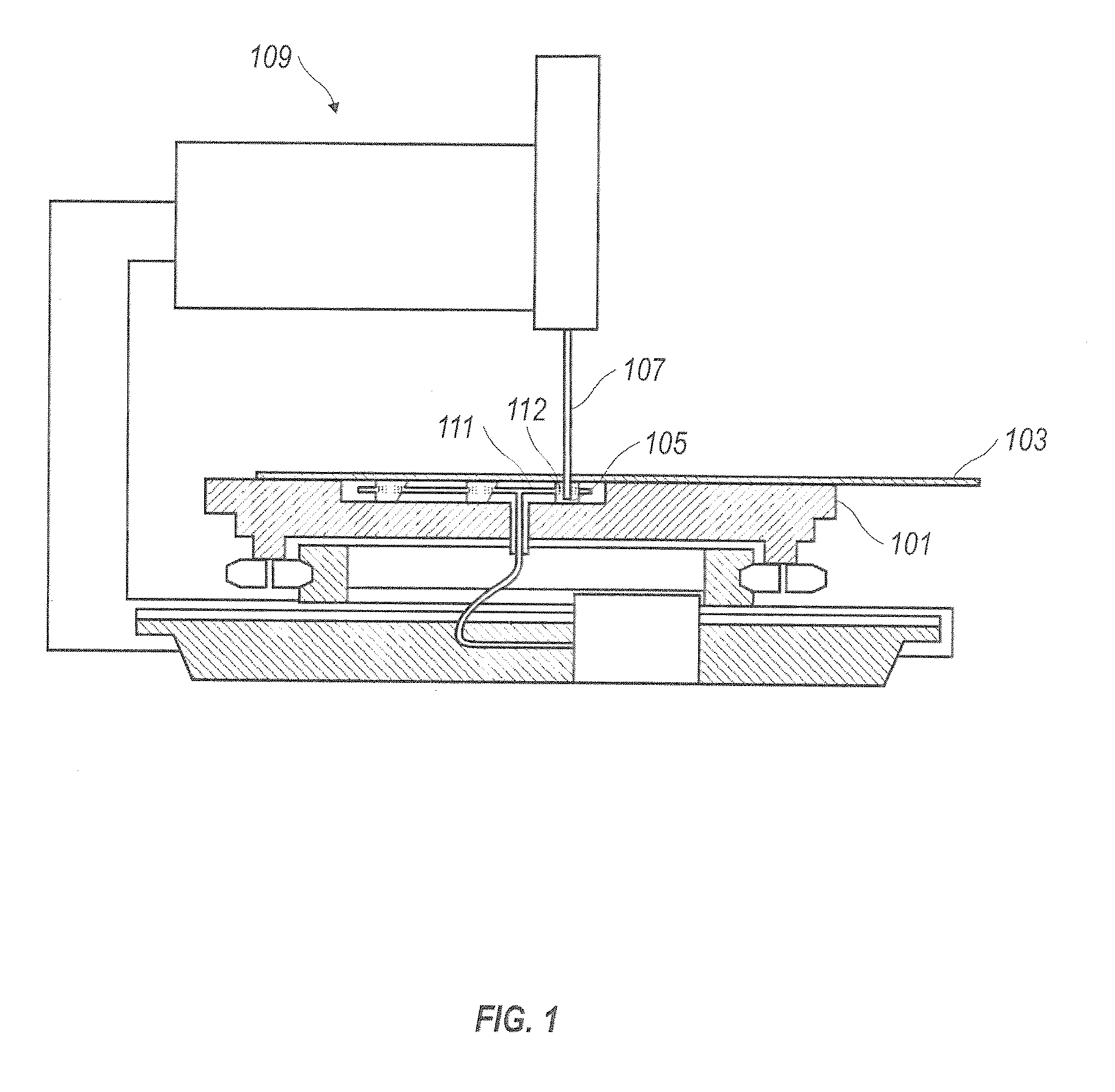

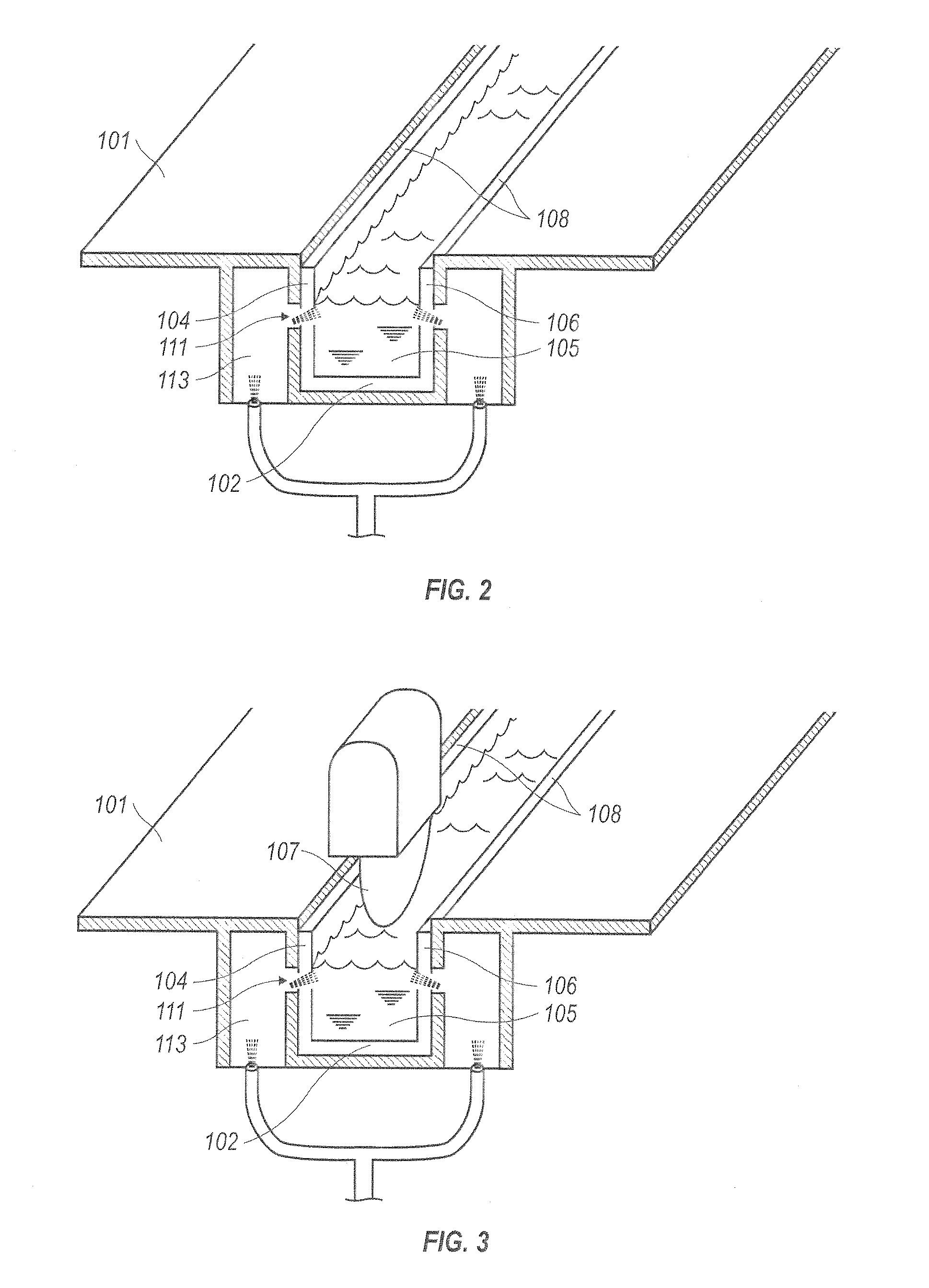

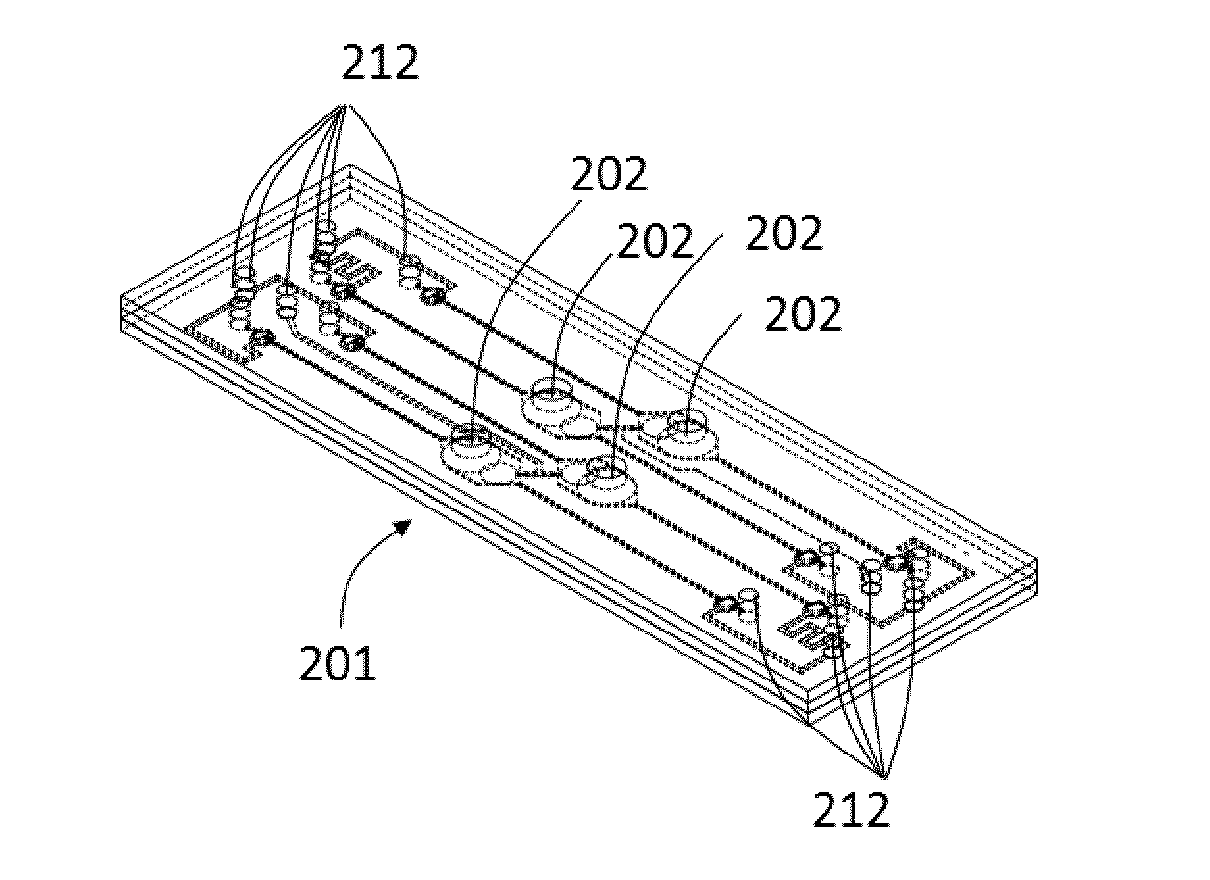

Device for in-vitro modelling in-vivo tissues of organs

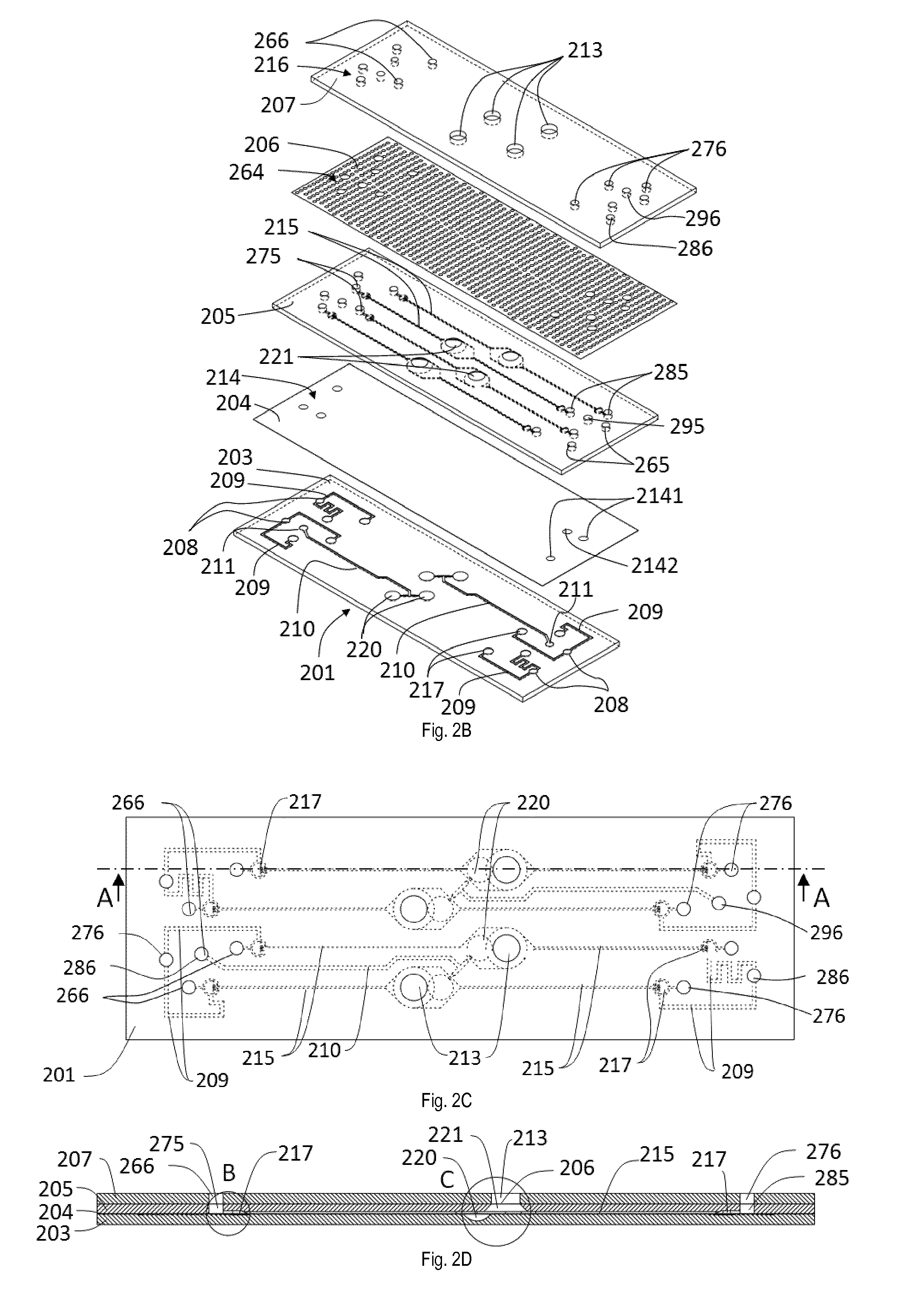

ActiveUS20160194588A1Easy to operateEasy SetupBioreactor/fermenter combinationsBiological substance pretreatmentsIn vivoBiology

A device (201) for in-vitro modelling in-vivo tissues of organs, comprises: a first body portion (207) with at least one access chamber (213), a second body portion (205) with at least one culturing chamber (221), and a culturing membrane (206) dividing the at least one access chamber (213) from the culturing chamber (221). The device further comprises a third body portion (203) with at least one actuation chamber (220) having at least one limitation cavity, and an actuation membrane (204) dividing the at least one culturing chamber (221) from the at least one actuation chamber (220). With the device according to the invention a robust actuation system can be provided that does not depend on the mechanical properties of the actuation membrane material, nor on the pressure, and that allows to mimic three-dimensional deformations of the tissue, in particular of lung alveoli.

Owner:UNIVERSITY OF BERN

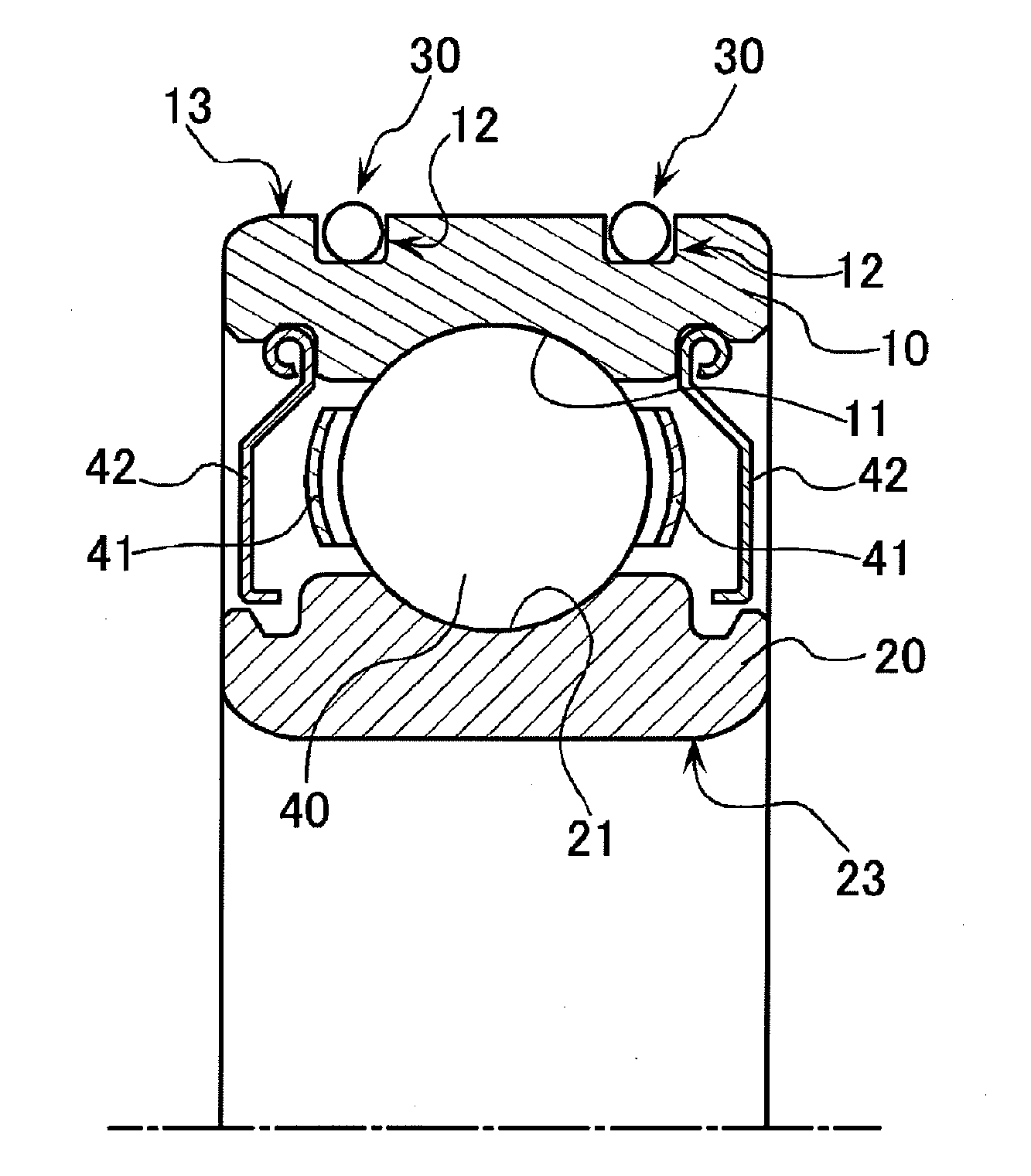

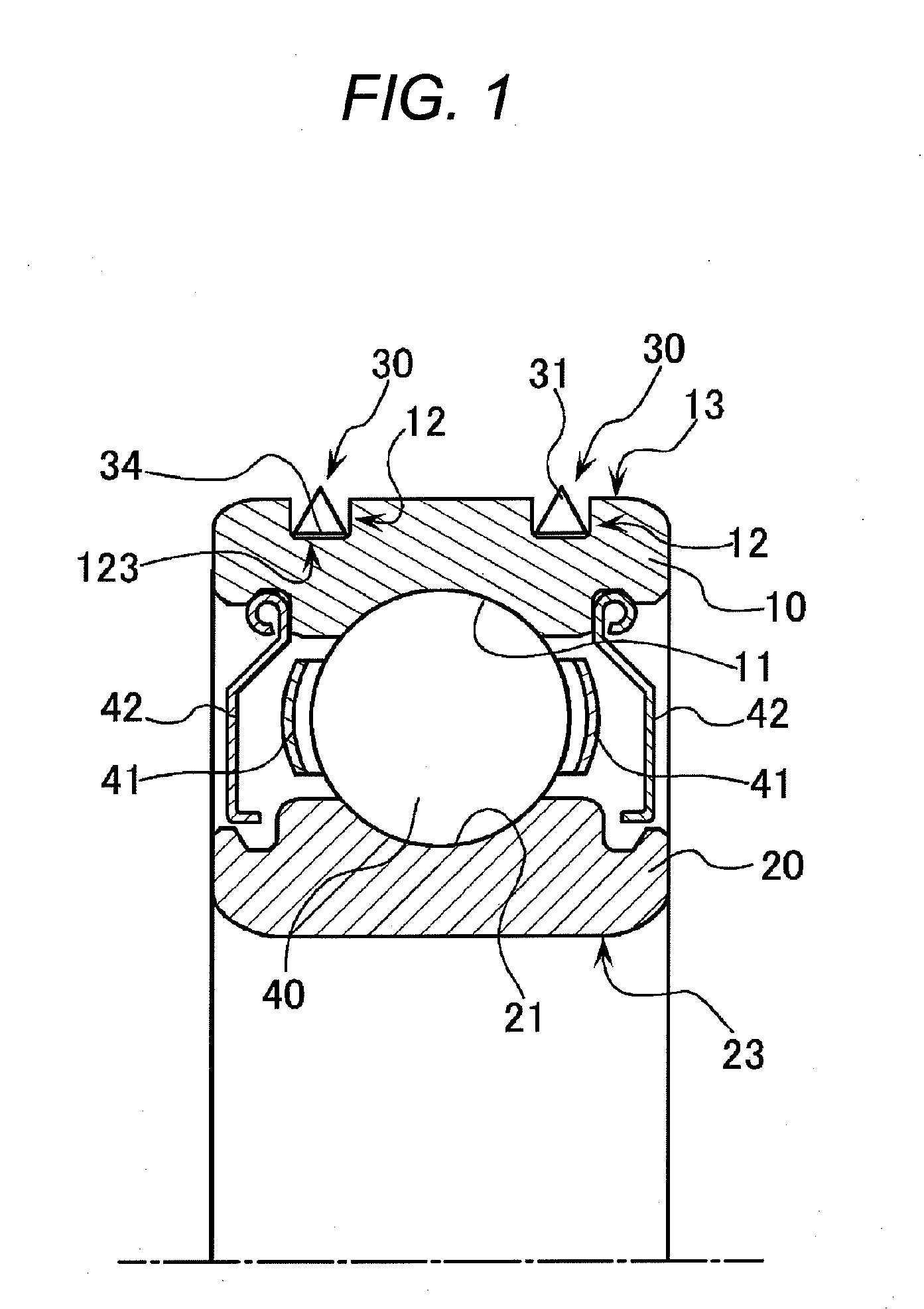

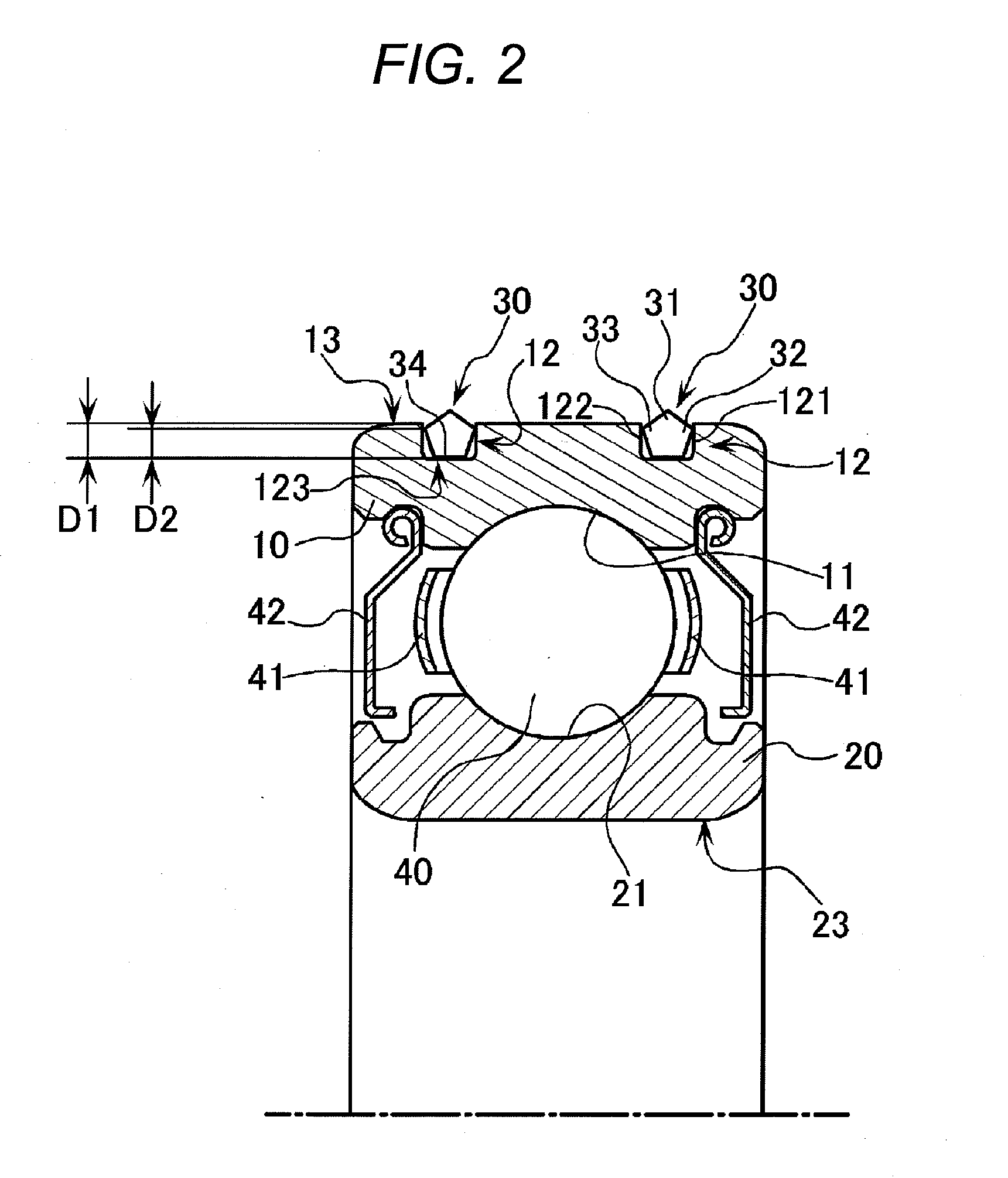

Rolling bearing

InactiveUS20100014794A1Reduce creep torqueInhibitionEngine sealsBearing assemblyRolling-element bearingEngineering

There is provided a rolling bearing which comprises at least: an outer ring 10 and an inner ring 20 disposed rotatable relative to each other; and plurality of rolling elements 40 respectively interposed rollably between the outer and inner rings. The outer ring is fitted into a housing (not shown) and the inner ring is fitted with a shaft (not shown), whereby the rolling bearing supports rotation between the shaft and housing. Between the fitting surface (not shown) of the housing and the outer circumferential surface 13 of the outer ring and / or between the fitting surface of the shaft and the inner circumferential surface 23 of the inner ring, there is interposed an O-ring 30 made of an elastic member having a reduced friction coefficient between the fitting surface of the housing and the outer circumferential surface of the outer ring or between the fitting surface of the shaft and the inner circumferential surface of the inner ring.

Owner:NSK LTD

Method and system for suppressing receiver audio regeneration

ActiveUS20070078647A1Prevent regenerationSuppression problemSpeech analysisTransducer acoustic reaction preventionPitch shiftEngineering

The invention concerns a method (500) and system (100) for suppressing receiver audio regeneration. The method (500) includes the steps of receiving a communication signal (502), at a Radio Frequency (RF) unit (102), demodulating the communication signal to an audio signal (504), monitoring a volume level of the audio signal (506), and shifting the pitch of the audio signal when the volume level reaches a predetermined threshold (508), and playing the pitch-shifted audio signal out of a speaker to produce a pitch-shifted acoustic signal (510). The method can shift the pitch of the audio signal to produce a pitch-shifted acoustic signal with signal properties suppressing regeneration of the acoustic signal onto the audio signal at the RF unit. The amount of pitch-shifting can be a function of the volume level.

Owner:MOTOROLA SOLUTIONS INC

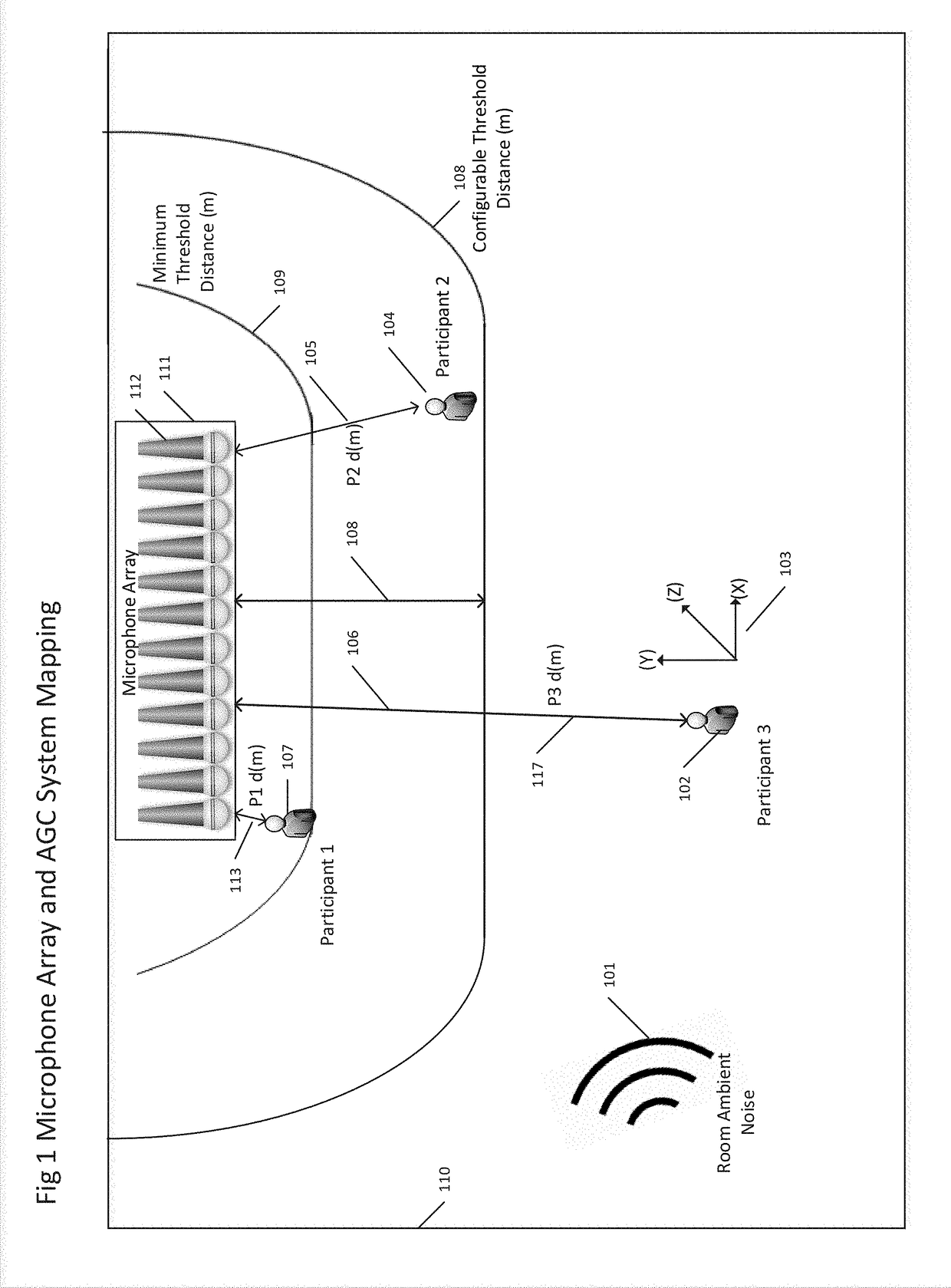

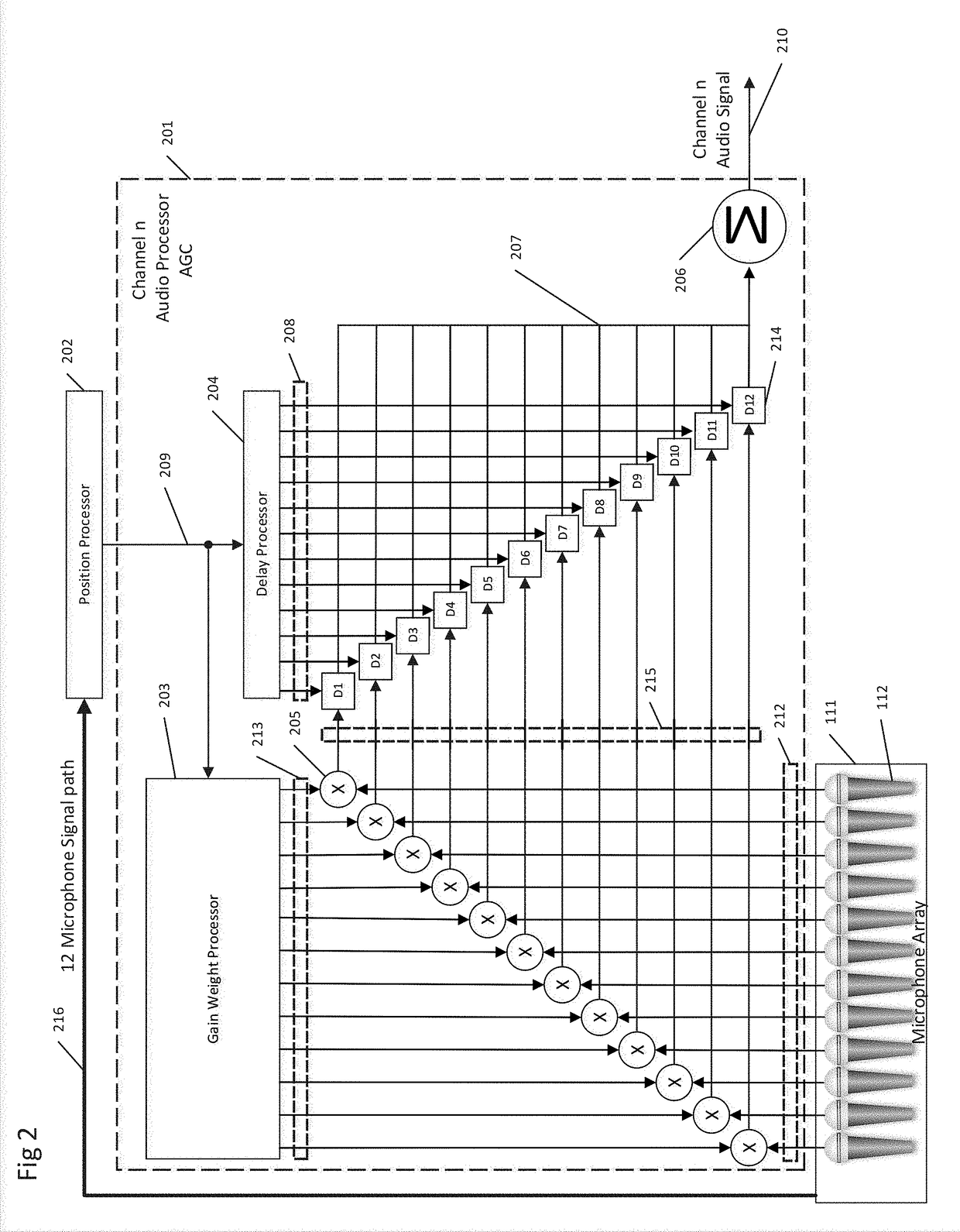

Method, apparatus and computer-readable media utilizing positional information to derive agc output parameters

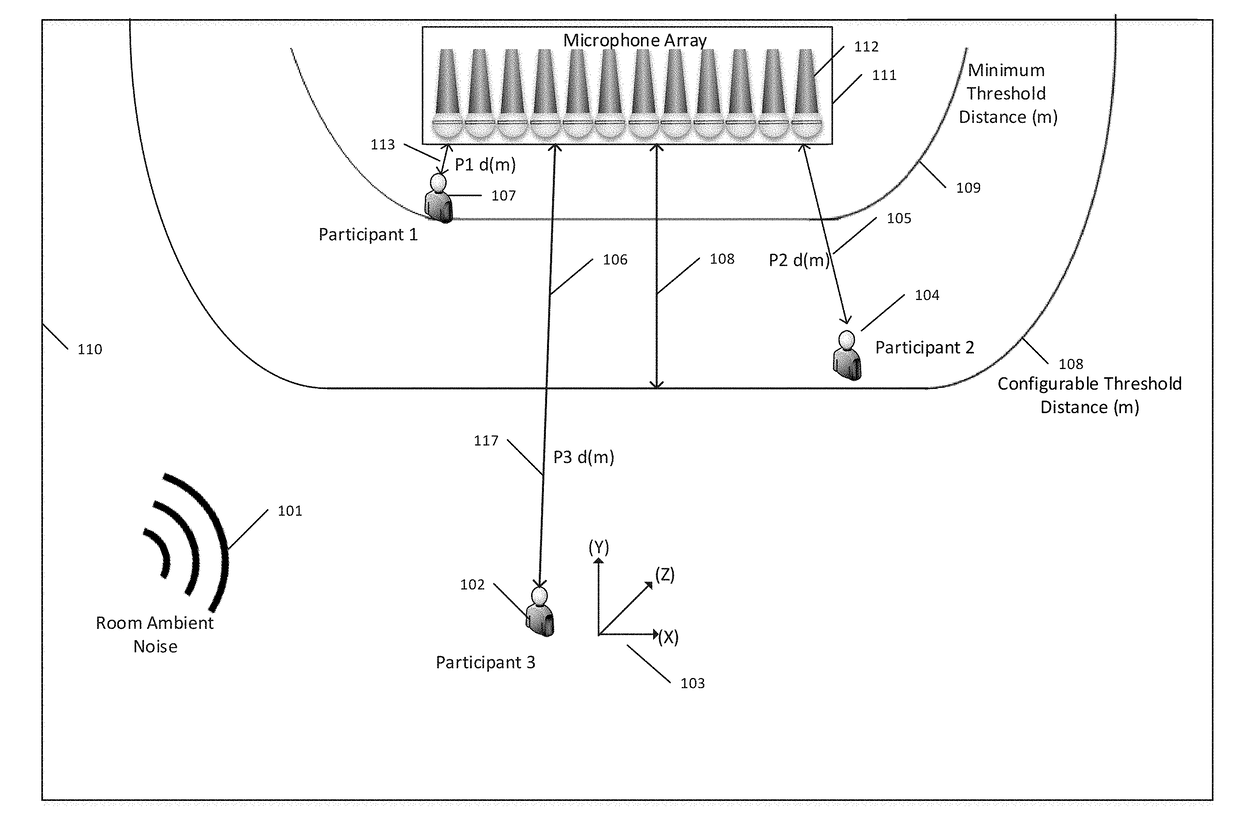

ActiveUS20180074782A1Stable background sound levelConsistent sound levelMicrophonesSignal processingSound source locationSound sources

Method and apparatus for automatic gain control utilizing sound source position information in a shared space having a plurality of microphones and a plurality of sound sources. Sound signals are received from the microphones. One or more processors locate position information corresponding to each of the sound sources. The processor(s) determine the distance to each of the sound sources from each of the microphones. The processor(s) define a predetermined gain weight adjustment for each of the microphones. The processor(s) apply the defined weight adjustments to the microphones to achieve a consistent volume of the desired plurality of sound sources. The processor(s) maintain a consistent ambient sound level regardless of the position of the sound sources and the applied gain weight adjustments. The processor(s) output a summed signal of the sound sources at a consistent volume with a constant ambient sound level across the plurality of sound source positions.

Owner:NUREVA INC

Centrifugal separator and a liquid phase discharge port member

A centrifugal separator comprises a bowl rotating in use around an axis of rotation. The axis of rotation extends in a longitudinal direction, and a radial direction extends perpendicular to the longitudinal direction. A base plate provided at one longitudinal end of the bowl, said base plate having an internal and external side, an outlet opening being provided in the base plate. A casing is projecting at the outlet opening on the external side of said base plate, said casing comprising a casing side, a normal to said casing side extending at an acute angle relative to a circumferential direction of the bowl at said casing and a discharge opening is provided in said casing side. The discharge opening is radially outwardly limited by a weir with an overflow edge and said discharge opening extending radially inwardly to a position above a highest intended level of liquid in the bowl.

Owner:ALFA LAVAL CORP AB

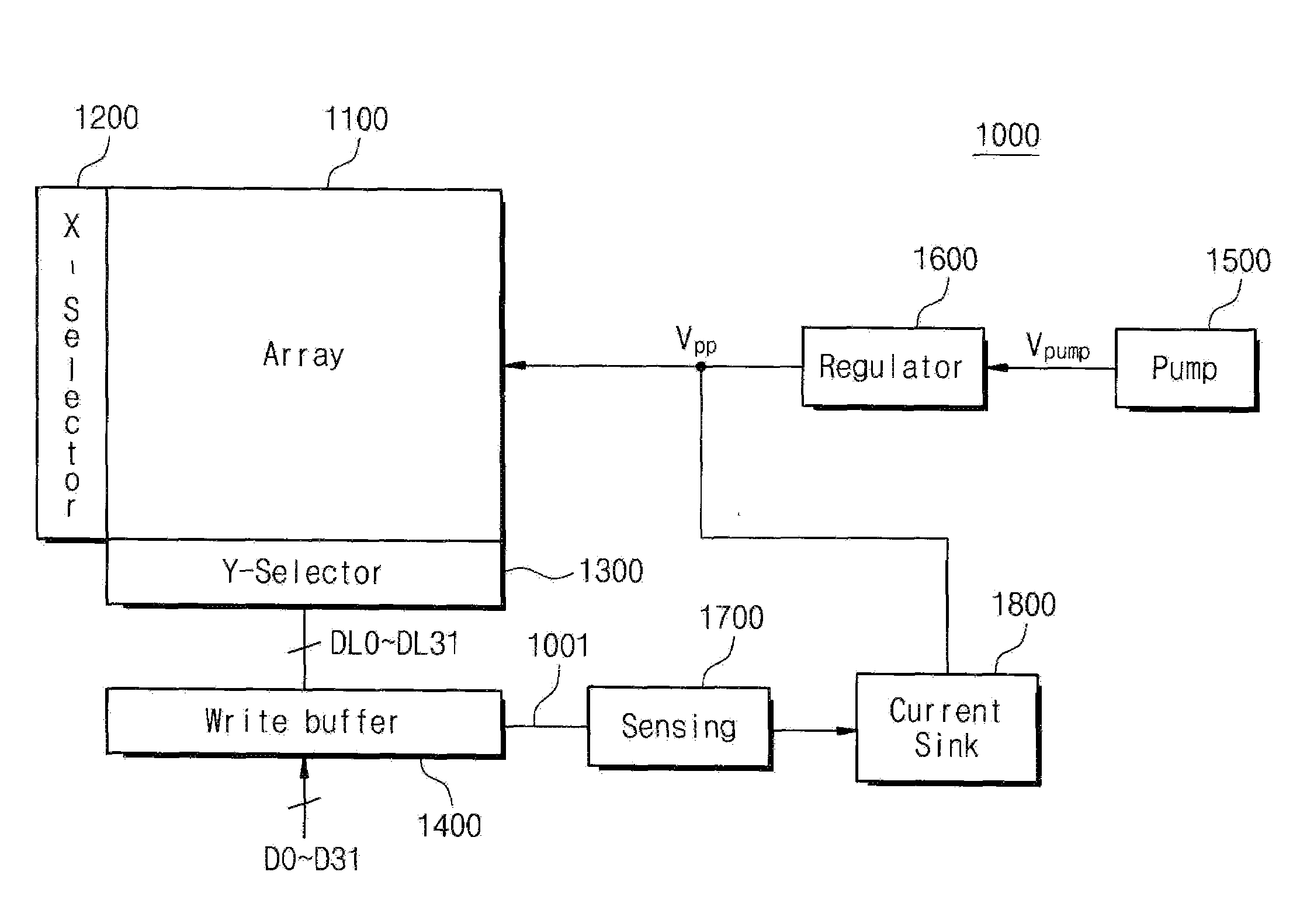

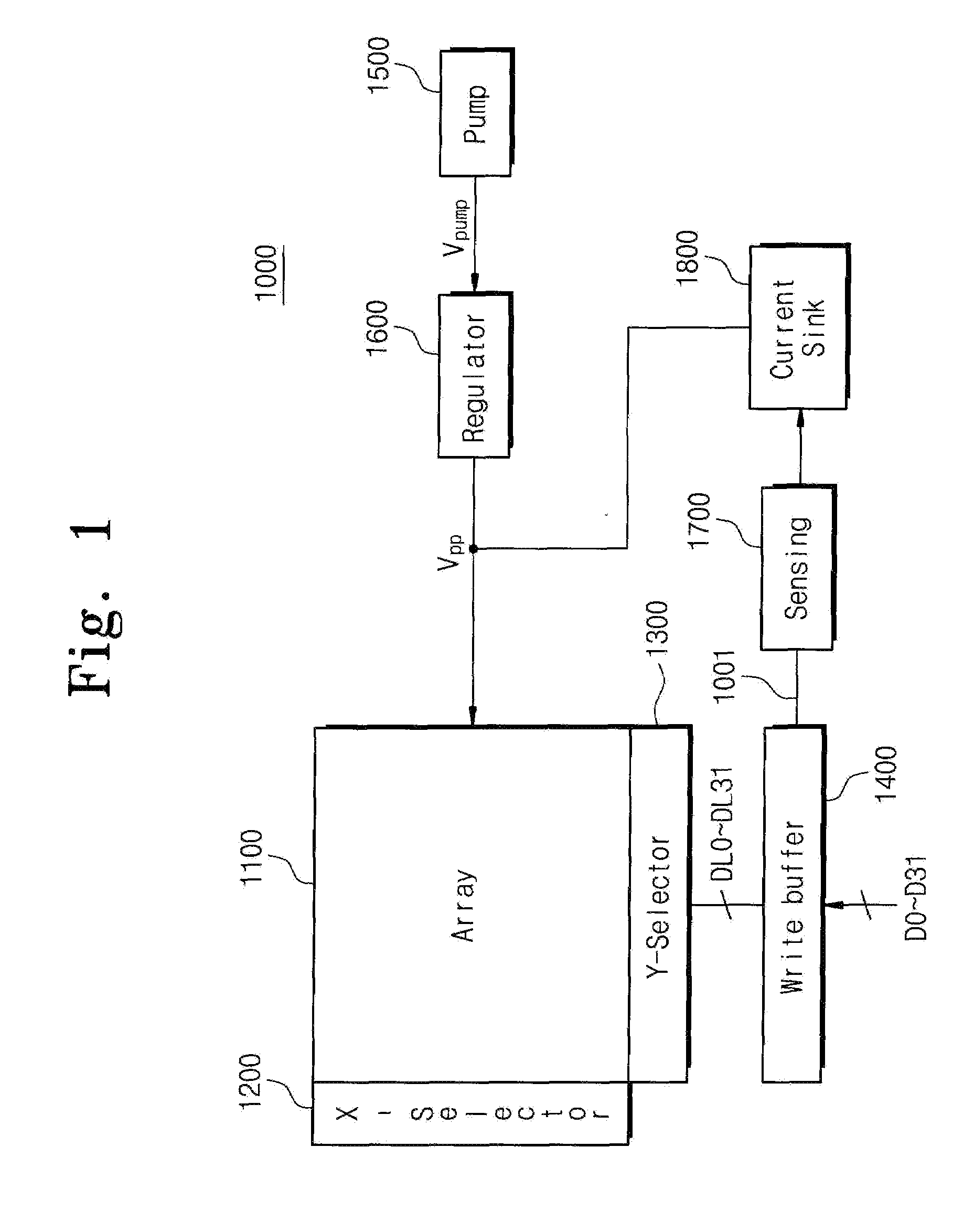

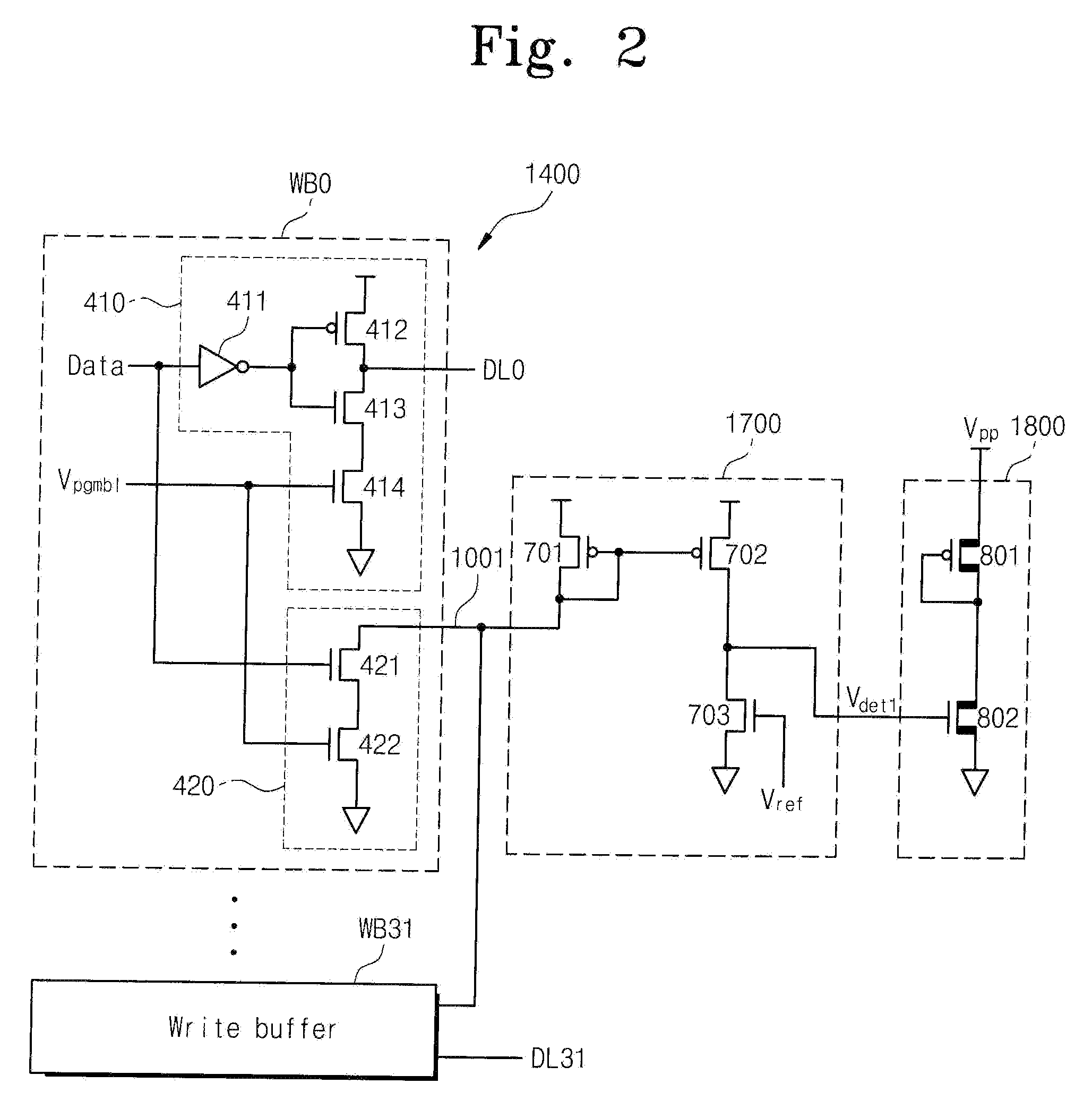

Flash Memory Device and Smart Card Including the Same

A flash memory device includes an array having memory cells arranged in rows and columns. A high voltage generator is configured to supply a high voltage to the array during a programming operation. Write buffers corresponding to selected memory cells drive the selected memory cells with a program voltage or a program-inhibition voltage in response to input data. Each write buffer consumes a dummy cell current when input data is program-inhibited data. A current-voltage conversion circuit connected to the write buffers through a common sensing line supplies a current to the write buffers as the dummy cell current through the common sensing line and outputs a voltage proportional to the current, supplied to the write buffers. A current sink circuit discharges a current from an output of the high voltage generator in response to a voltage output from the current-voltage conversion circuit.

Owner:SAMSUNG ELECTRONICS CO LTD

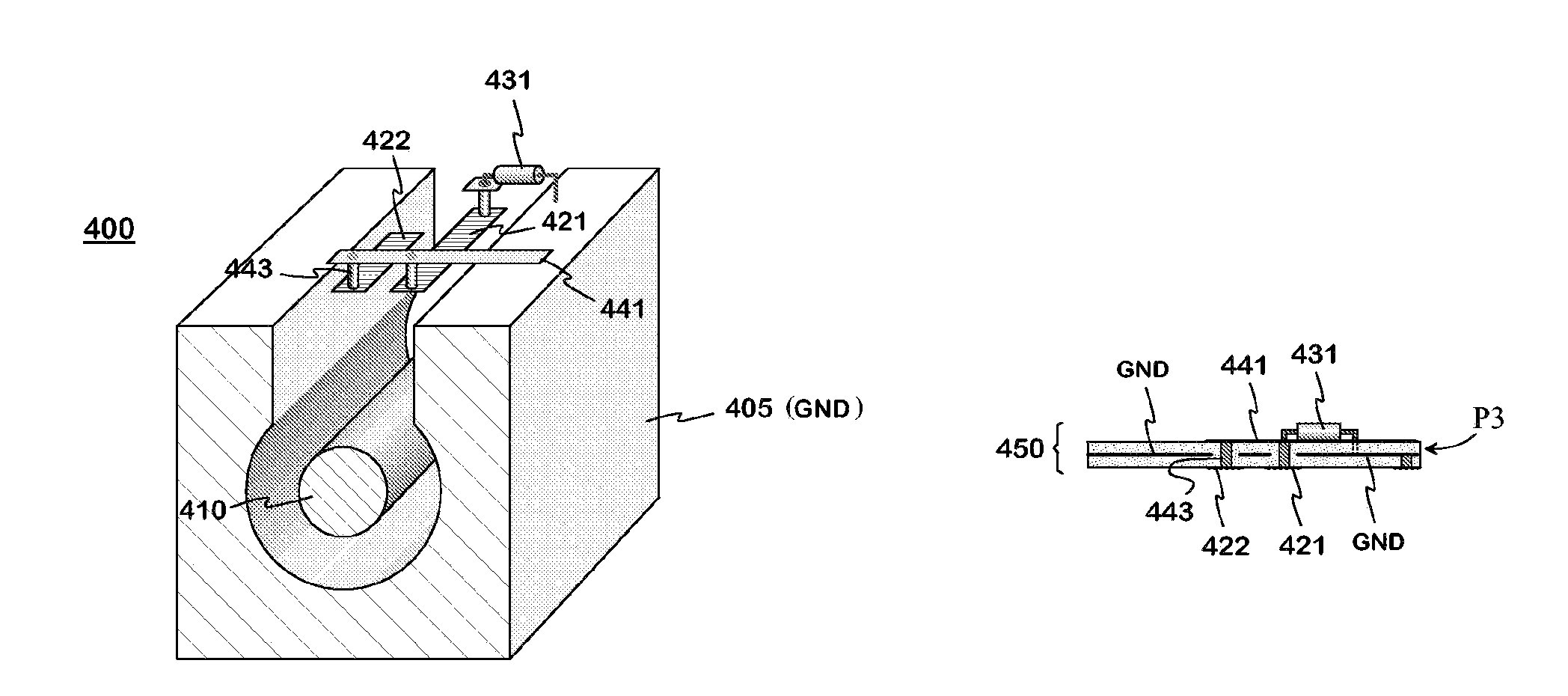

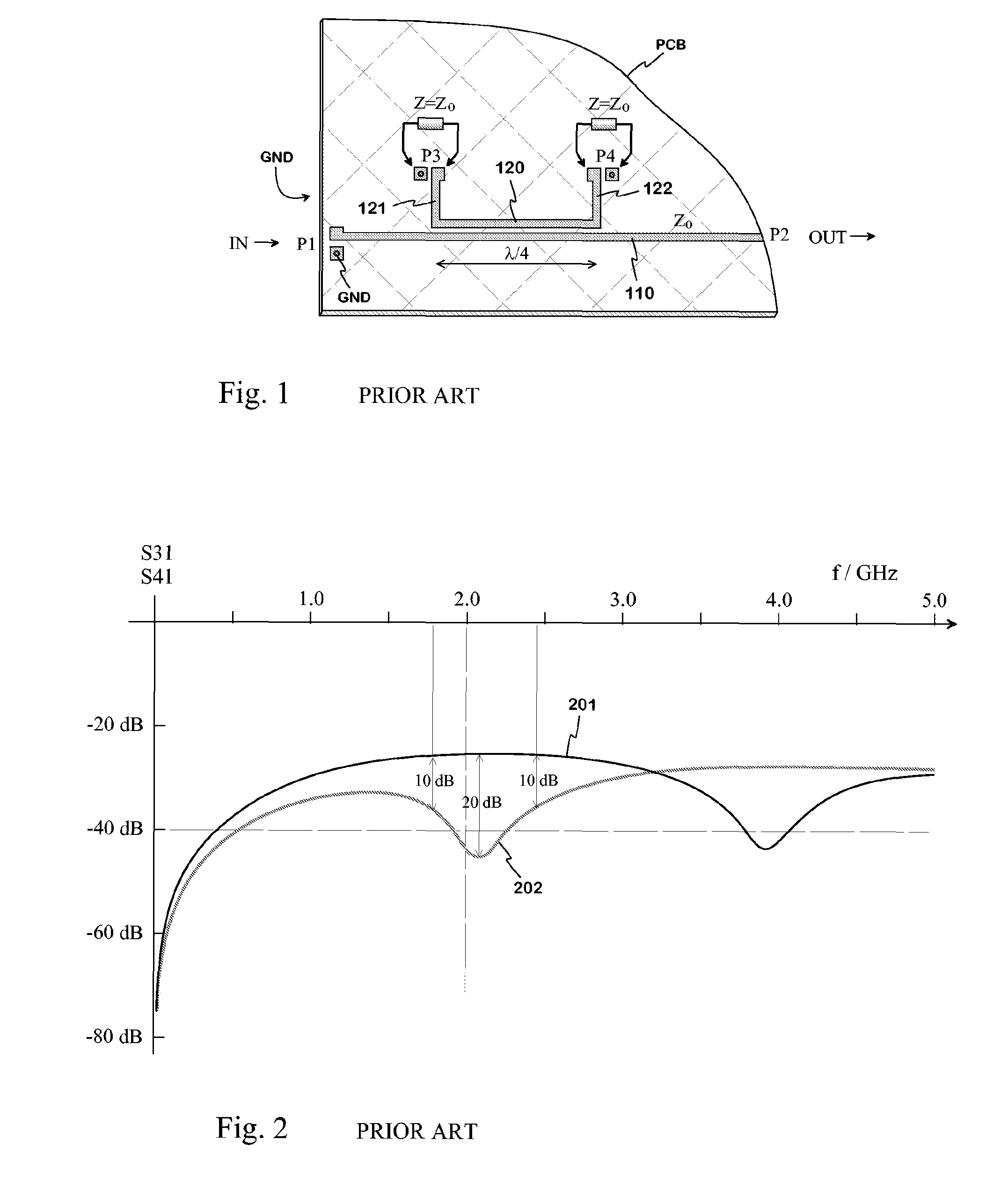

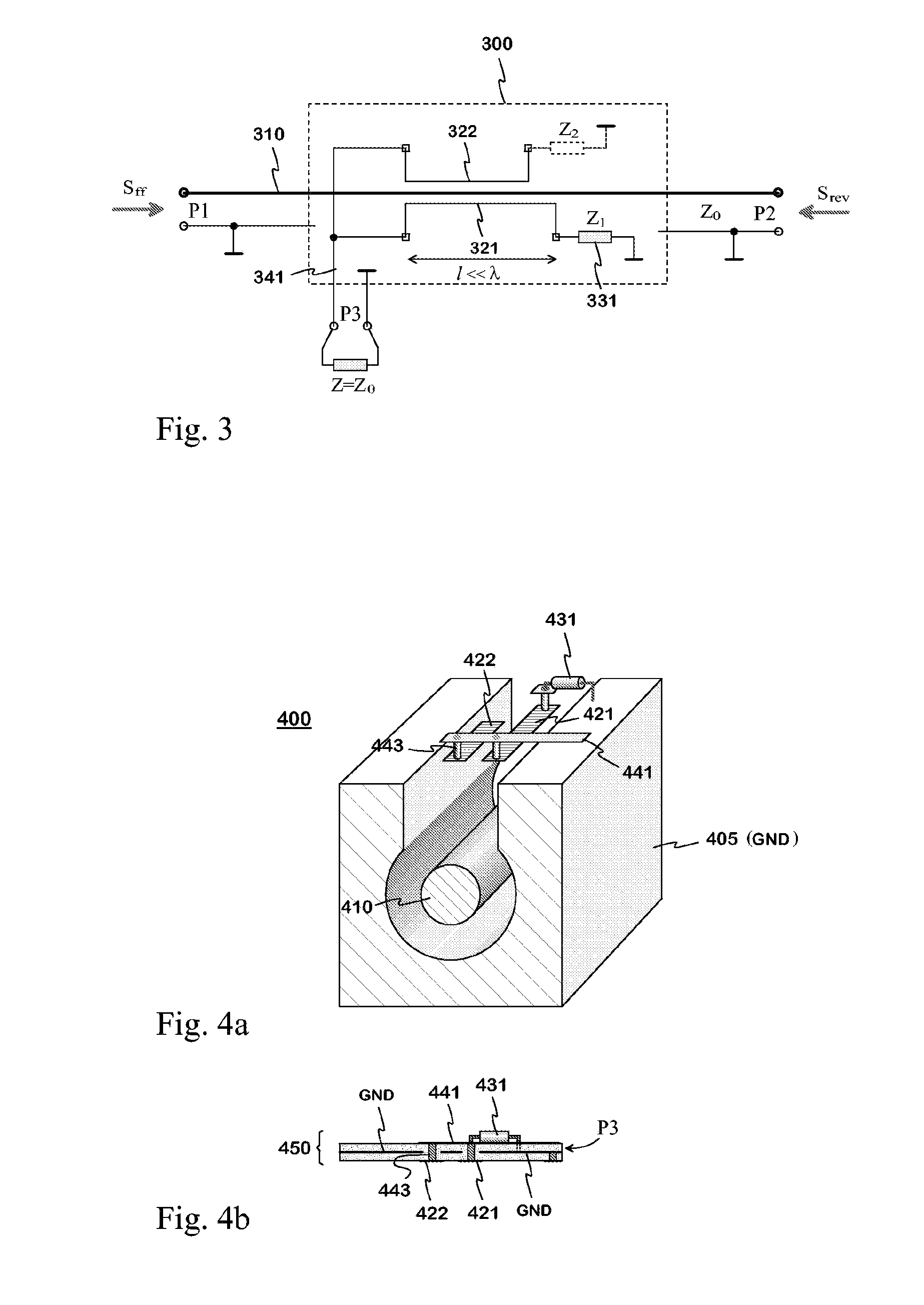

Directional coupler

ActiveUS7567146B2Easy to manufactureReduced frequency dependenceMultiple-port networksWaveguidesElectrical conductorCoupling

A directional coupler with two sensing conductors and a basic coupler and a supplementary coupler corresponding to them. The basic coupler is based on the coupling between a first sensing conductor (421) and the transmission conductor (410), and the supplementary coupler is based on the coupling between a second sensing conductor (422) and the transmission conductor. The sensing conductors are substantially shorter than a quarter wave, because of which the directivity of both the basic and the supplementary coupler is low. The other ends of the sensing conductors are connected to each other and further to the measurement port of the directional coupler. The coupling signals caused by a reverse signal in the connecting point of the sensing conductors are arranged equal by their absolute value but oppositely phased, in which case their sum signal in the measurement port is insignificantly small. For this purpose, for example, the transmission line formed by the first sensing conductor and the ground is terminated with a matching element at its opposite end, and the transmission line formed by the second sensing conductor and the ground is left open at its opposite end. The termination impedances can be adjustable and the directional coupler thus tunable. In this manner, the directivity of the total directional coupler is improved by means of the second sensing conductor. The directional coupler is small-sized, and good directivity is achieved in a very large frequency range.

Owner:INTEL CORP

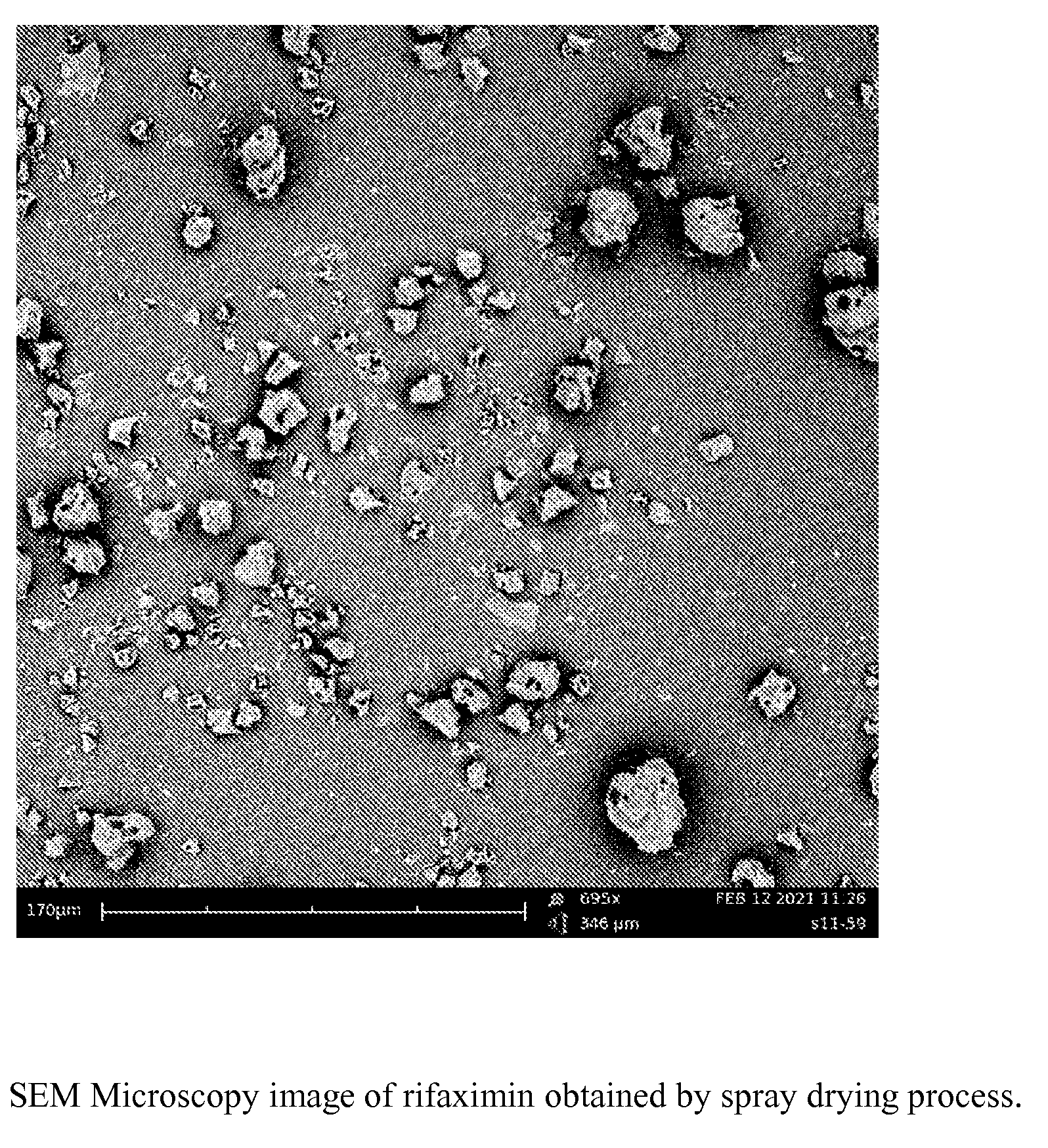

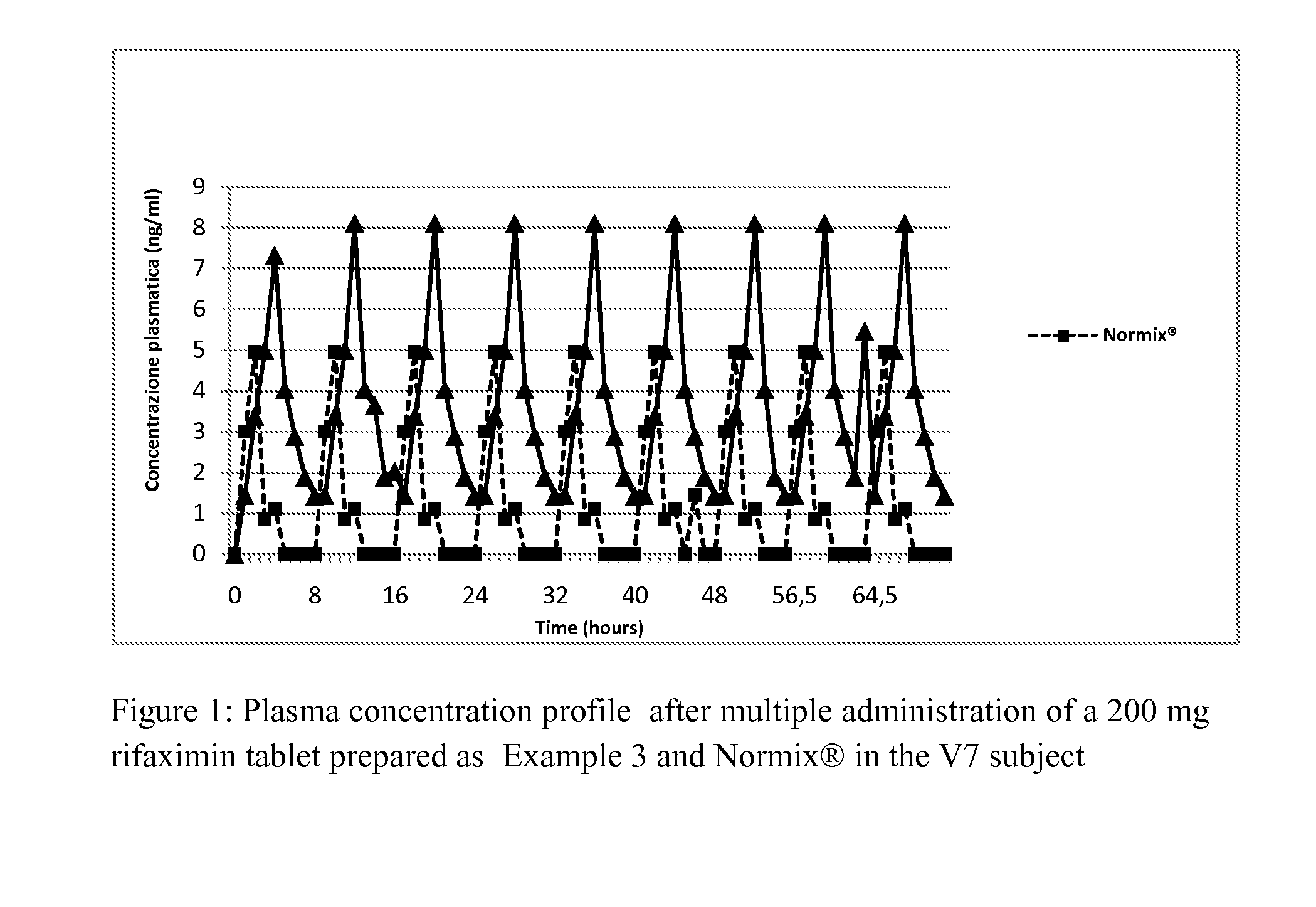

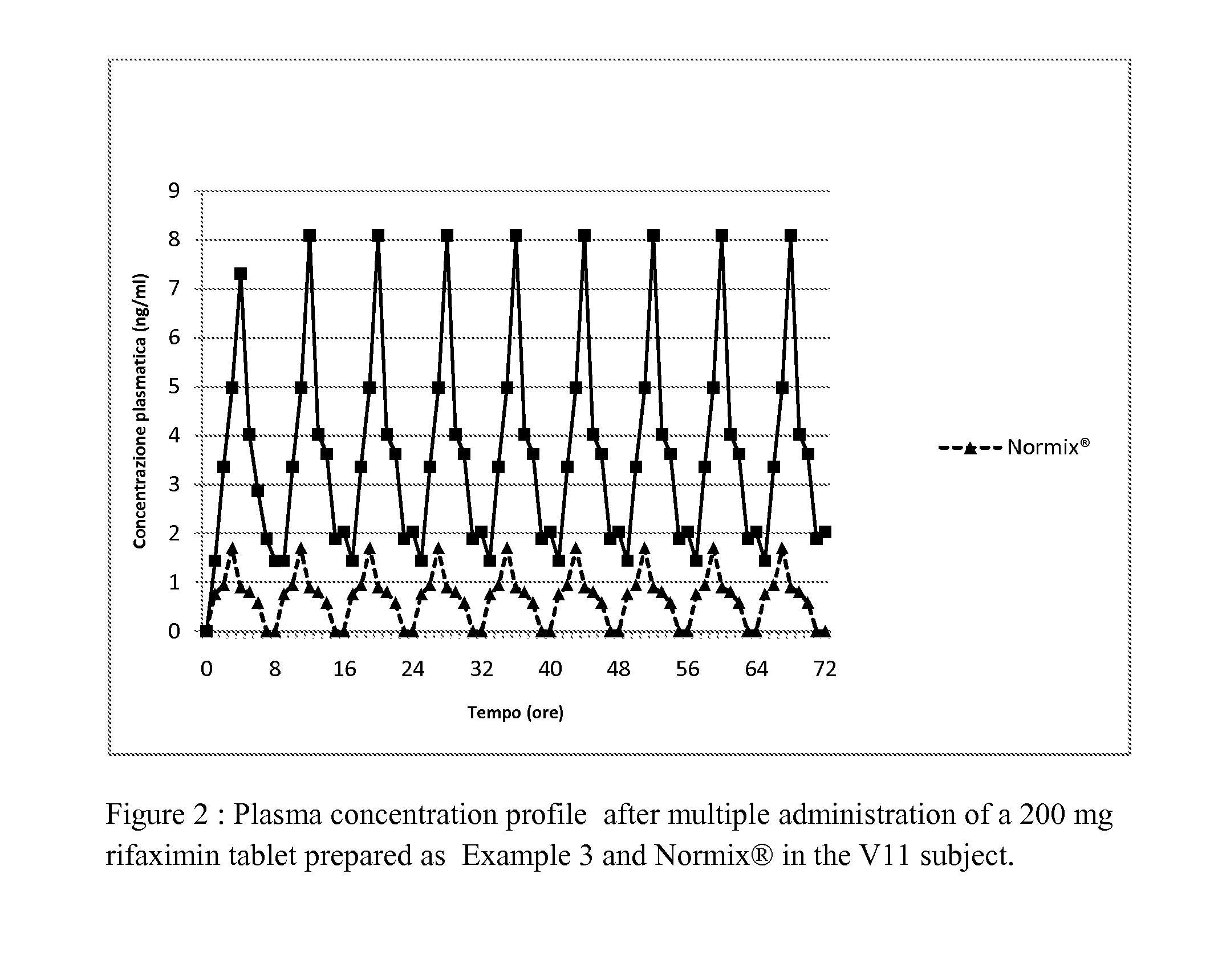

Rifaximin powder, process for preparing the same and controlled release compositions containing said rifaximin useful for obtaining a long-lasting effect

ActiveUS20130004576A1Improve treatment efficiencyConstant levelAntibacterial agentsPowder deliveryControl releaseOral medication

The present invention describes rifaximin powder and to a process for preparing the same. The invention relates also to a pharmaceutical composition in solid form comprising said rifaximin, pharmaceutically acceptable excipients and optionally other ingredients. The compositions according to the invention are suitable for oral administration and are characterized by producing a controlled release of rifaximin, whereby a long-lasting effect is obtained in a patient.

Owner:ALFASIGMA SPA

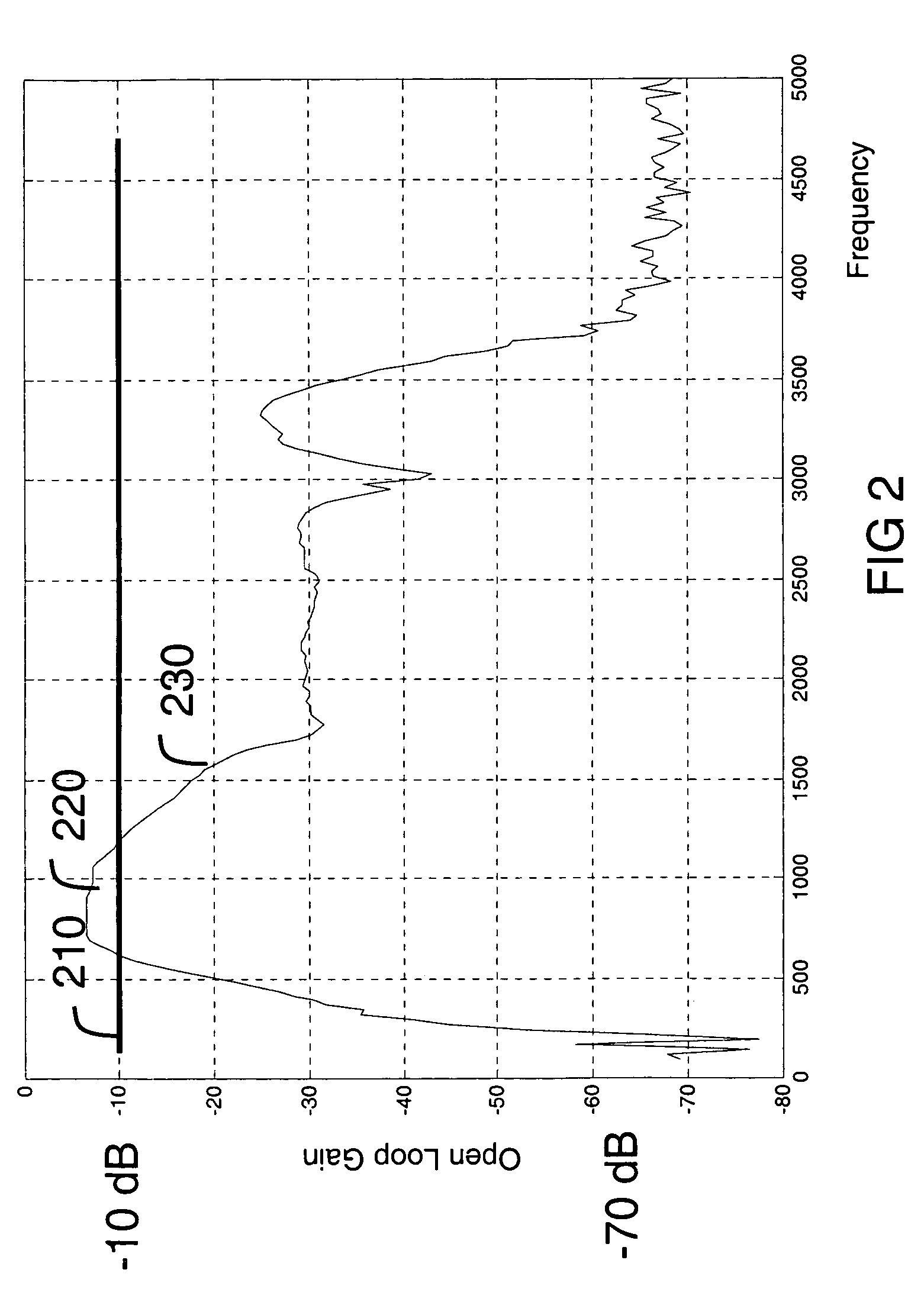

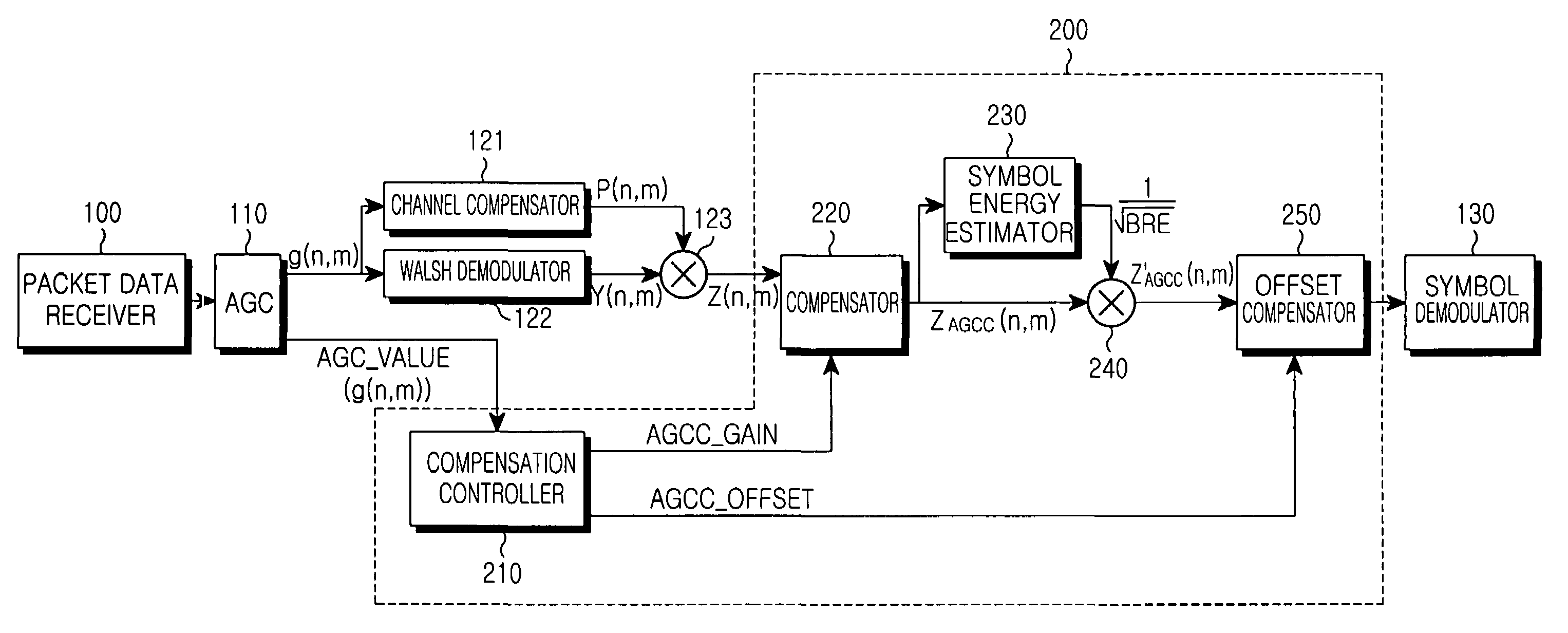

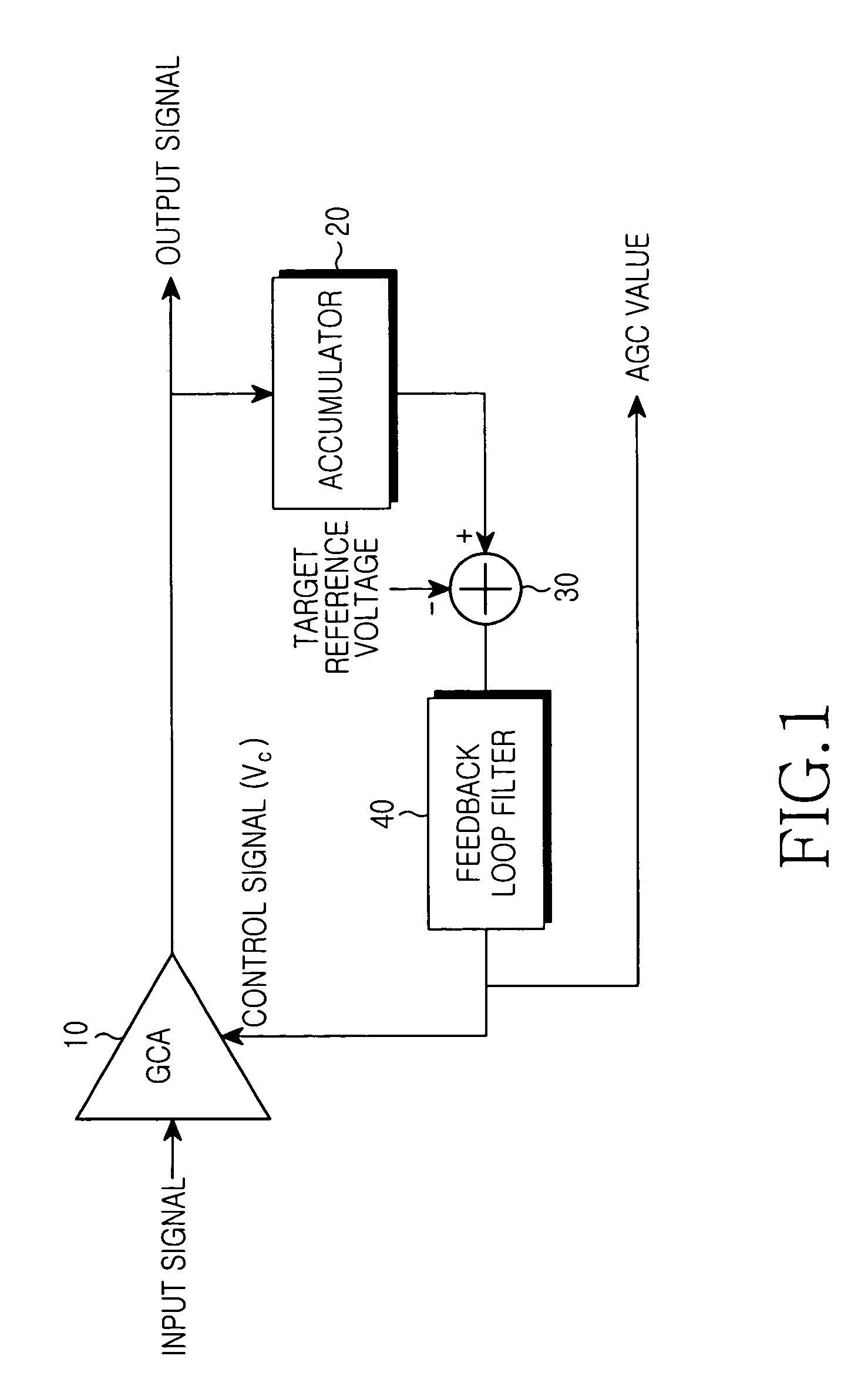

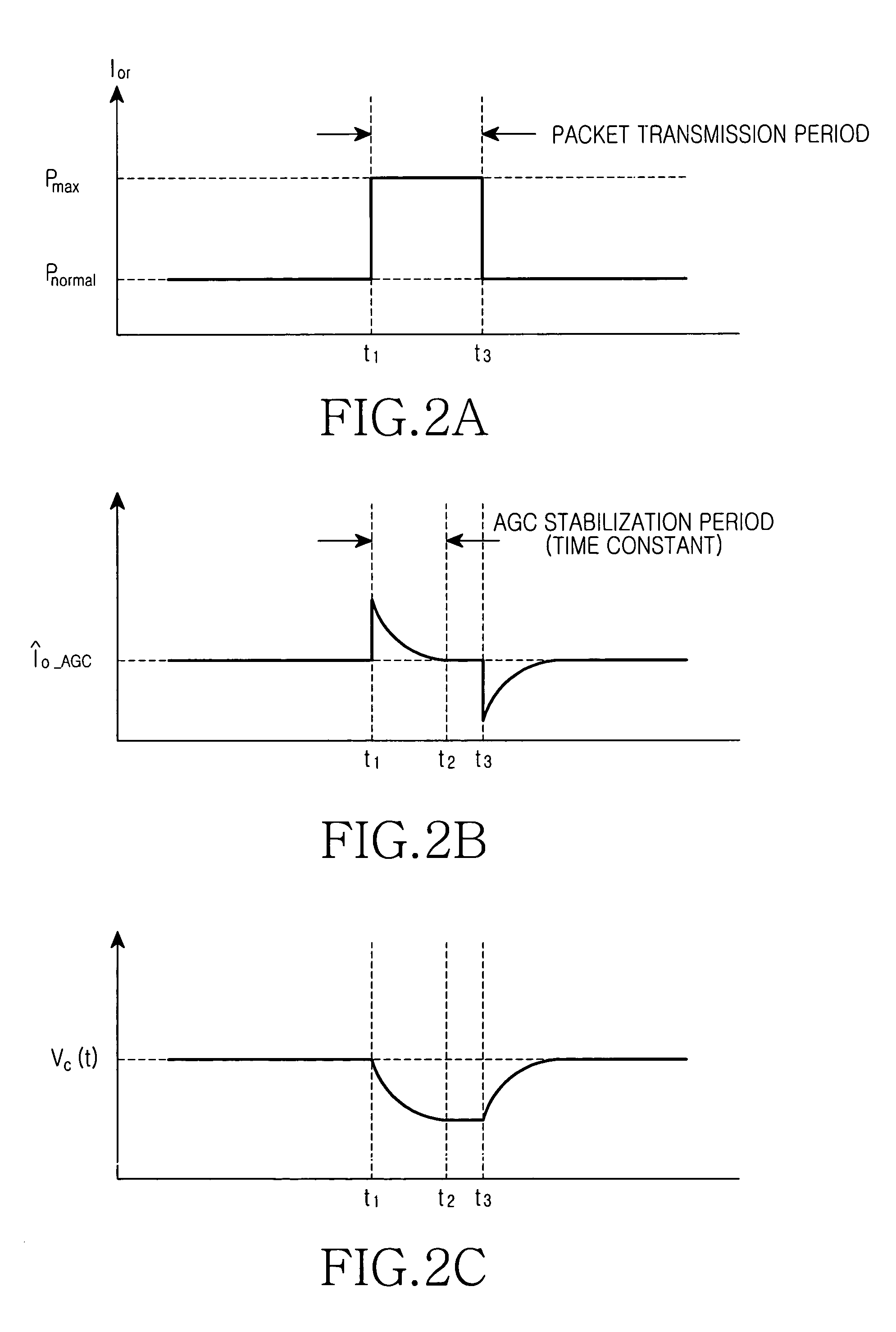

Apparatus and method for compensating gain of an automatic gain controller

ActiveUS7239856B2Constant levelPreventing decrease of reception qualityResonant long antennasTransmission control/equalisingMobile communication systemsControl theory

An apparatus and method for compensating the gain of an Automatic Gain Controller (AGC) for stabilizing the reception power of discontinuously transmitted packet data in a mobile communication system are disclosed. A compensation controller receives an AGC value from the AGC, sampling the AGC value by a predetermined sample number for a predetermined period, and obtains an AGC compensation gain by comparing a predetermined value with the difference between a sampled AGC value with a reference gain for the predetermined period. A compensator compensates the AGC value with the AGC compensation gain, thereby correcting errors generated in view of the nature of the AGC.

Owner:SAMSUNG ELECTRONICS CO LTD

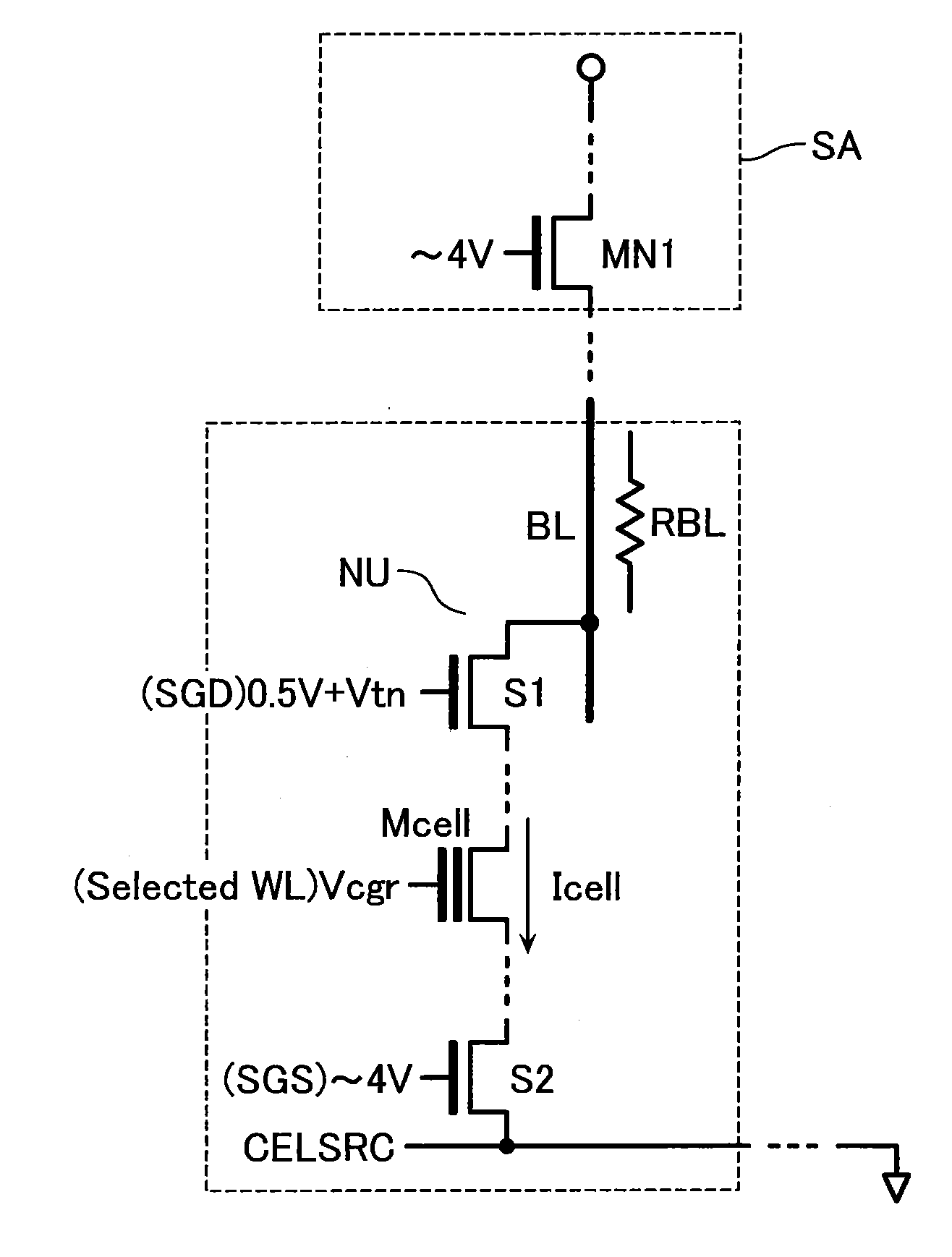

Semiconductor memory device

A semiconductor memory device including: a memory cell coupled to a bit line via a select gate transistor; a sense amplifier configured to have a current source for supplying current to the bit line, and detect cell current of the memory cell flowing on the bit line; and a select gate line driver configured to drive the select gate transistor so as to keep the memory cell applied with substantially constant drain-source voltage independently of the bit line resistance at a read time.

Owner:KK TOSHIBA

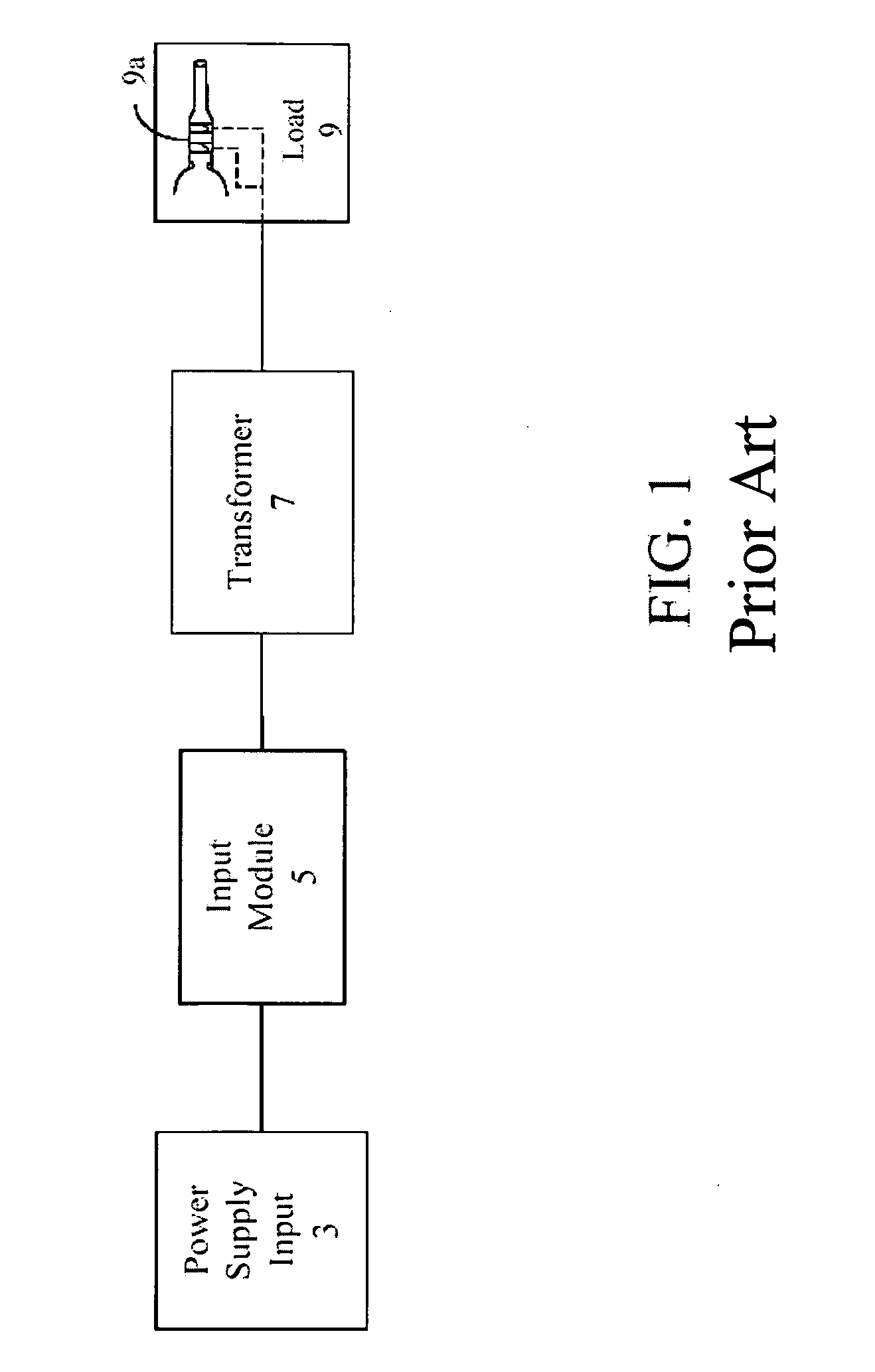

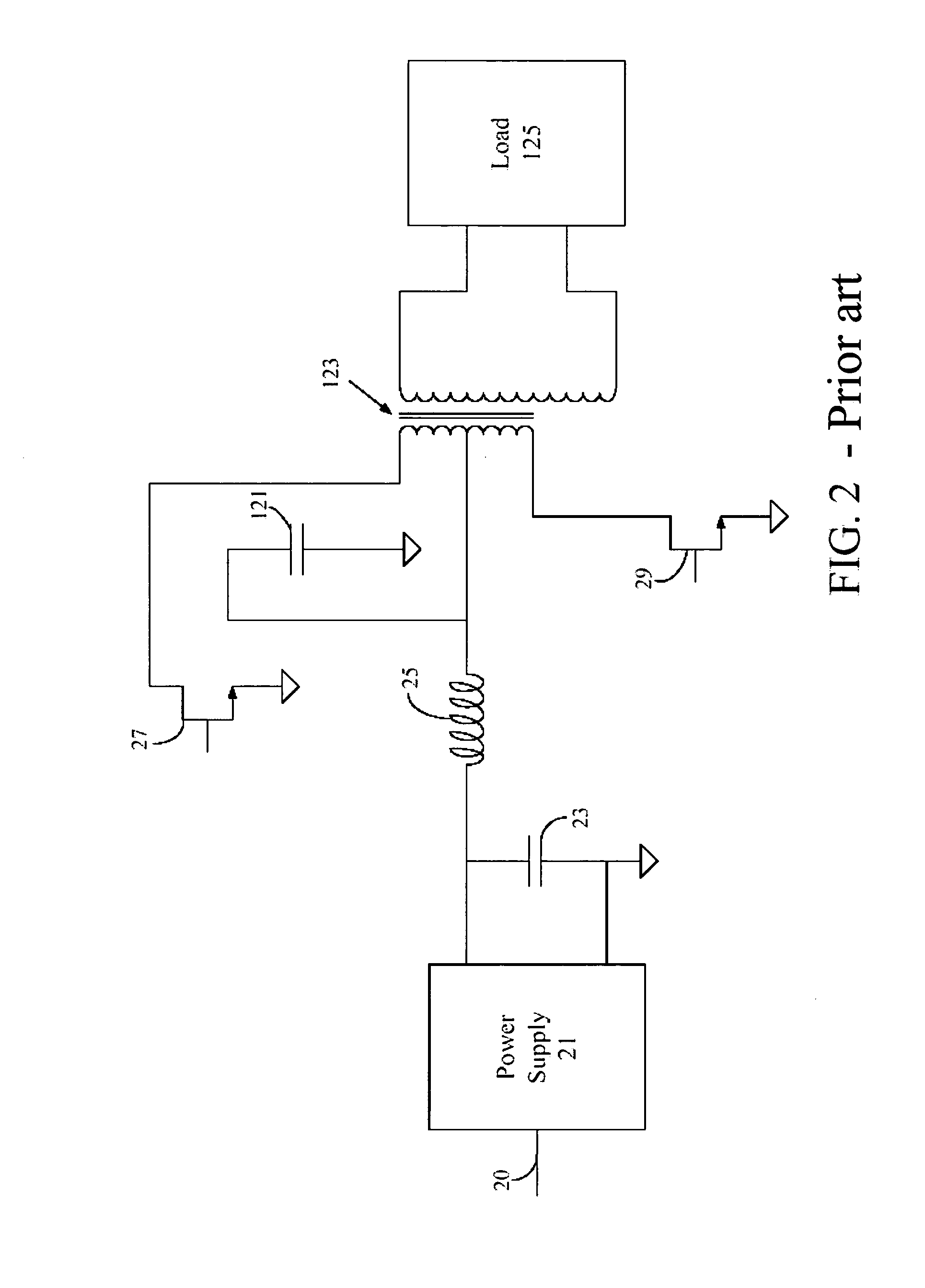

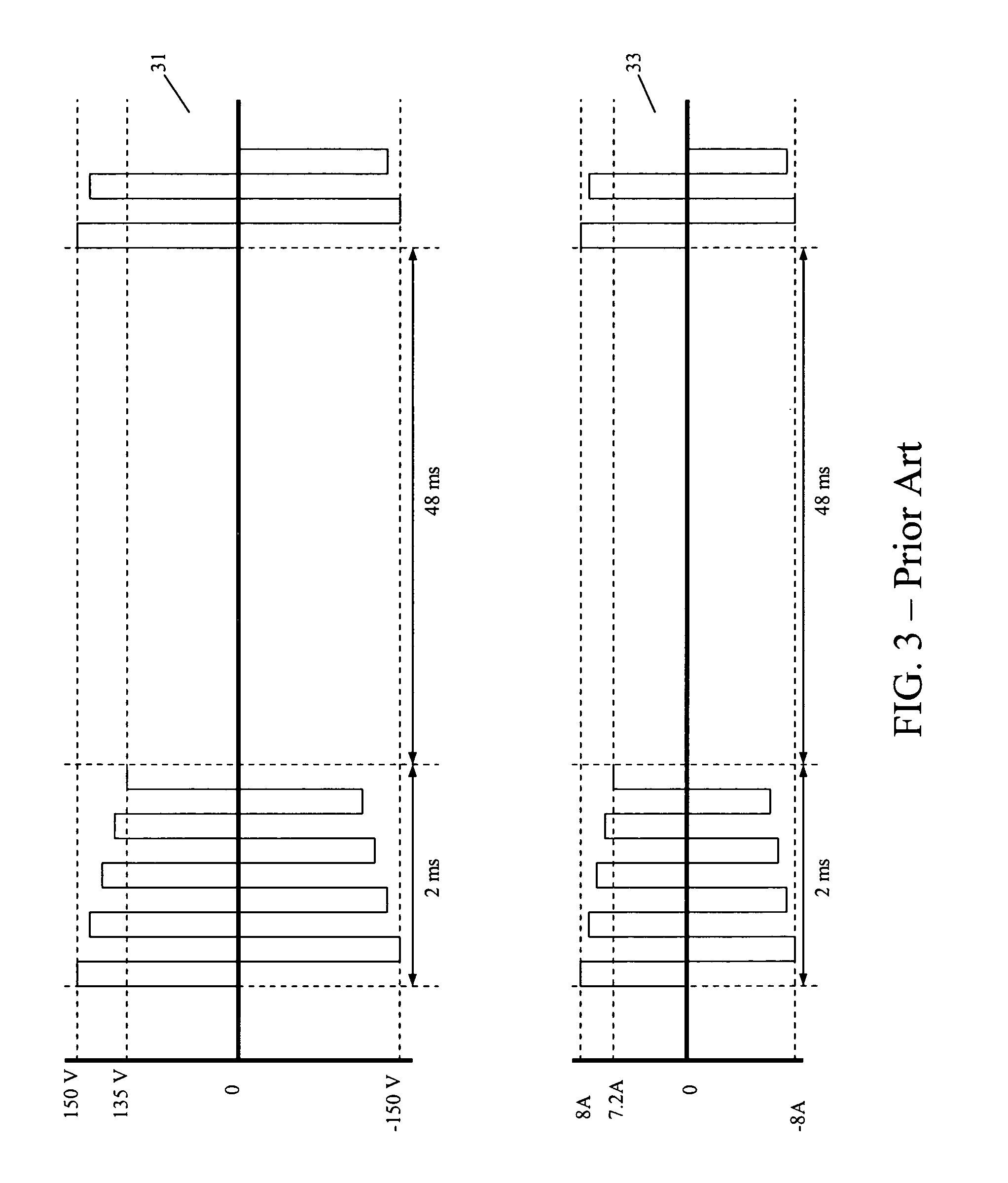

Method and system for providing current leveling capability

InactiveUS20060279258A1Eliminate needConstant levelElectric powerBattery overvoltage protectionHigh rateEngineering

The present invention relates to systems and methods for leveling a power supply current into a circuit that drives a pulsed load, such as a surgical cataract handpiece. According to various embodiments for current leveling of the present invention, the input current is leveled to regulate power being drawn from a power supply to prevent supply current surges that can: a) warrant a higher-rated supply; b) cause large voltage dips on a supply that supports other devices; or c) both.

Owner:ALCON INC

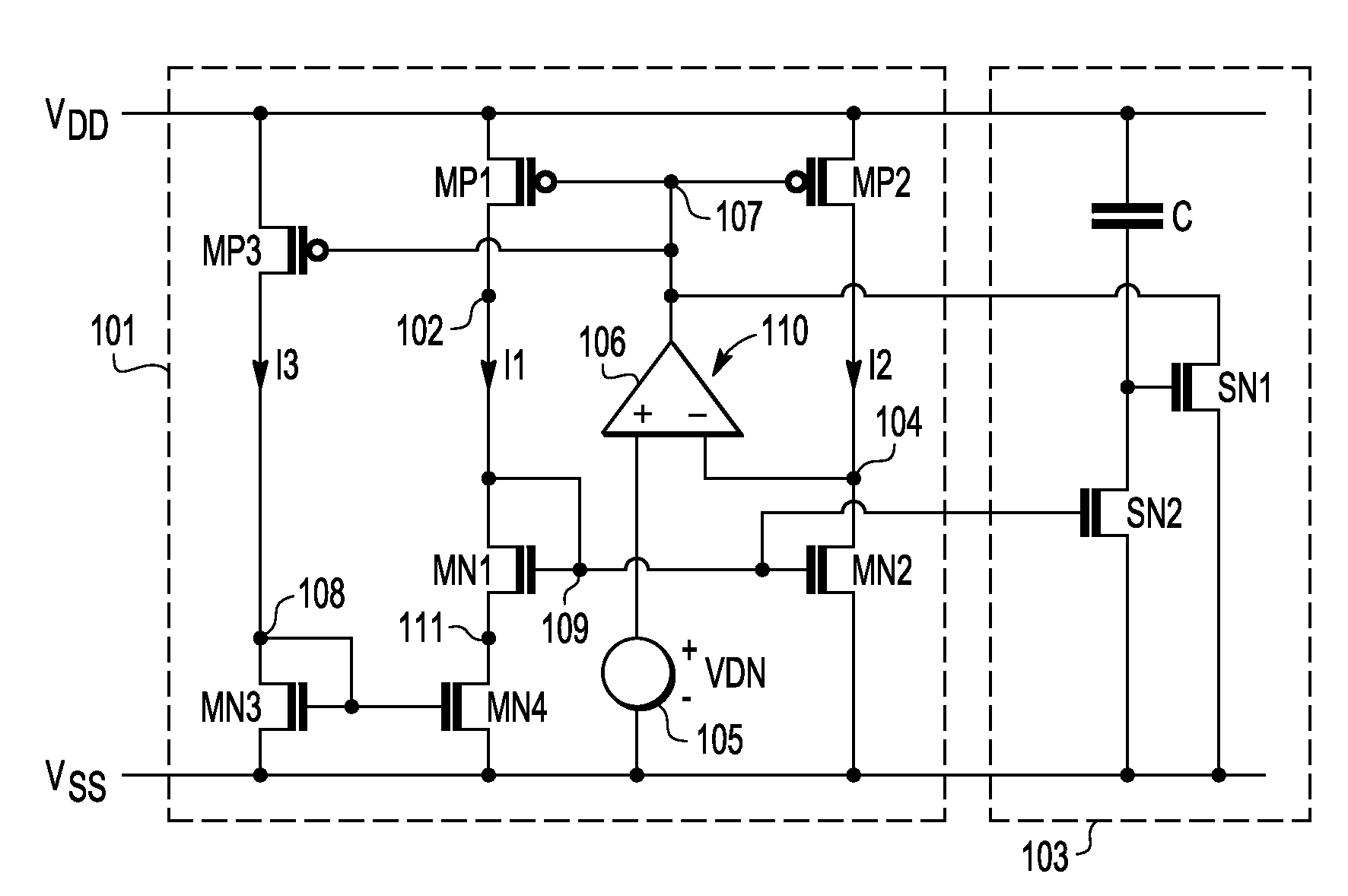

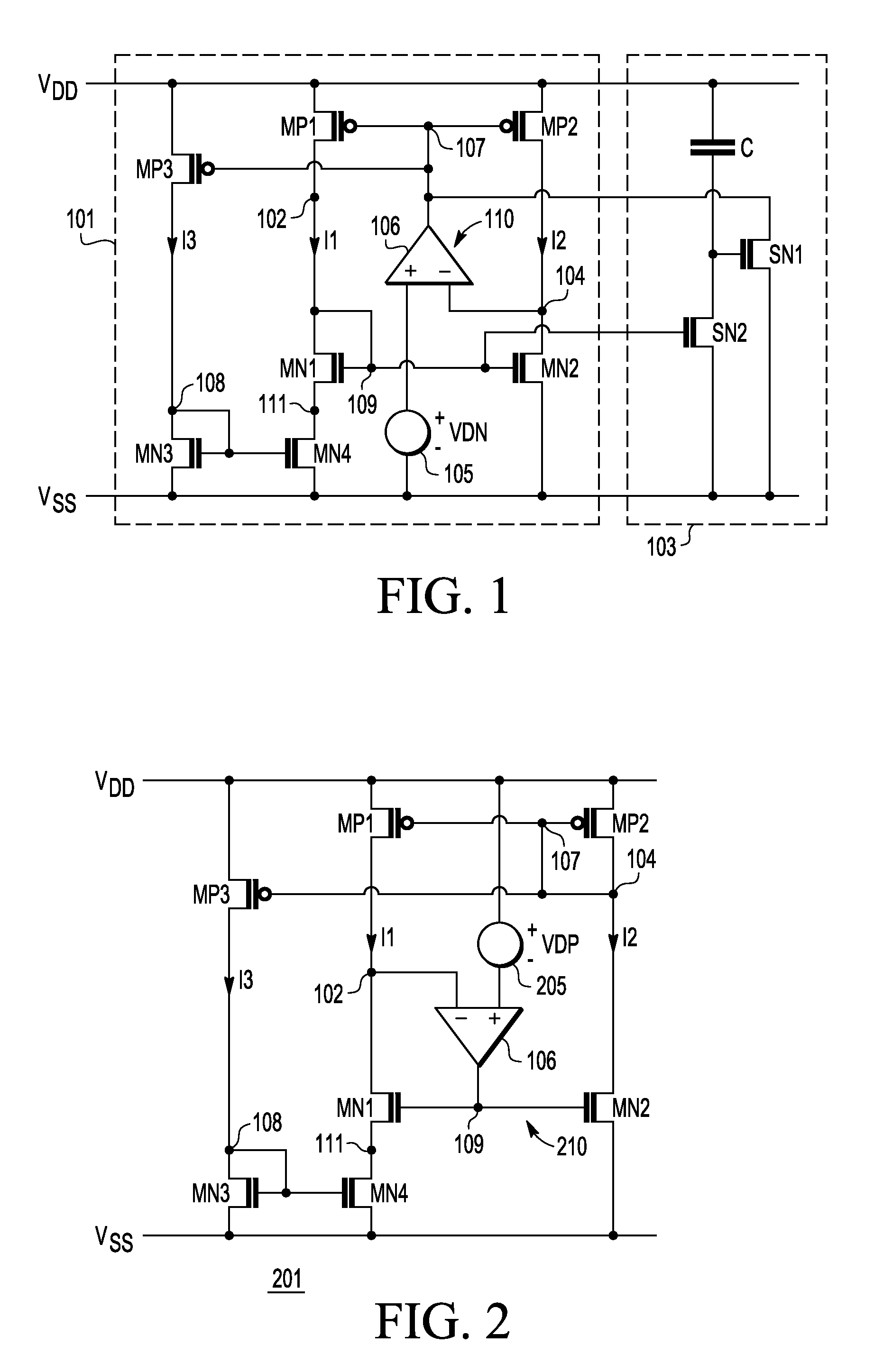

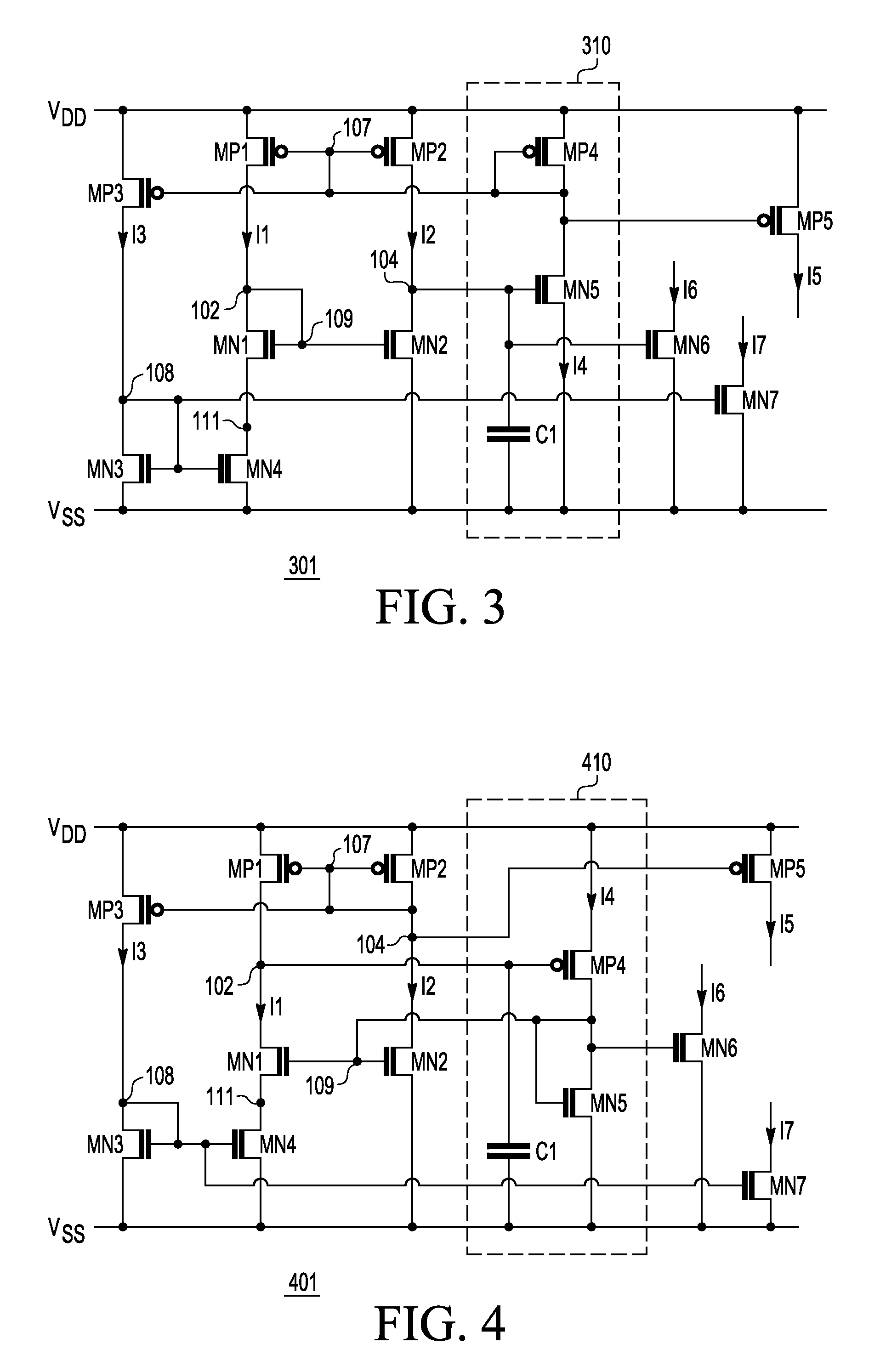

Supply independent current reference generator in CMOS technology

A current reference generator including a current network, a bias network, and a loop amplifier. The current network includes first and second transistors of a first conductivity type and third, fourth and fifth transistors of a second conductivity type. The first, third and fifth transistors are series-coupled between voltage supply lines forming a first current path, and the second and fourth transistors are series-coupled between the supply lines forming a second current path. The control terminals of the first and second transistors are coupled together and the control terminals of the third and fourth transistors are coupled together. The bias network biases the fifth transistor. The loop amplifier is coupled to the current network and is operative to maintain constant current level through the first and second current paths independent of voltage variations of the supply lines and at very low supply voltage.

Owner:SILICON LAB INC

Sustained release composition of prostacyclin

Owner:ASCENDIS PHARM AS

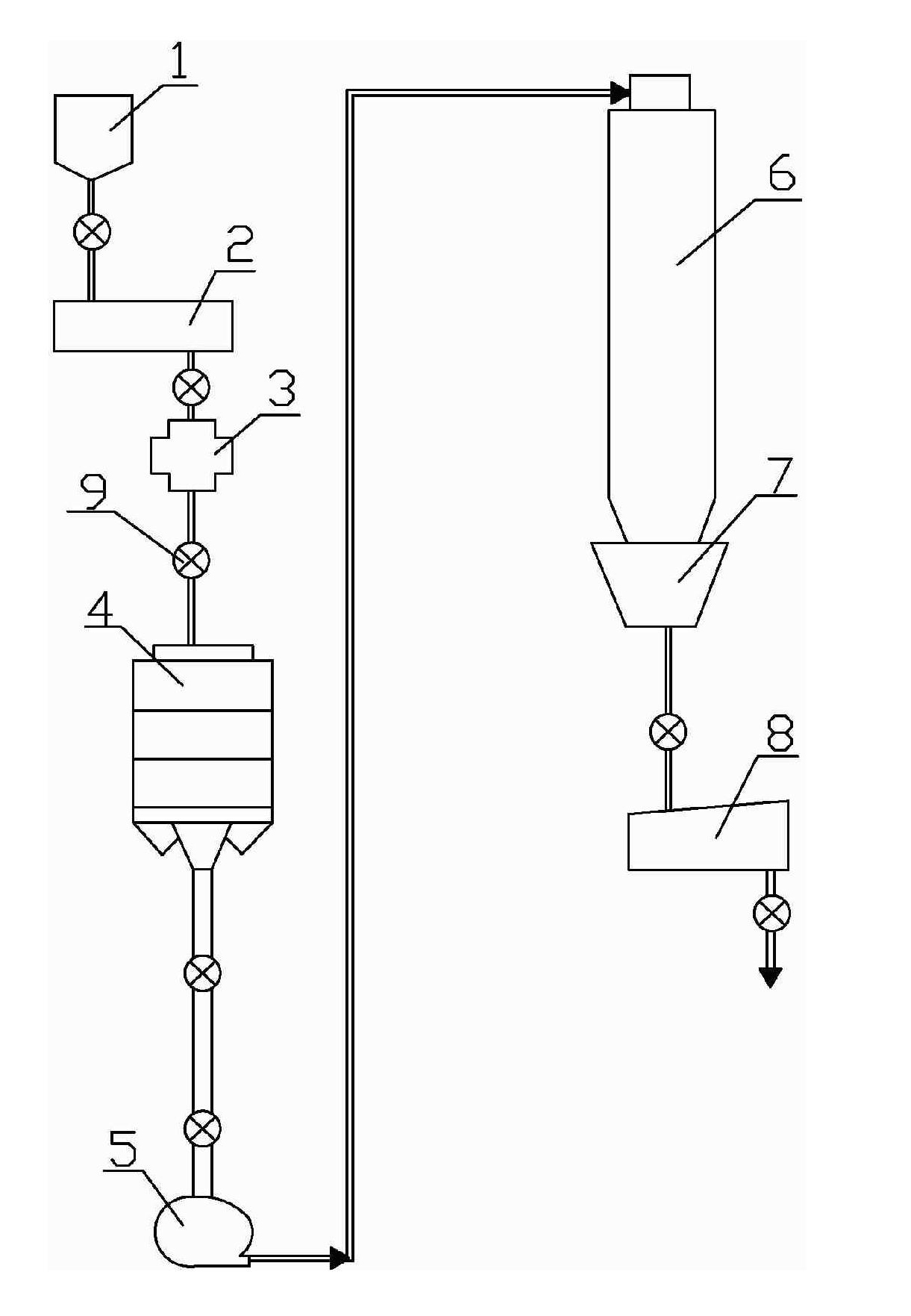

Solid state polymerization technique of polyester industry

The invention discloses a solid phase polymerization technique of the polyester industry. The technique comprises the following steps: the pre-crystallization processing of raw materials, then on-line dust removal, recrystallization, heat transport, main reaction, discharging of machinery, cooling and dust removal to obtain a finished product. The solid phase polymerization technique adopts a reasonable technological route and technological parameters and the whole technique is provided with reasonable production equipment for the solid phase polymerization of the polyester industry, thereby realizing high output, low energy consumption, convenient quality control and regulation and stable product quality.

Owner:ZHEJIANG UNIFULL IND FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com