Linear motor-driven plunger pump

A linear motor and drive column technology, applied in the direction of machines/engines, pumps, mechanical equipment, etc., can solve the problems of large inertial force and large rated thrust of the linear motor, and achieve the effect of reducing the number and enhancing the pollution resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

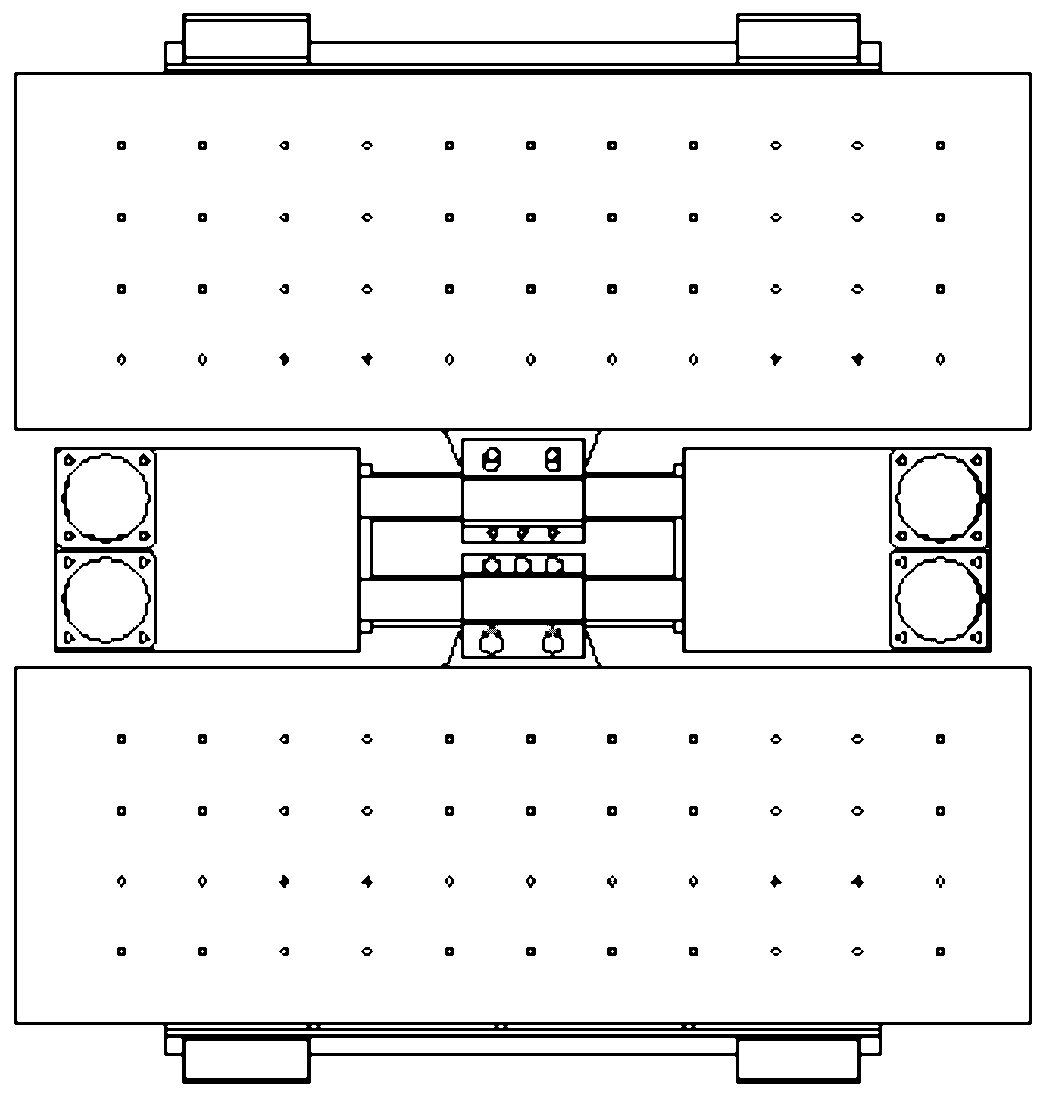

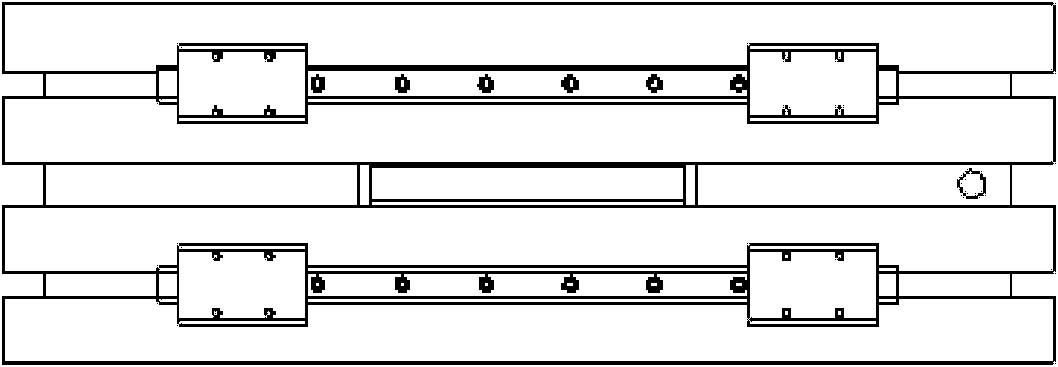

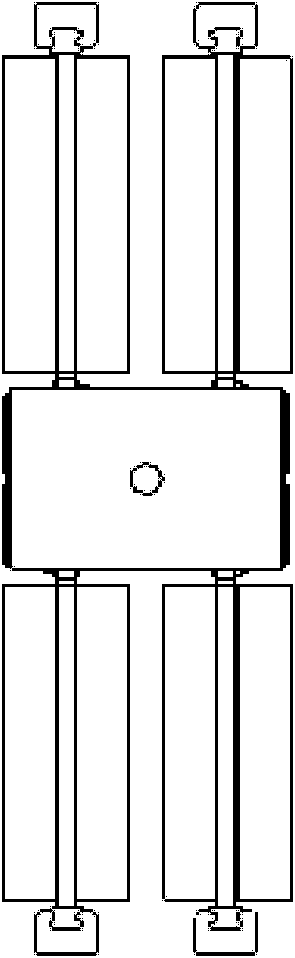

[0047] The linear motor driven plunger pump includes a mechanical part and an electrical part, and the mechanical part and the electrical part are connected by a linear motor mover. Taking a plunger pump with four linear motors as an example, each linear motor of the linear motor driven plunger pump is driven by a corresponding driver, and the controller outputs control signals with a certain phase difference to the four drivers. After the control signal is amplified, it is output to the corresponding linear motor stator 11 respectively, thereby driving the corresponding linear motor mover 9, and the mover 9 drives the plunger rod 6 to reciprocate and linearly move in a certain motion plan through the compression flange 13 .

[0048] A group of coil-type stators 11 drives the permanent magnet mover 9 to reciprocate on the fixed slider 8, the permanent magnet mover 9 drives the double-acting plunger rod 6 to reciprocate through the compression flange 13, and the double-acting p...

Embodiment 2

[0053] The two cylinders of the plunger pump are symmetrical, and both adopt the structure of cylinder I. The inner sides of the two suction through holes of the two cylinders are connected through the suction connecting pipe, and the outer ends of the two suction through holes are connected with the suction main pipe. The inner side of the hole is connected by the extruding connecting pipe, and the outer end of the extruding through hole is connected with the extruding main pipe, so as to realize the communication between the suction circuit and the extruding circuit of the two cylinders. The beneficial effect of the cylinder structure is that it can adapt to the field application environment of the plunger pump, and can suck liquid from one end of the plunger pump and press liquid from the other end or suck liquid and press liquid from the same end of the plunger pump.

[0054] Through material reselection and structural fine-tuning, the plunger pump can be used as the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com