Patents

Literature

51results about How to "Reduce feed rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

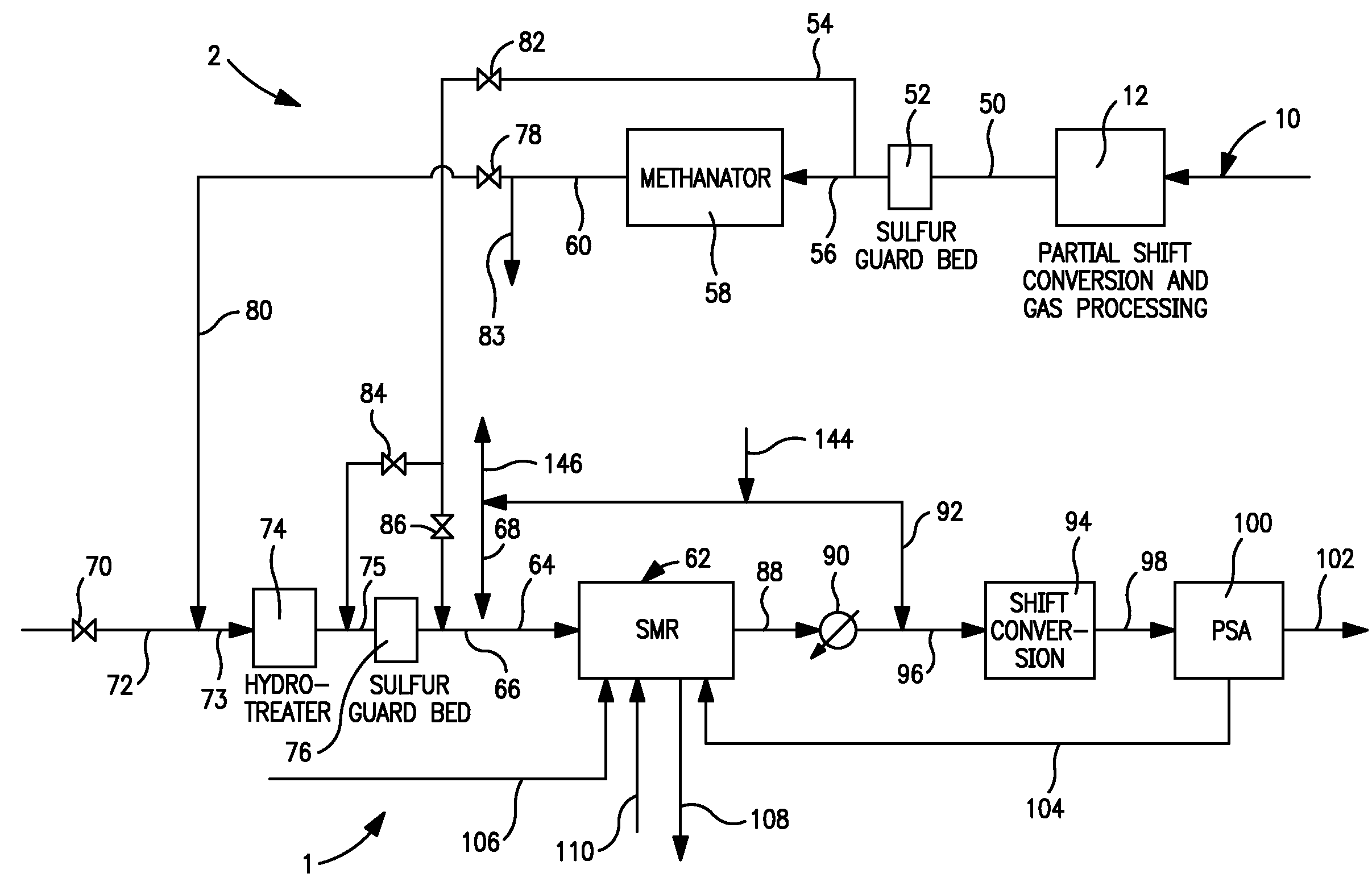

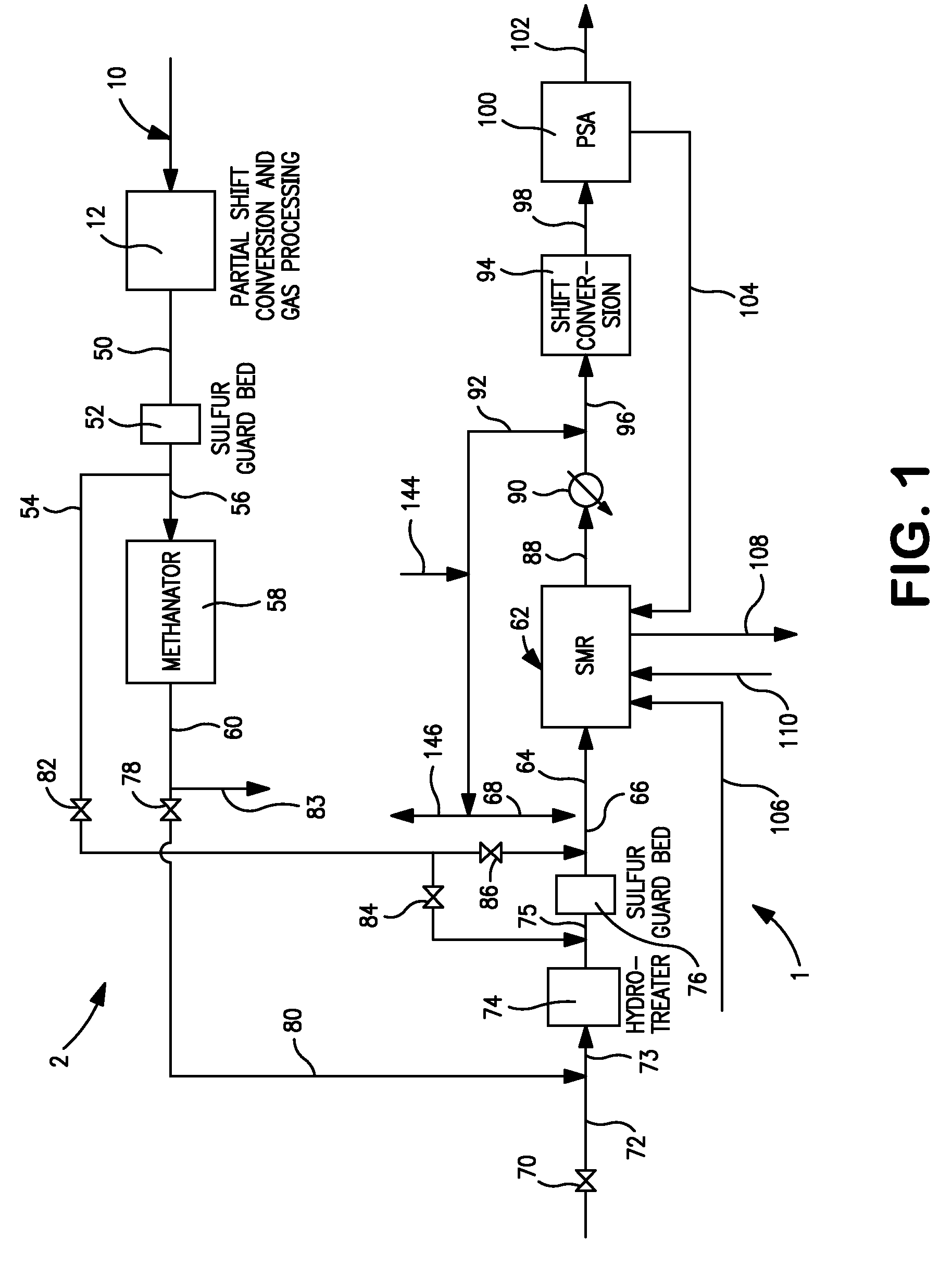

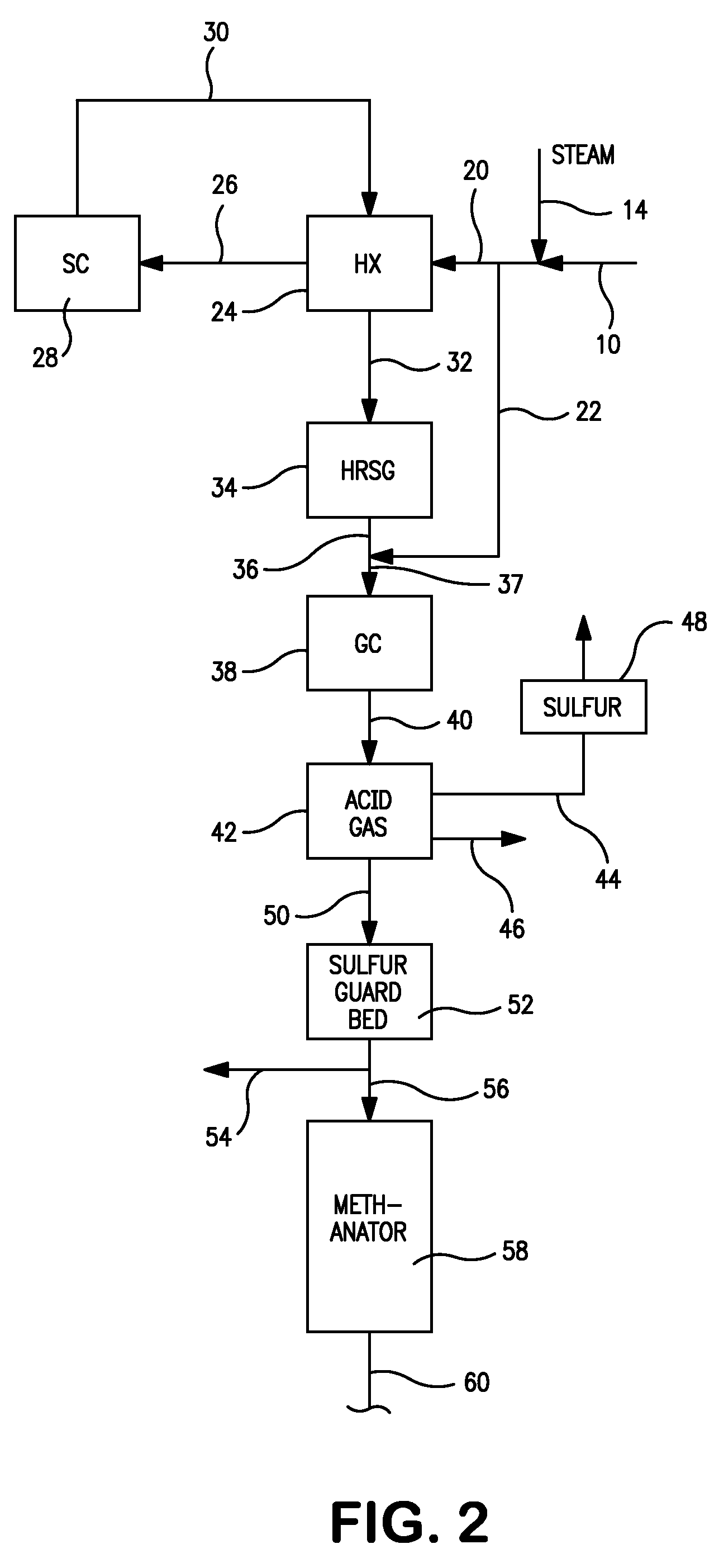

Hydrogen production method

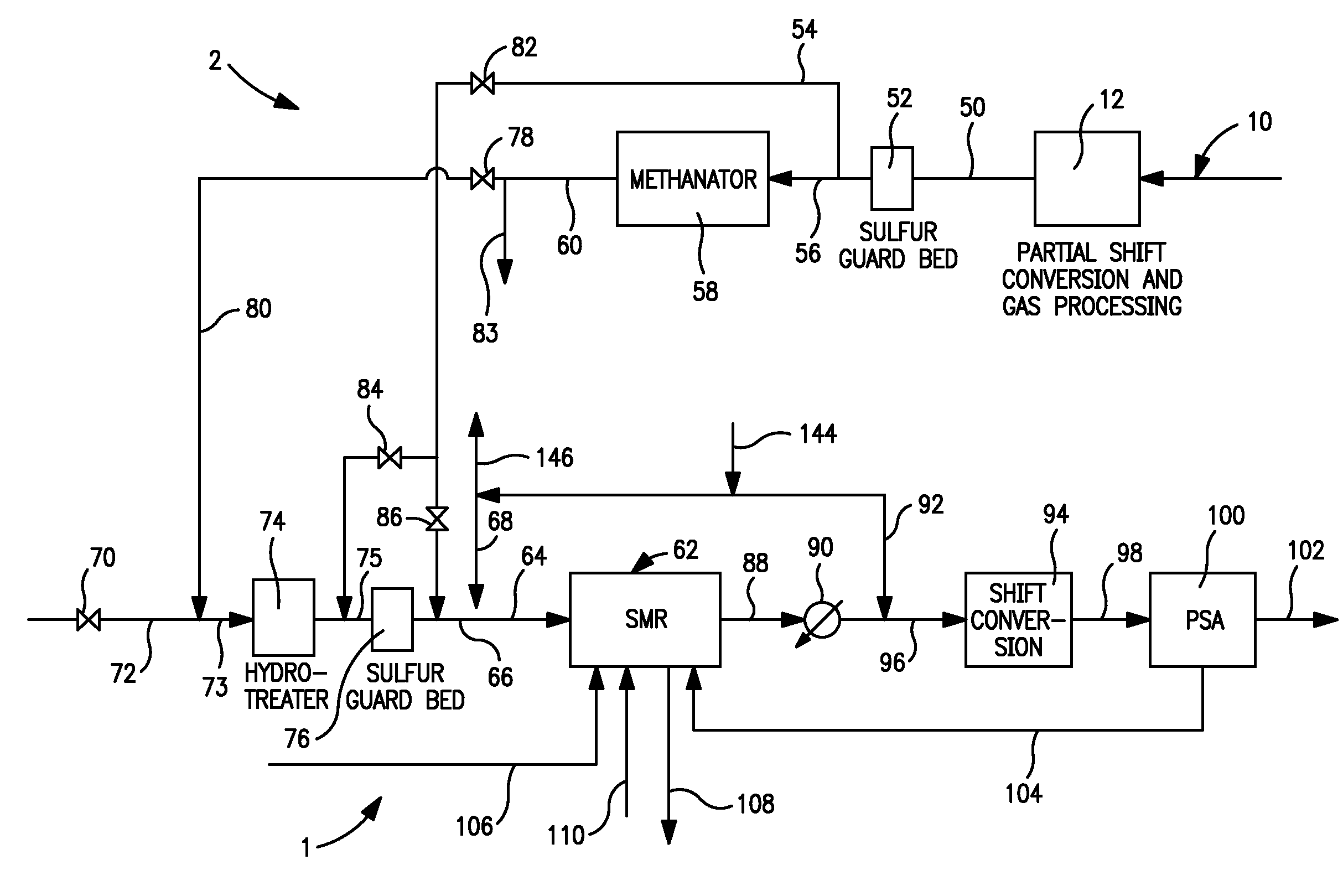

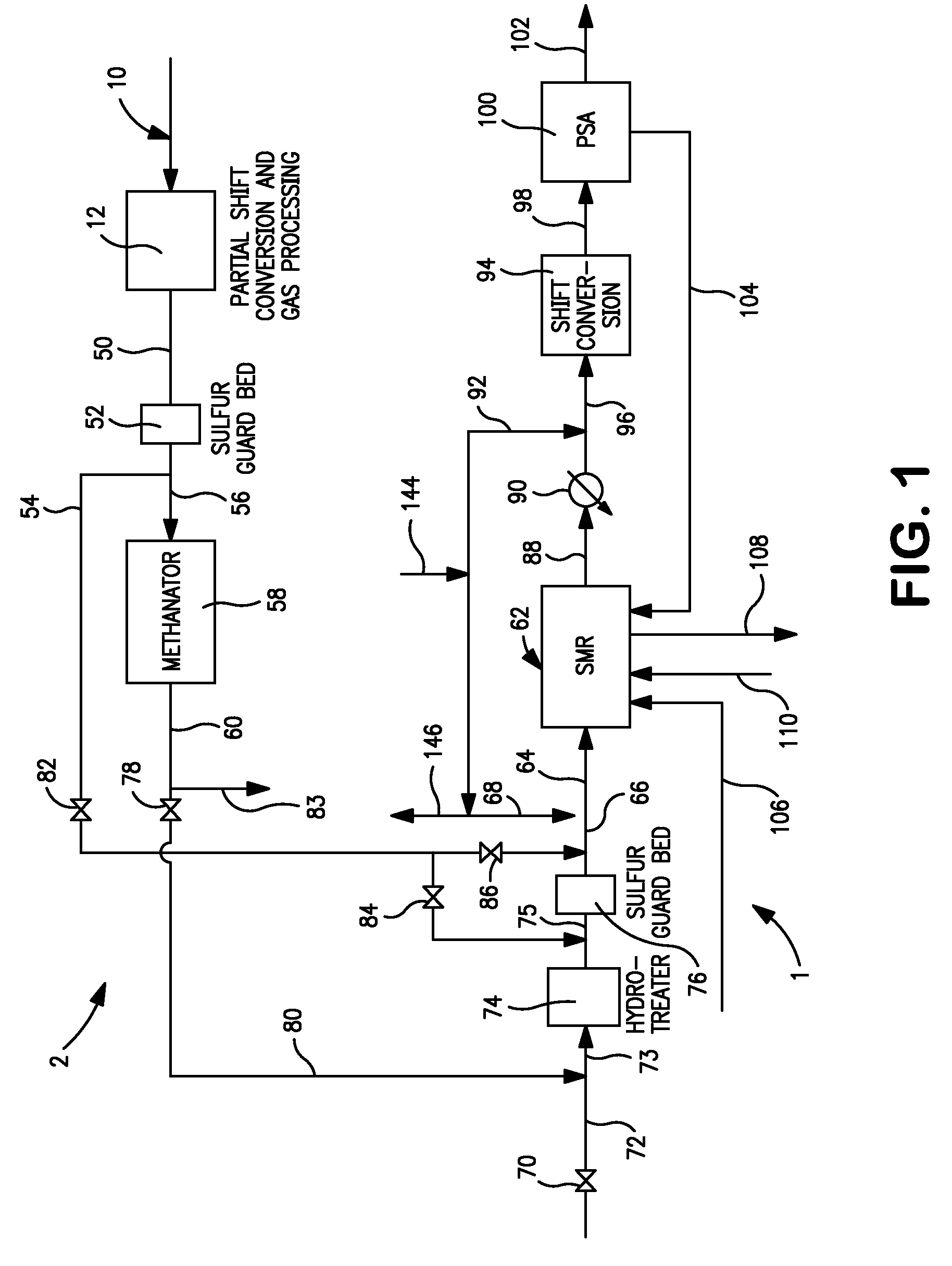

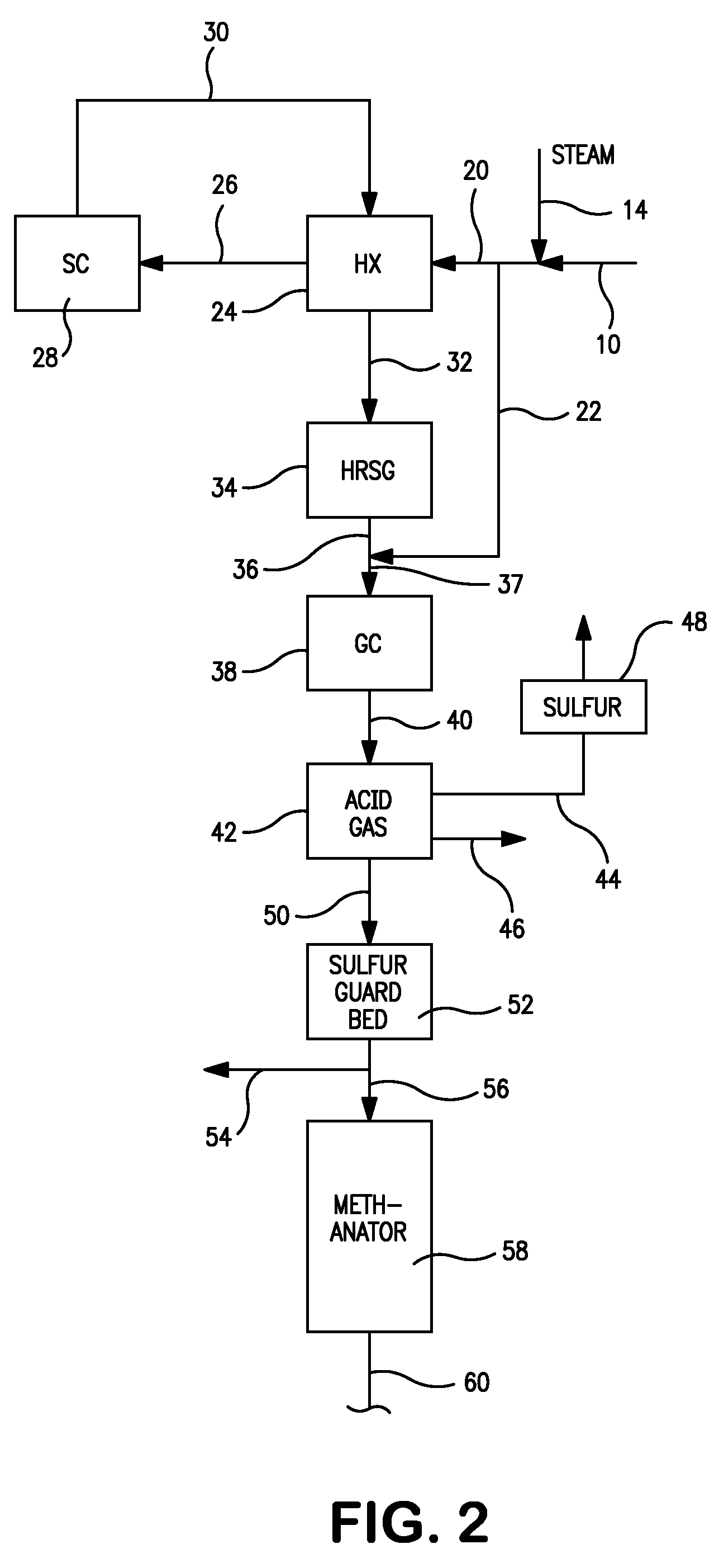

ActiveUS7931888B2Maximize productionSteam flow rate essentially constantHydrogenCombustible gas catalytic treatmentMethane reformerMethane

A method of producing a hydrogen product stream in which a steam stream is reacted with a hydrocarbon containing stream within a steam methane reformer. The resulting product stream is subjected to a water gas shift reaction and then to pressure swing adsorption to produce the hydrogen product stream. The hydrocarbon stream is alternatively formed from a first type of feed stream made up of natural gas, refinery off-gas, naphtha or synthetic natural gas or combinations thereof and a second type that is additionally made up of a hydrogen and carbon monoxide containing gas. During use of both of the types of feed streams, the flow rate of the steam stream is not substantially changed and reformer exit temperatures of both the reactant and the flue gas side are held essentially constant.

Owner:PRAXAIR TECH INC

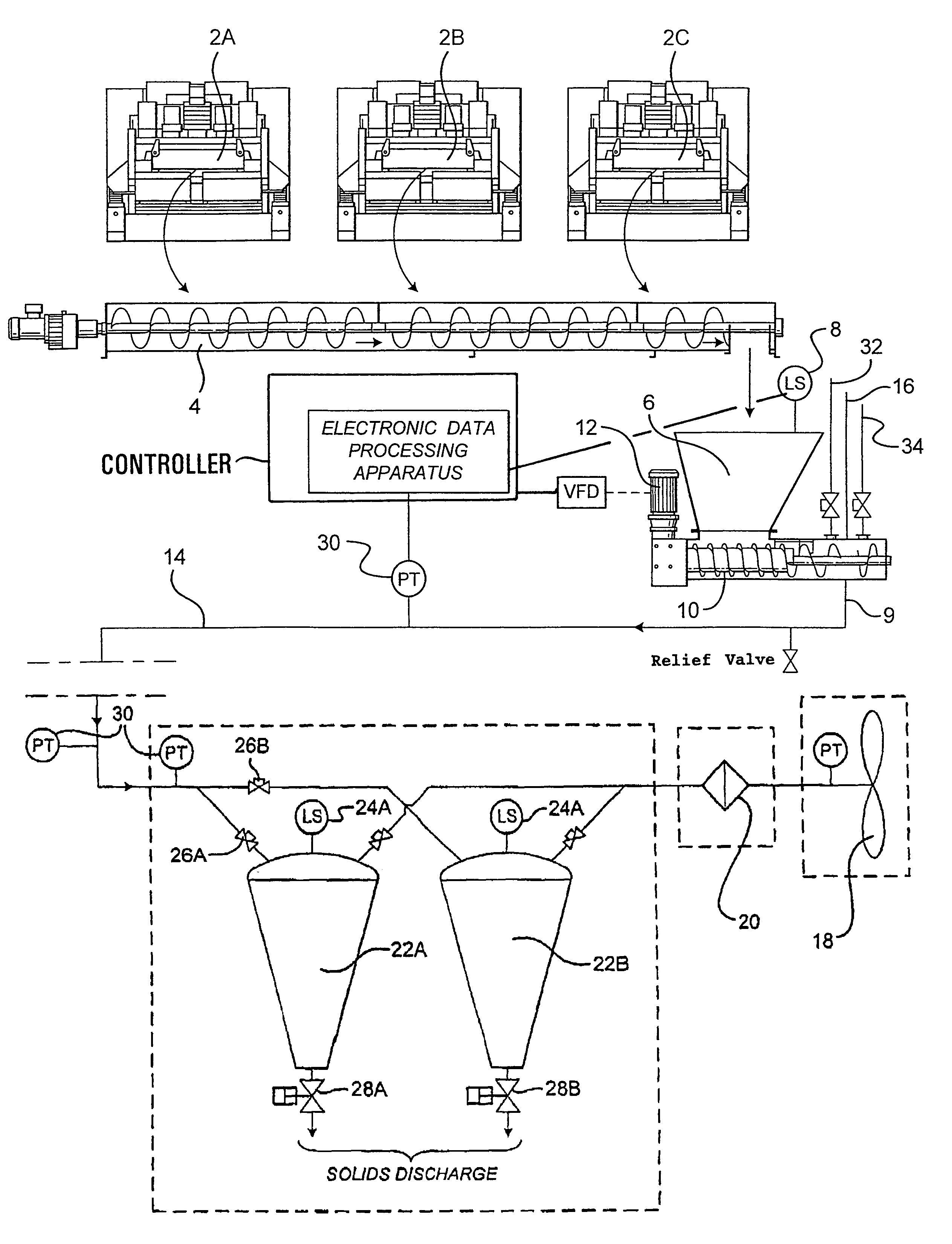

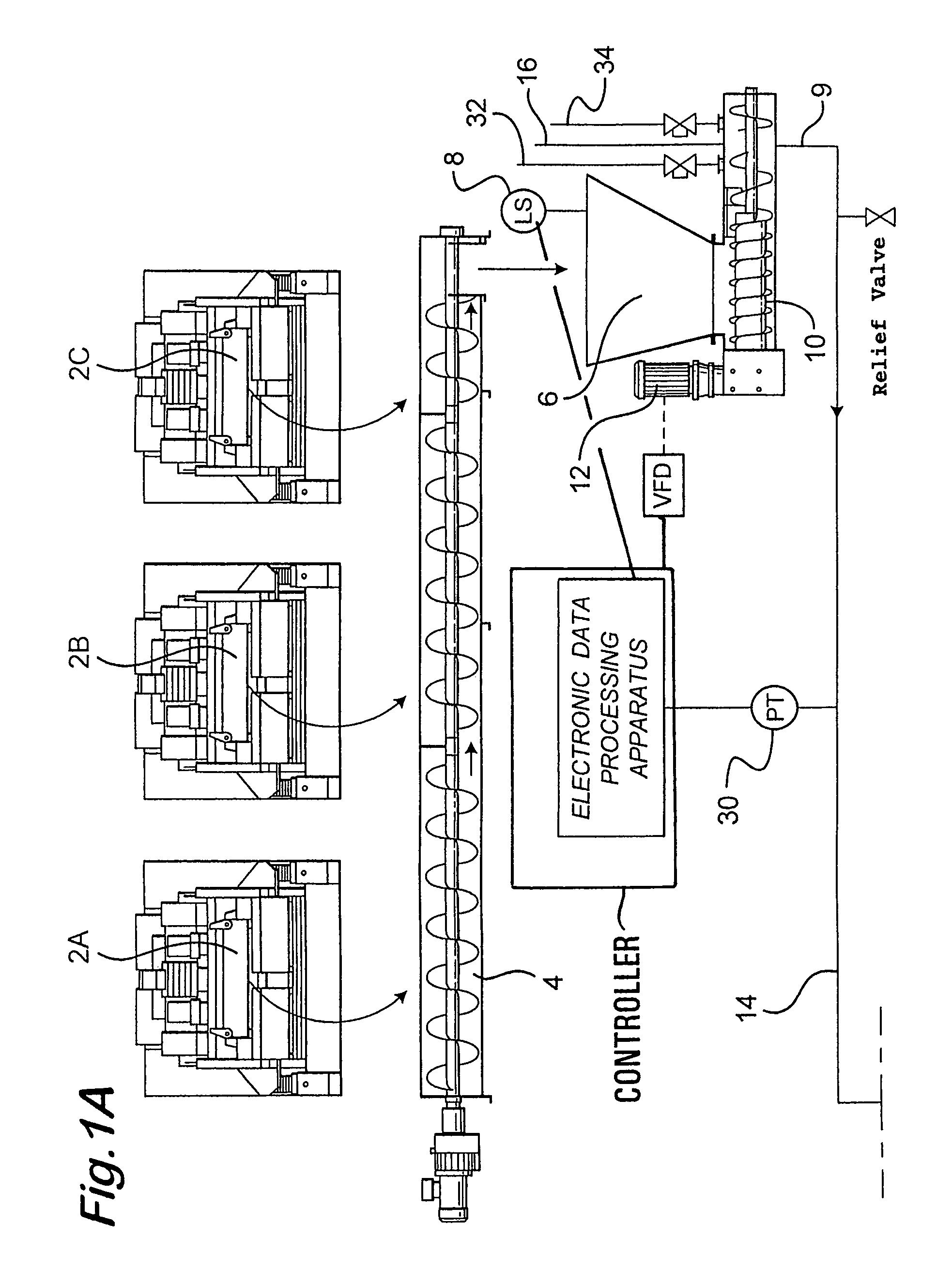

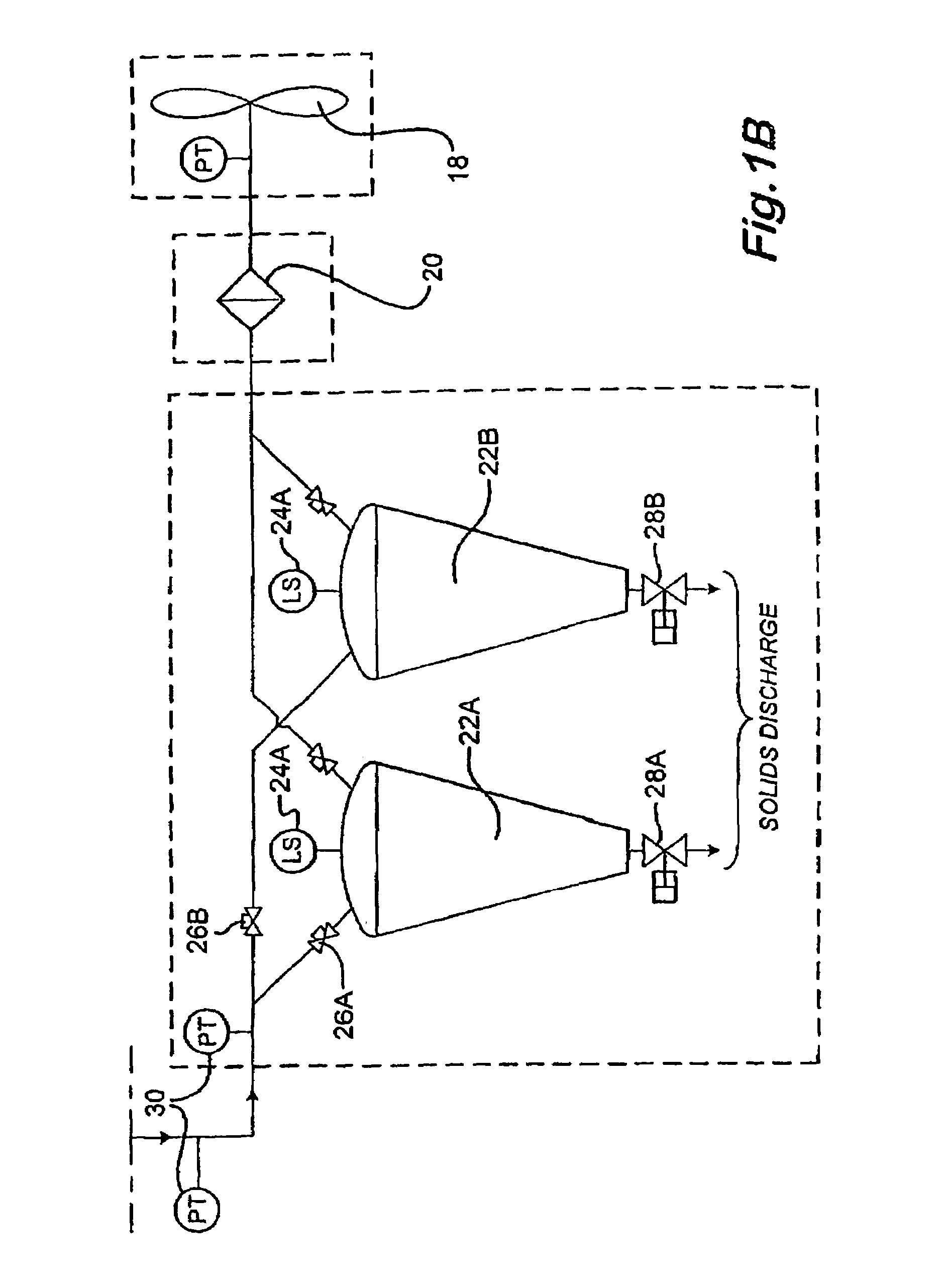

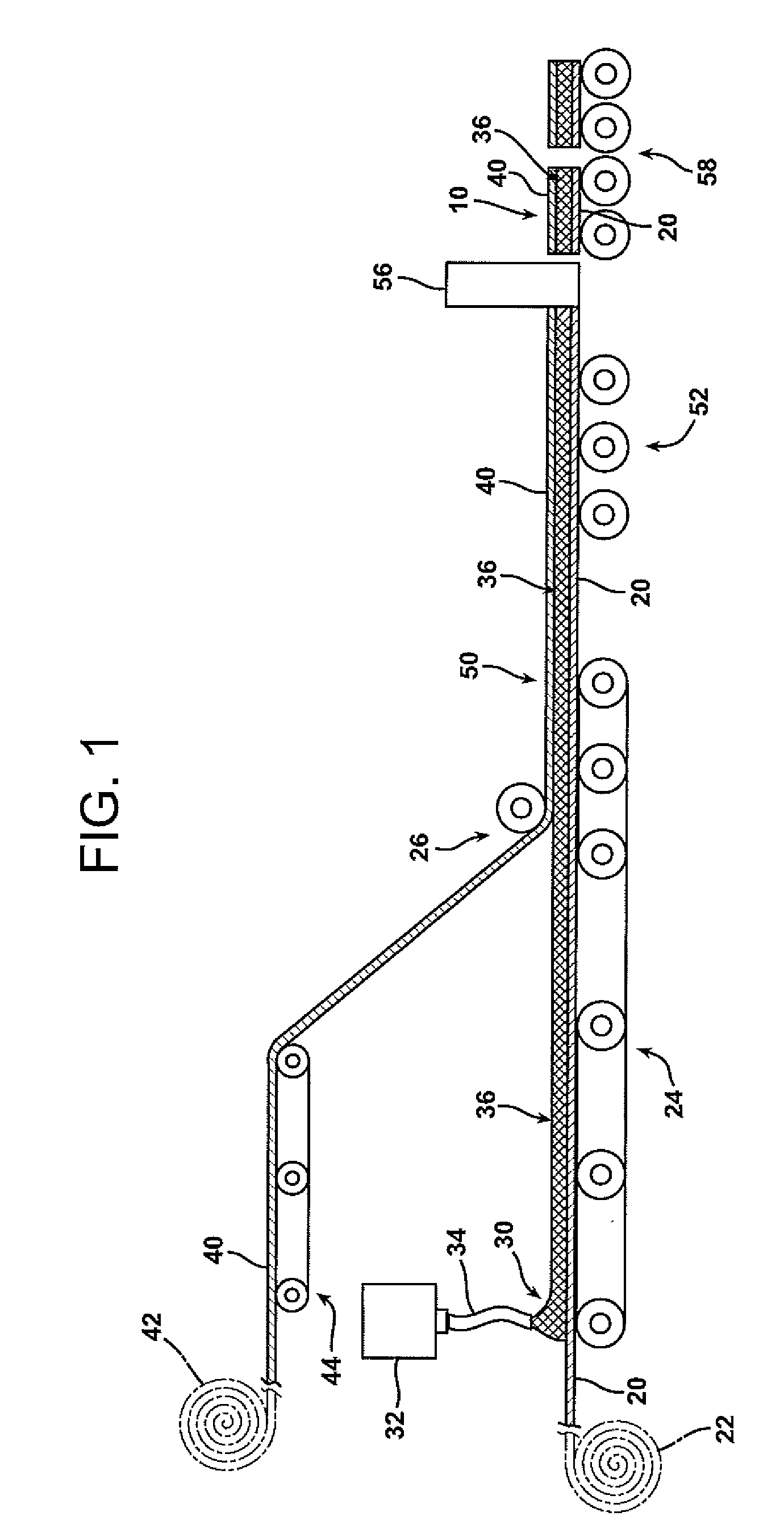

Apparatus and method for transporting waste materials

InactiveUS7080960B2Reduce feed rateHigh speedControl devices for conveyorsFlushingDrill cuttingsWaste material

Owner:VARCO I P INC

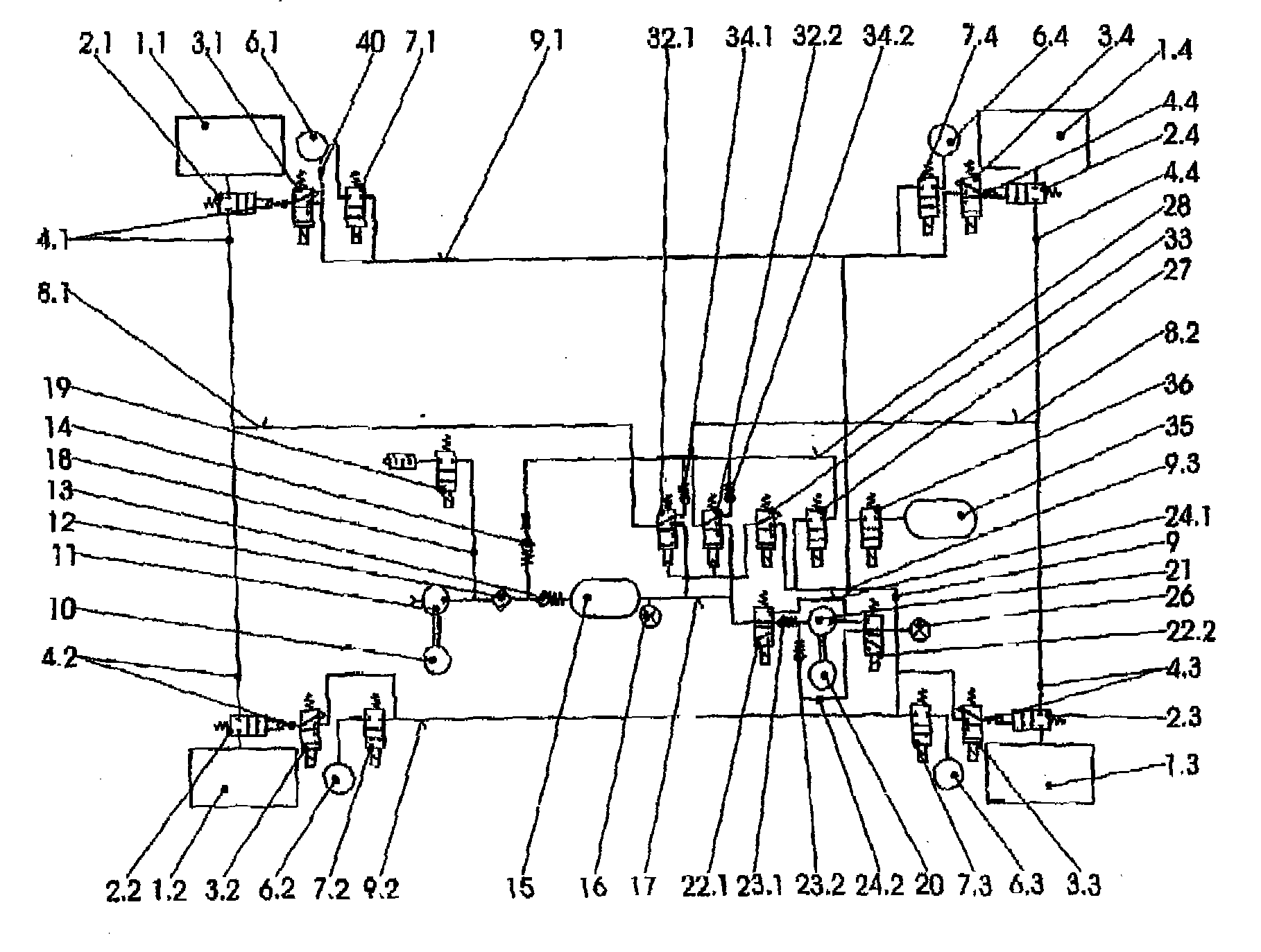

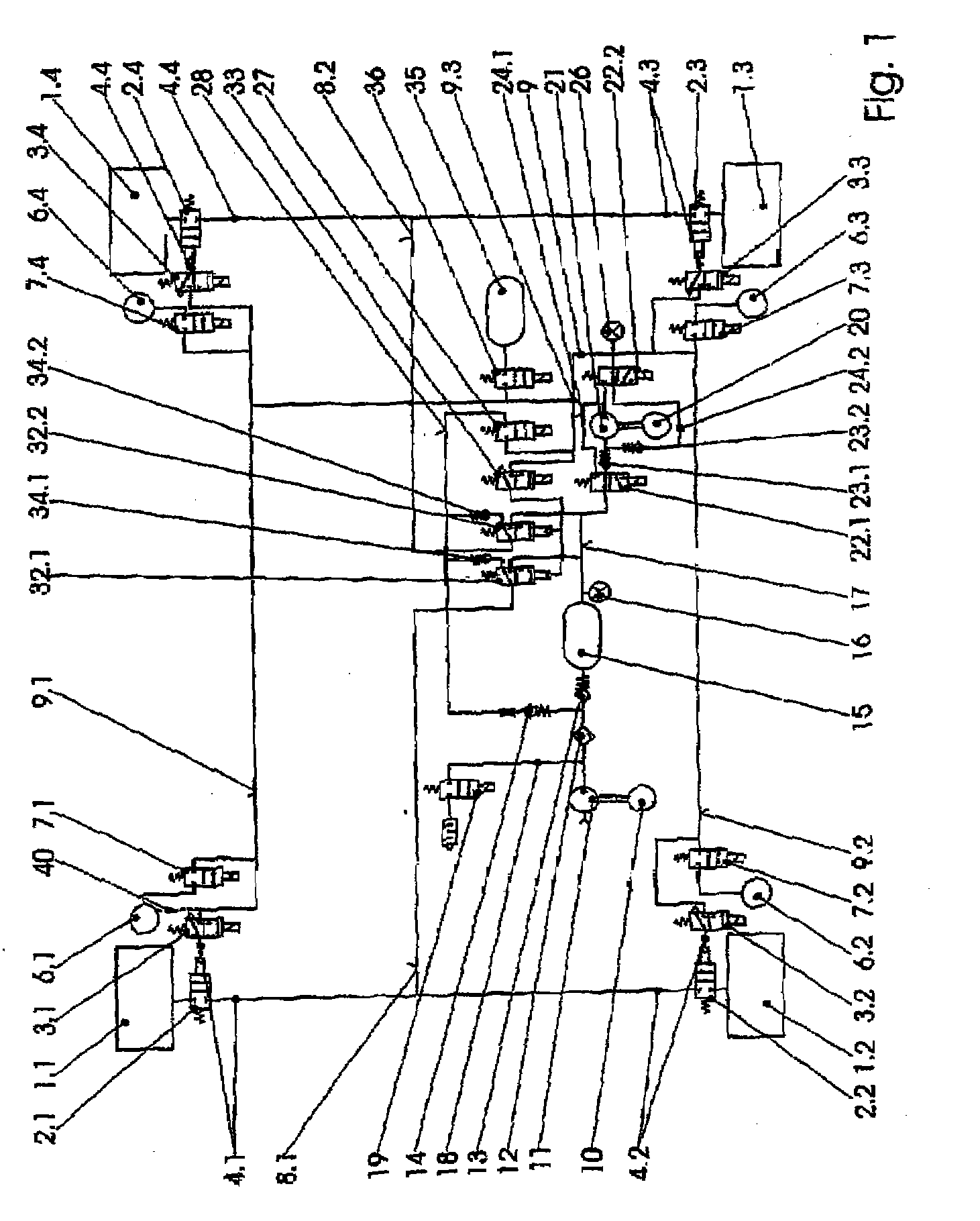

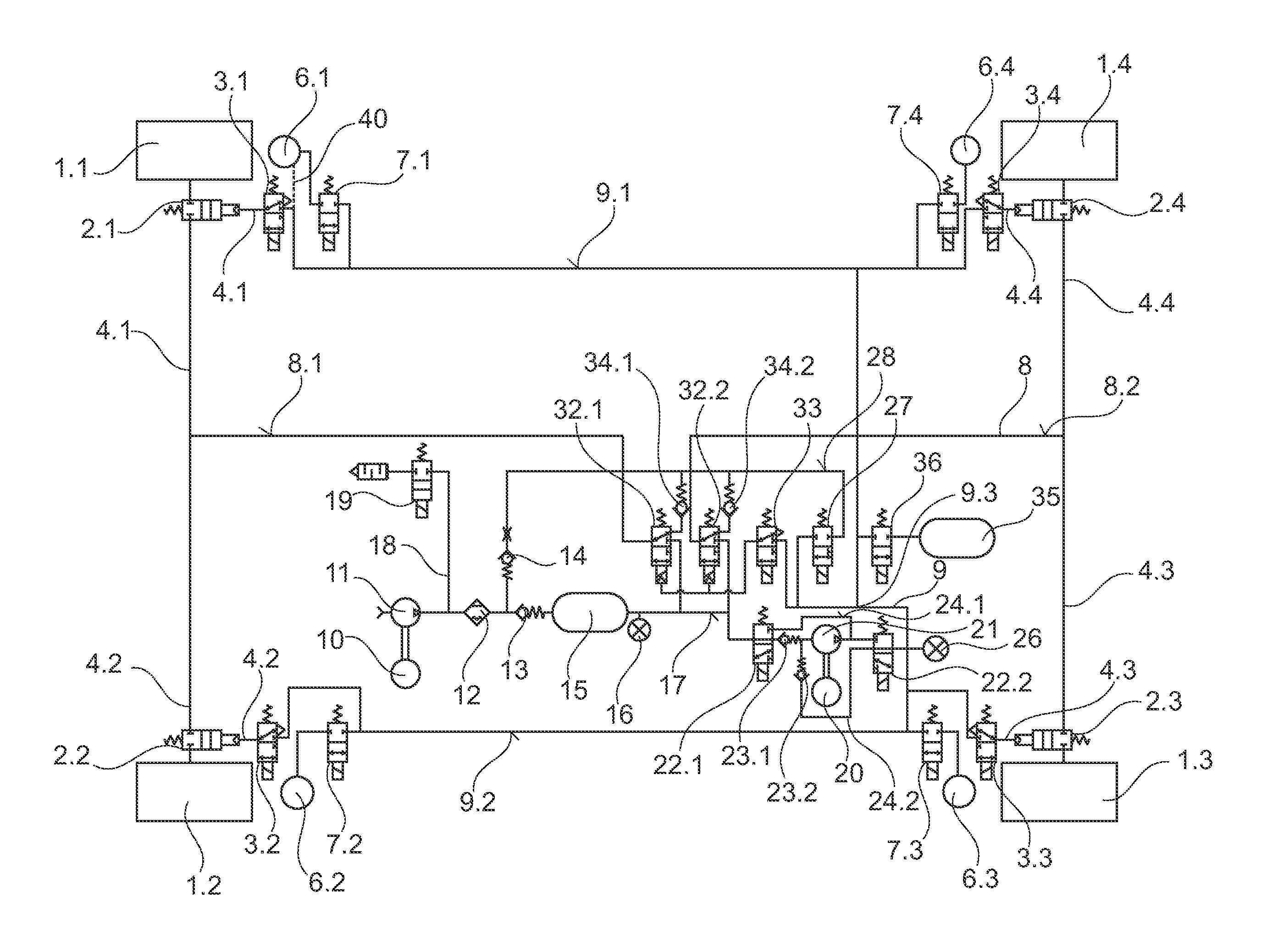

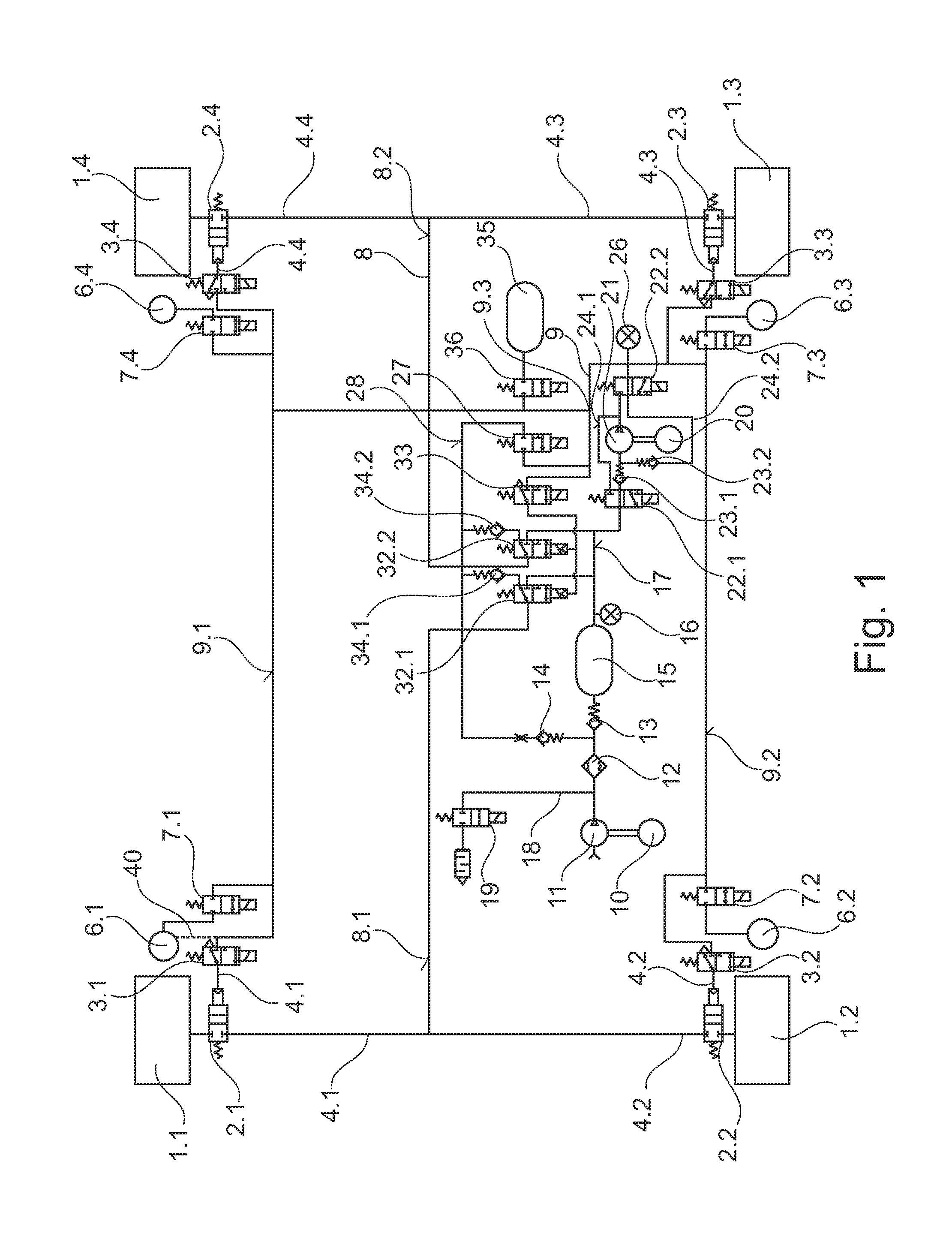

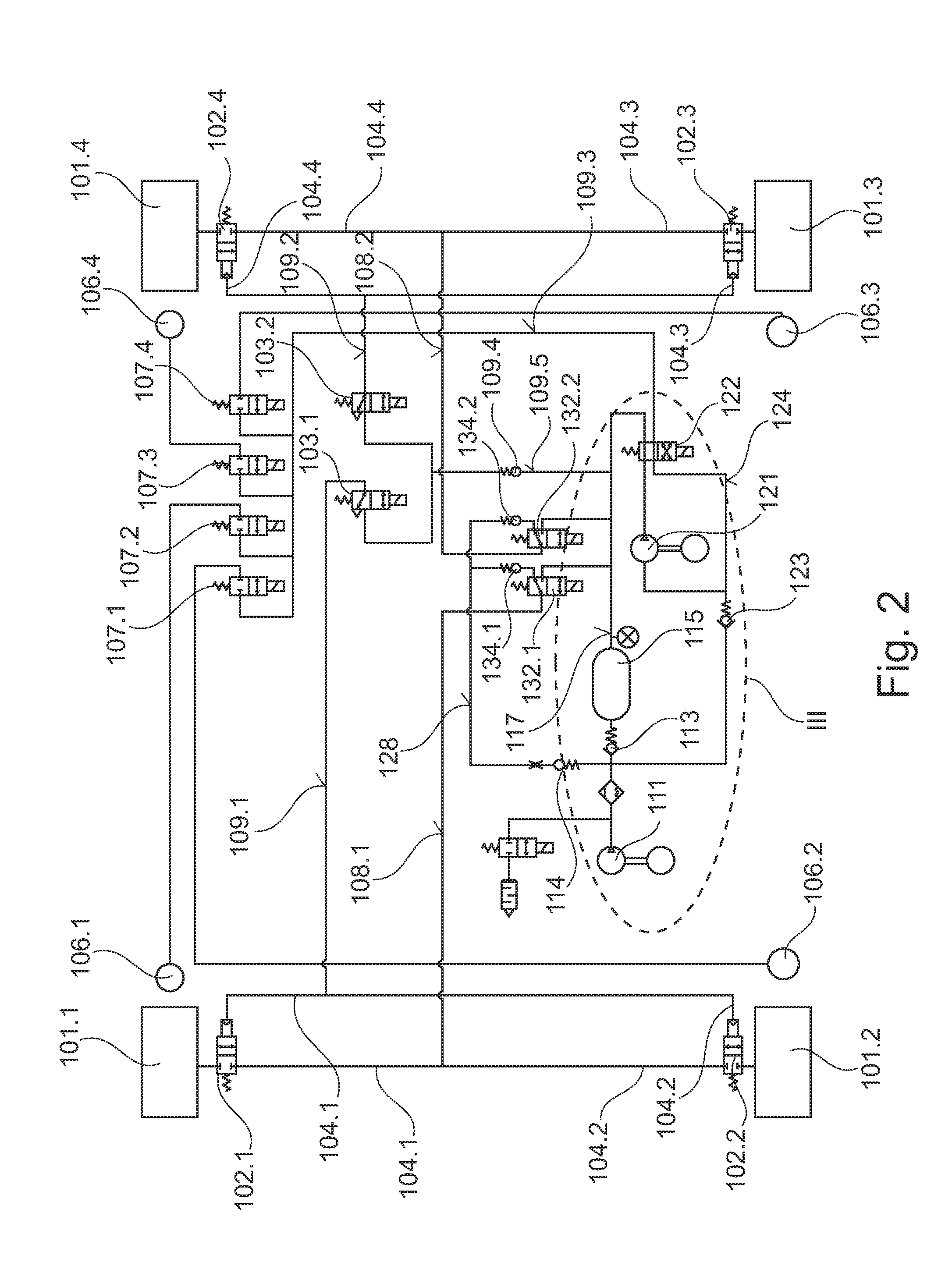

Tire inflation system

InactiveUS20090032158A1Minimal numberQuick and reliable operationTyre measurementsTyre-inflating valvesHigh pressureVehicle control

A tire inflation system comprising pneumatically controlled wheel valves that are situated in the wheels of a motor vehicle. An electrically actuated pilot valve that is fixed to the vehicle controls the respective wheel valves. To produce a small, low-cost, reliable tire inflation system, a first and a second compressor are provided. The first compressor supplies a first compressed air system with medium-pressure compressed air and the second compressor supplies a second compressed air system with high-pressure compressed air. The wheel valves are situated in the first compressed air system and the pilot valves are situated in the second compressed air system.

Owner:MAGNA STEYR FAHRZEUGTECHN

Hydrogen production method

ActiveUS20100074839A1Hydrogen production is maximizedLess utilizationHydrogenCombustible gas catalytic treatmentMethane reformerHydrogen production

A method of producing a hydrogen product stream in which a steam stream is reacted with a hydrocarbon containing stream within a steam methane reformer. The resulting product stream is subjected to a water gas shift reaction and then to pressure swing adsorption to produce the hydrogen product stream. The hydrocarbon stream is alternatively formed from a first type of feed stream made up of natural gas, refinery off-gas, naphtha or synthetic natural gas or combinations thereof and a second type that is additionally made up of a hydrogen and carbon monoxide containing gas. During use of both of the types of feed streams, the flow rate of the steam stream is not substantially changed and reformer exit temperatures of both the reactant and the flue gas side are held essentially constant.

Owner:PRAXAIR TECH INC

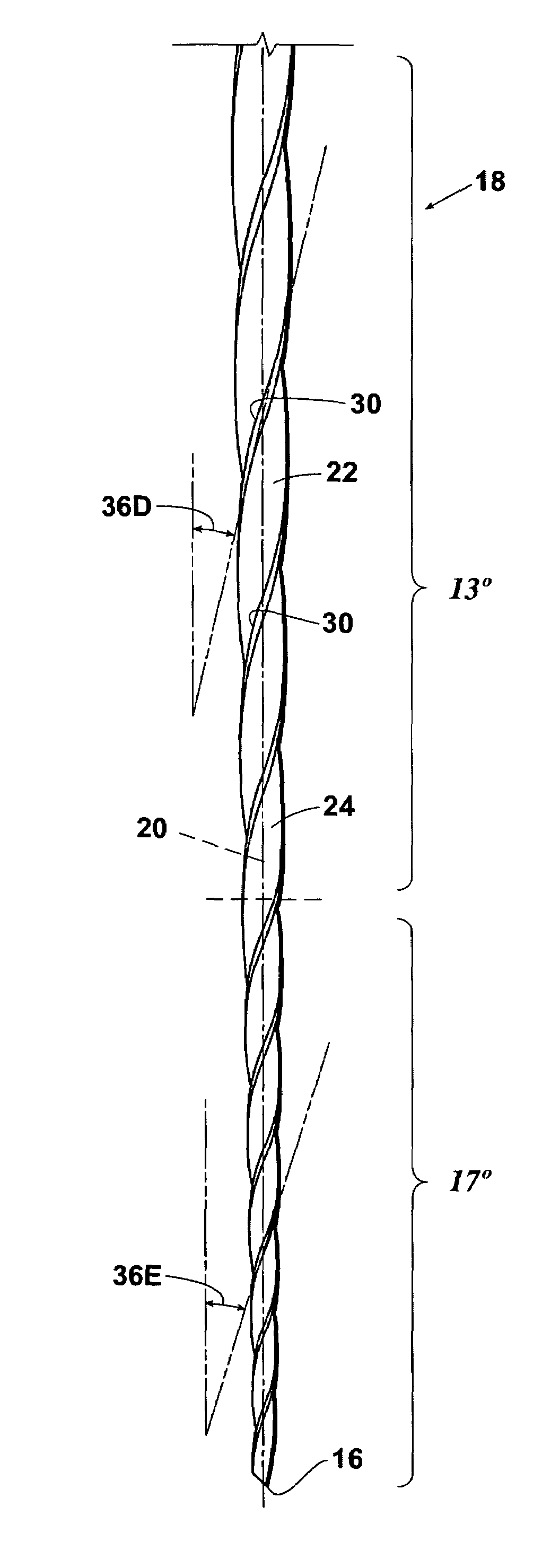

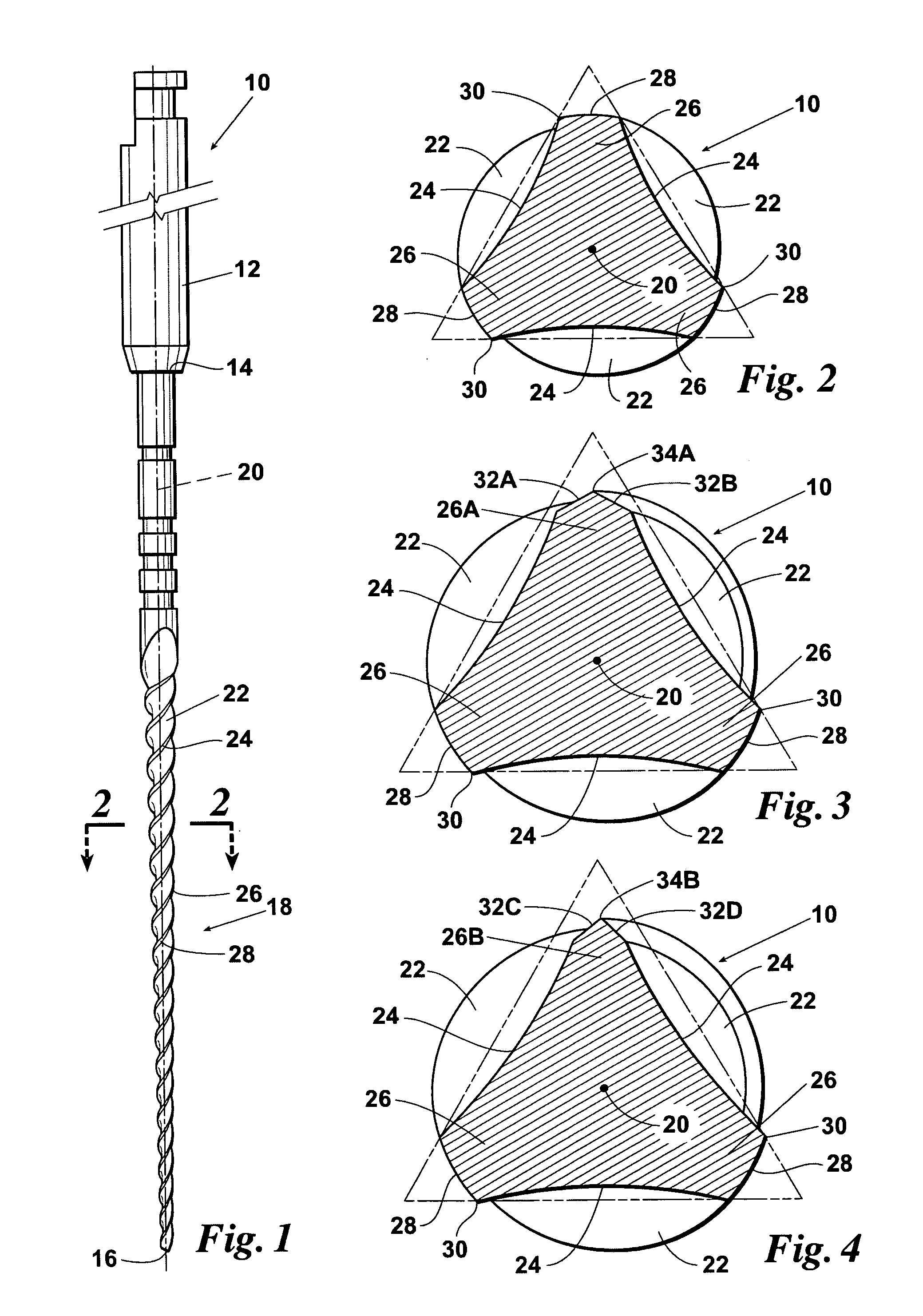

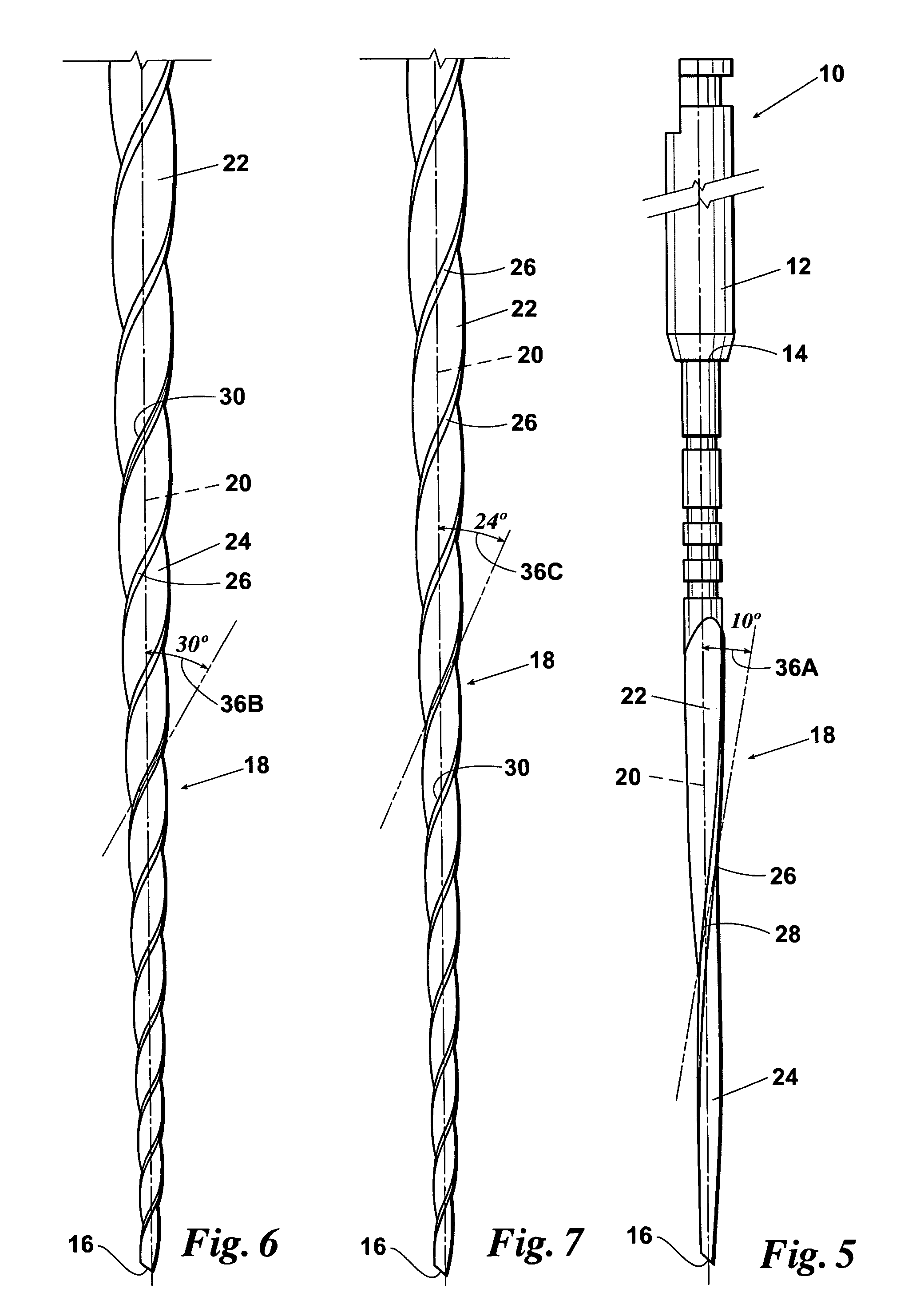

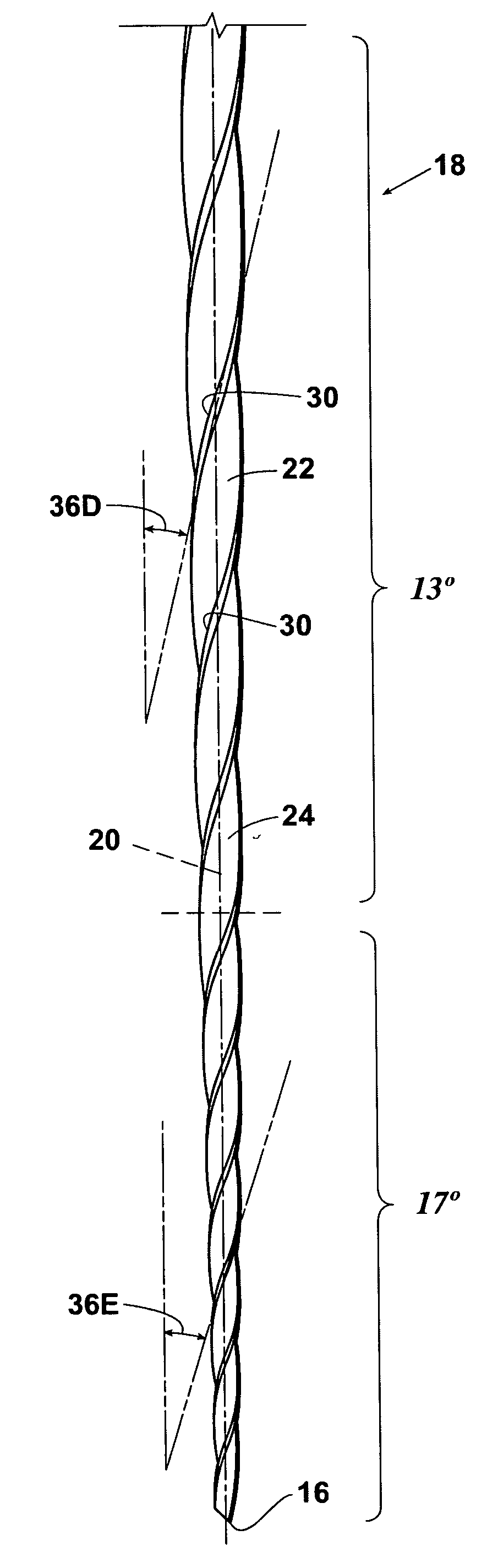

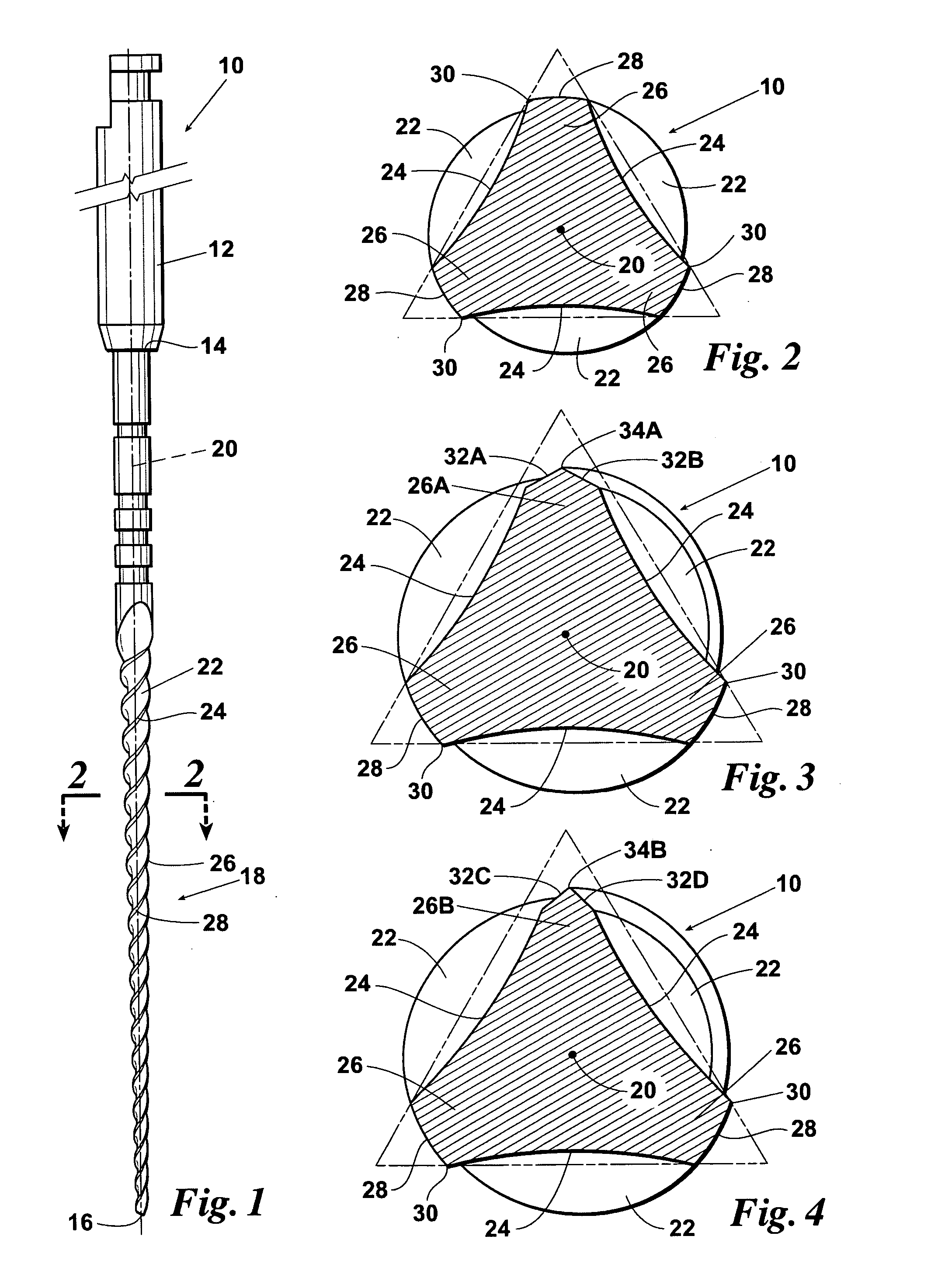

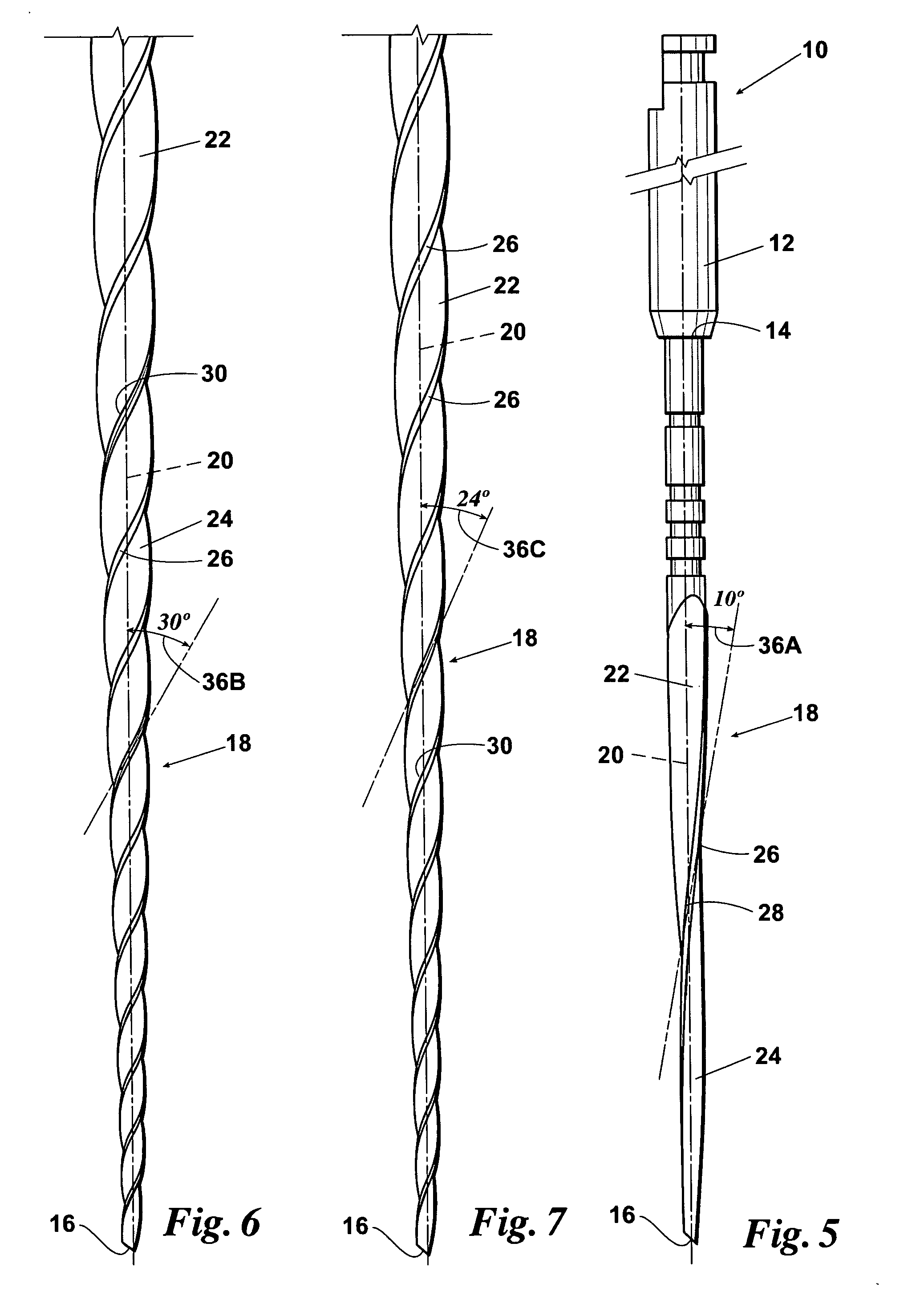

Endodontic files having variable helical angle flutes

ActiveUS7270541B1Reduce feed rateSmall surface areaTeeth cappingTeeth nerve/root treatment implementsFluteRotational axis

Owner:DENTSPLY SIRONA INC

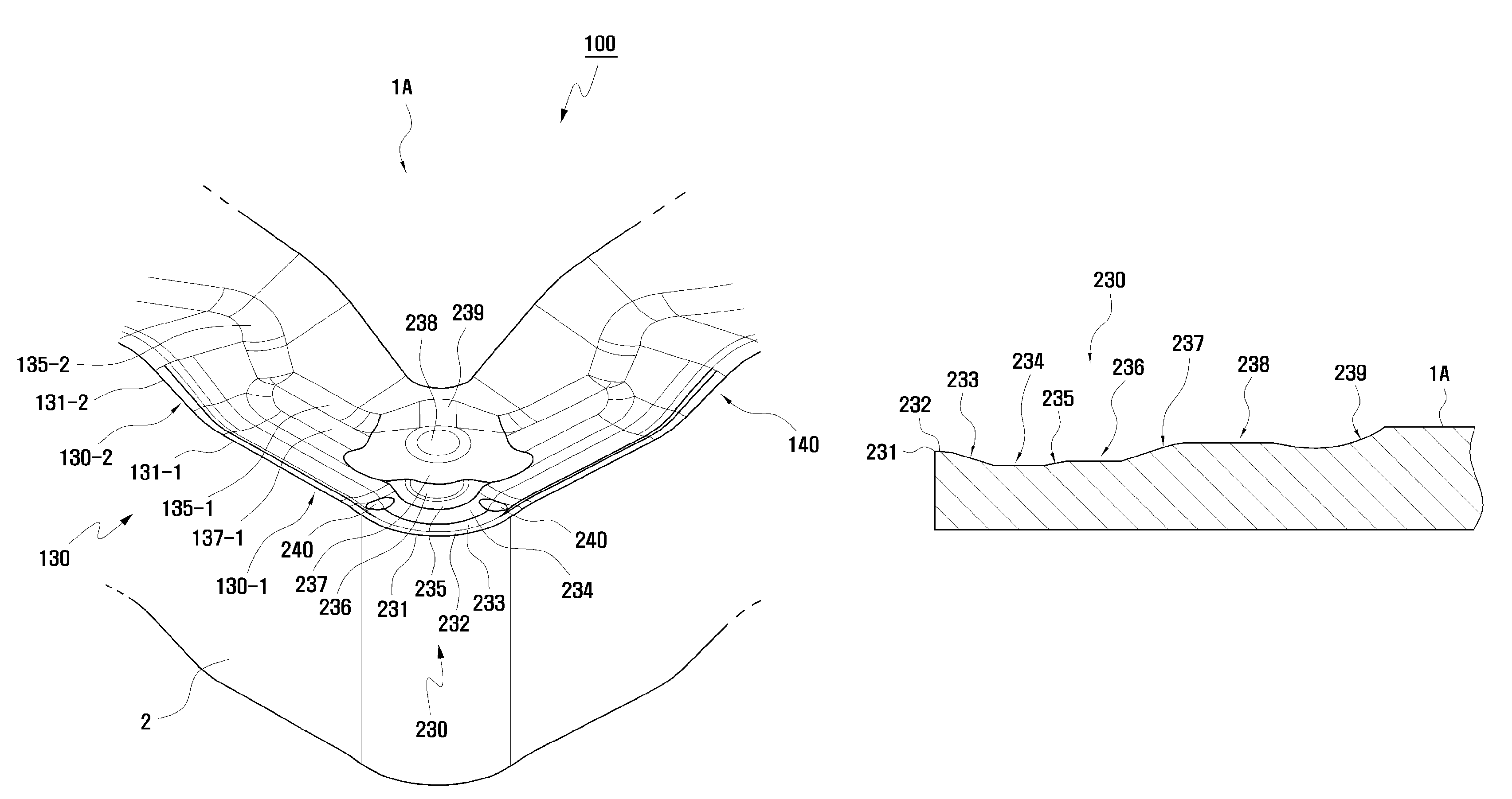

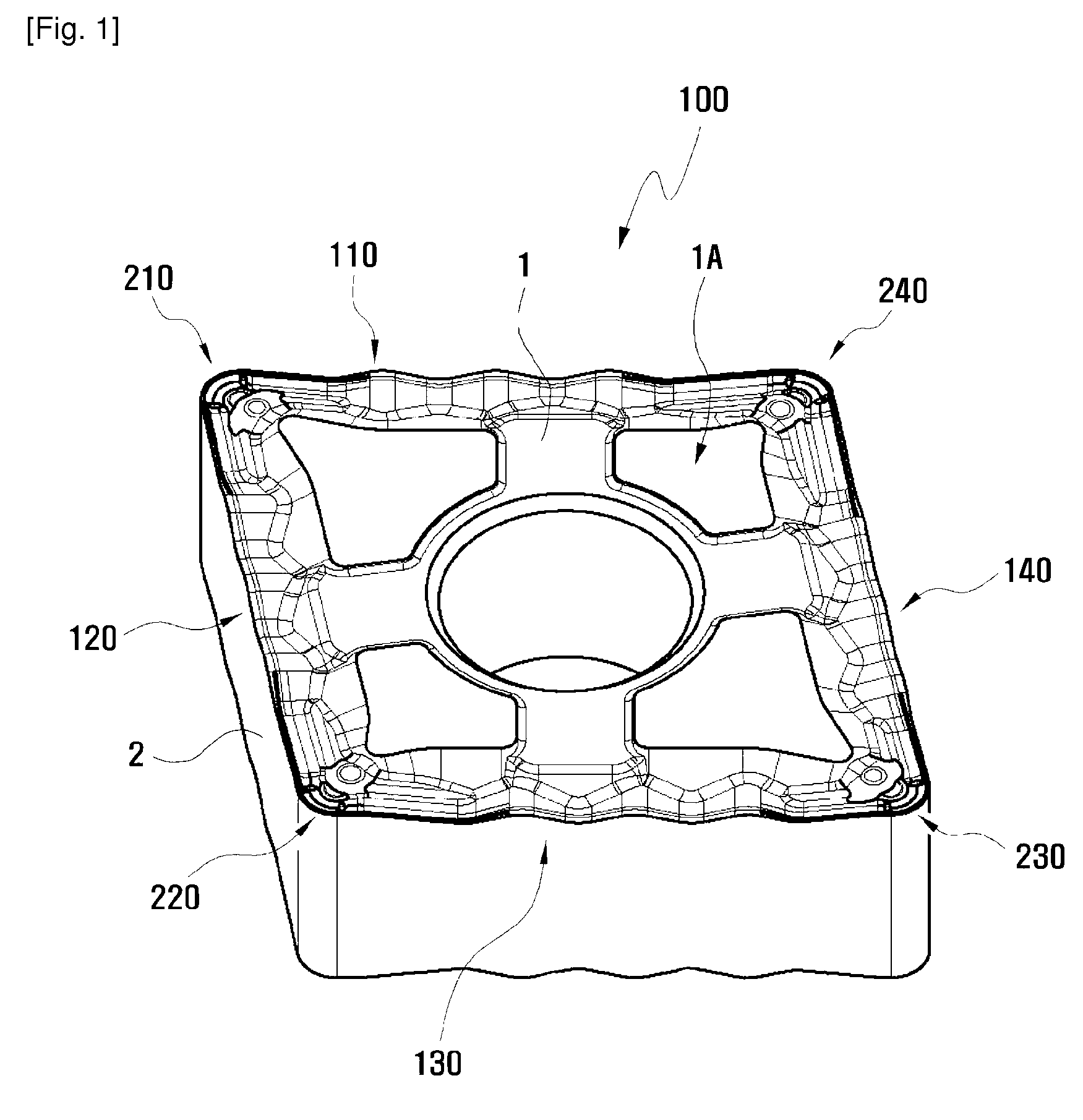

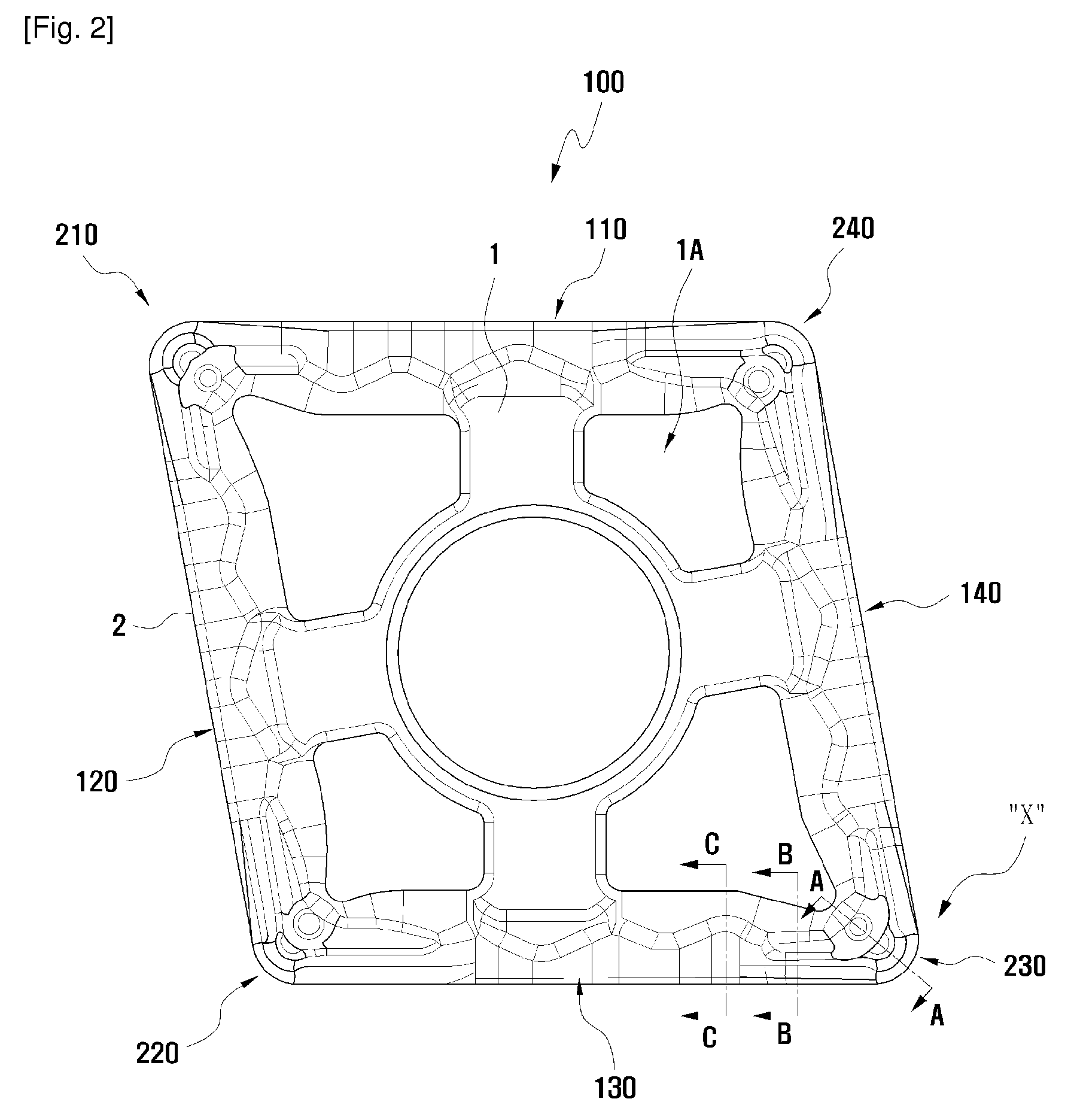

Cutting insert having a corner recess

A cutting insert for a machining tool has a structure capable of effectively controlling chips generated on a work-piece. The cutting insert includes an upper surface, a lower surface, a plurality of side surfaces connecting the upper surface and the lower surface and a central hole formed at a central portion thereof. In the cutting insert, a seating surface is formed on a highest portion of the upper surface, a plurality of side cutting edge portions are formed at border portions of the upper surface and the side surfaces. Each side cutting edge portion has a side cutting edge formed at an upper end thereof and a corner cutting edge portion is formed at an intersection of two adjacent side cutting edge portions. The corner cutting edge portion has a cutting edge formed at a front end thereof, a land portion, a downward inclined surface, a corner bottom surface, a first upward inclined surface, a first protrusion, a second upward inclined surface, a second protrusion, an upward grooved surface and the seating surface sequentially formed along a diagonal line directed from the corner cutting edge toward the central hole. The corner bottom surface has the smallest height along the diagonal line.

Owner:TAEGUTEC

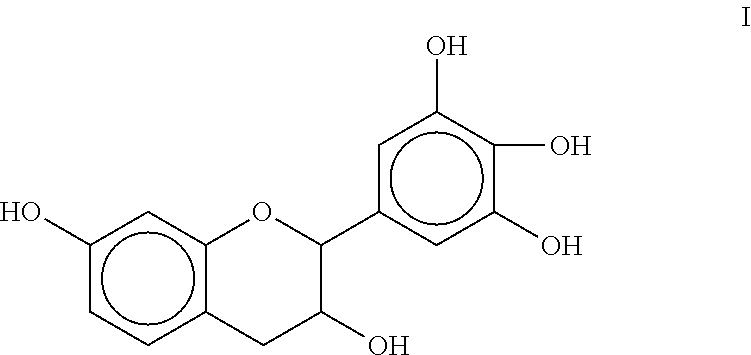

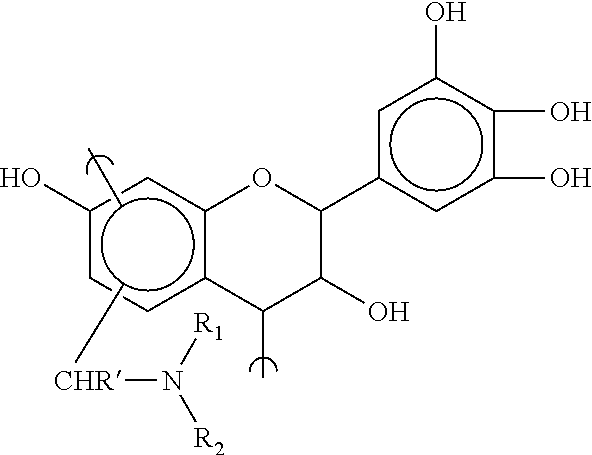

Methods of removing microbes from surfaces

InactiveUS20130266669A1Reduce feed rateImprove compatibilityBiocideSpecific water treatment objectivesEnvironmental profileTannin

A method has been found for the inhibition of microbial biofilm on surfaces in contact with systems, such as aqueous systems. In accordance with the method, an effective amount of a modified tannin biofilm control agent is fed to the system water. The modified tannin biofilm control agent comprises a reaction product of an amine, an aldehyde and tannin and provides a good environmental profile.

Owner:GENERAL ELECTRIC CO

Tire inflation system

InactiveUS7963307B2Quick and reliable operationImprove overall utilizationTyre measurementsTyre-inflating valvesHigh pressureVehicle control

A tire inflation system comprising pneumatically controlled wheel valves that are situated in the wheels of a motor vehicle. An electrically actuated pilot valve that is fixed to the vehicle controls the respective wheel valves. To produce a small, low-cost, reliable tire inflation system, a first and a second compressor are provided. The first compressor supplies a first compressed air system with medium-pressure compressed air and the second compressor supplies a second compressed air system with high-pressure compressed air. The wheel valves are situated in the first compressed air system and the pilot valves are situated in the second compressed air system.

Owner:MAGNA STEYR FAHRZEUGTECHN

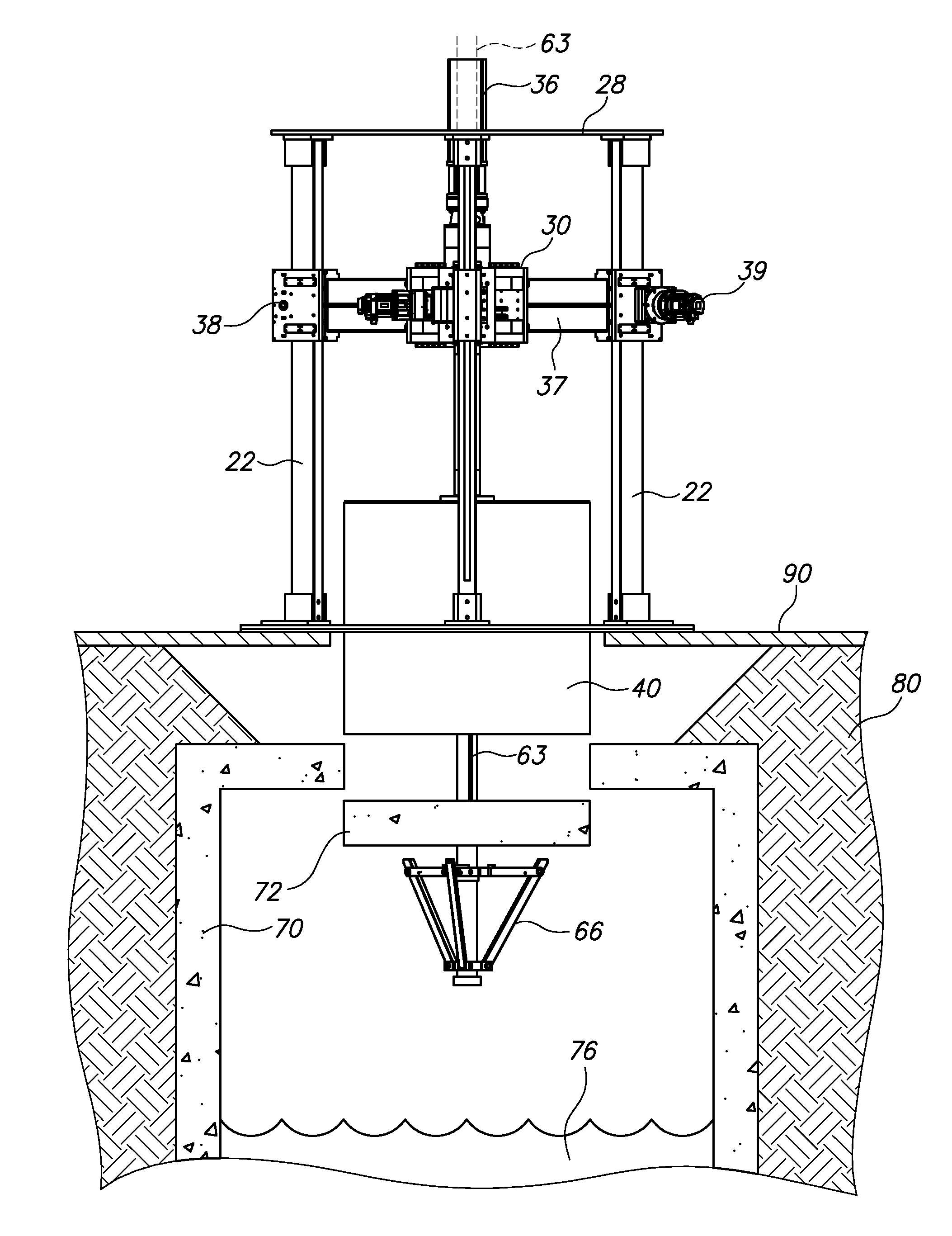

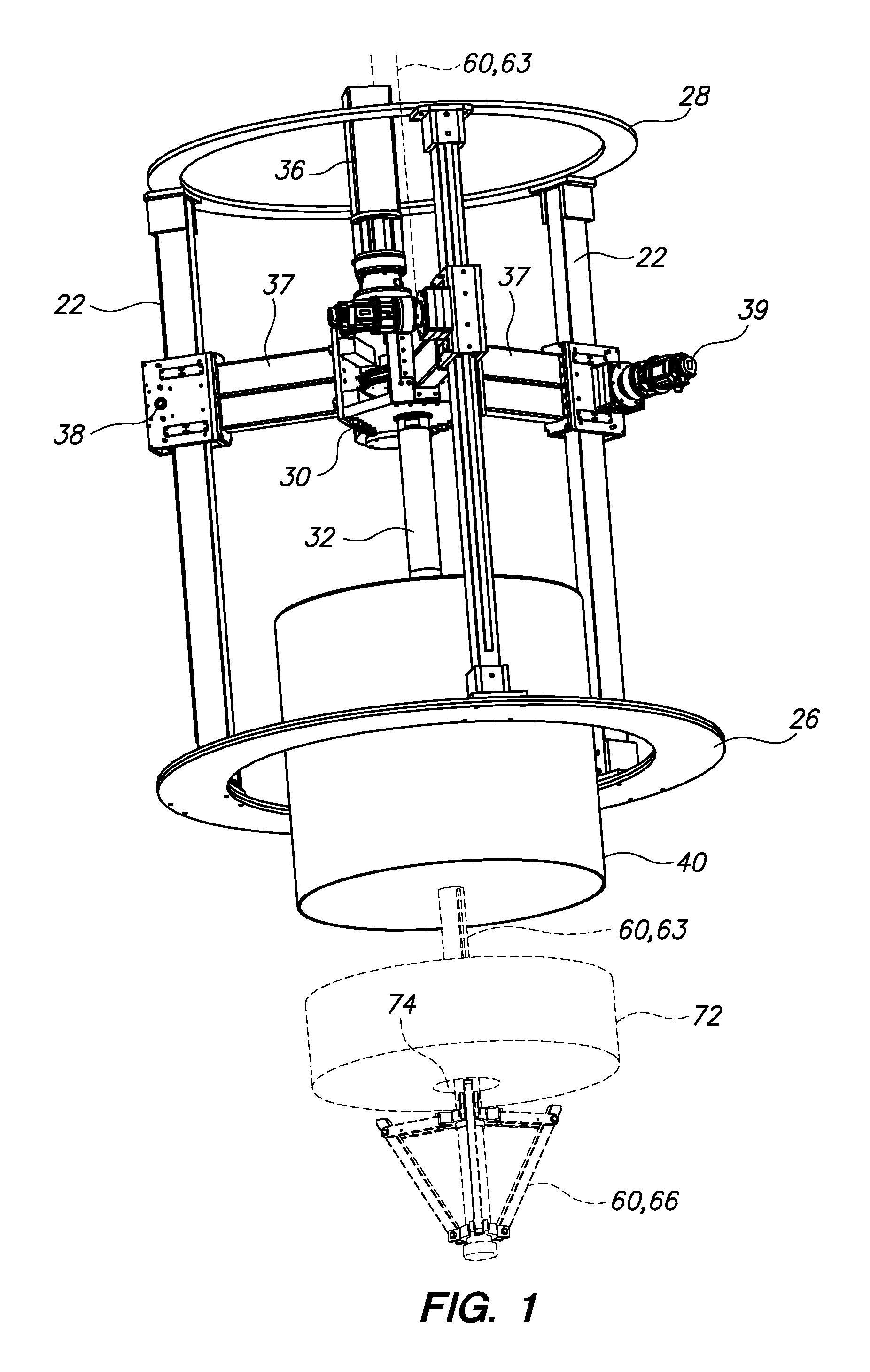

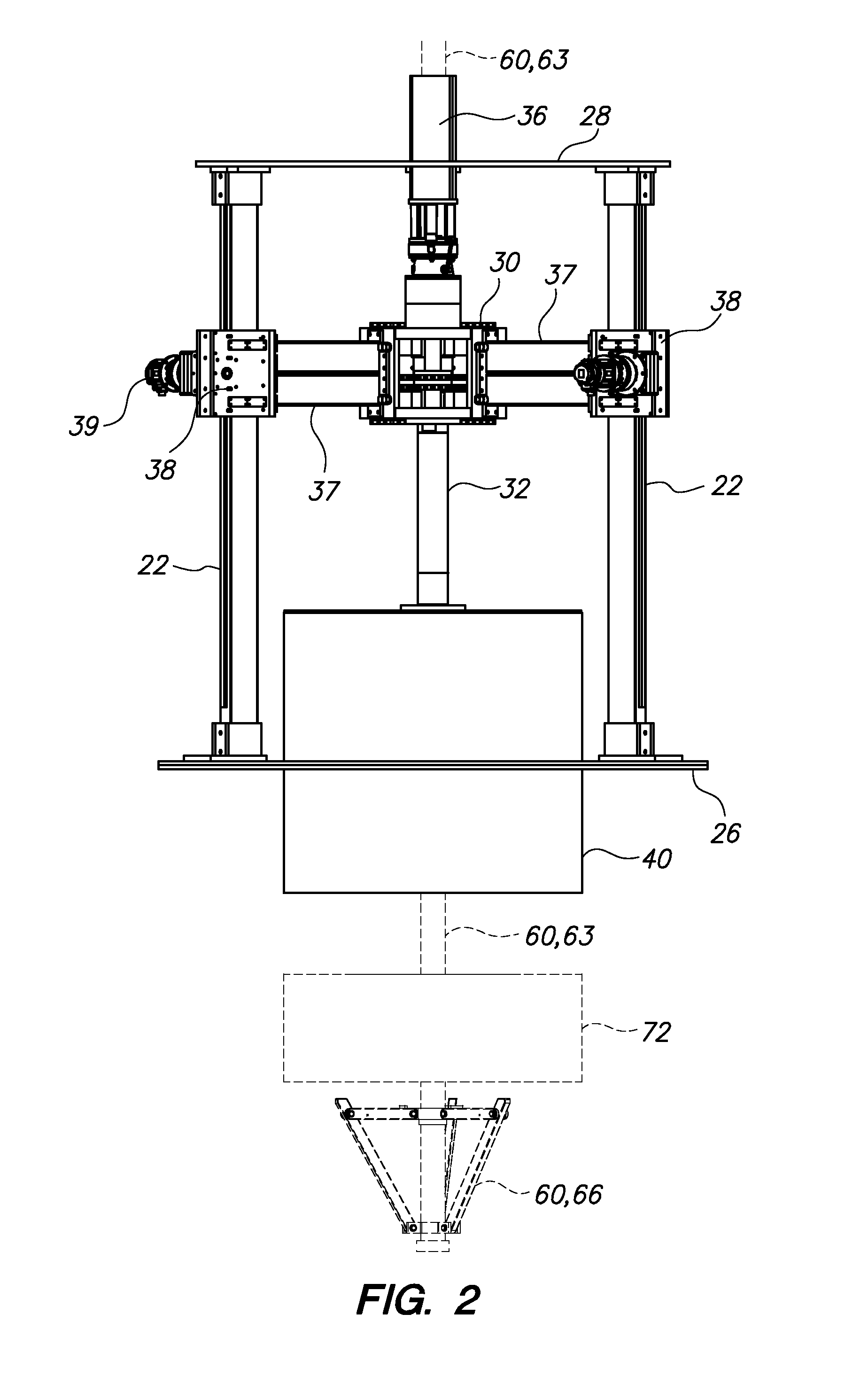

Automated core drilling device capable of mating with a center-mounted core-catching device

ActiveUS20140334891A1Lower resistanceIncrease pressureDrilling/boring measurement devicesThread cutting machinesRotational axisPower flow

An automated core drilling device comprising a rigid drilling tower, a floating chuck assembly, and a drill bit. Rigid drilling tower comprising at least three vertical column members, a lower perimeter frame, and an upper perimeter frame. Floating chuck assembly comprising a drill bit axis-of-rotation vertical clearance channel, at least three horizontal support arms, at least three feed motor platforms, at least three feed motors, a hub casing, a hollow-centered bit driveshaft, a bit driveshaft sprocket, an offset spindle driveshaft sprocket, an offset spindle driveshaft, and an offset spindle motor. An automated core drilling device further comprising a computer with custom software, a monitor point for the electric current draw of said offset spindle motor or a monitor point for the revolution rate of said offset spindle driveshaft, and a control point for the electric current draw of each of said at least three feed motors.

Owner:SANDLER GREG

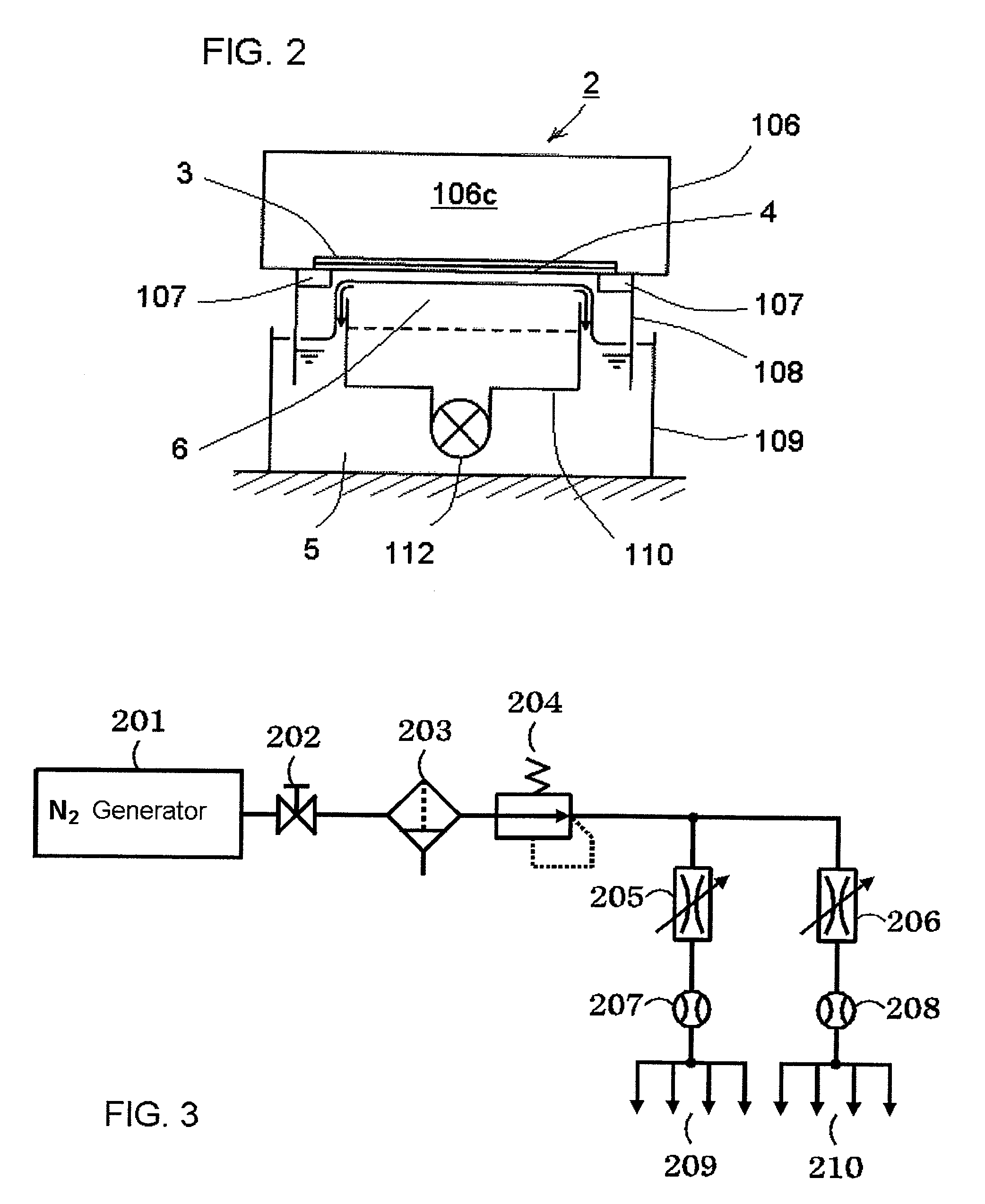

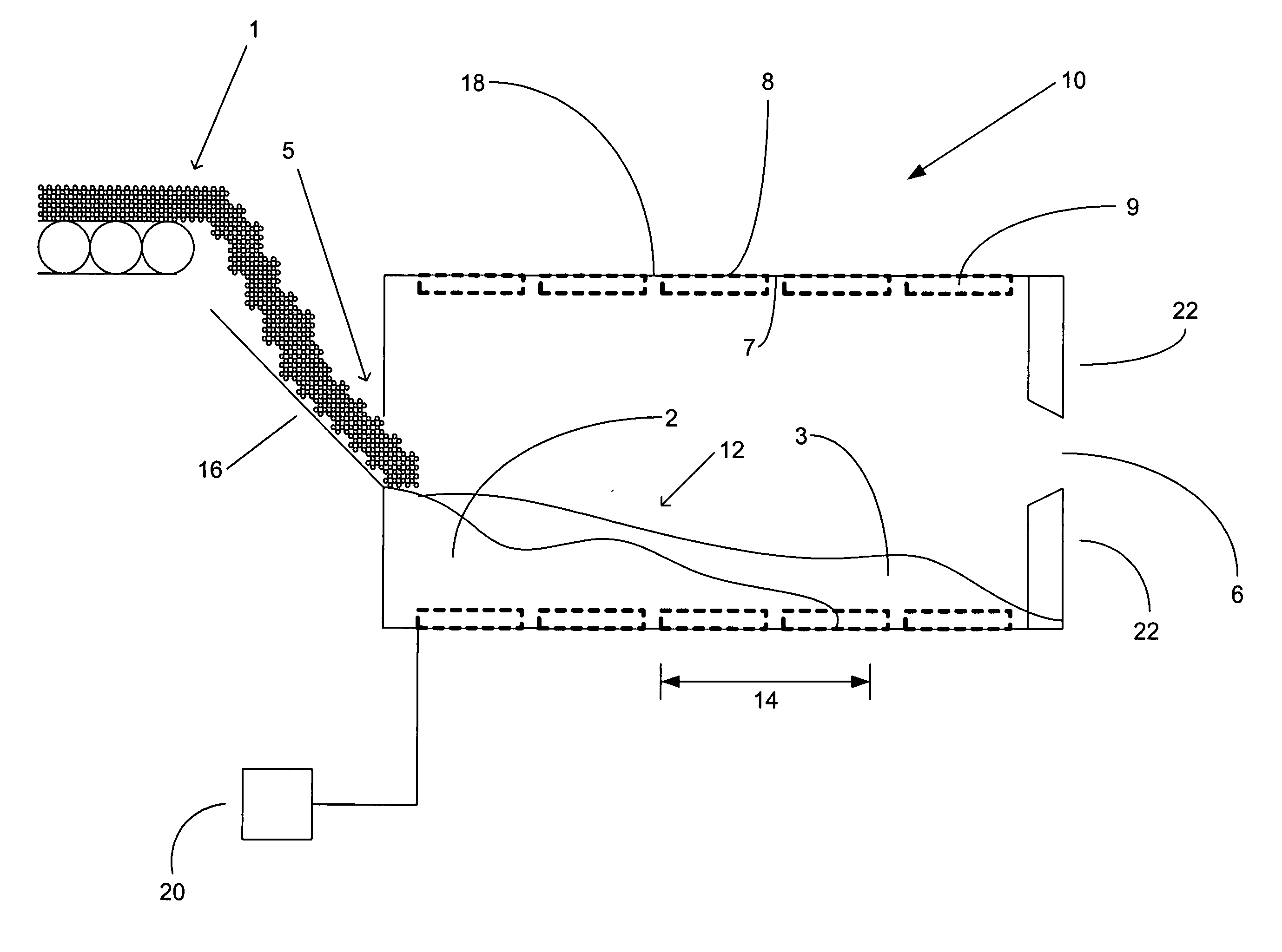

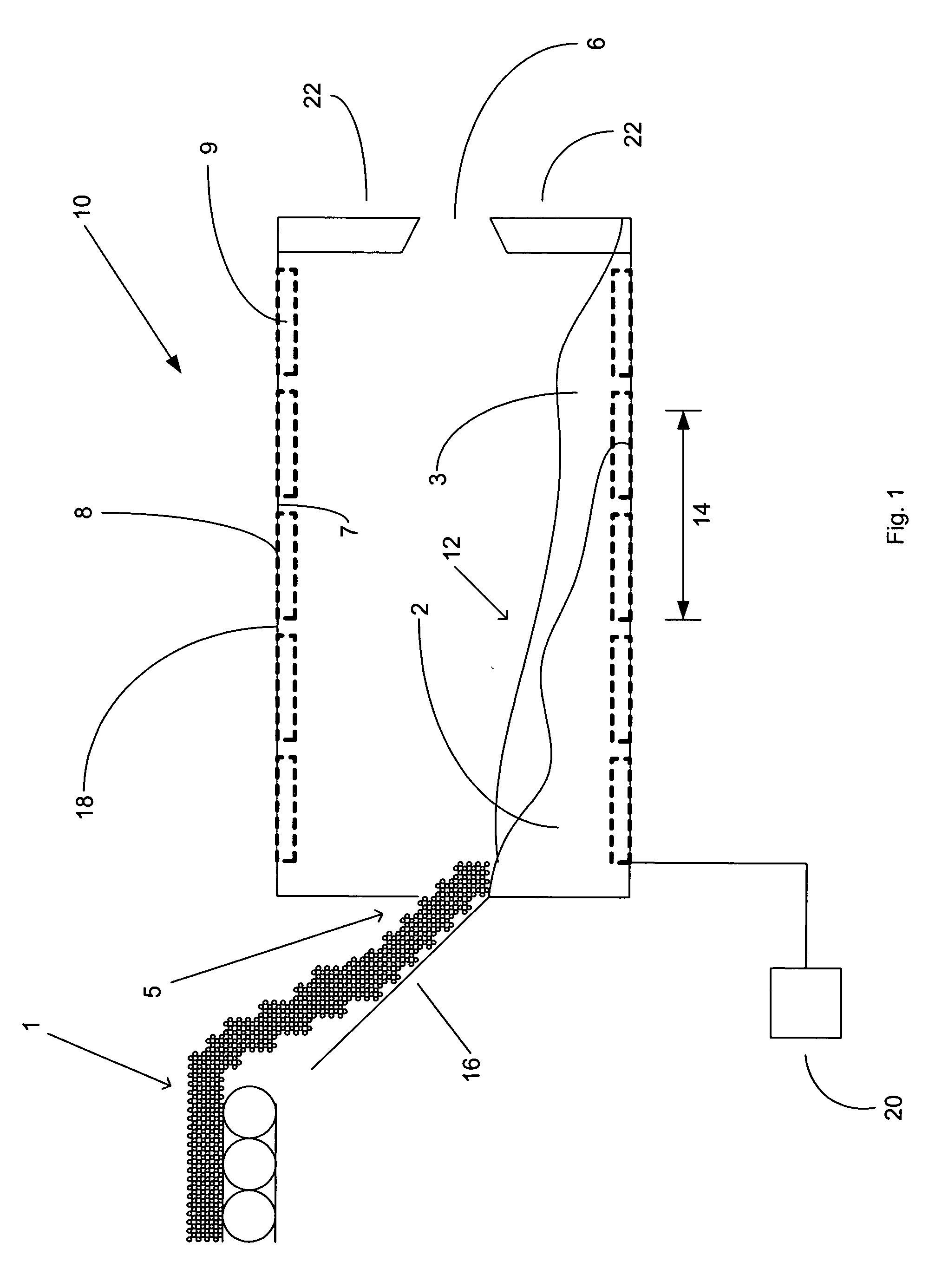

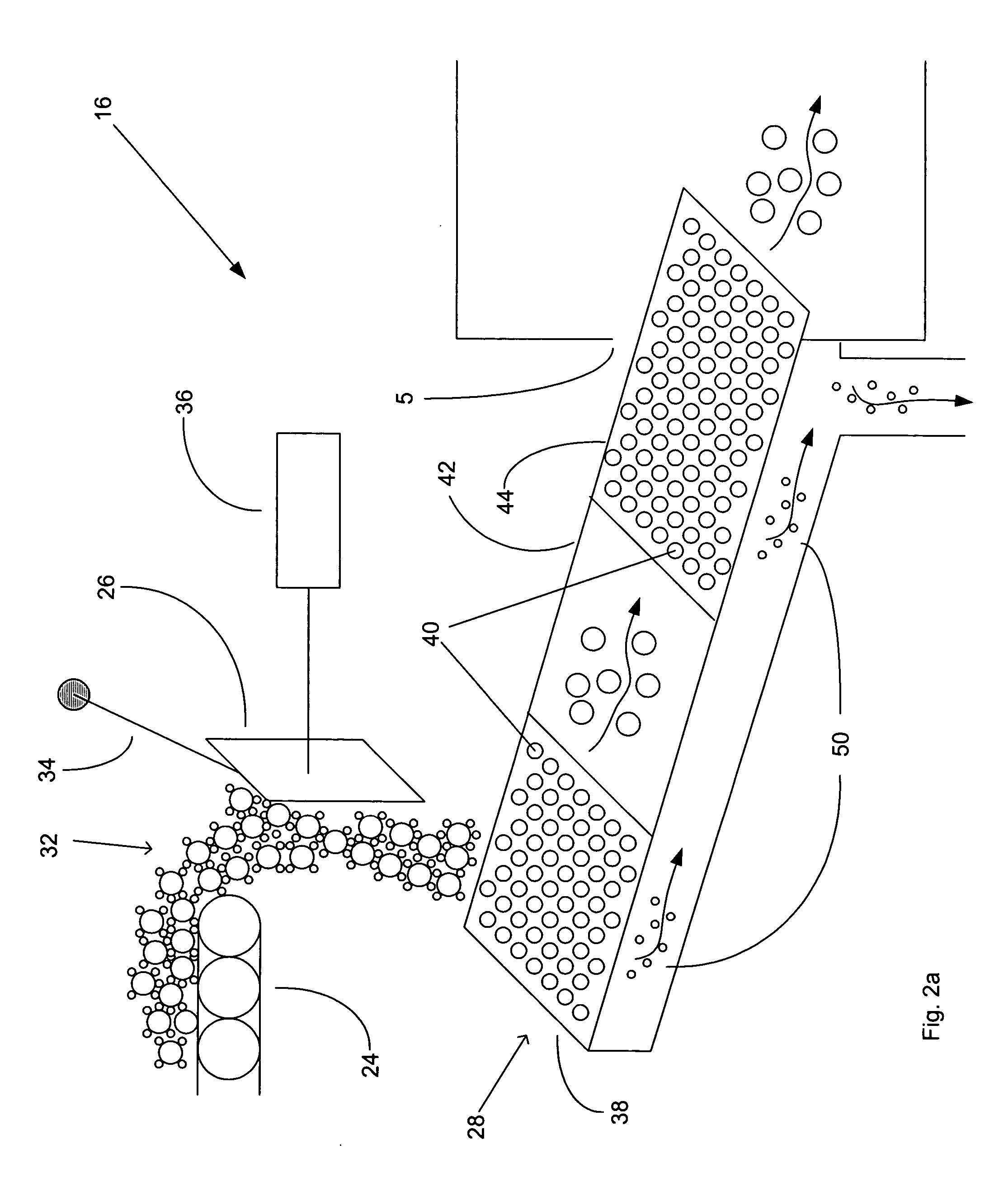

Apparatus and method for soldering flat work piece

ActiveUS20100264197A1Reduce feed rateReduce consumptionWelding/cutting auxillary devicesFeeding apparatusEngineeringActuator

A soldering apparatus including a vessel containing a molten solder, a casing defining therewithin a soldering chamber in which a flat overflowing wave of the molten solder is formed, a conveyor physically integrated with the casing for movement therewith and operable for transferring a printed circuit board through the soldering chamber, actuators and for vertically moving the casing, inert gas feeders for feeding an inert gas to the soldering chamber, and a controller for controlling the operation of the actuators and, so that the printed circuit board is contacted with the surface of the flat overflowing wave in an atmosphere of the inert gas during its passage through the soldering chamber.

Owner:FUJITSU GENERAL LTD +1

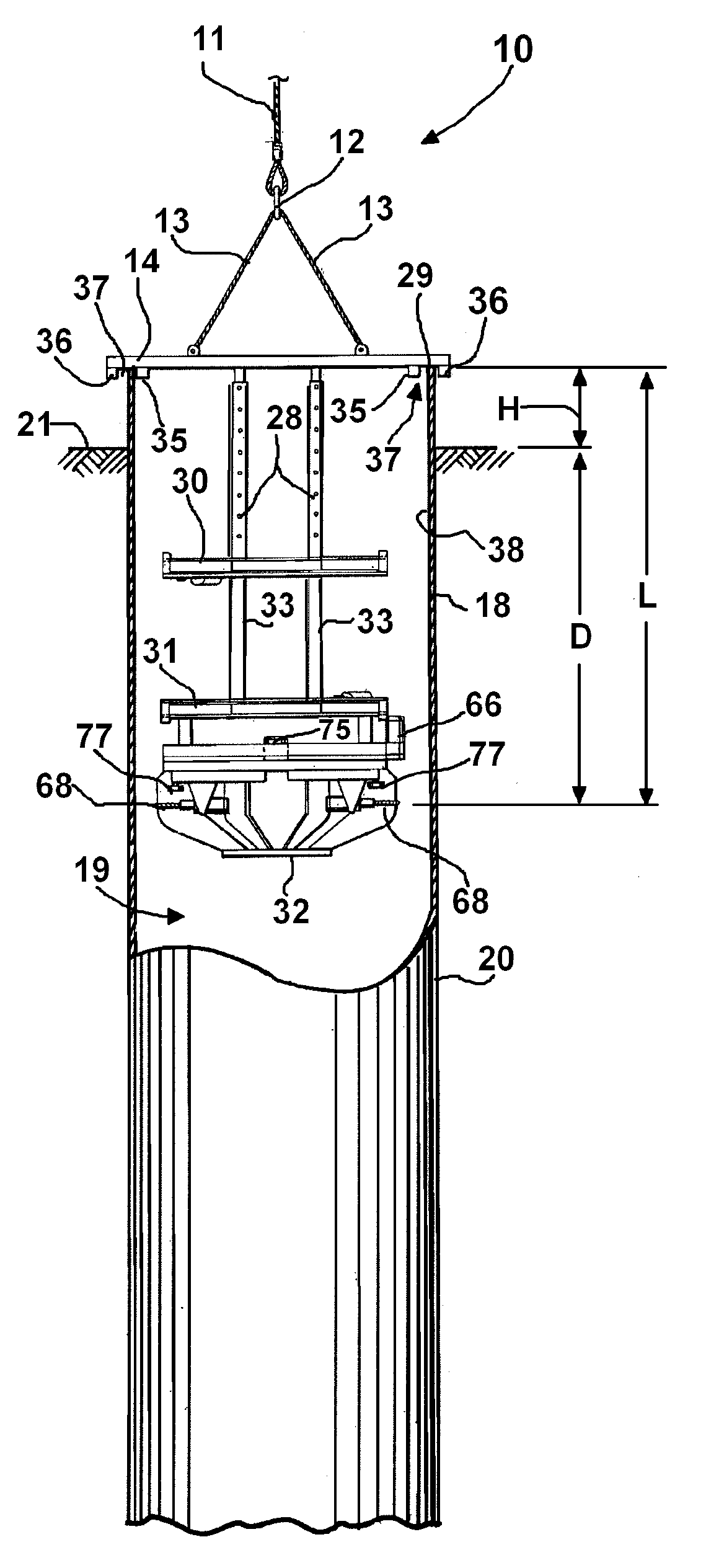

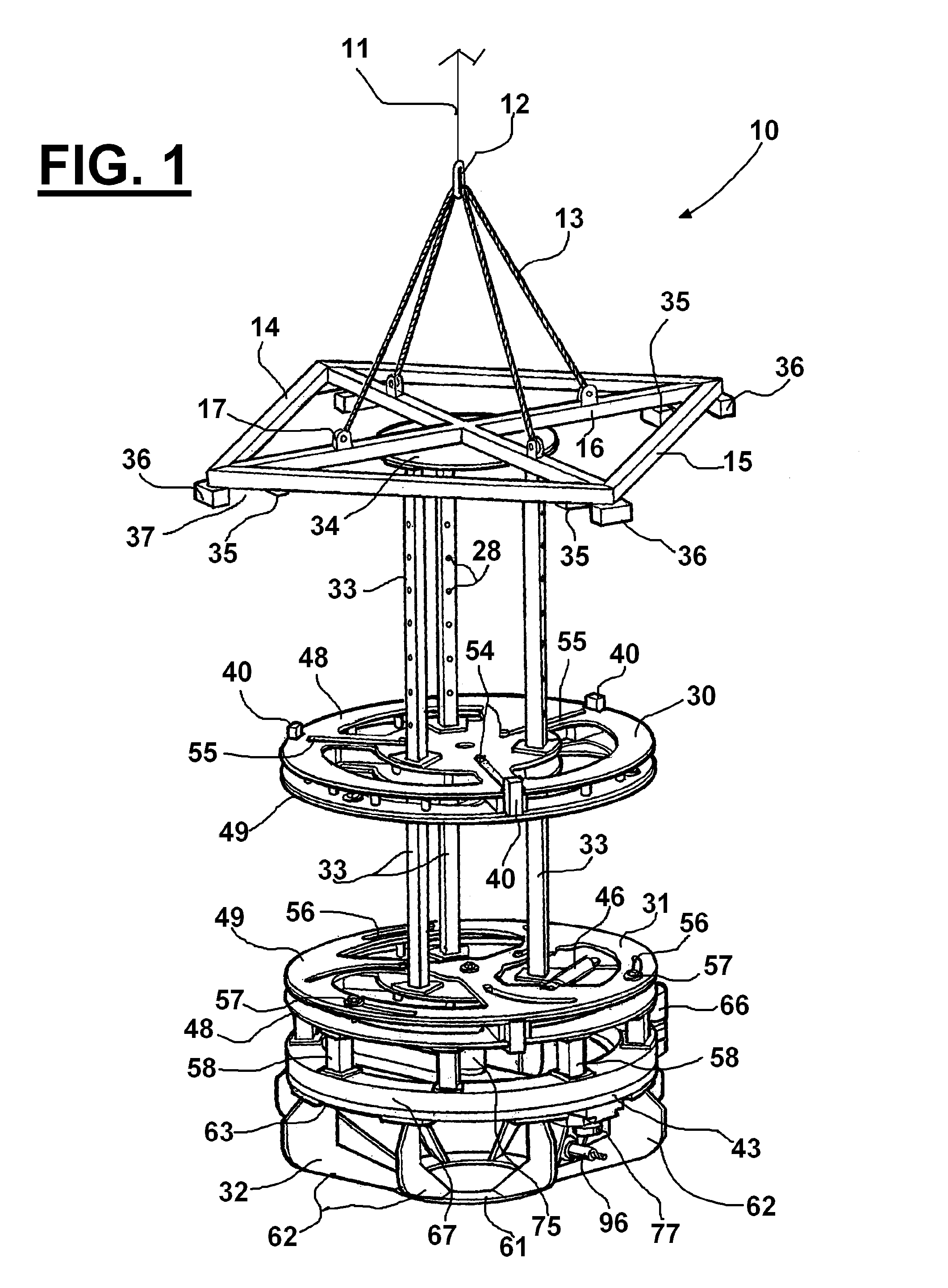

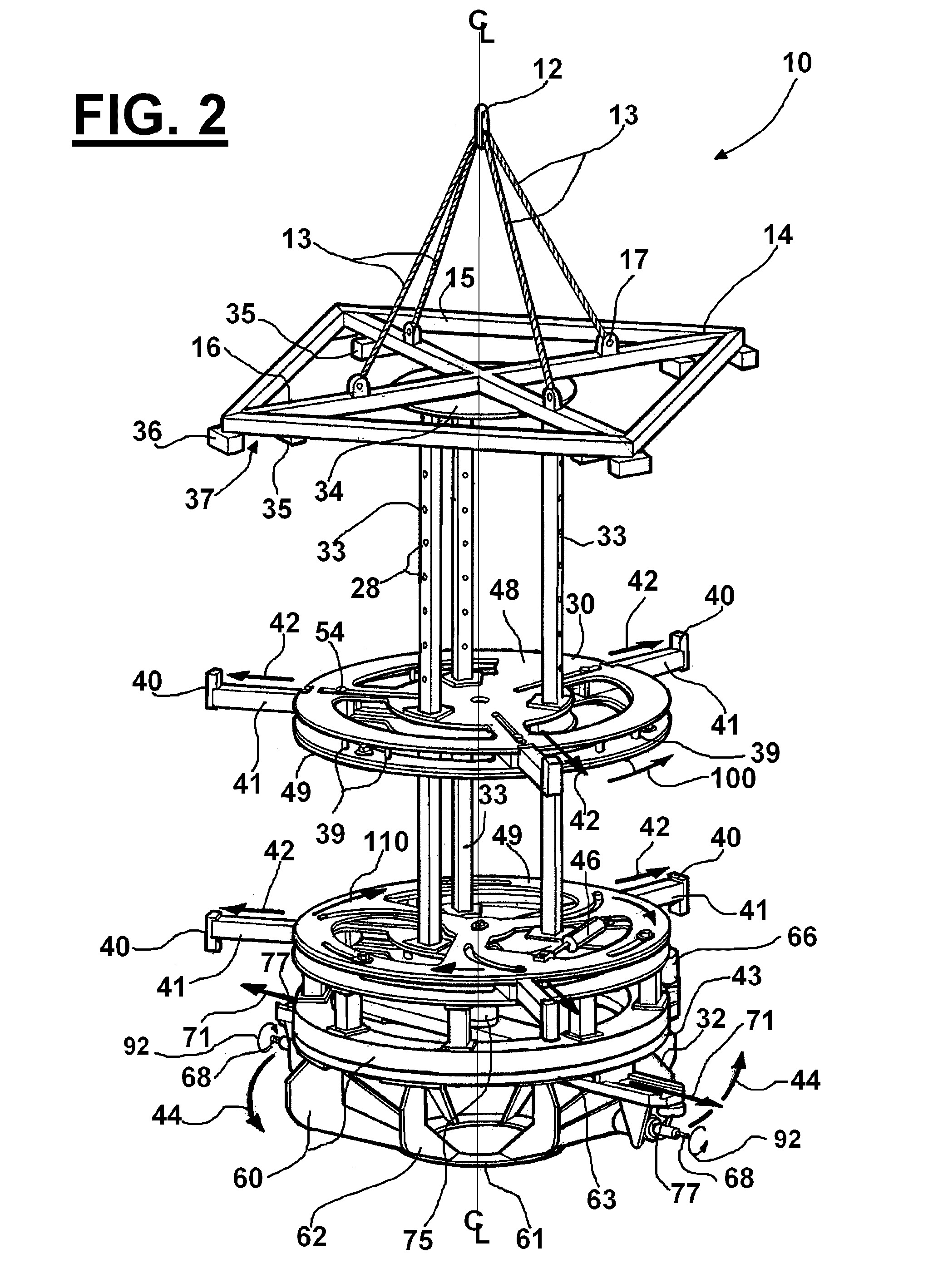

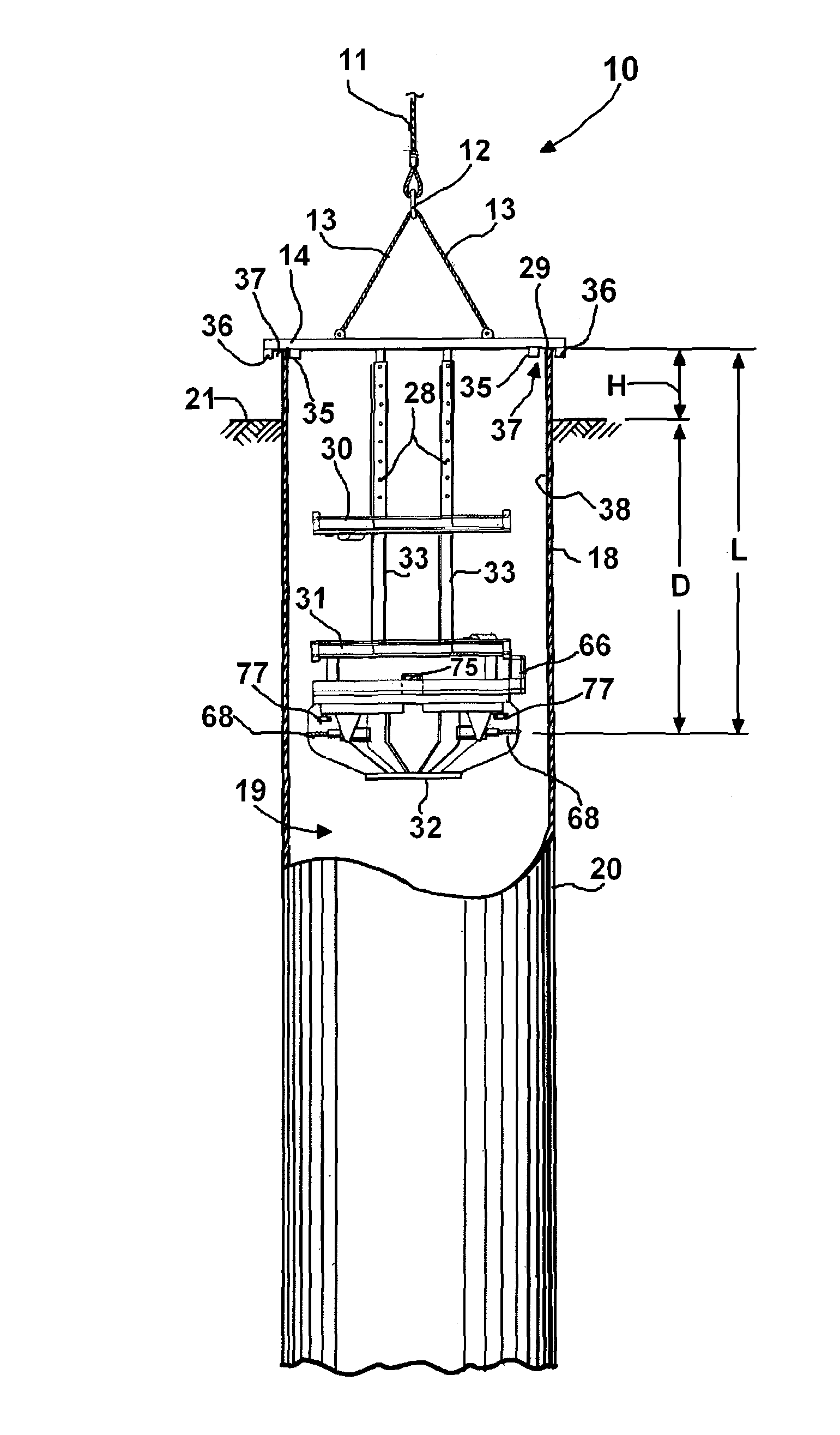

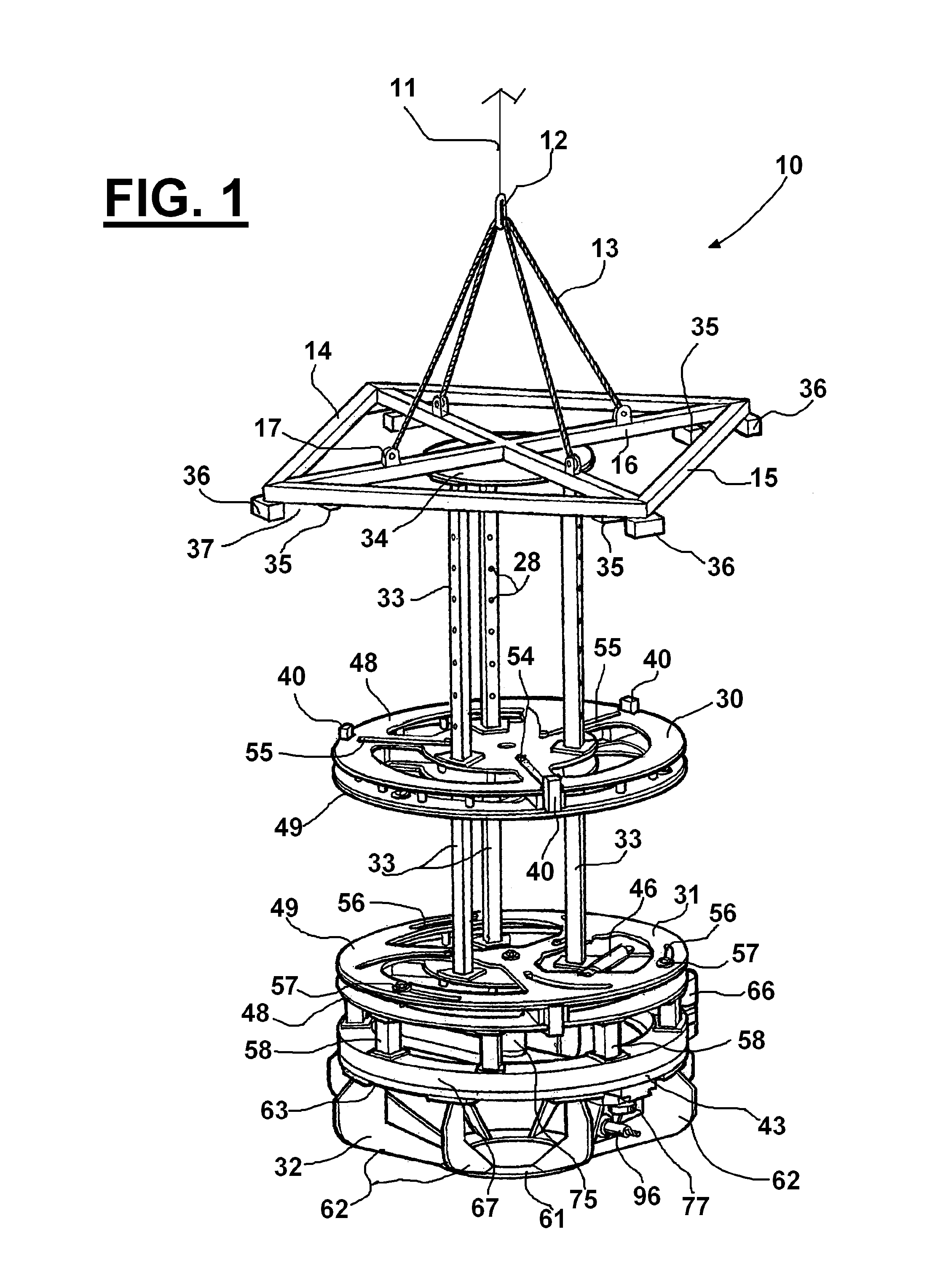

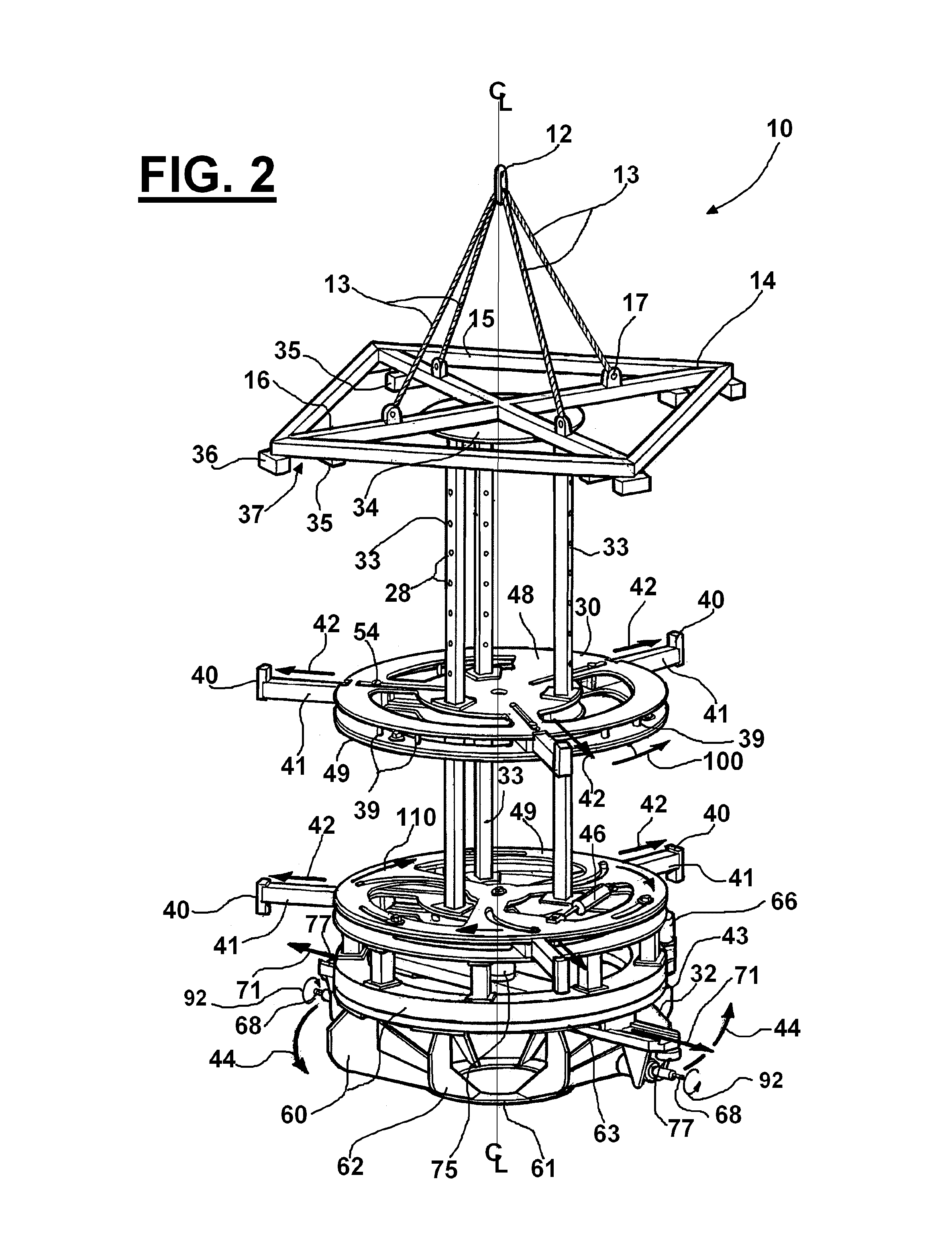

Internal jacket leg cutter and method

ActiveUS20110290091A1Increase feed rateReduce feed rateTube shearing machinesMetal working apparatusMechanical engineeringEngineering

An internal caisson / jacket leg cutter and method provides a frame having upper and lower end portions. The upper end portion has rigging that enables the frame to be lifted. Extensible arms are movably supported upon the frame. The arms extend and retract along generally radially extending lines. Extension of the arms enables them to contact the inside surface of a caisson / jacket leg and thus center and anchor the frame within the caisson / jacket leg interior. A cutting mechanism at the lower end portion of the frame includes one or more rotary cutters or milling devices that cut the caisson / jacket leg wall as these cutters traverse an arc shaped path, tracking the caisson / jacket leg wall.

Owner:AES EOT EQUIP HLDG LLC

Endodontic files having variable helical angle flutes

ActiveUS20070207438A1Reduce feed rateSmall surface areaTeeth cappingTeeth nerve/root treatment implementsFluteRotational axis

A rotatable endodontic file for cleaning / shaping a tooth root canal, comprising an elongated shaft having a proximal end portion, a distal end and a tapered working portion having a rotational axis, the working portion extending from the proximal portion to the distal end, the external surface of the shaft working portion having a plurality of at least two spiraled, spaced apart continuous helical flutes, the flutes having therebetween an equal number of spiraled, spaced apart flanges, each flange having in a plane perpendicular the rotational axis an outer end surface forming a continuous spiraled scraping / cutting edge extending the length of the shaft working portion, the flutes having helical angles relative to the rotational axis of between 10° and 30° and wherein the helical angles vary at selected longitudinal locations.

Owner:DENTSPLY SIRONA INC

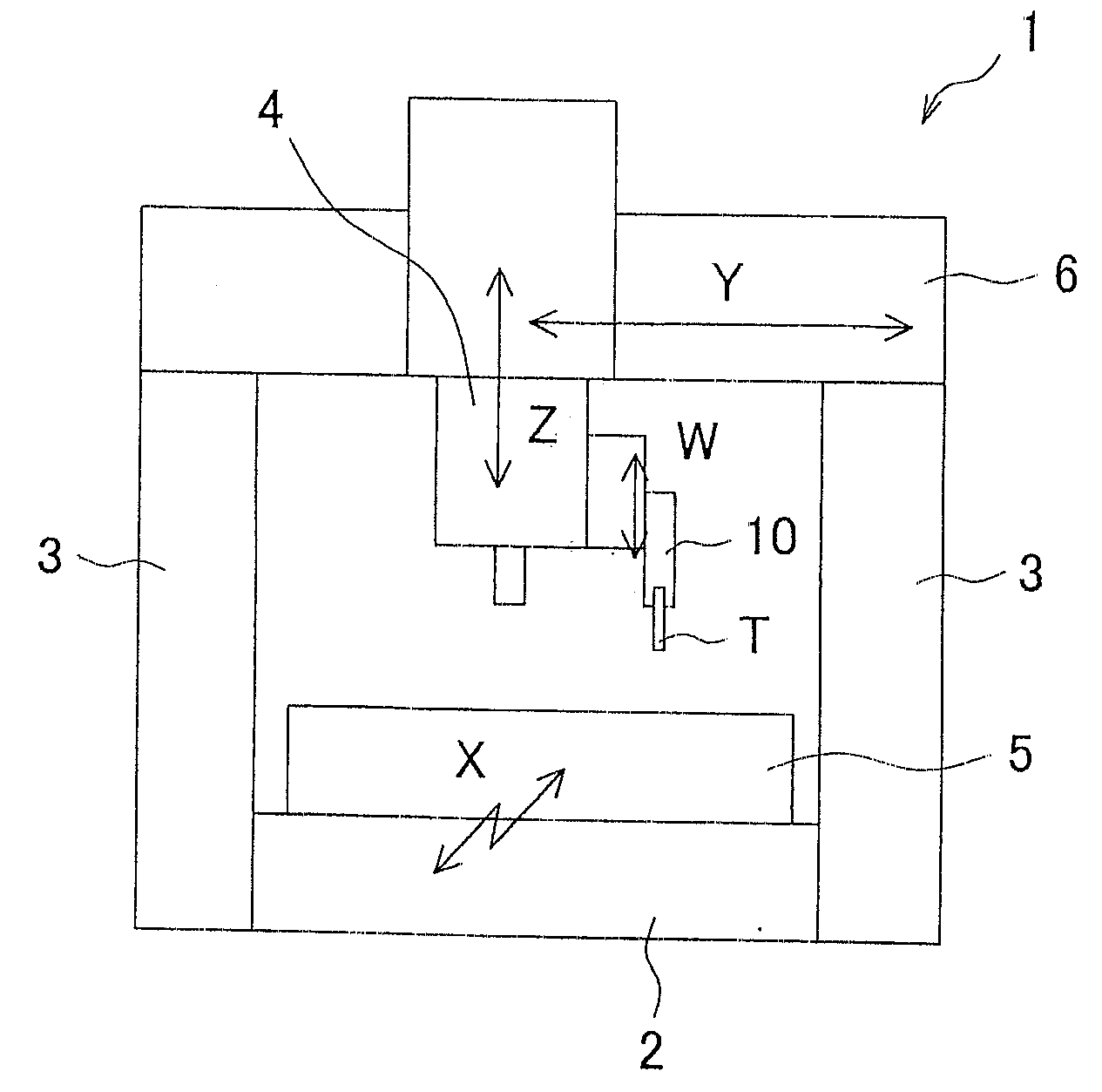

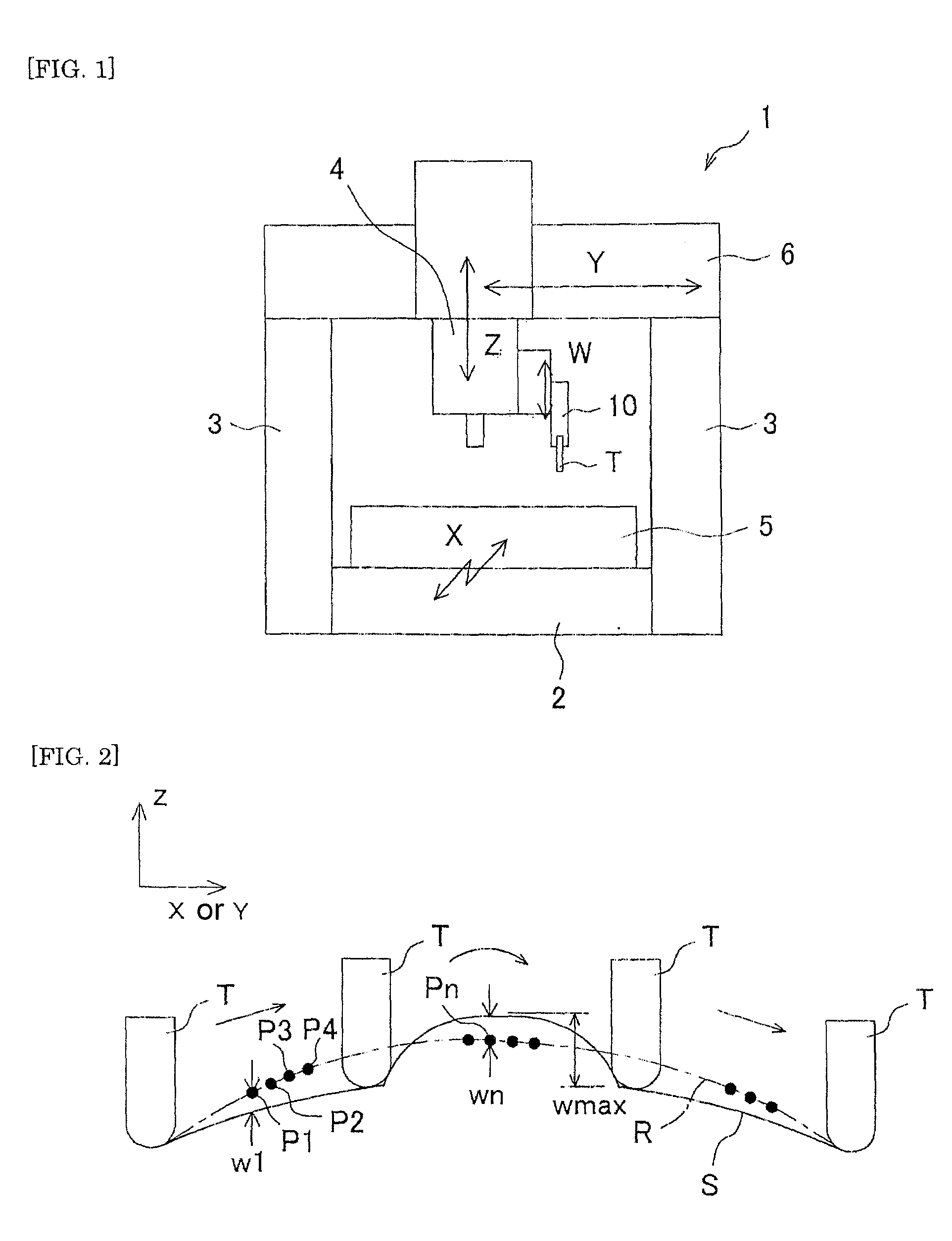

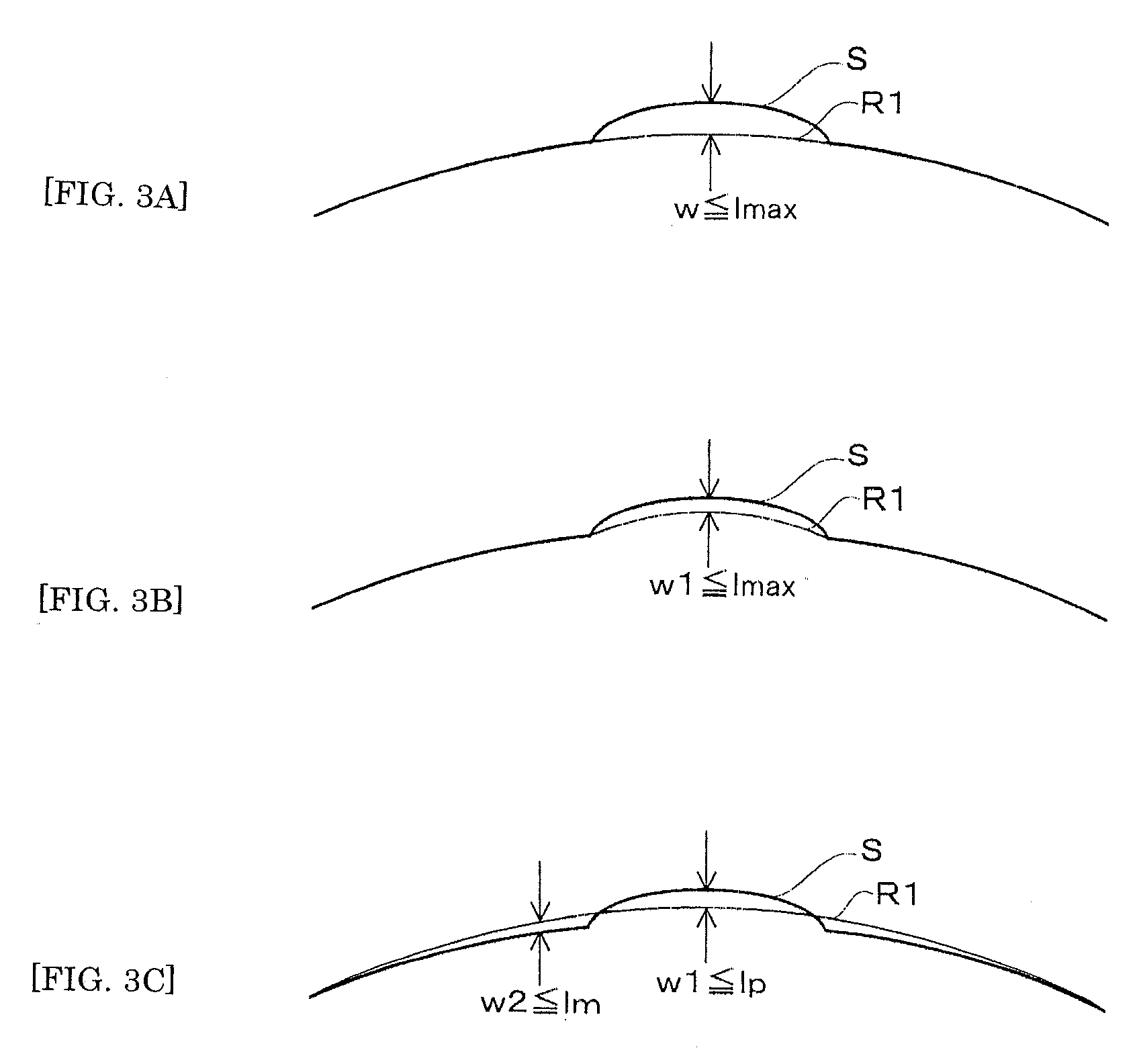

Machining control method and machining information generating method for machine tool

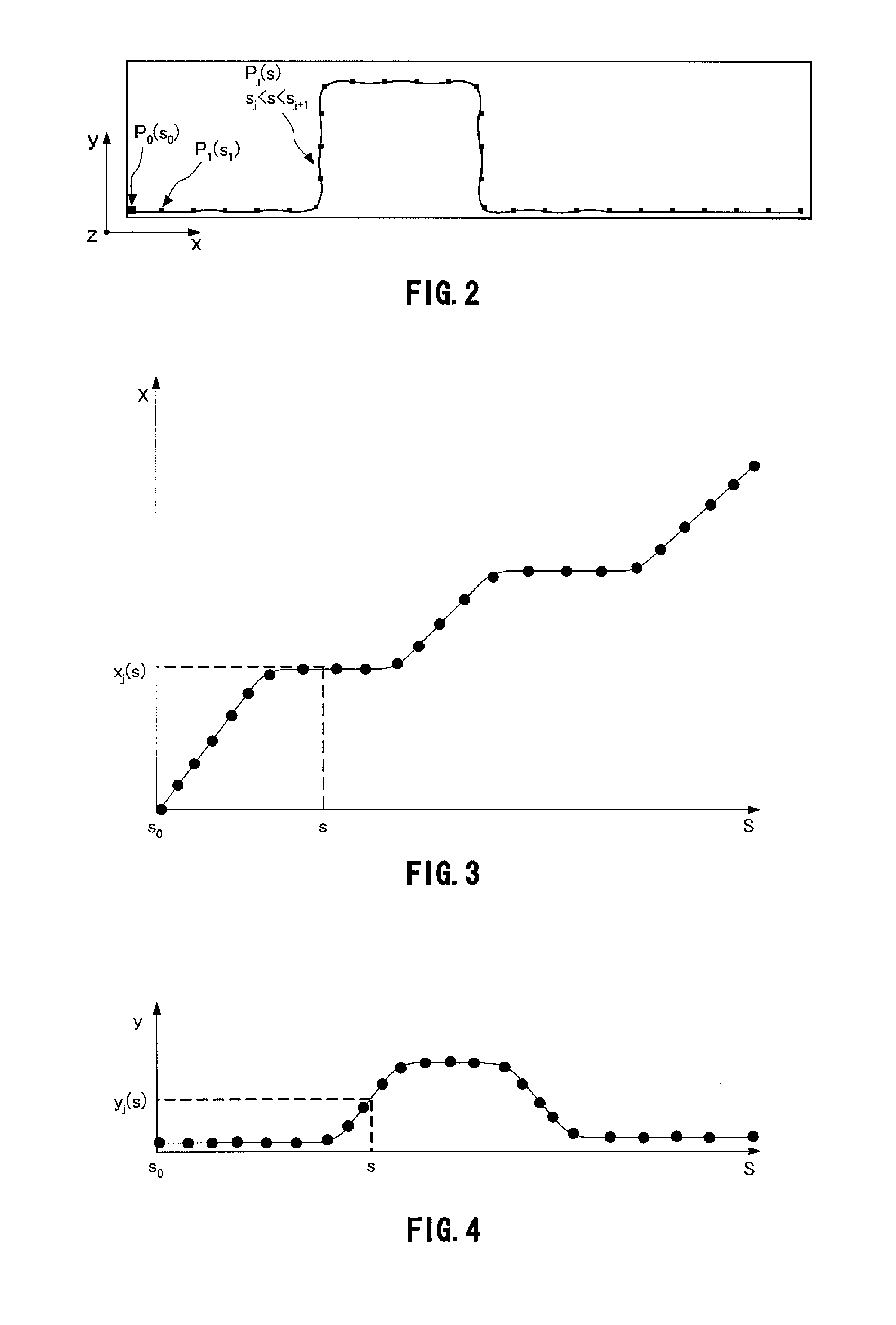

InactiveUS20080082202A1Machining accuracy and machining efficiencyReduce feed rateProgramme controlComputer controlMachine controlEngineering

To provide a method to carry out complicated surface machining such as graining or the like without decreasing machining accuracy and machining efficiency. In a machine tool including a main spindle head capable of relatively moving in three perpendicular directions with respect to a workpiece and an additional spindle being provided at the main spindle head and capable of moving in a Z spindle direction, while the main spindle head relatively moves with respect to a working surface S of the workpiece along a smoothly curved surface R which is smoothed so as to be restricted within the movement distance in the moving direction of the additional spindle, the additional spindle moves by a difference between the working surface S and the smoothly curved surface R, and makes a tool T to machine the working surface S.

Owner:OKUMA CORP

Centrifugal separator and a liquid phase discharge port member

A centrifugal separator comprises a bowl rotating in use around an axis of rotation. The axis of rotation extends in a longitudinal direction, and a radial direction extends perpendicular to the longitudinal direction. A base plate provided at one longitudinal end of the bowl, said base plate having an internal and external side, an outlet opening being provided in the base plate. A casing is projecting at the outlet opening on the external side of said base plate, said casing comprising a casing side, a normal to said casing side extending at an acute angle relative to a circumferential direction of the bowl at said casing and a discharge opening is provided in said casing side. The discharge opening is radially outwardly limited by a weir with an overflow edge and said discharge opening extending radially inwardly to a position above a highest intended level of liquid in the bowl.

Owner:ALFA LAVAL CORP AB

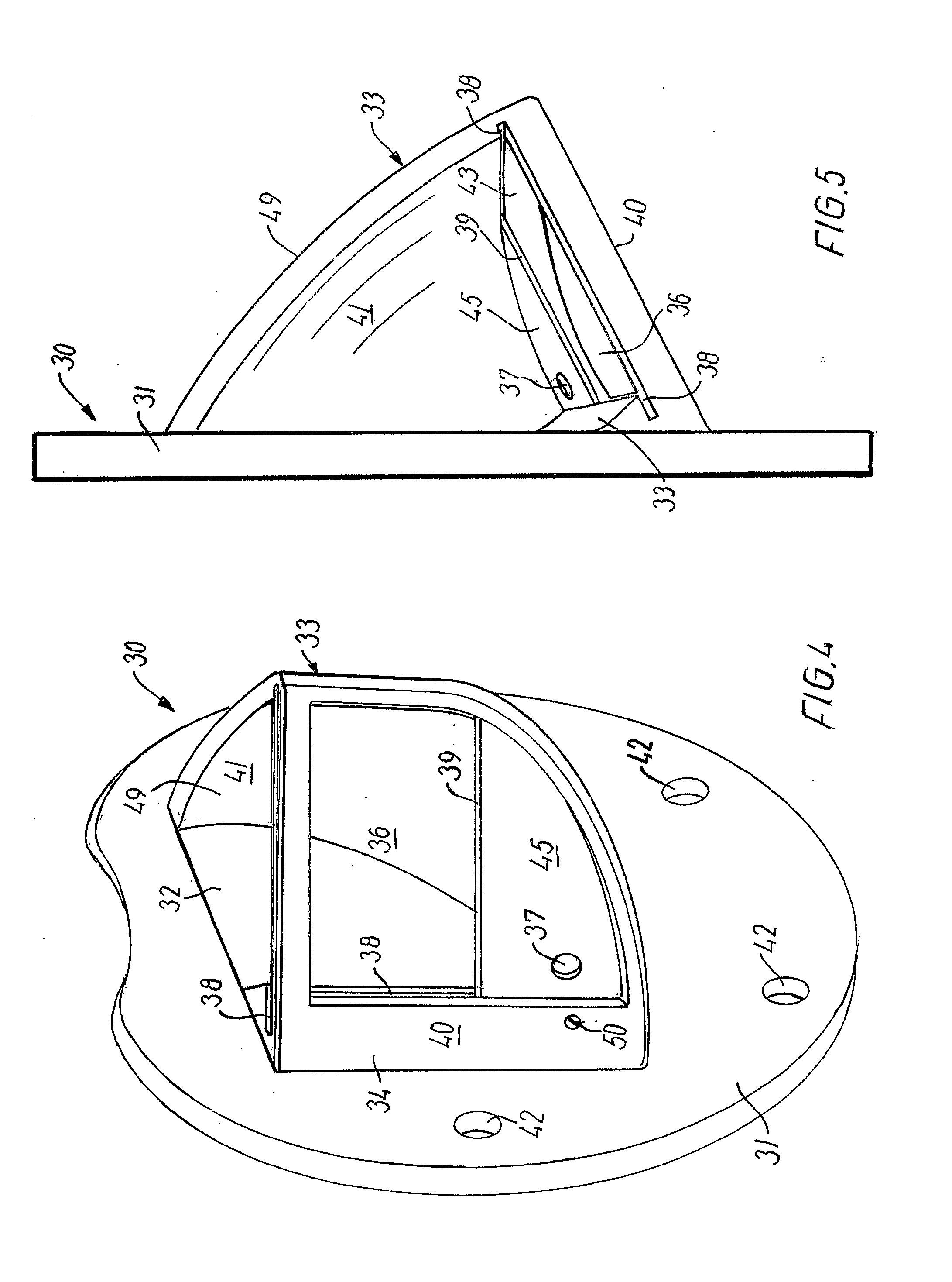

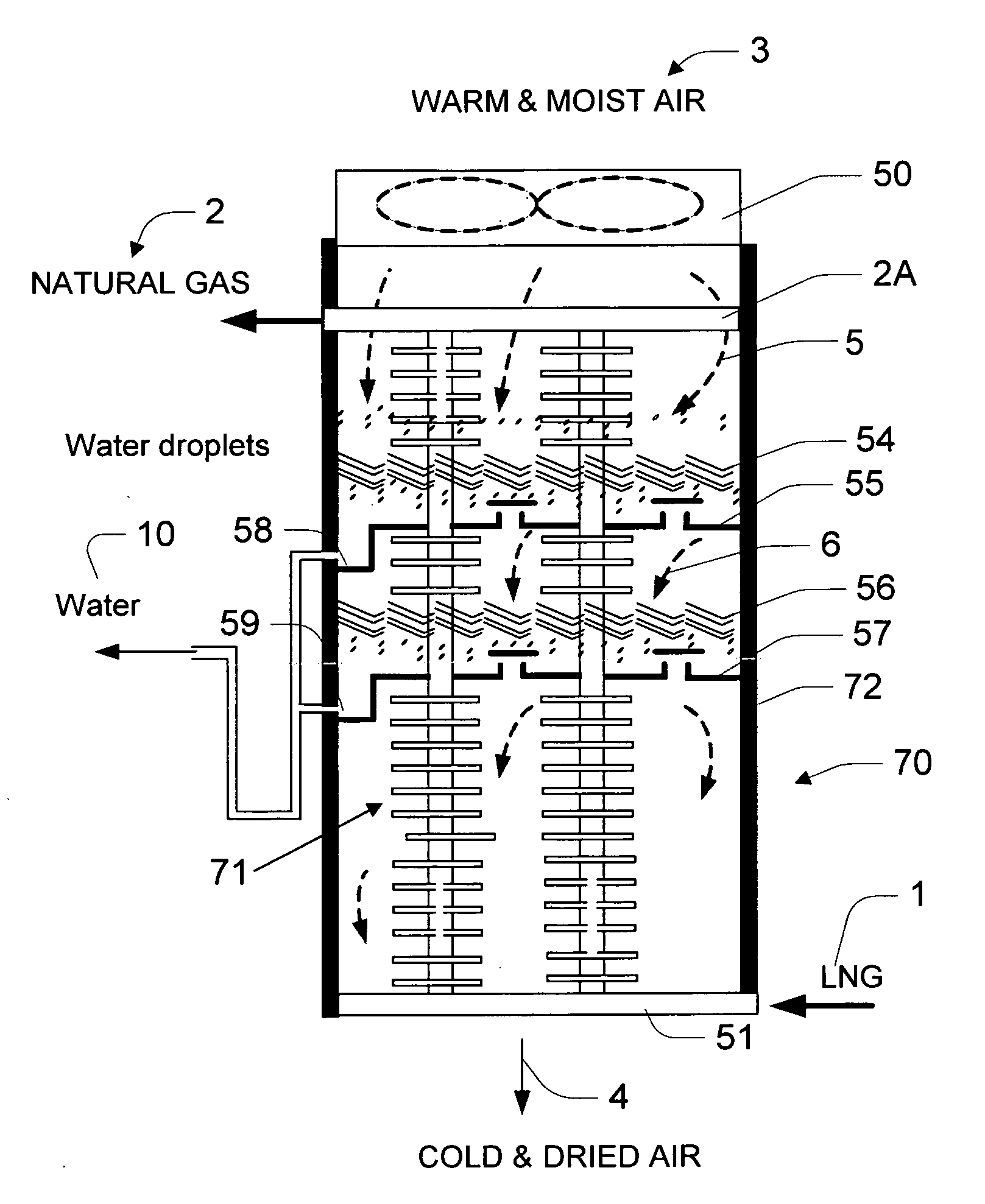

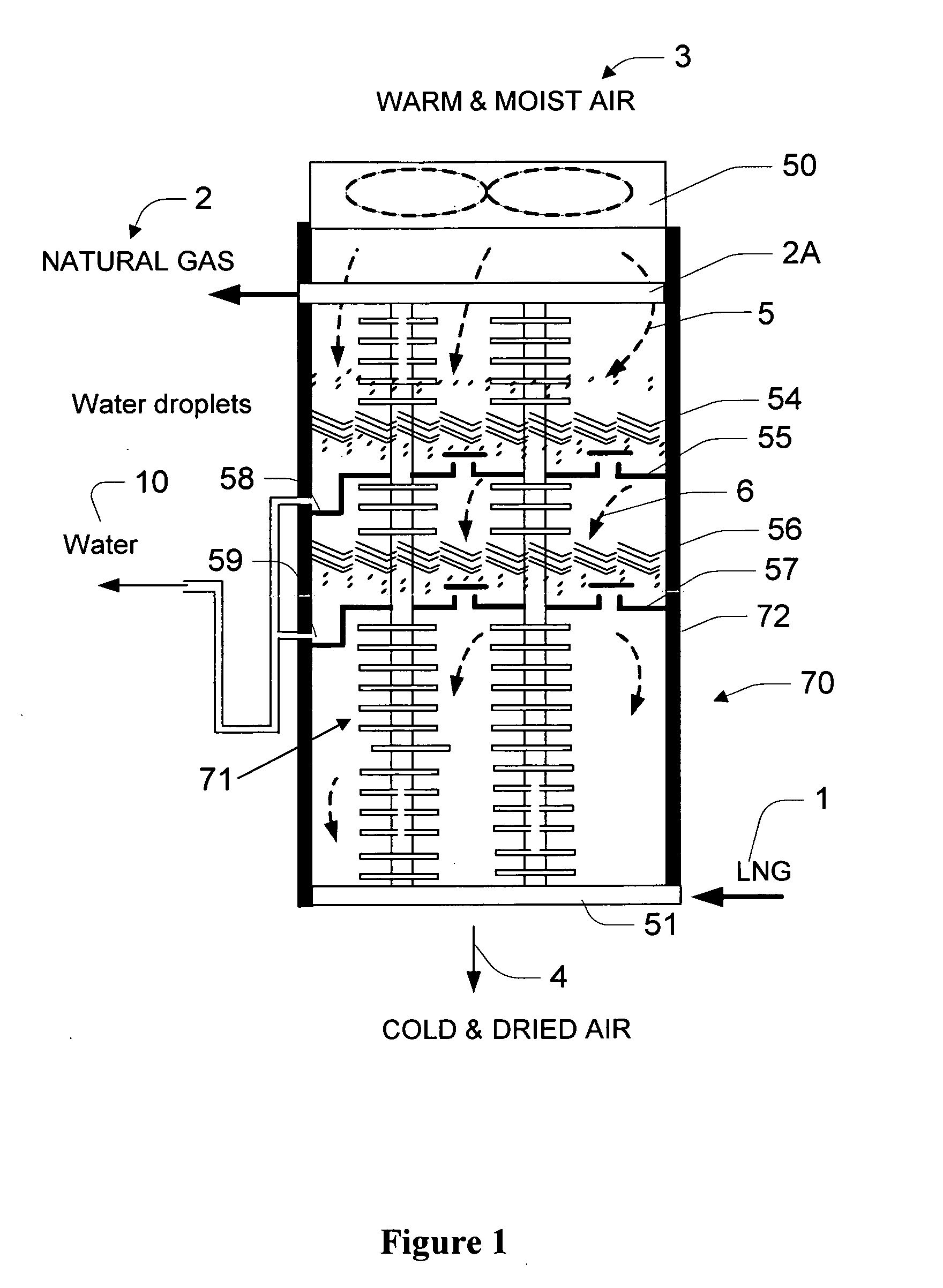

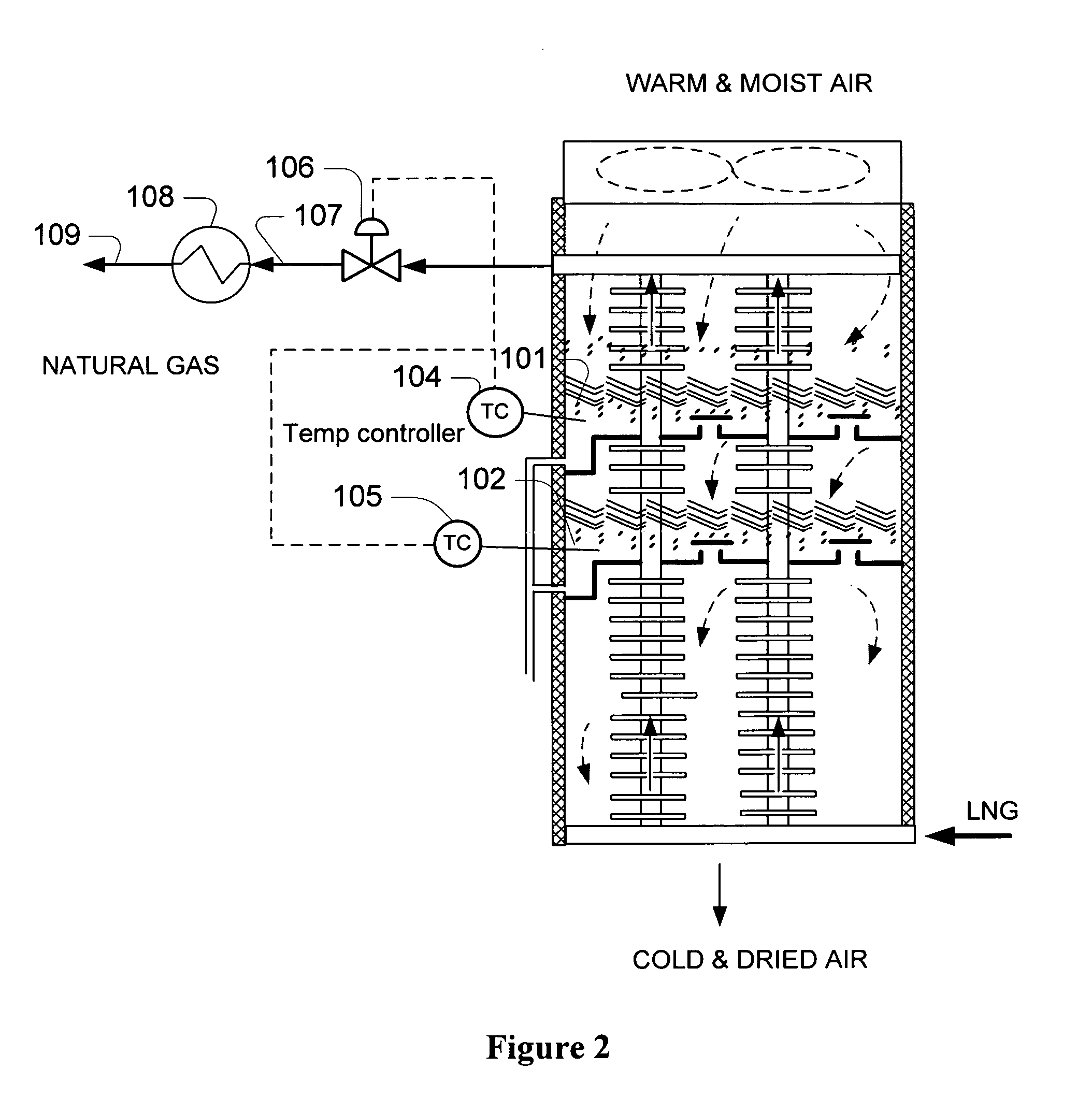

Configurations and Methods for Ambient Air Vaporizers

InactiveUS20100101240A1Reduce energy consumptionReduce feed rateGas handling/storage effectsFluid transferredWater useProcess engineering

Cryogenic fluid is vaporized using two sections of an ambient air vaporizer where in the first section ambient air is dehydrated at a temperature at or above freezing point of water using refrigeration content of partially heated cryogenic fluid, wherein the dehydrated air is used in the second section to form the partially heated cryogenic fluid from a cryogenic fluid.

Owner:FLUOR TECH CORP

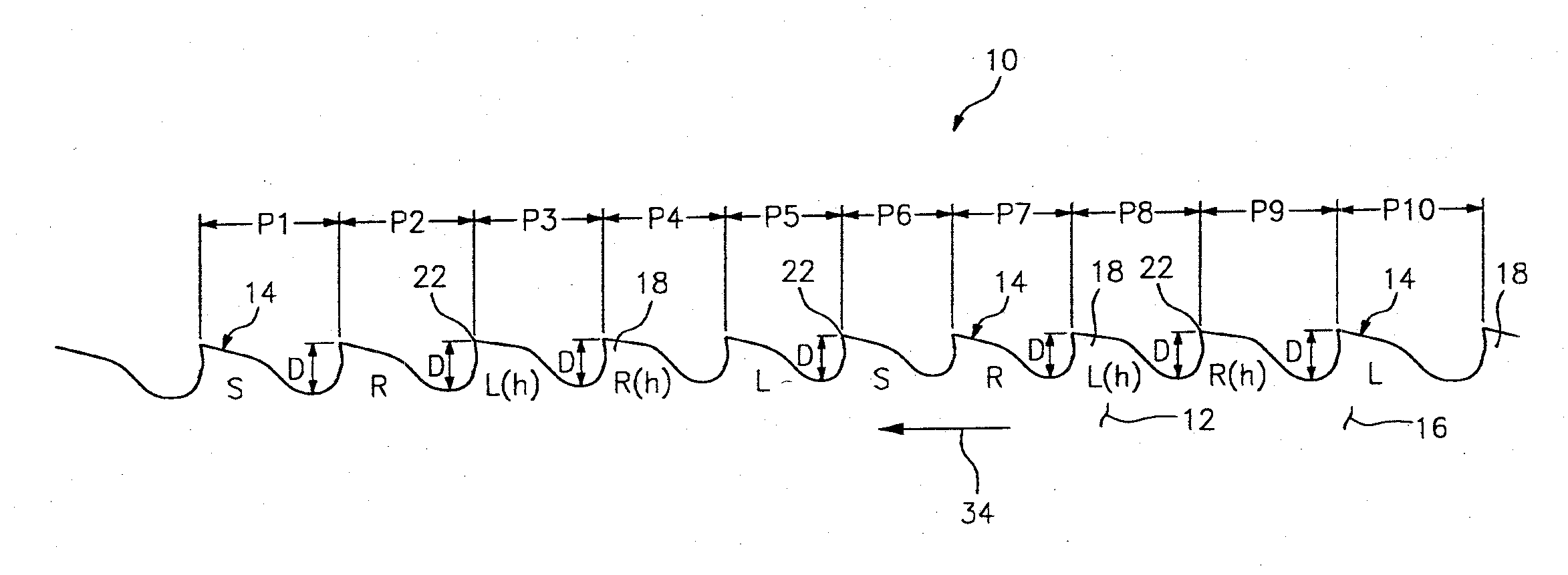

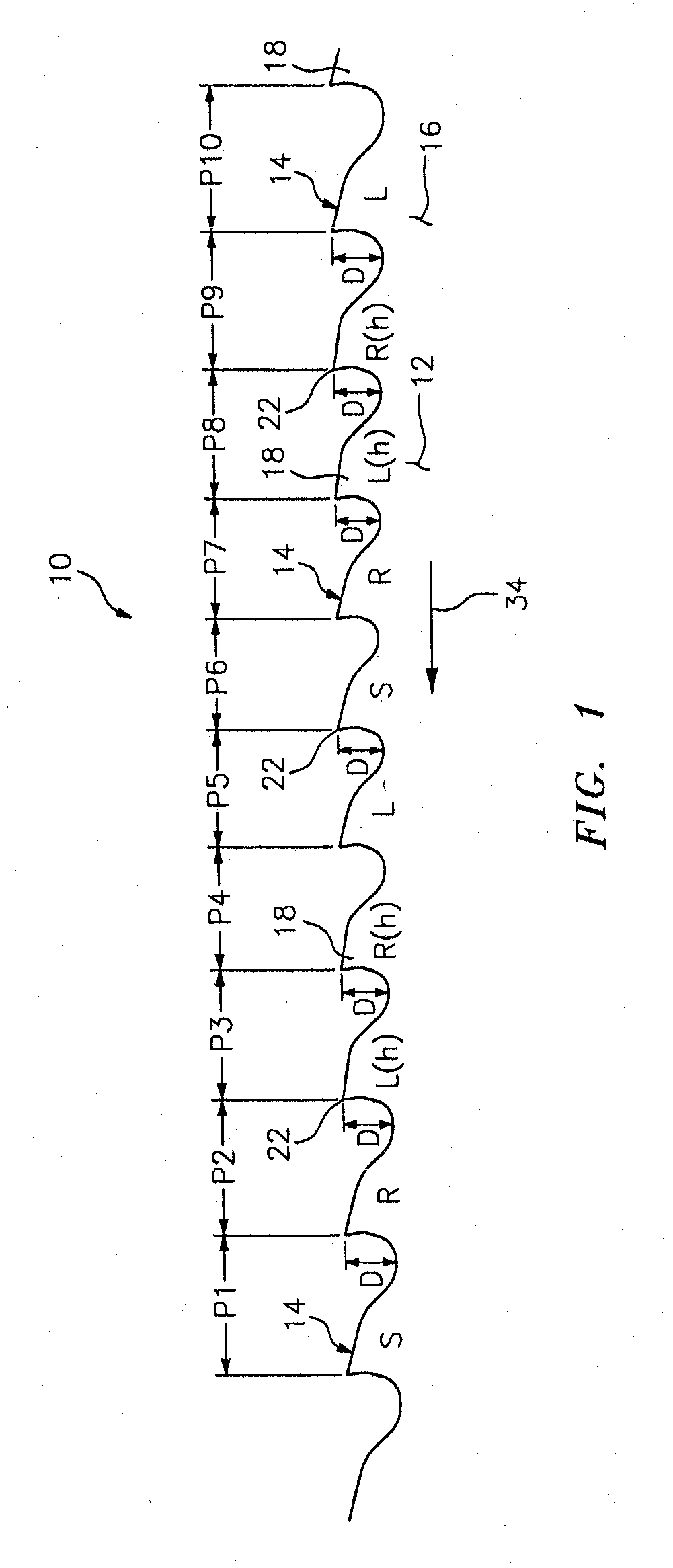

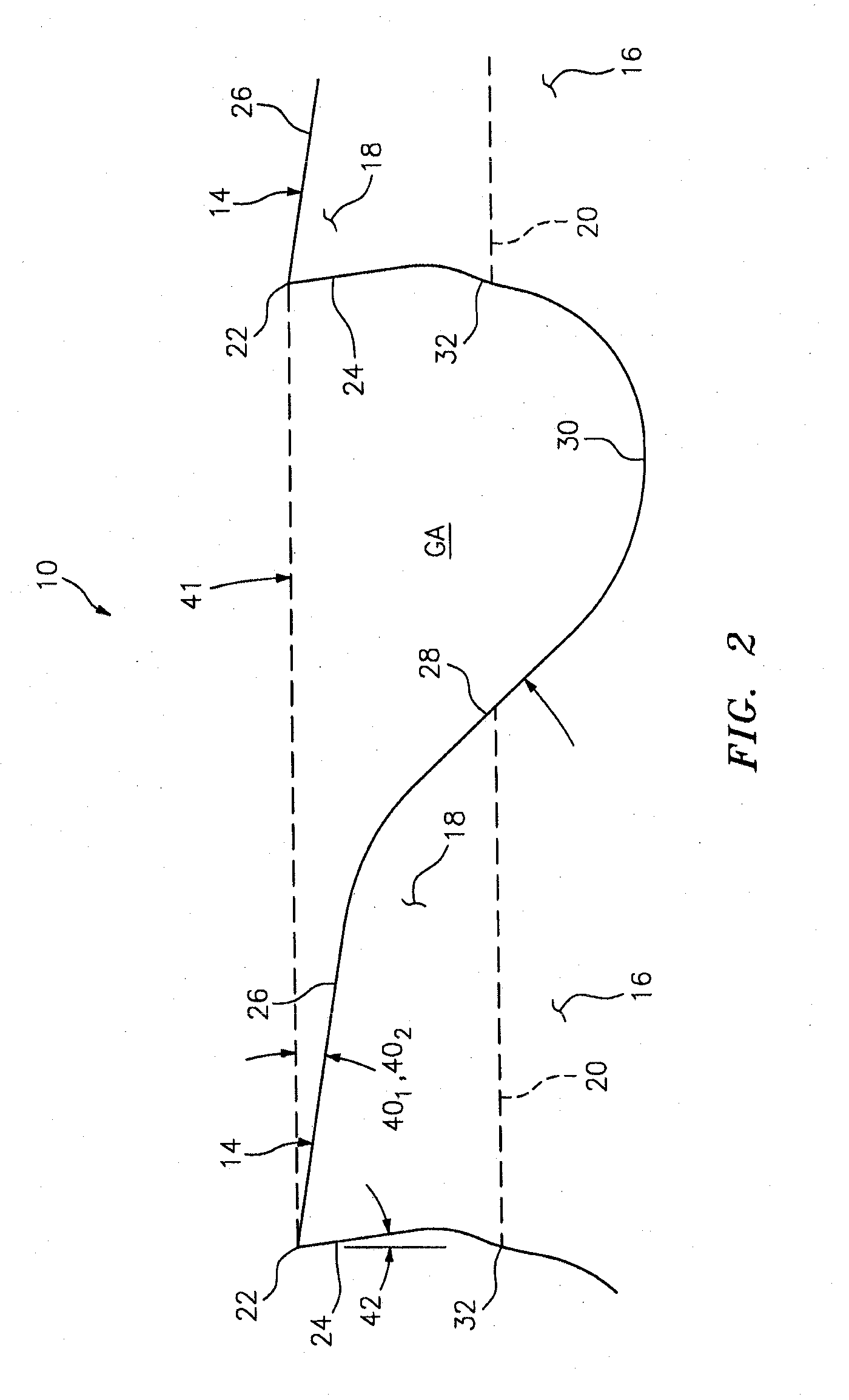

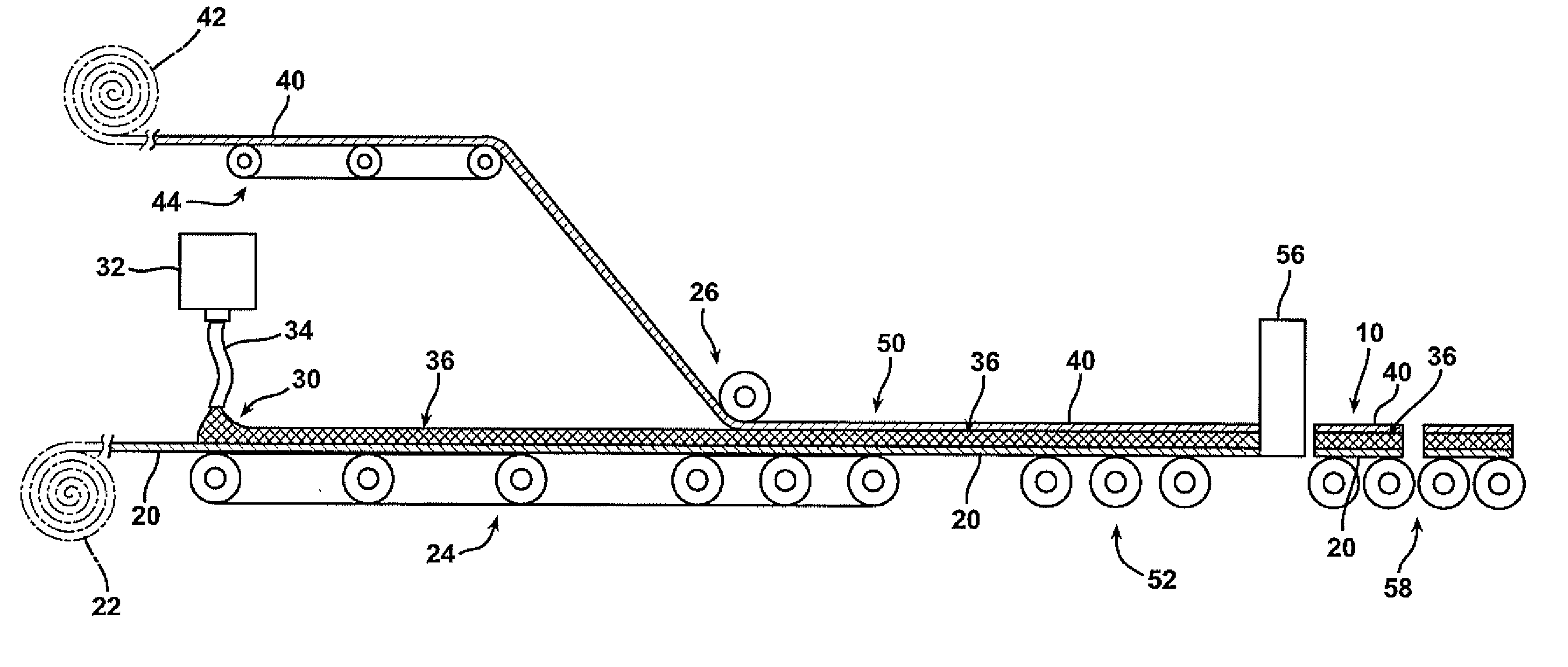

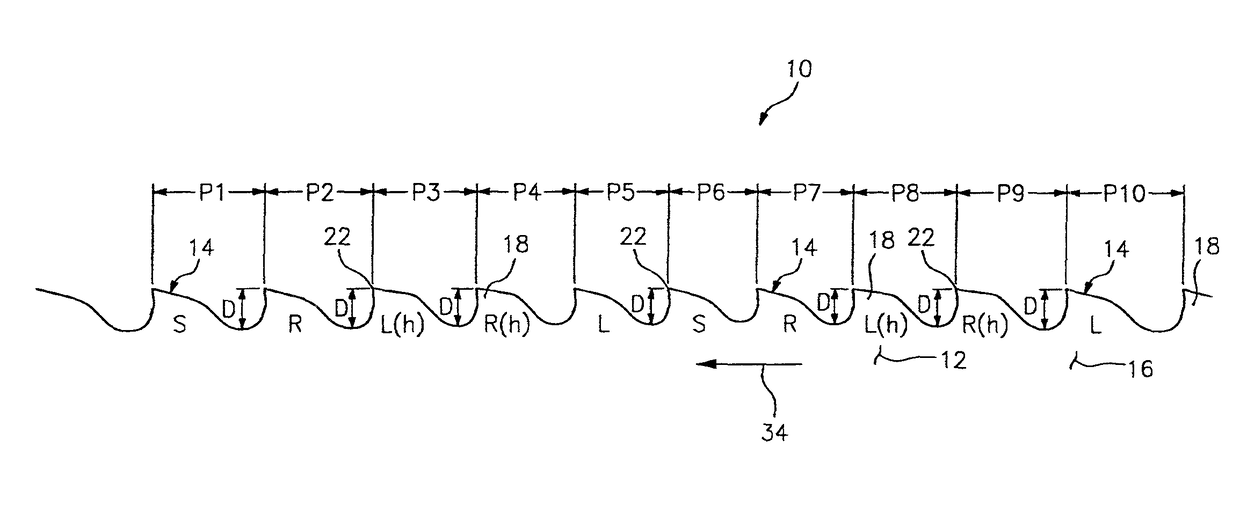

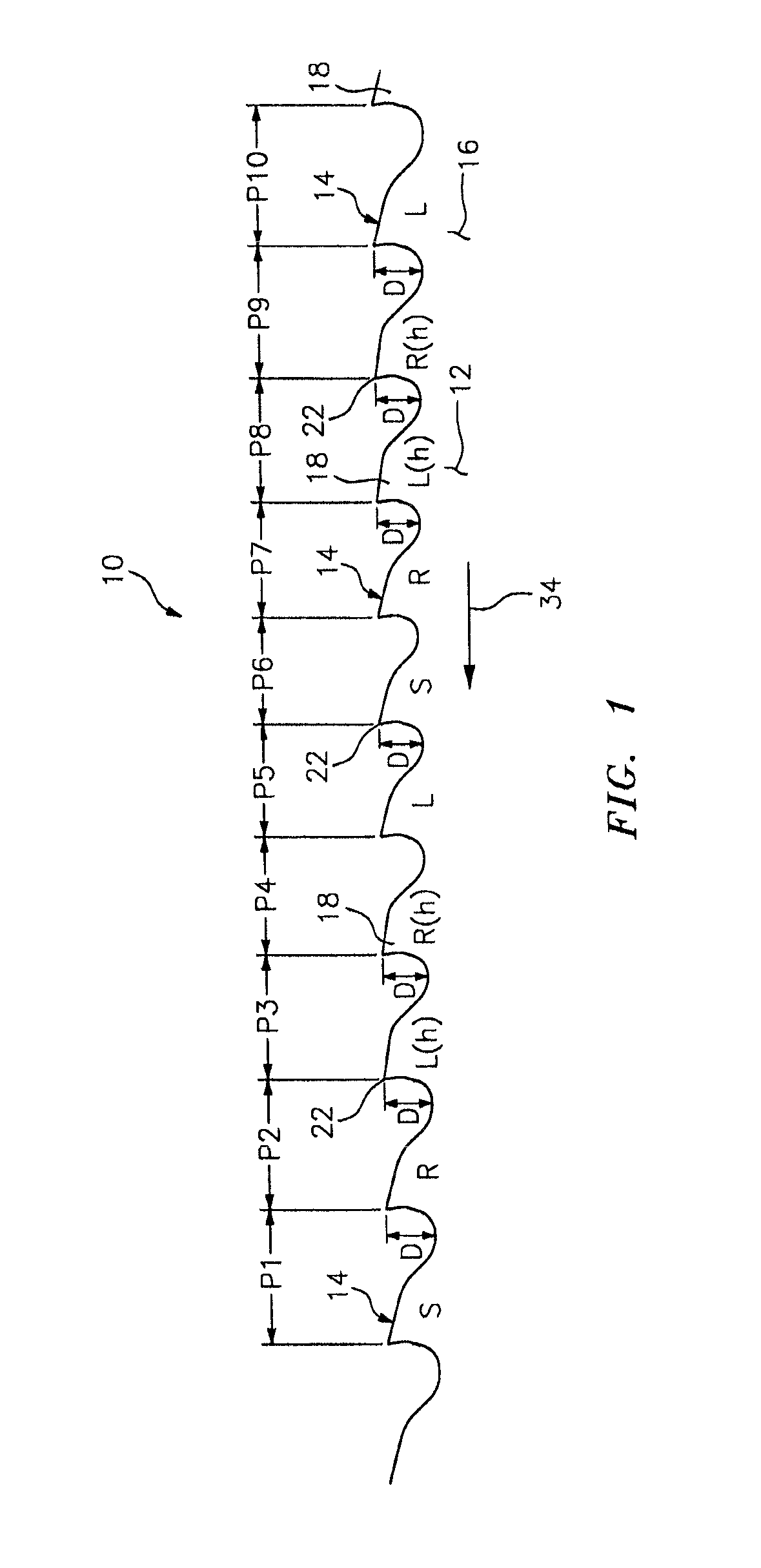

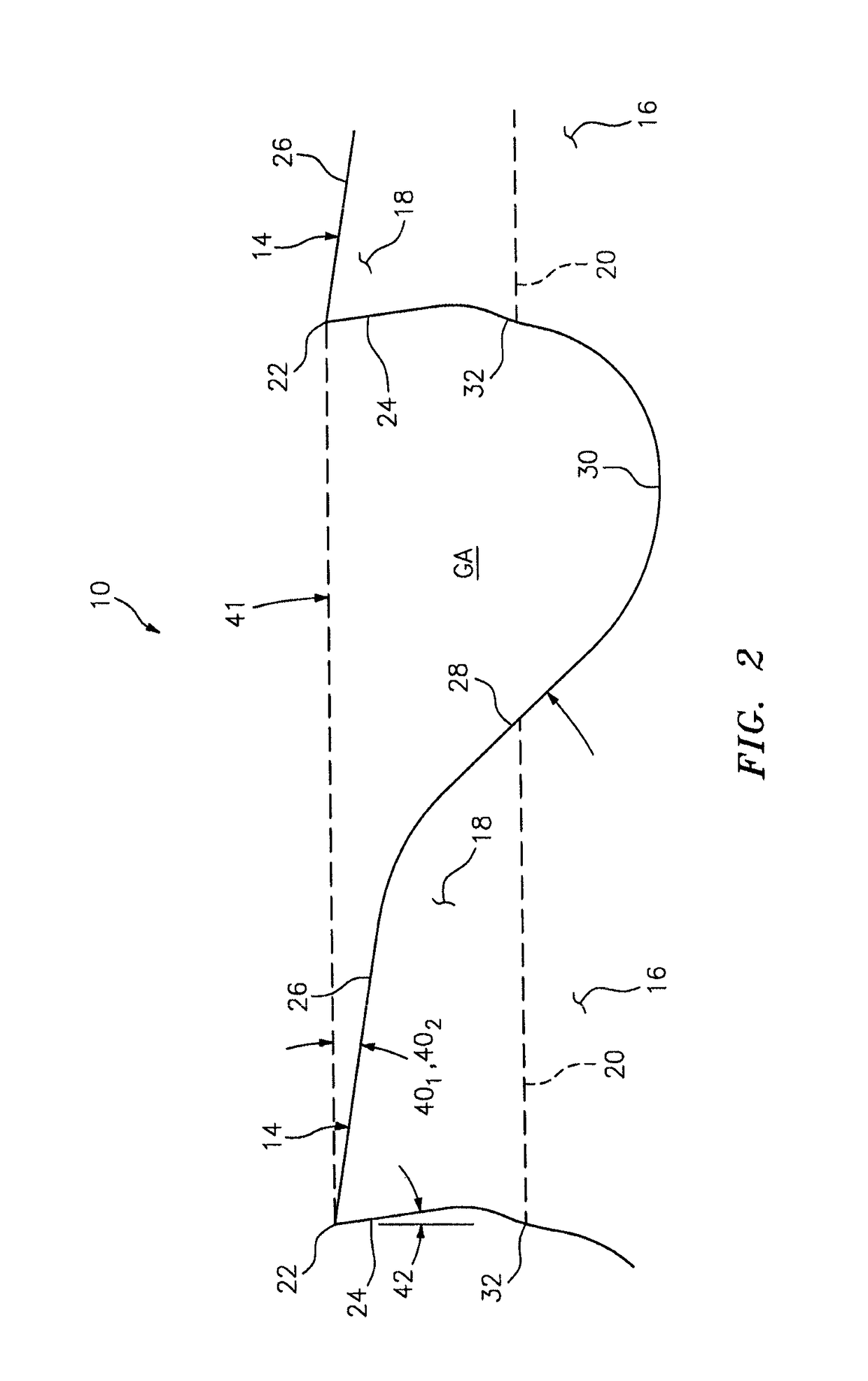

Band saw blade

A bimetal band saw blade has a cutting edge with a plurality of cutting teeth defining repeating, variable pitch patterns and variable set patterns within pitch patterns. Each relatively heavy set tooth defines a first primary clearance angle, and each unset and relatively light set tooth defines a second primary clearance angle. Each first primary clearance angle is less than or equal to about 20°, each second primary clearance angle is less than or equal to about 25°, and each first primary clearance angle is within the range of about 4° to about 6° less than each second primary clearance angle. Each unset or light set tooth defines a greater gullet area than a respective heavy set tooth and / or a finer pitch than the respective heavy set tooth. Each tooth defines a positive rake angle within the range of about 3° to about 10°.

Owner:BLACK & DECKER INC

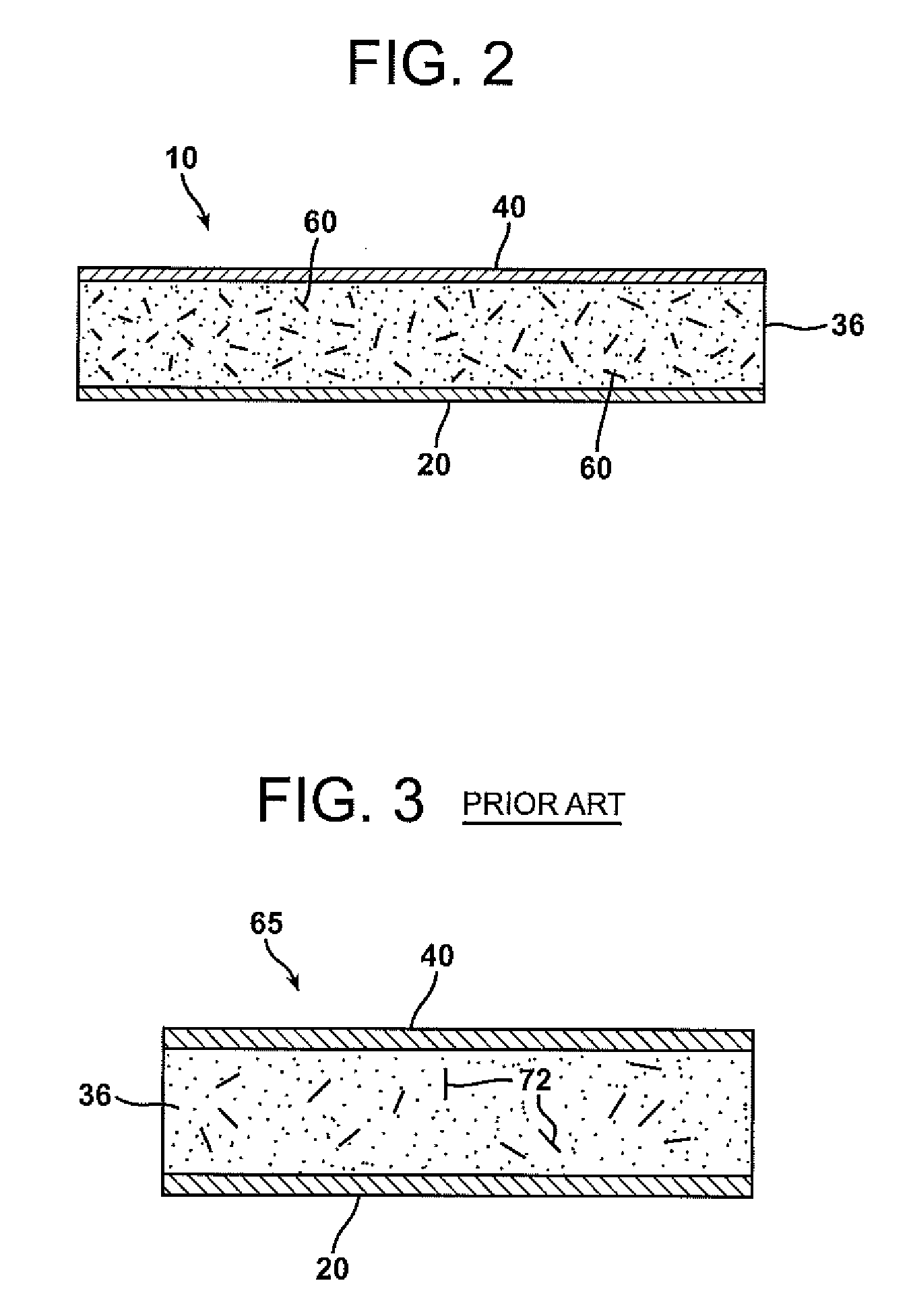

WUCS Fibers Having Improved Flowing And Dispersing Properties

InactiveUS20100055439A1Improve liquidityWeaken energyBuilding componentsConstructions elementsFiberPolyamide

A sizing composition including one or more primary lubricants, at least one secondary lubricant, and at least one coupling agent is provided. The primary lubricant is a fatty amide lubricant that is the condensation product of a saturated fatty acid having at least 16 carbon atoms and a polyamine. Additionally, the primary lubricant acts both as a lubricant and as a cationic surfactant in the size composition when it is neutralized with a weak acid to assist in dispersing the fibers in a gypsum slurry. The secondary lubricant is polyamide or a polyvinyl amine, and acts as a film forming agent in the fiberizing process to protect the glass fibers from interfilament abrasion. The sizing composition provides improved fiber feeding, fiber flow, and fiber dispersion in a gypsum matrix or slurry. The weight ratio by dry solids of primary to secondary lubricant in the size composition is at least 5:1.

Owner:OCV INTELLECTUAL CAPITAL LLC

Apparatus and process for control of rotary breakers

InactiveUS20050279868A1Shorten speedRate at which oversized ROM coal is broken can be controlledSievingScreeningDischarge rateCrusher

Efficient process control of a rotary breaker is dependent upon the rate at which aggregate material is delivered to the rotary breaker. An improved pre-screening apparatus provides enhanced control of the amount of undersized material allowed to bypass the rotary breaker, thus allows some control of feed rate other than the upstream mining conditions. Further, a variable speed drive mechanism allows for enhanced control of the breaking process occurring within the rotary breaker. These improvements allow for the increase in maximum feed rate to an existing rotary breaker or allows for the installation of smaller and more economical original equipment. In addition, an improved discharge mechanism is provided to increase the discharge rates of a breaker without varying size or speed of rotation. These improvements allow for advanced automated process control.

Owner:FULLER LARRY

Method for producing wood fibre-plastics composite products

ActiveUS20120172494A1Improve mechanical propertiesGood dispersionGlass/slag layered productsFlat articlesCelluloseOligomer

A process for producing a composite product comprising fibres of a lignocellulosic material or natural fibres and a plastics material utilises a liquid or particulate binder formulation comprising a thermoset resin and a thermoplastic polymer, monomer, or oligomer. A composite product is formed for use as or in forming a feedstock in plastics manufacture may be broken down under heat and mechanical shearing in a plastics extrusion machine to release the major fraction of the fibres, or the product may be useful as an intermediate product in other form or as an end product.

Owner:NEW ZEALAND FOREST RES INST

Method of milking a dairy animal by means of a milking system

InactiveUS20120204798A1Reduce feed portion sizeIncrease feed rateCathetersAnimal feeding devicesPortion sizeEngineering

The invention provides a system and method of milking and feeding a dairy animal, wherein feed is dispensed in portions during the milking. At a predetermined moment the portion size is reduced, in order to increase the chance that the animal has actually eaten the last allocated portion at the moment when the milking has been ended, so that it will not hesitate to leave the milking parlour. This will result in a reduction of the time during which the milking parlour is unnecessarily occupied, and in an enhanced efficiency.

Owner:LELY PATENT

Internal jacket leg cutter and method

ActiveUS9103088B2Increase feed rateReduce feed rateTube shearing machinesMetal working apparatusMechanical engineeringClassical mechanics

Owner:AES EOT EQUIP HLDG LLC

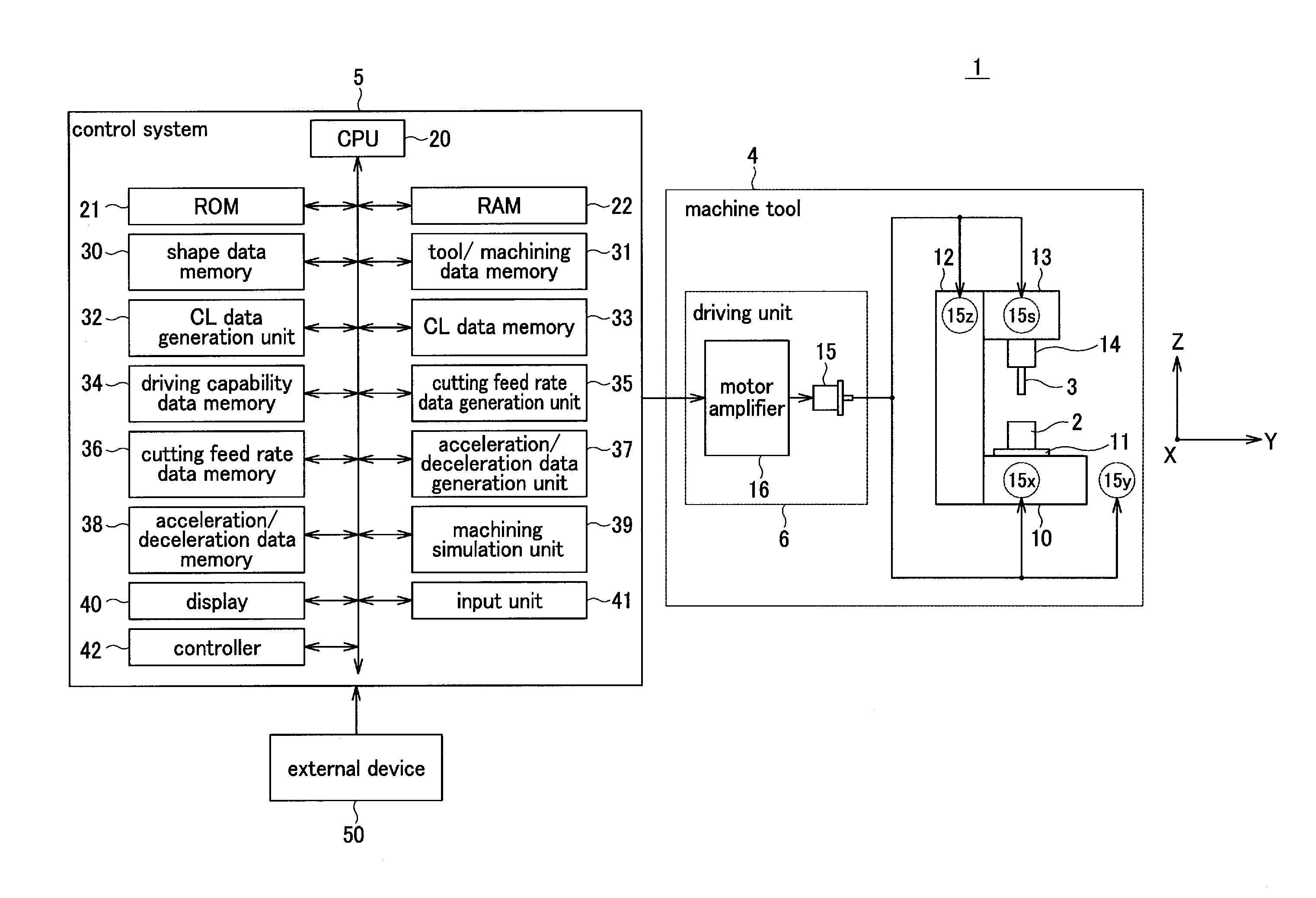

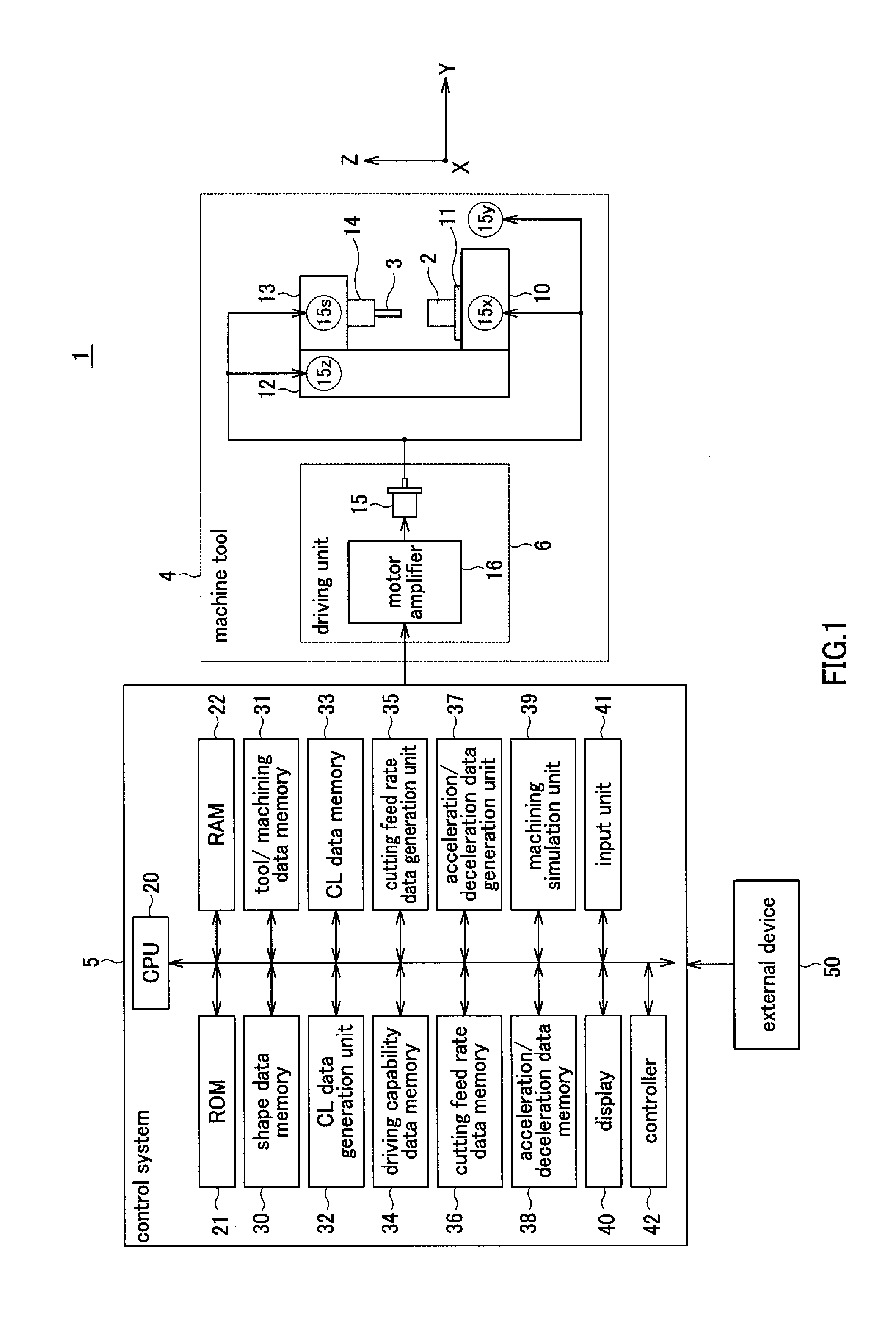

Machine tool control system

InactiveUS20120197421A1Reduce feed rateReduce processing timeProgramme controlComputer controlControl systemMachine tool control

An optimum cutting feed rate of a machine tool is calculated at the outset and a tool path as well as the optimum cutting feed rate calculated is directly output to a driving unit of the machine tool. A relative movement between the work and a tool is made to occur along the tool path at the optimum cutting feed rate for each part of the tool path. To this end, a control system includes a CL data generating unit 32, a CL data memory 33, a driving capability data memory 34, a cutting feed rate data generation unit 35, a cutting feed rate data memory 36, and a controller 42.

Owner:DMG MORI SEIKI CO LTD

Control system for a decanter centrifuge

InactiveUS20140235420A1Easy to modifyReduce feed rateDispersed particle separationRotary centrifugesControl systemClassical mechanics

A torque sensing device capable of measuring the force exerted by a torque arm on a lever is positioned between the torque arm and the lever. The torque arm is connected to the pinion of a planetary gearbox for rotating the bowl and screw conveyer of a decanter centrifuge at different speeds. The torque sensing device measures the torque between the pinion gear and the planetary gearbox. The sensor can be connected to a controller which can reduce the flow of the liquid / solid mixture to the decanter centrifuge thereby / reducing the torque and avoiding substantial damage to the planetary gearbox.

Owner:ENGIP LLC

Band saw blade

ActiveUS10112245B2Improve the immunityRobust tooth formMetal sawing toolsStructural engineeringMechanical engineering

A bimetal band saw blade has a cutting edge with a plurality of cutting teeth defining repeating, variable pitch patterns and variable set patterns within pitch patterns. Each relatively heavy set tooth defines a first primary clearance angle, and each unset and relatively light set tooth defines a second primary clearance angle. Each first primary clearance angle is less than or equal to about 20°, each second primary clearance angle is less than or equal to about 25°, and each first primary clearance angle is within the range of about 4° to about 6° less than each second primary clearance angle. Each unset or light set tooth defines a greater gullet area than a respective heavy set tooth and / or a finer pitch than the respective heavy set tooth. Each tooth defines a positive rake angle within the range of about 3° to about 10°.

Owner:BLACK & DECKER INC

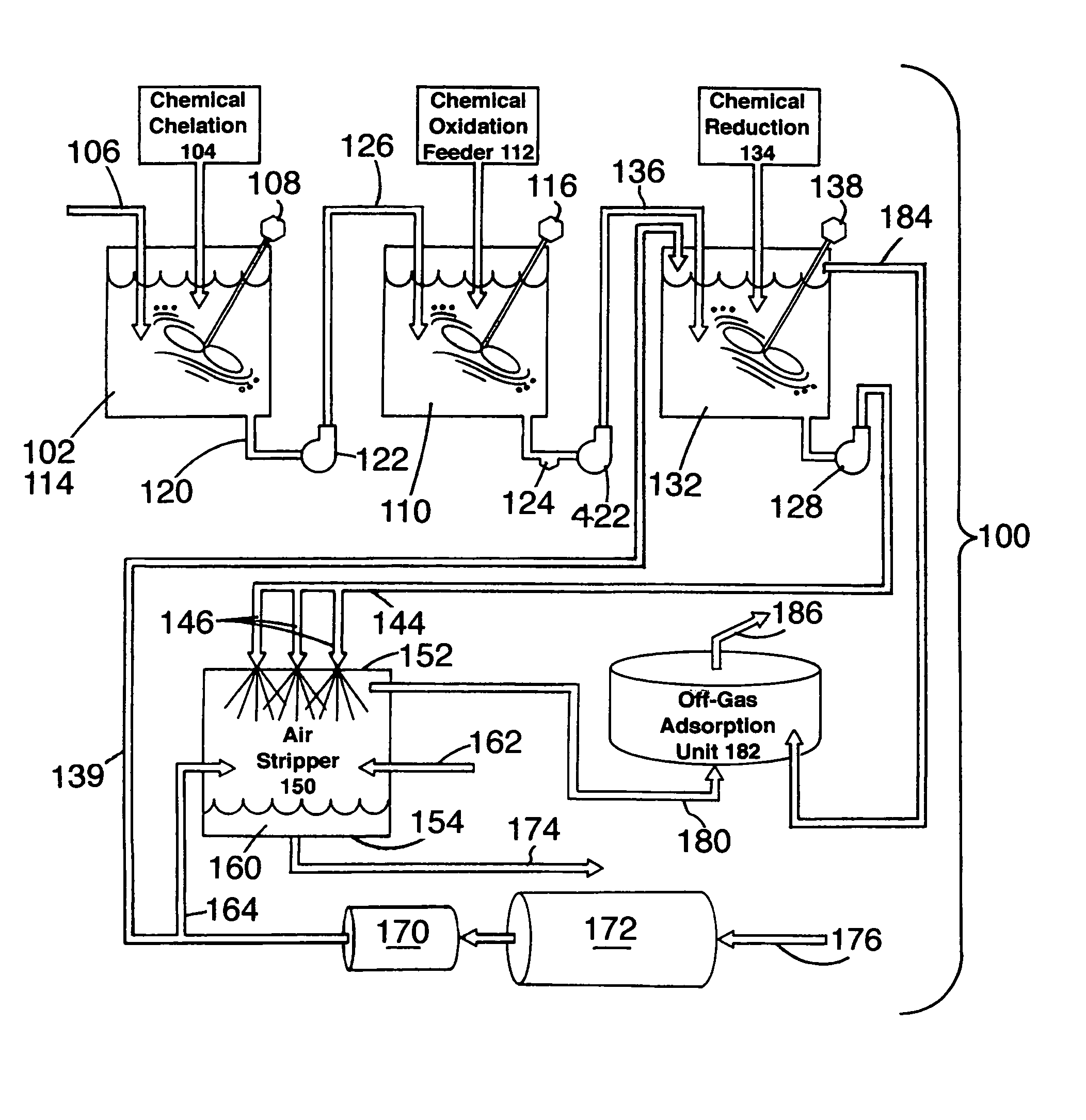

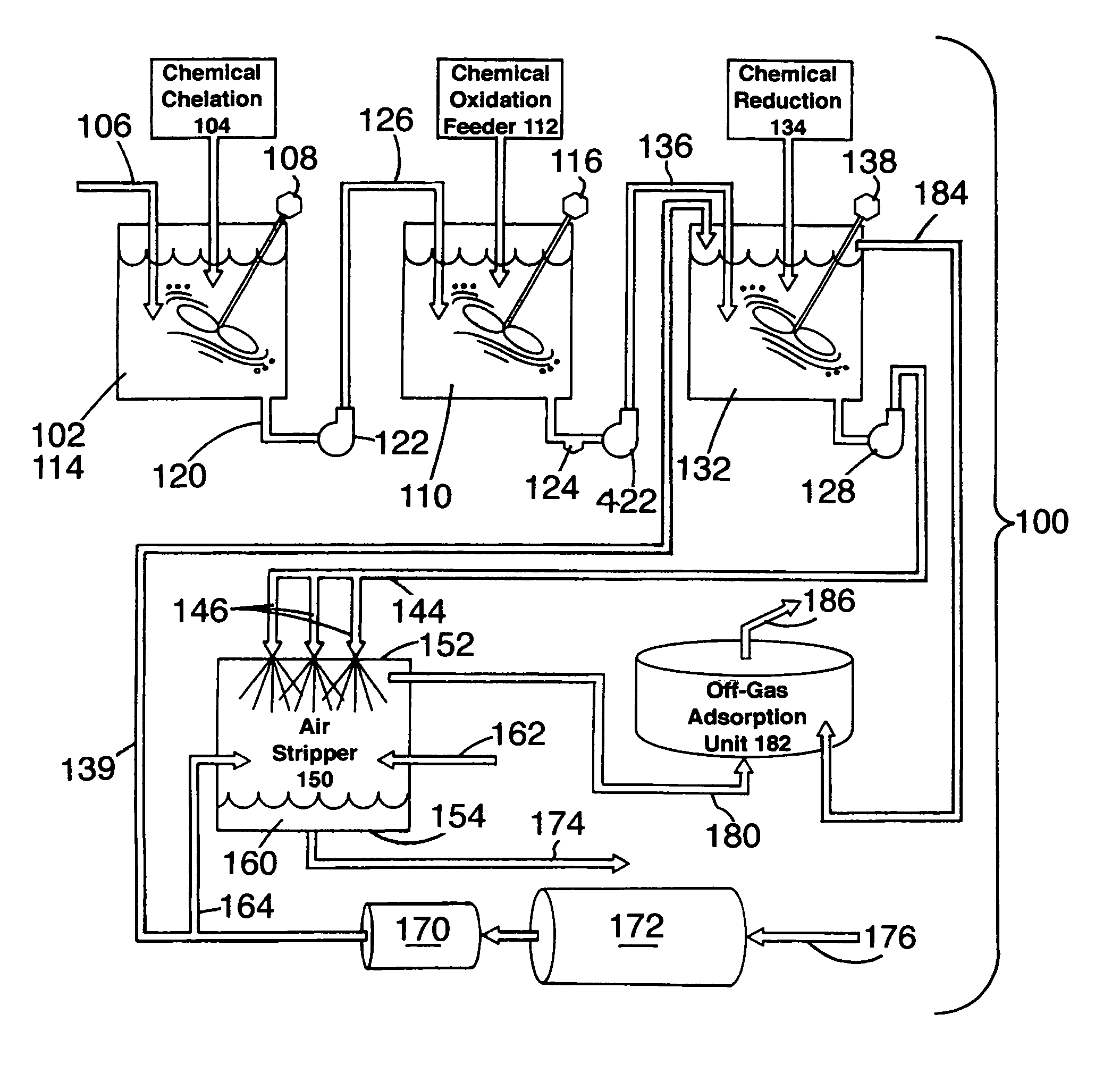

Mercury remediation method and apparatus

ActiveUS8734653B1Reduce feed rateReduce the amount requiredWater contaminantsScale removal and water softeningMercury levelChelation

A mercury remediation method and apparatus for reducing mercury levels in water to a nanogram per liter level that uses four treatment steps: (1) chelation; (2) oxidation; (3) reduction; and (4) air stripping, vapor / liquid separation. There is a fifth step in the process, which does not involve the wastewater. It is to scrub the stripper air of the volatile mercury in an off-gas adsorption unit or to condense volatile mercury in a cryogenic mercury trap.

Owner:AYLESWORTH TERRENCE W

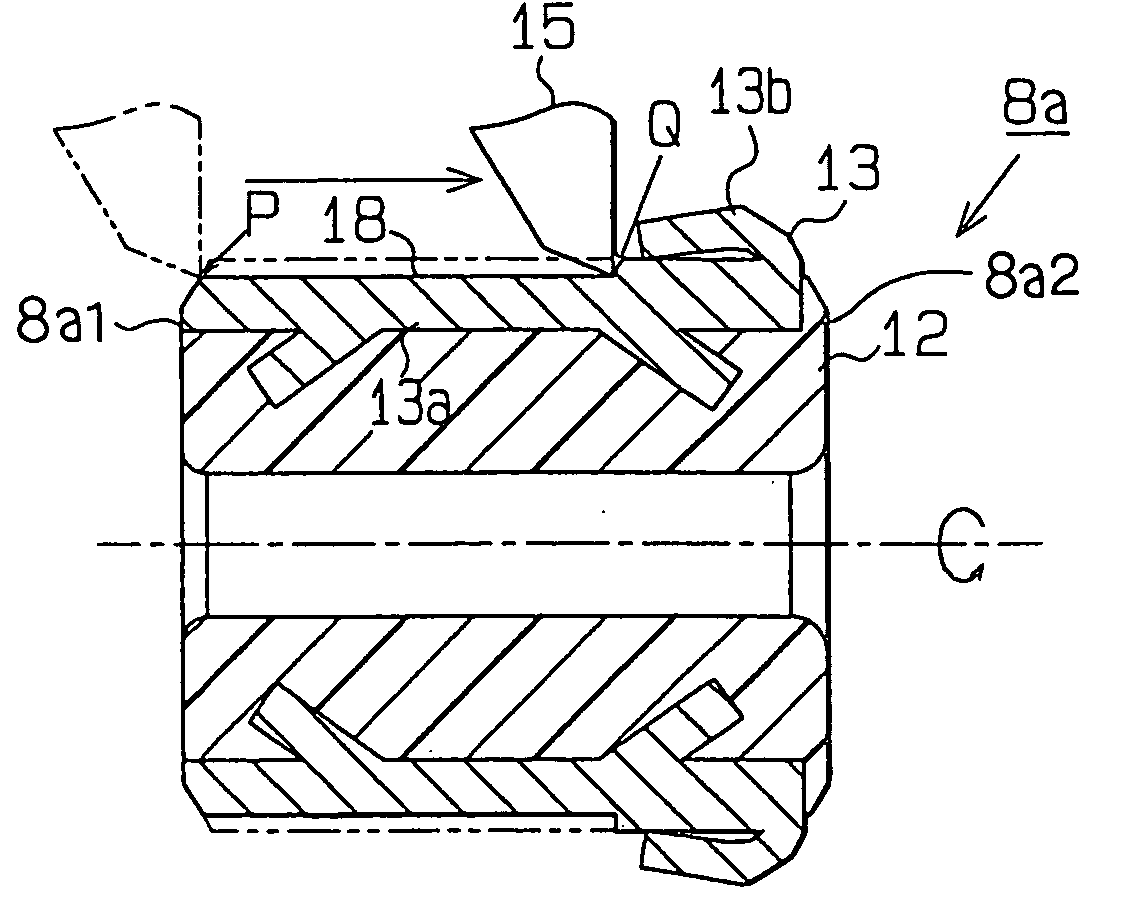

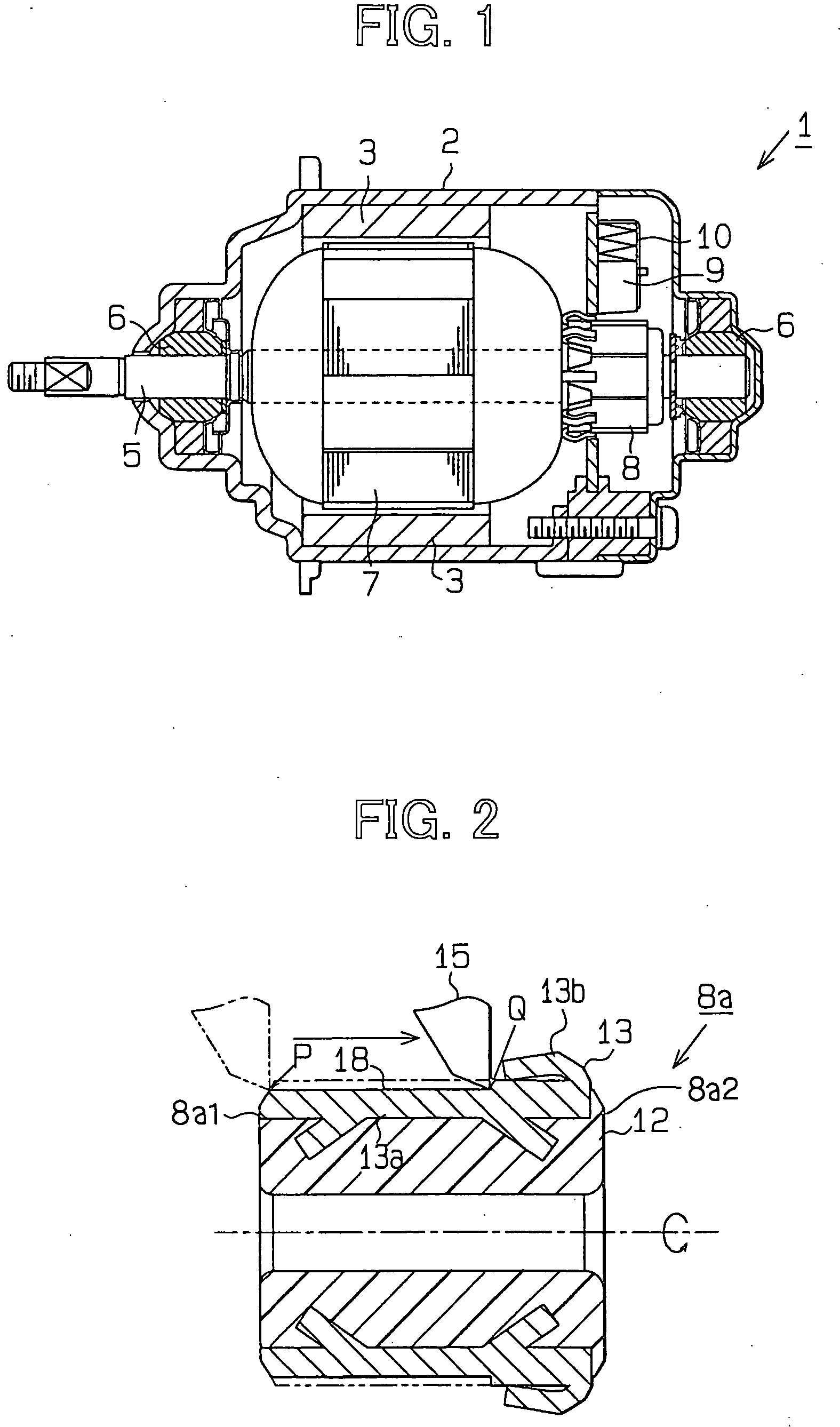

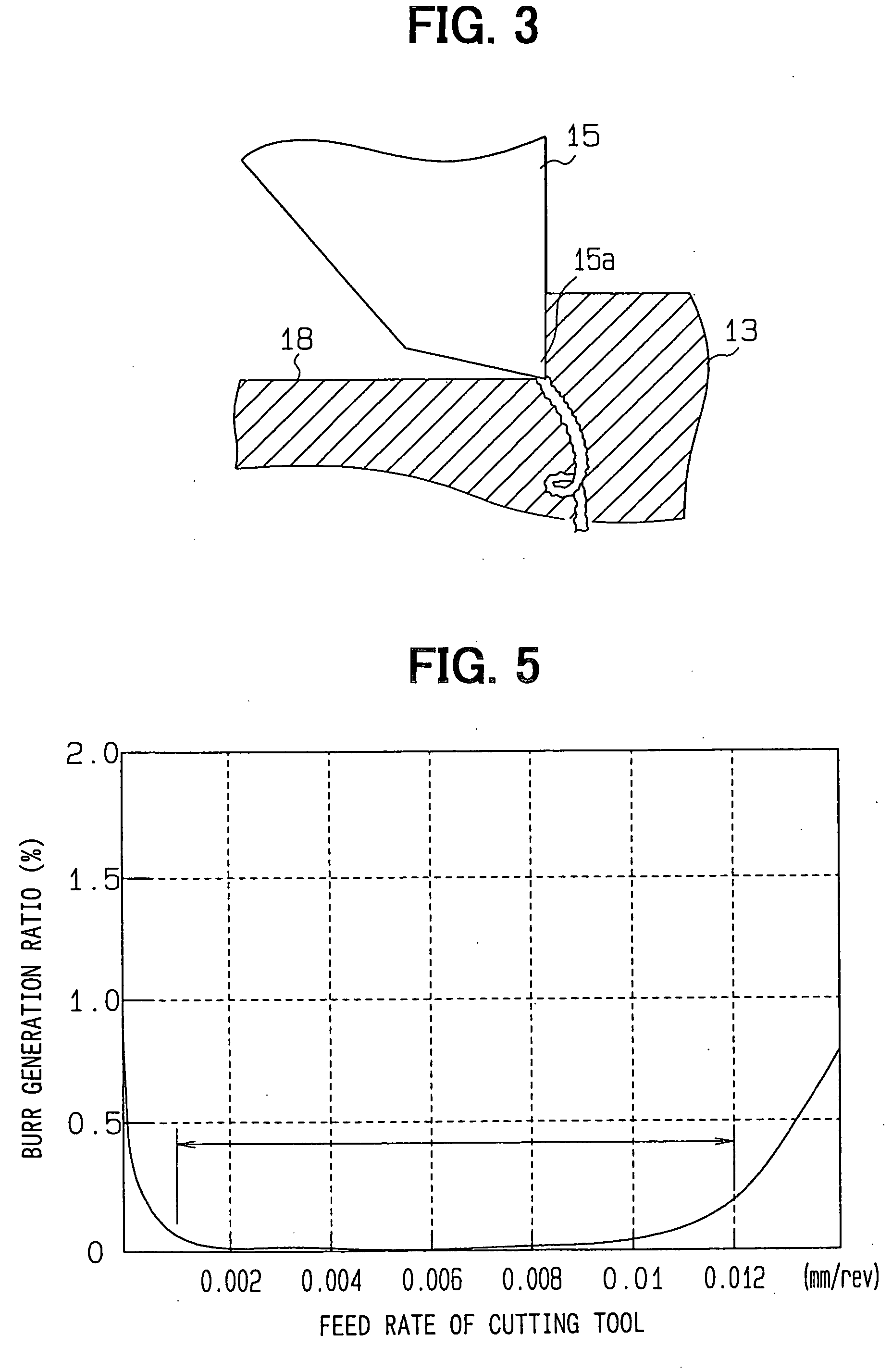

Method for manufacturing commutator having commutator segments

InactiveUS20040181930A1Reduce feed rateLathesAutomatic/semiautomatic turning machinesEngineeringMechanical engineering

A feed rate of a single-point cutting tool, which is an axial relative moving distance of the cutting tool along an outer peripheral surface of an unfinished commutator product per revolution of the unfinished commutator product, is reduced in an end part of a cutting region of the outer peripheral surface of the unfinished commutator product, which is adjacent to a commutator riser of each commutator segment provided in the outer peripheral surface of the unfinished commutator product.

Owner:ASMO CO LTD

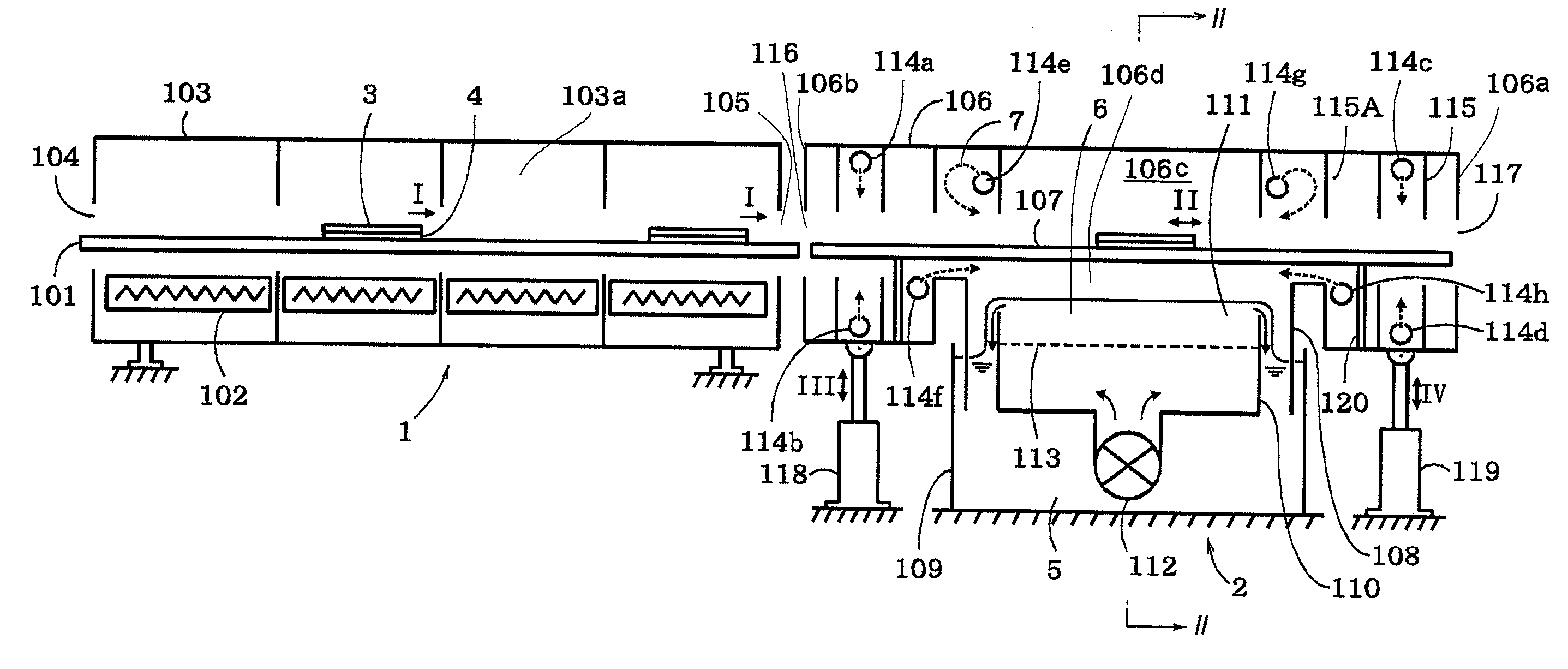

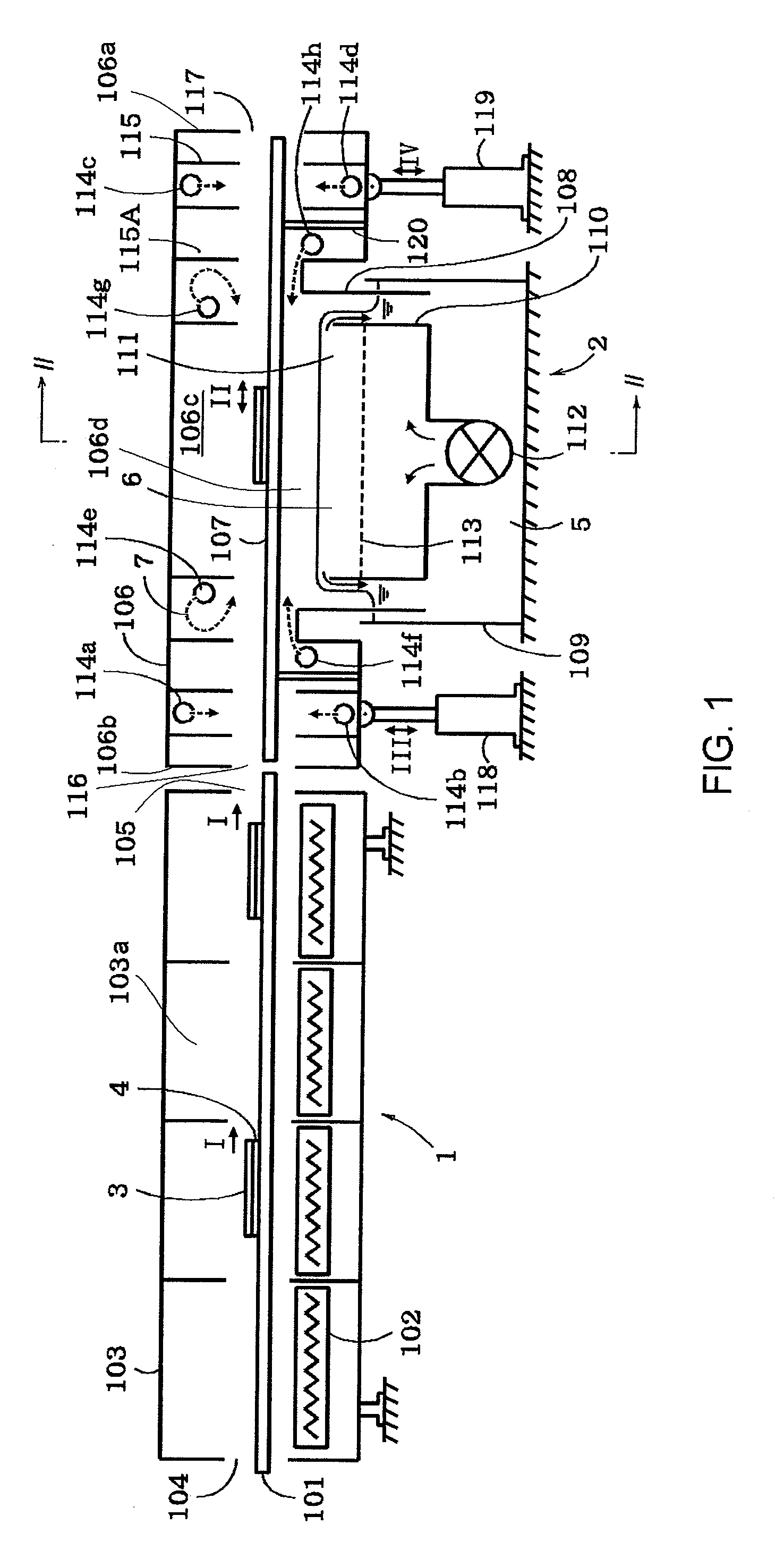

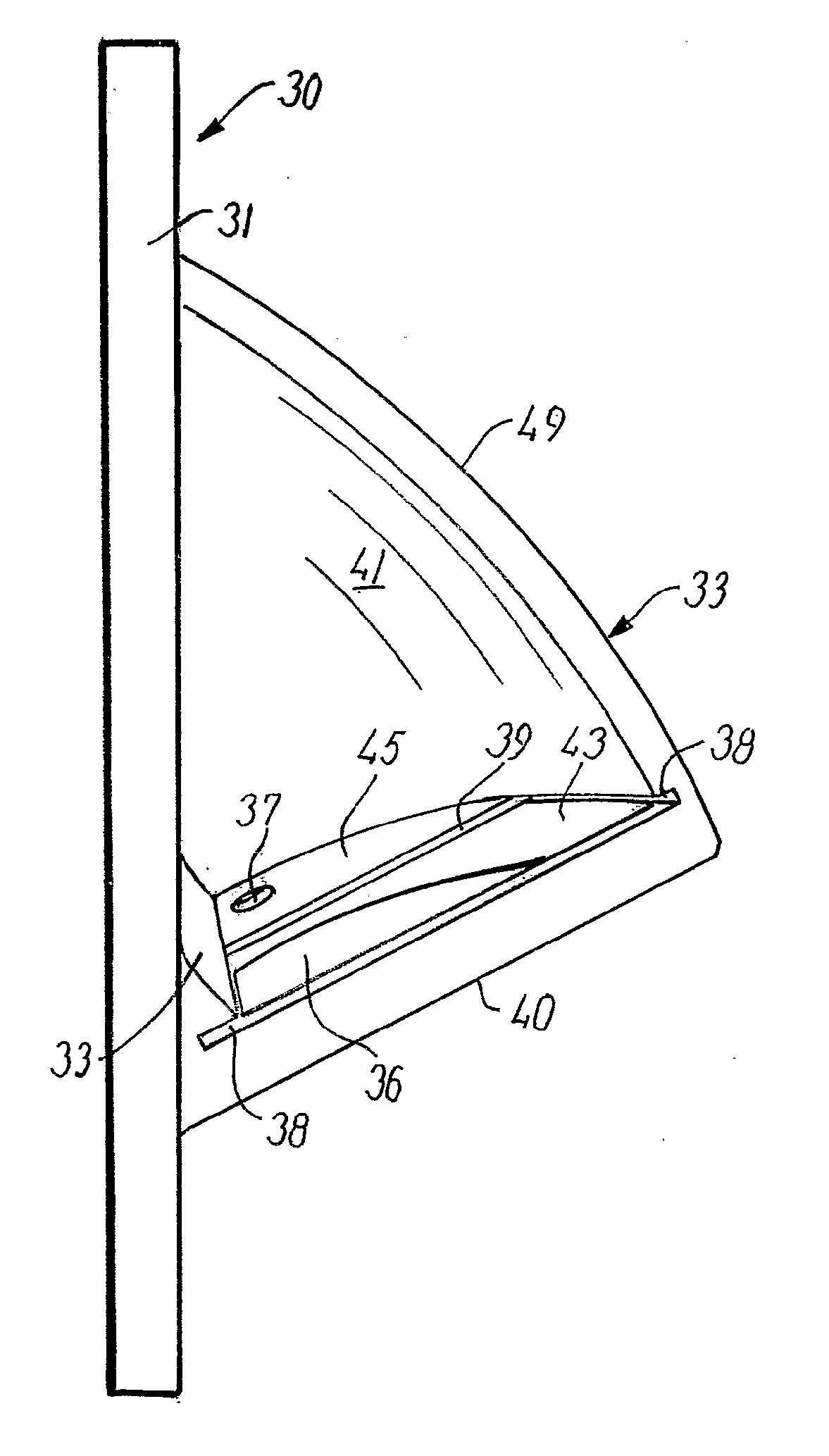

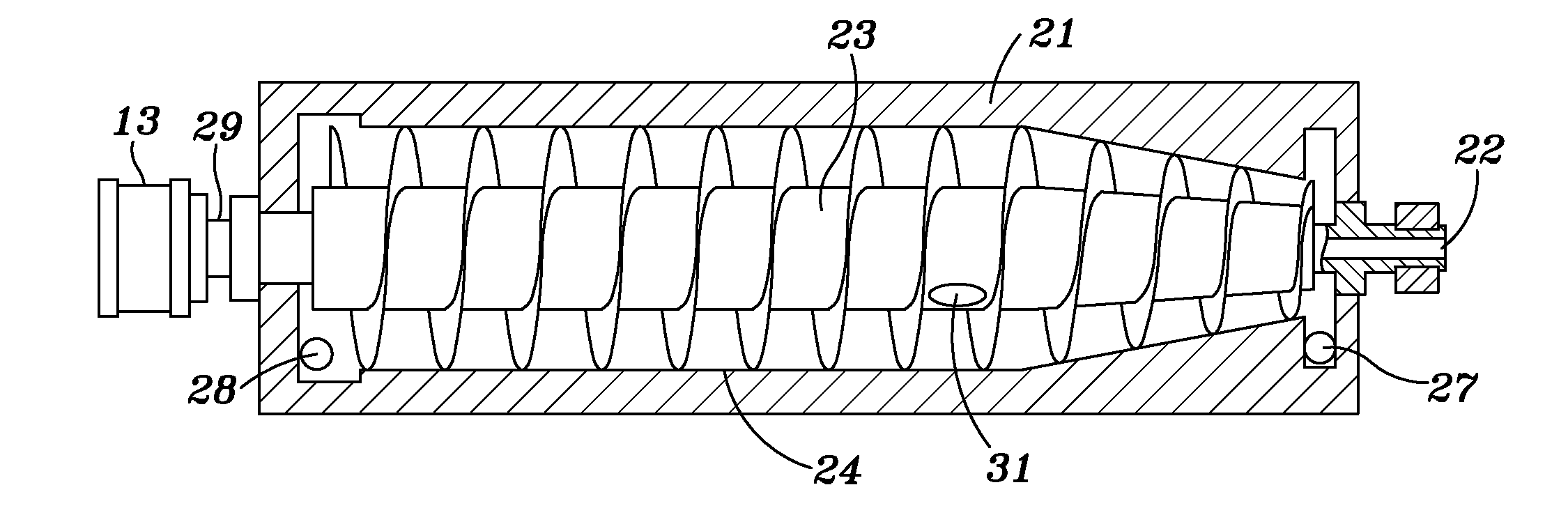

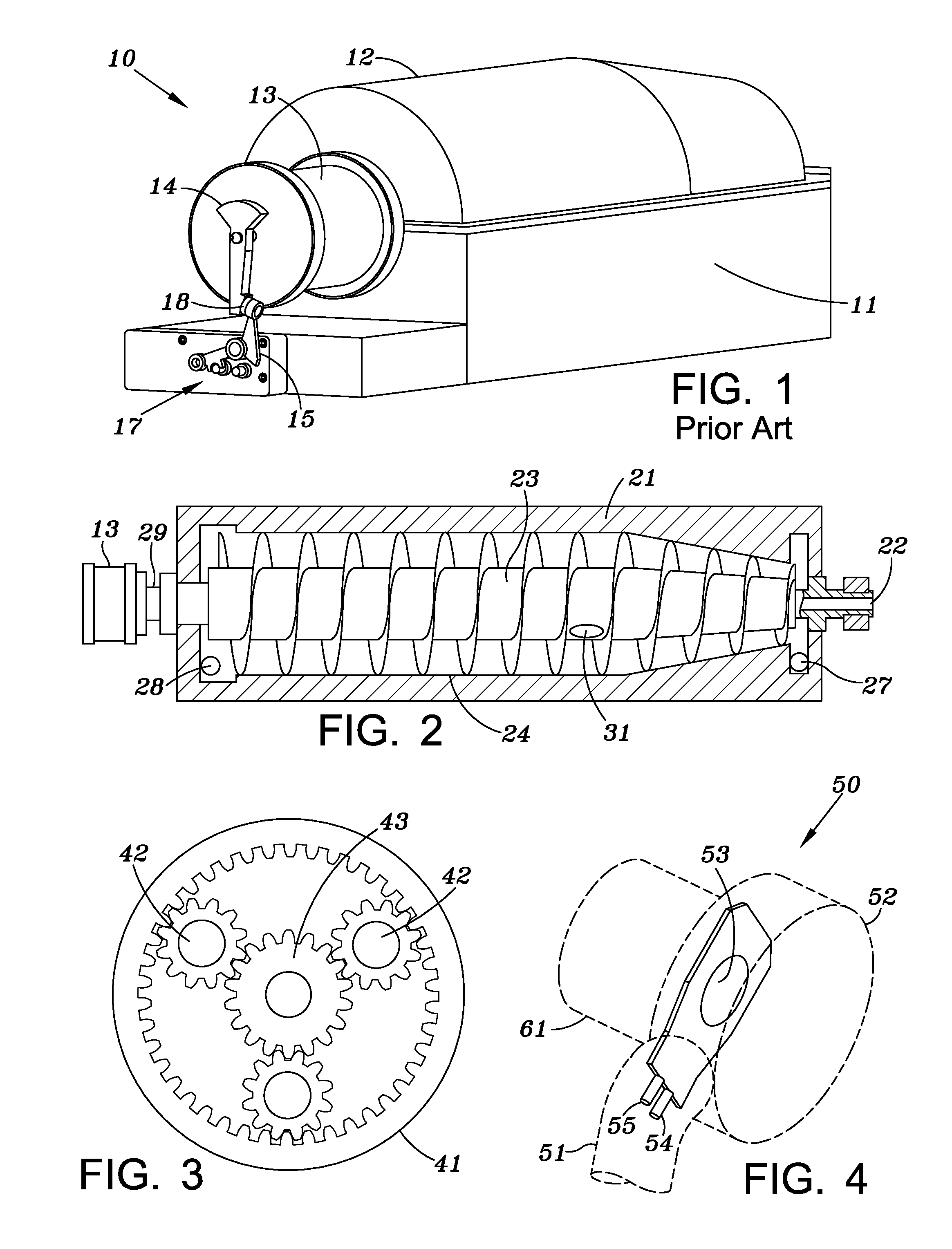

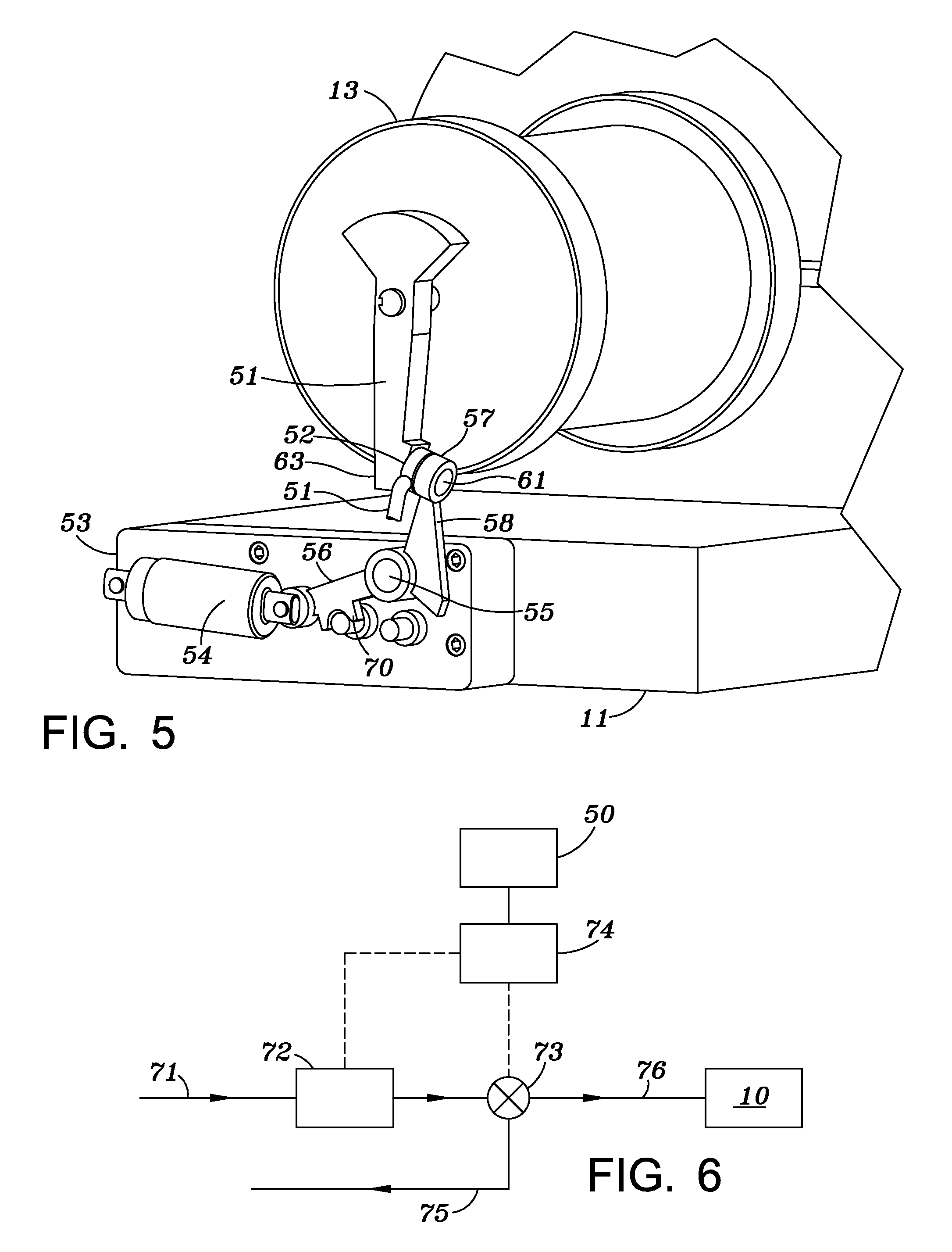

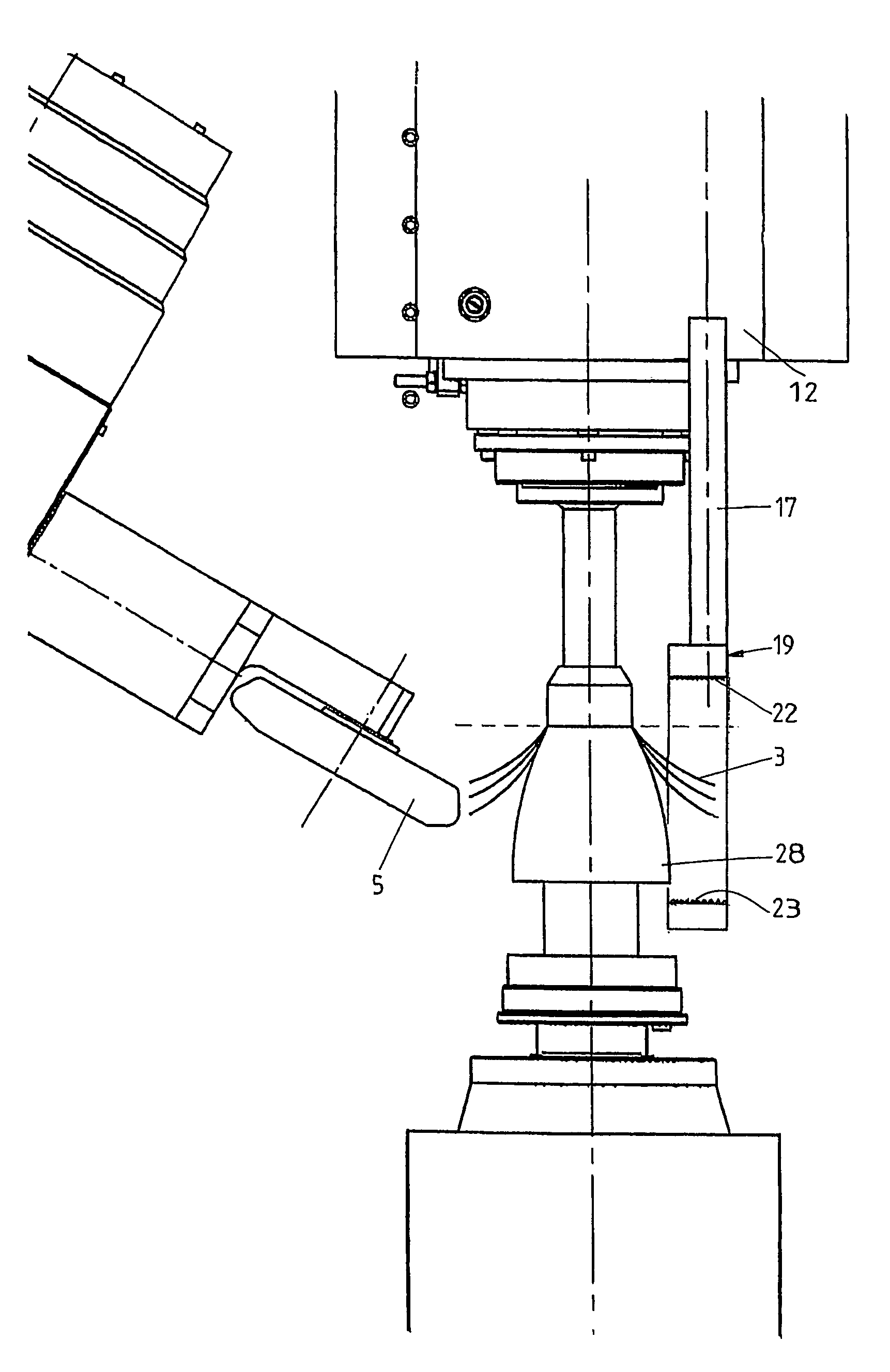

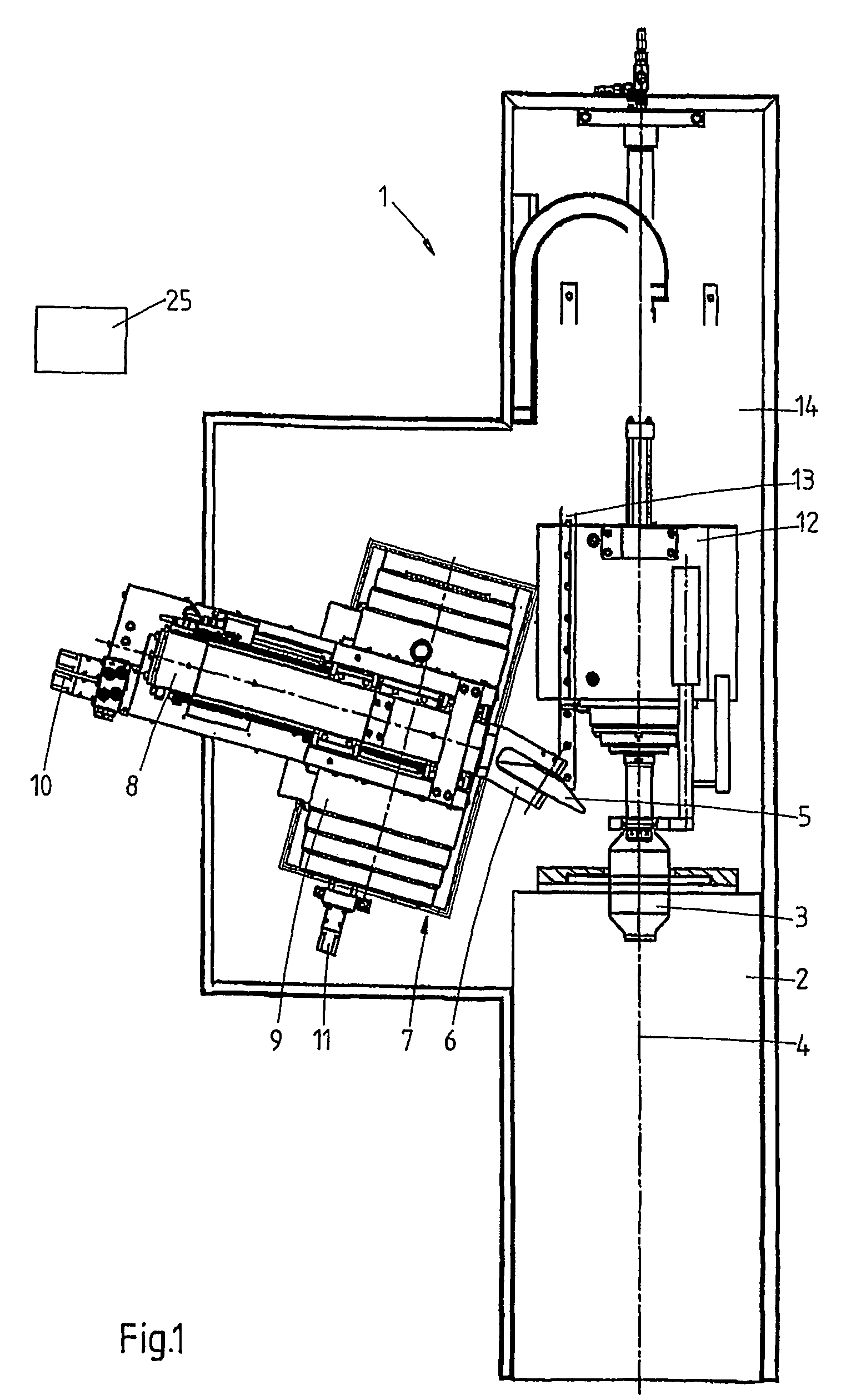

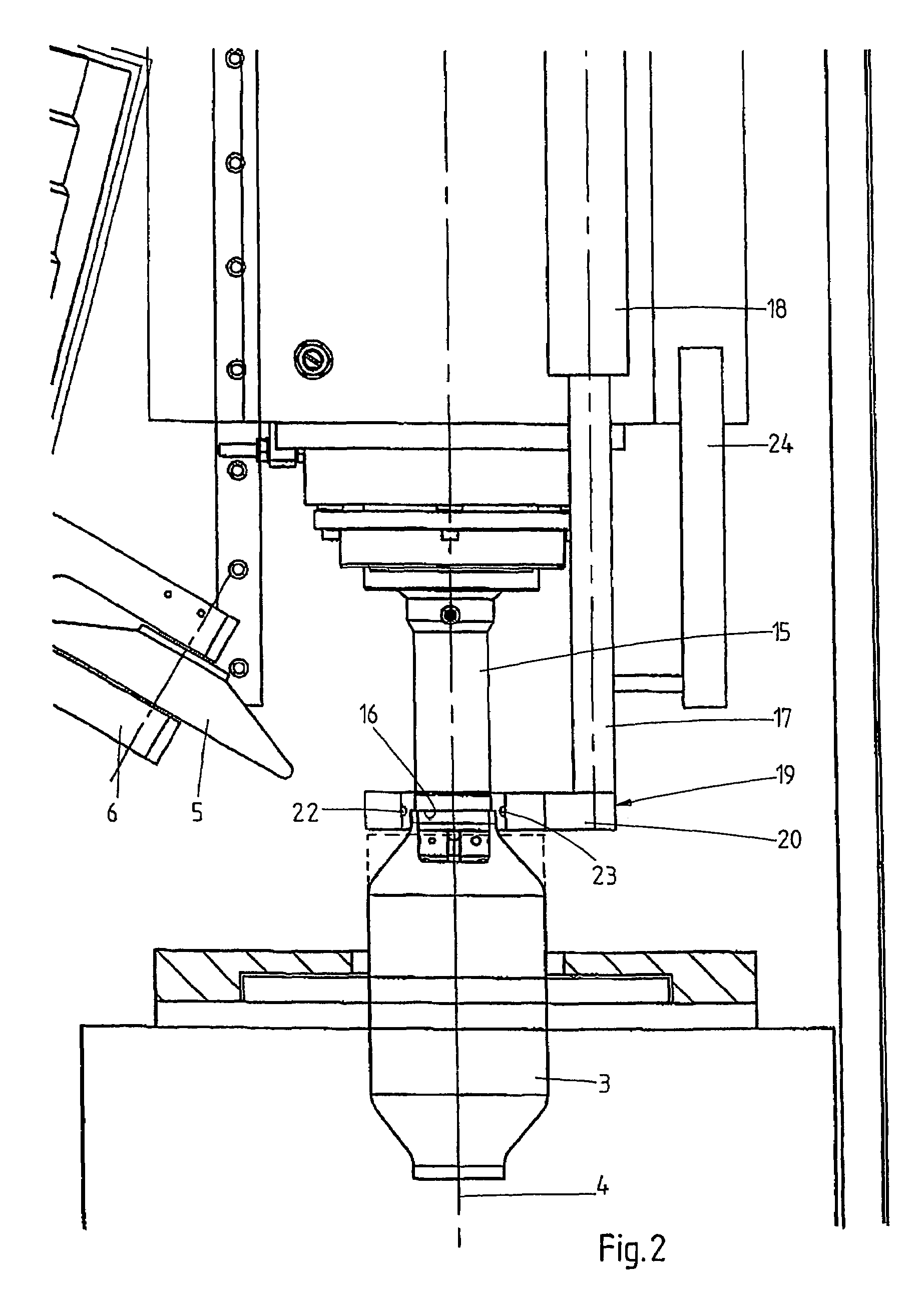

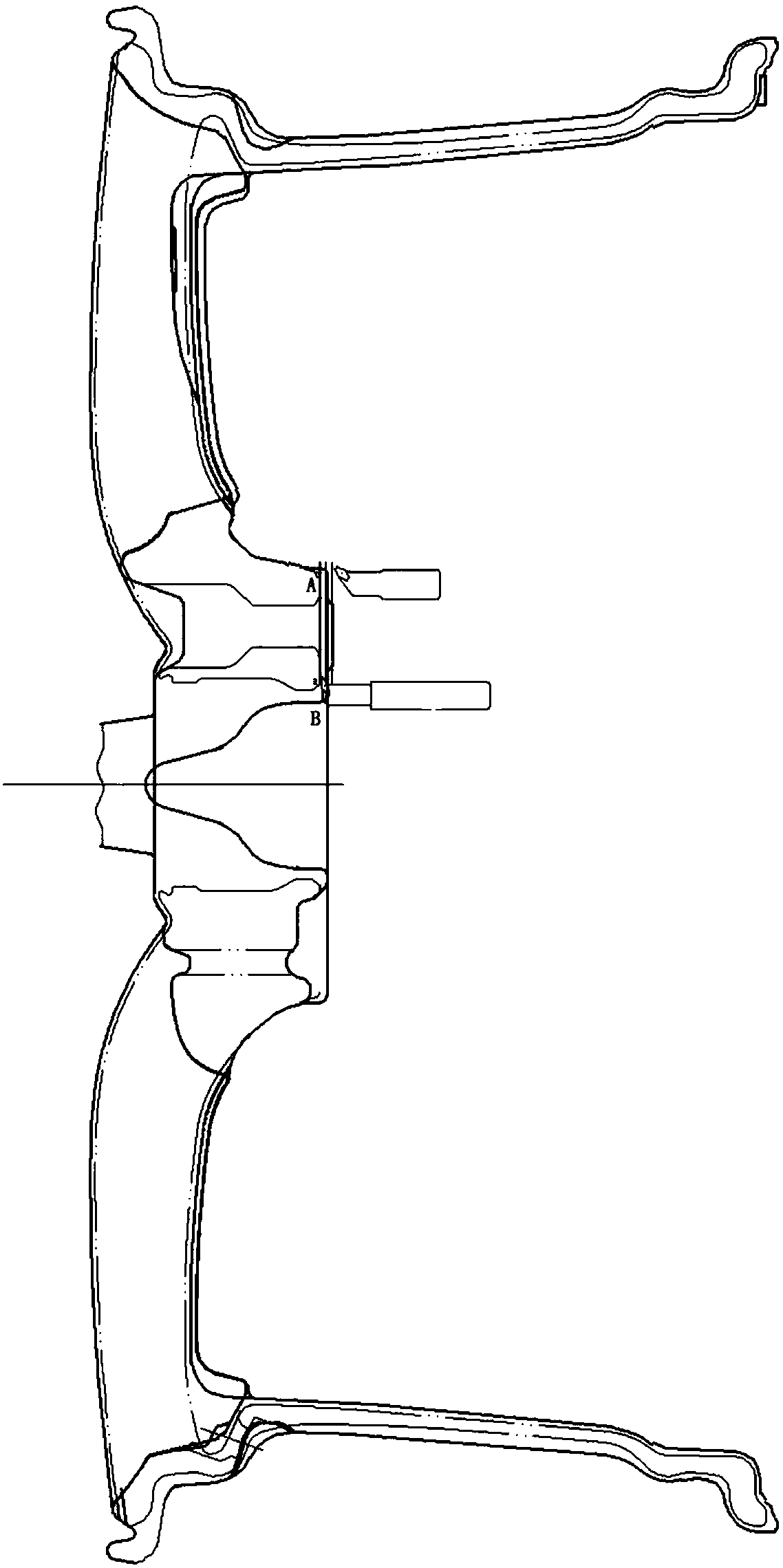

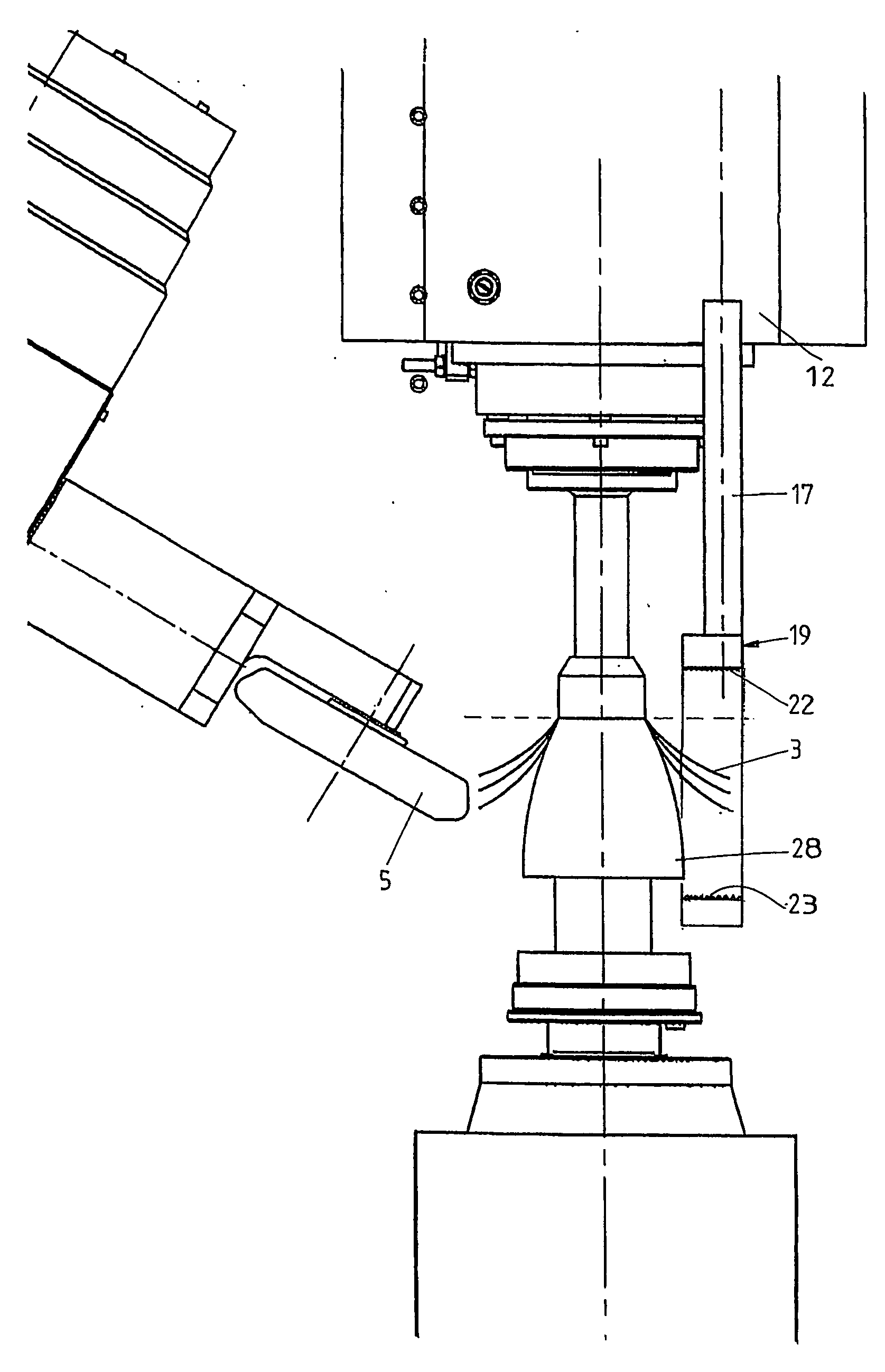

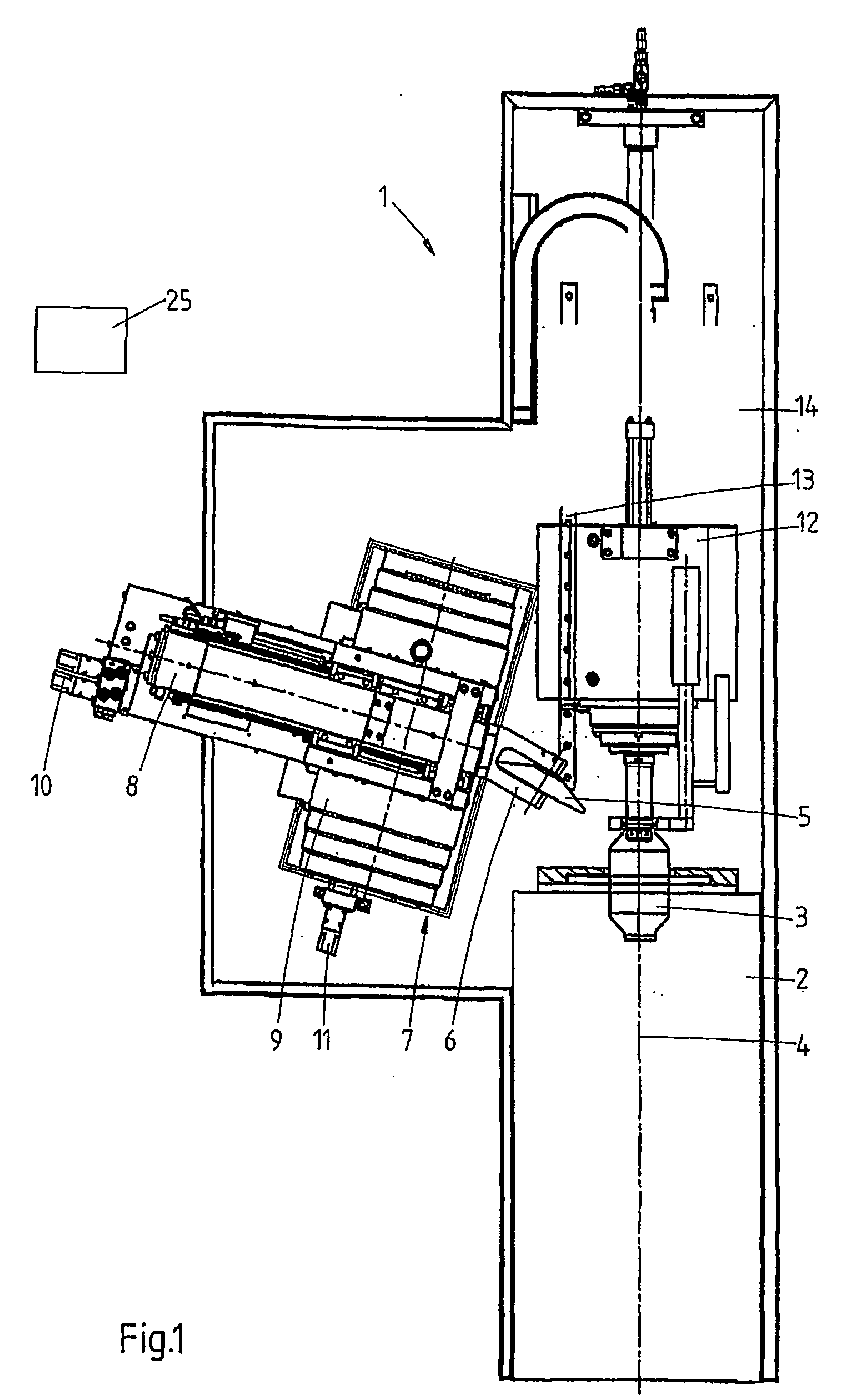

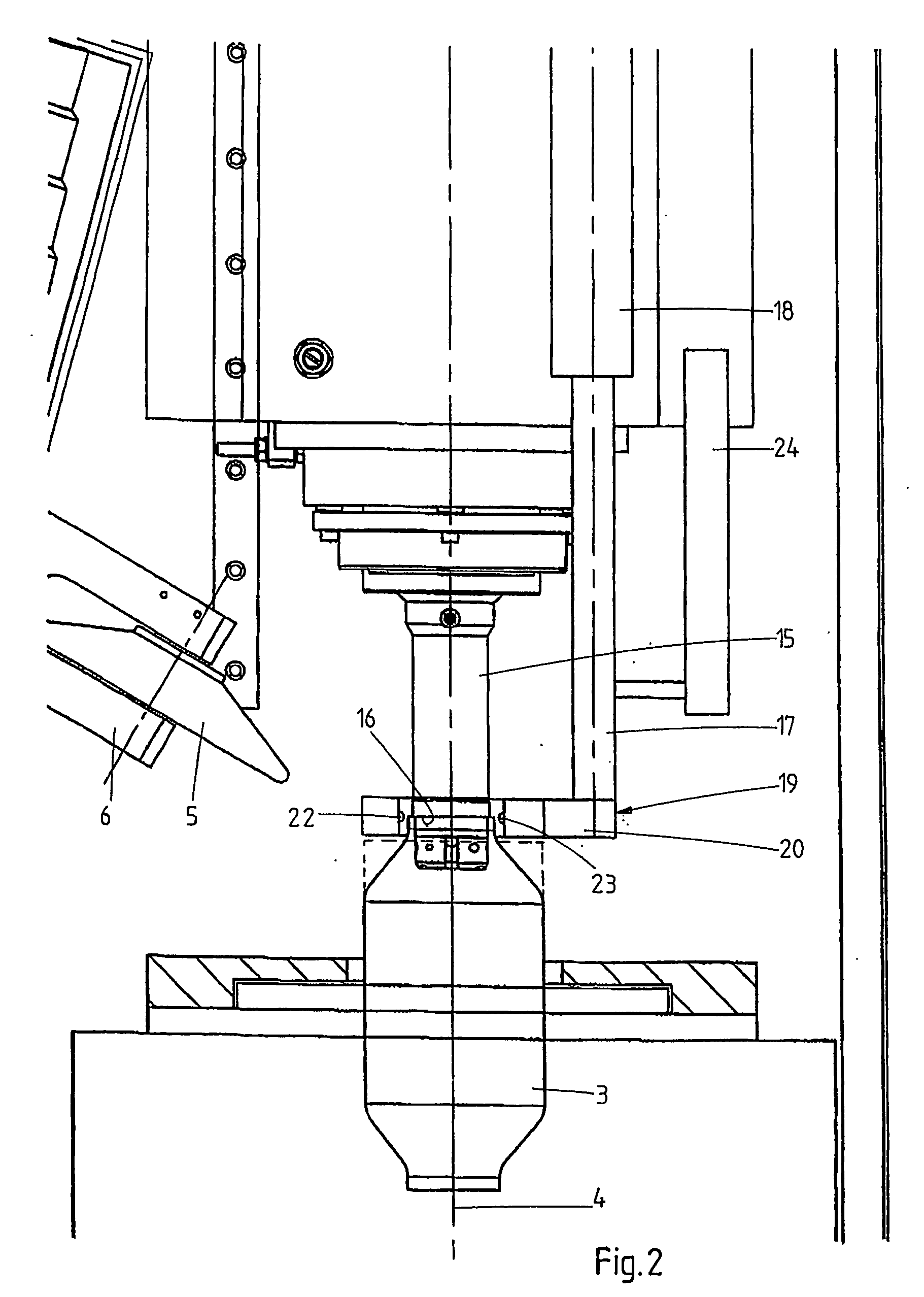

Method and forming machine for deforming a workpiece

InactiveUS7516635B2Reduce feed rateIncrease speedRare end control deviceMetal rolling arrangementsMechanical engineeringMetal cylinder

The invention relates to a method and a forming machine for deforming a workpiece, such as a metal cylinder or plate (3), by means of a tool, in particular one or more forming rollers (5), wherein the workpiece and / or the tool are rotated about an axis (4) relative to each other, the tool move; through one or more deforming curves and at least part of the workpiece is deformed. During the deforming process, values of one or more coordinates of the position of the extreme: edge of the workpiece are measured, and one or more parameters of the deforming process is / are changed on the basis of the measured values.

Owner:MASSE ACUTE OVER ()) ACUTE OVER ( ) E JOHAN

Method for machining of aluminum alloy hub flange face

The invention provides a method for machining of an aluminum alloy hub flange face. The method for machining of the aluminum alloy hub flange face is characterized by comprising the steps that (I) pre-machining is performed on a hub flange plate; (II), a 120-degree R3 boring cutter is used, machining is performed twice, the accumulated machining amount is 2 mm, and after machining is completed, 2.4 mm machining allowance of a flange face blank is reserved; (III) the 120-degree R3 boring cutter is used, machining is performed twice, the accumulated machining amount is 2 mm, and after machiningis completed, 0.4 mm machining allowance of the flange face blank is reserved; (IV) a 95-degree R0.8 hook cutter is used for machining, and after machining is completed, 0.05 mm machining allowance ofthe flange face is reserved; and (V) the 95-degree R0.8 hook cutter is used for machining, the remaining flange allowance is machined, and machining is completed. The method for machining of the aluminum alloy hub flange face has the beneficial effects that firstly, the feeding rate and the turning amount of the last time of finish turning of the flange face are reduced, and the qualification rate of the flange planeness is guaranteed; and secondly, the feeding direction is from the inner side of the flange plate to the outer side, a cutter bar bears force during turning, the feeding path isnot prone to deformation, and it is guaranteed that capacity is high.

Owner:CITIC DICASTAL

Method and forming machine for deforming a workpiece

InactiveUS20070101788A1Reduce feed rateIncrease speedRare end control deviceMetal rolling arrangementsEngineeringMechanical engineering

The invention relates to a method and a forming machine for deforming a workpiece, such as a metal cylinder or plate (3), by means of a tool, in particular one or more forming rollers (5), wherein the work piece and / or the tool are rotated about an axis (4) relative to each other, the tool move; through one or more deforming curves and at least part of the workpiece is deformed. During the deforming process, values of one or more coordinates of the position of the extreme: edge of the workpiece are measured, and one or more parameters of the deforming process is / are changed on the basis of the measured values.

Owner:MASSE ACUTE OVER ()) ACUTE OVER ( ) E JOHAN

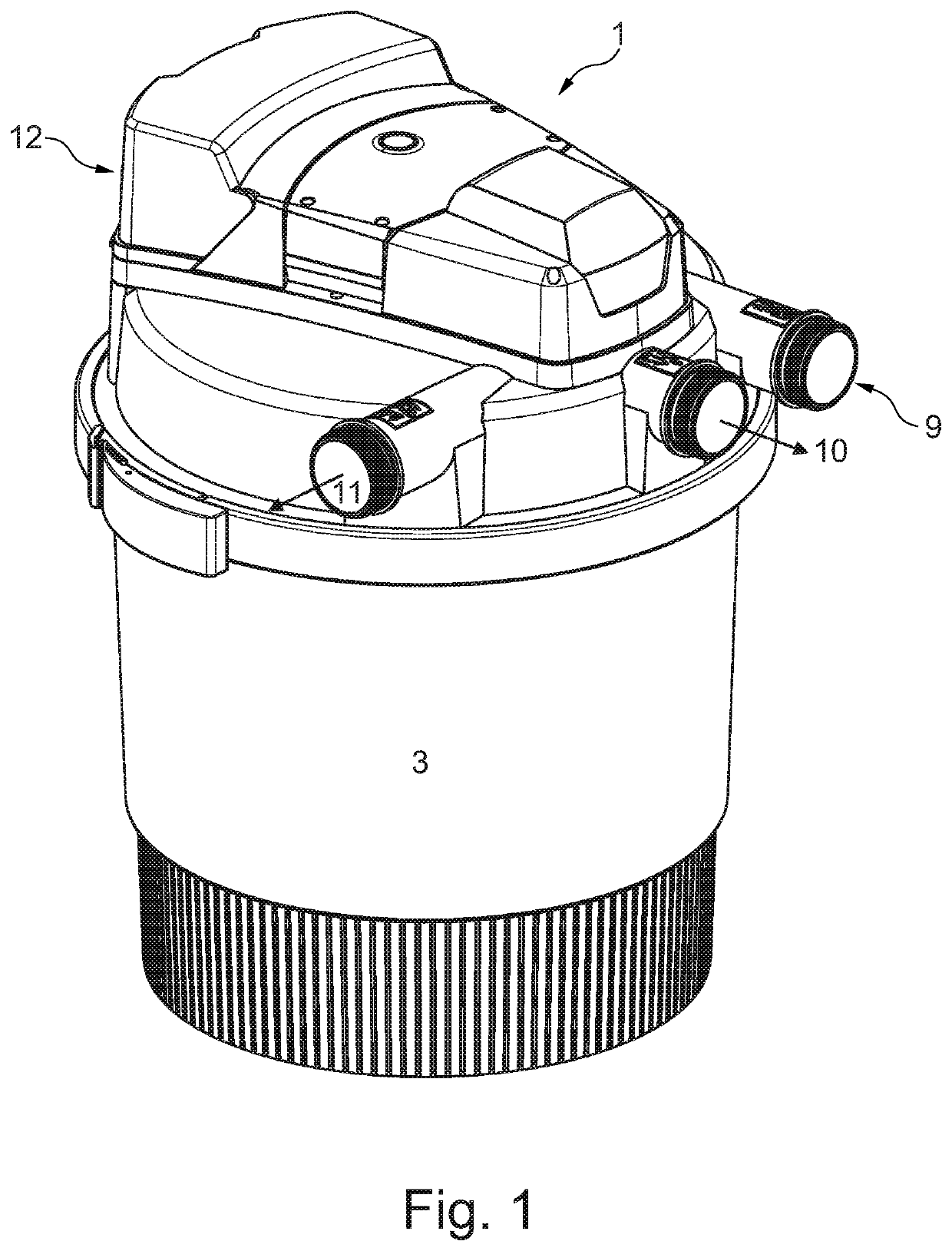

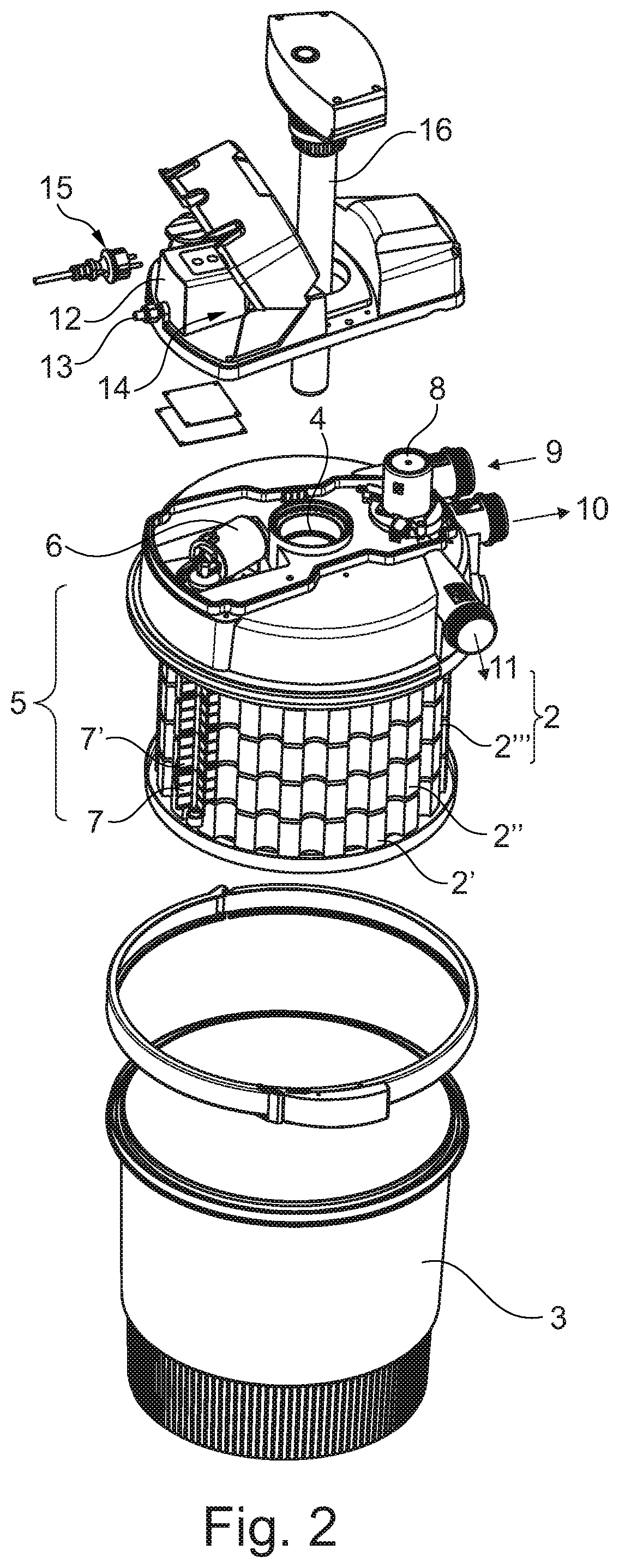

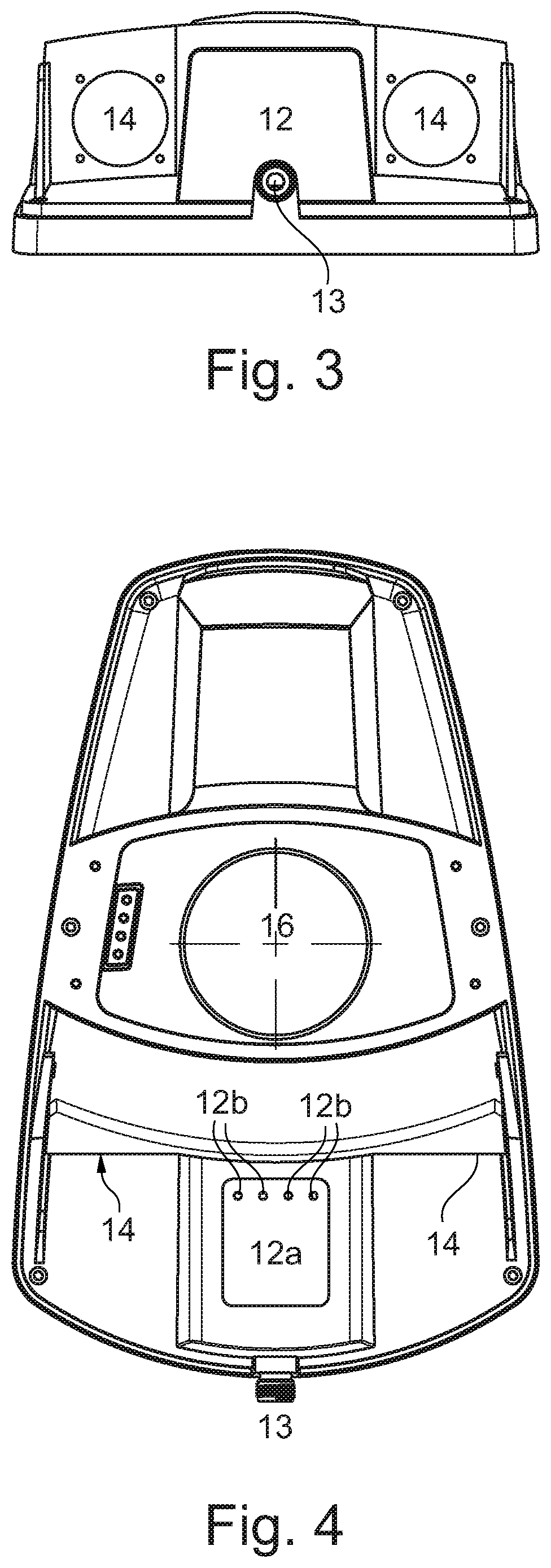

Pond filter and method for operating the pond filter

ActiveUS20210101816A1Low and no riskIncrease loadTreatment involving filtrationEnergy based wastewater treatmentAir pumpControl cell

A pond filter unit and a method for operating a pond filter unit is provided. A control unit controls the operation of the pond filter unit, including the cleaning cycle of the filter. The pond filter unit further includes one or more plugs for connecting one or more auxiliary devices, such as a separate pump, one or more additional pond filter units, illumination means / lamps, air pumps, and / or feed automats. The control unit of the pond filter further controls the one or more auxiliary devices connected to the plugs, such as pumps, air pumps, automatic feeding devices based on input settings for each of the one or more auxiliary devices. The control unit further controls the cleaning cycle for cleaning of the filter in the vessel.

Owner:EASYFIRM APS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com