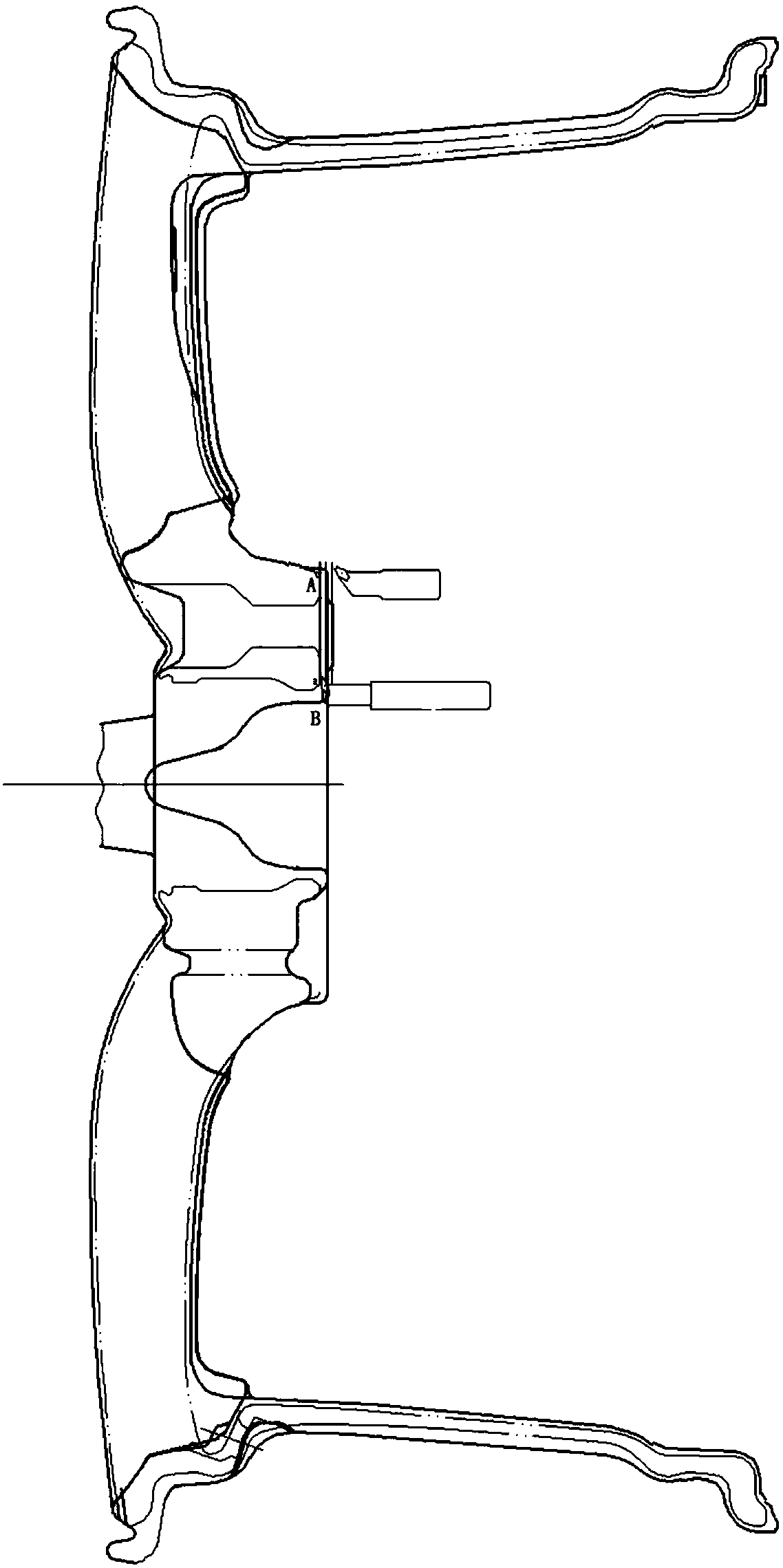

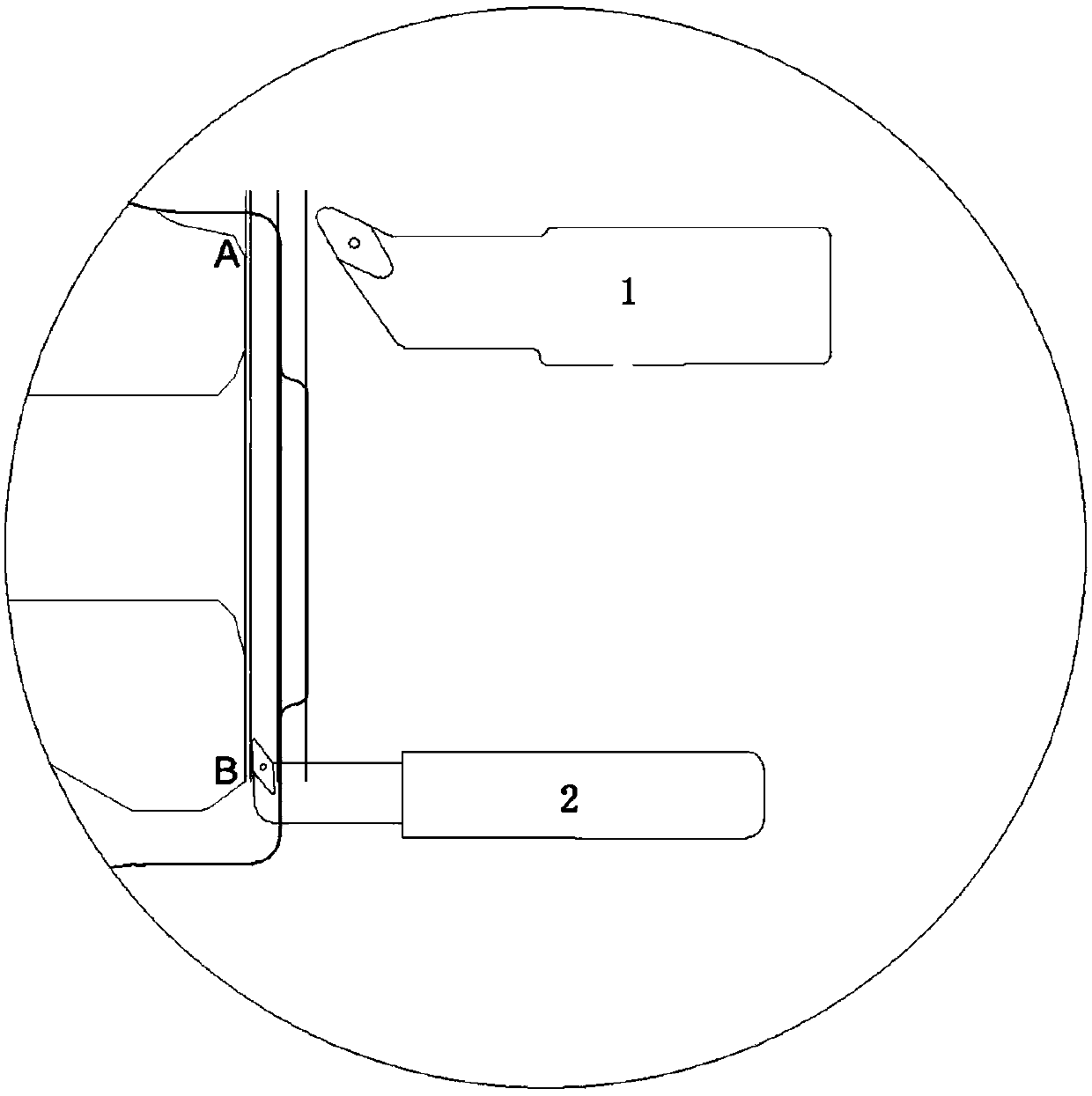

Method for machining of aluminum alloy hub flange face

一种铝合金轮毂、法兰面的技术,应用在金属加工设备、用于车床的刀具、轮毂等方向,能够解决车削量过大、车削量大、影响人身安全等问题,达到减小进给率、保证能力强、减小车削量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Flange turning four times, when using 120°R3 boring tool for rough turning, the forward rotation speed of the wheel hub is set to 1200r / min, the roughing feed rate is 0.40mm / r, and the turning amount on each side is 1mm; use 95°cutter for fine turning When the wheel hub forward speed is set to 1200r / min, the feed rate of the first pass of finishing turning is 0.15mm / r, the turning amount is 0.35mm, the second feeding rate of finishing turning is 0.1mm / r, and the turning amount is 0.05mm.

Embodiment 2

[0019] Flange turning four times, when using 120°R3 boring tool for rough turning, the wheel hub forward speed is set to 1400r / min, the roughing feed rate is 0.45mm / r, and the turning amount on each side is 1mm; use 95°cutter for fine turning When the wheel hub forward speed is set to 1300r / min, the feed rate of the first pass of fine turning is 0.18mm / r, the turning amount is 0.35mm, the feed rate of the second pass of fine turning is 0.11mm / r, and the turning amount is 0.05mm.

Embodiment 3

[0021] Flange turning four times, when using 120°R3 boring tool for rough turning, the wheel hub forward speed is set to 1500r / min, the rough turning feed rate is 0.5mm / r, and the turning amount on each side is 1mm; use 95°cutter for fine turning When the wheel hub forward speed is set to 1500r / min, the feed rate of the first pass of fine turning is 0.2mm / r, the turning amount is 0.35mm, the feed rate of the second pass of fine turning is 0.12mm / r, and the turning amount is 0.05mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com