Wear-resistant super-hydrophilic anti-reflecting coating

A super-hydrophilic and coating technology, applied in the field of super-hydrophilic anti-reflection coating, can solve the problems of high cost, high energy consumption, difficult to achieve, etc., and achieve good anti-reflection performance, simple preparation process, and simple equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

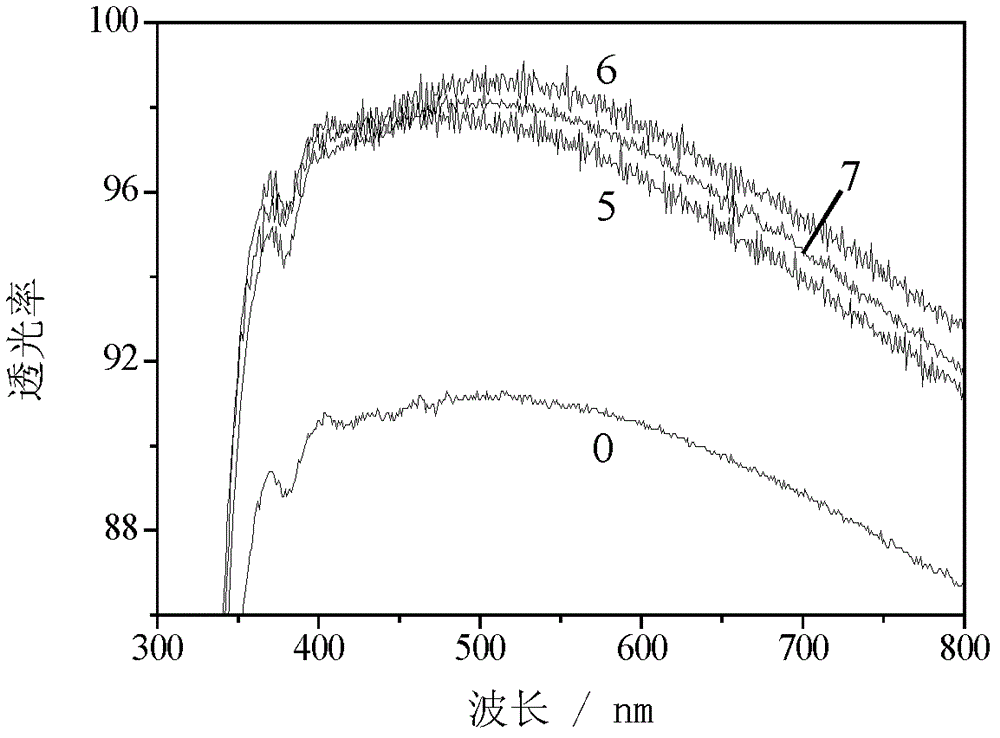

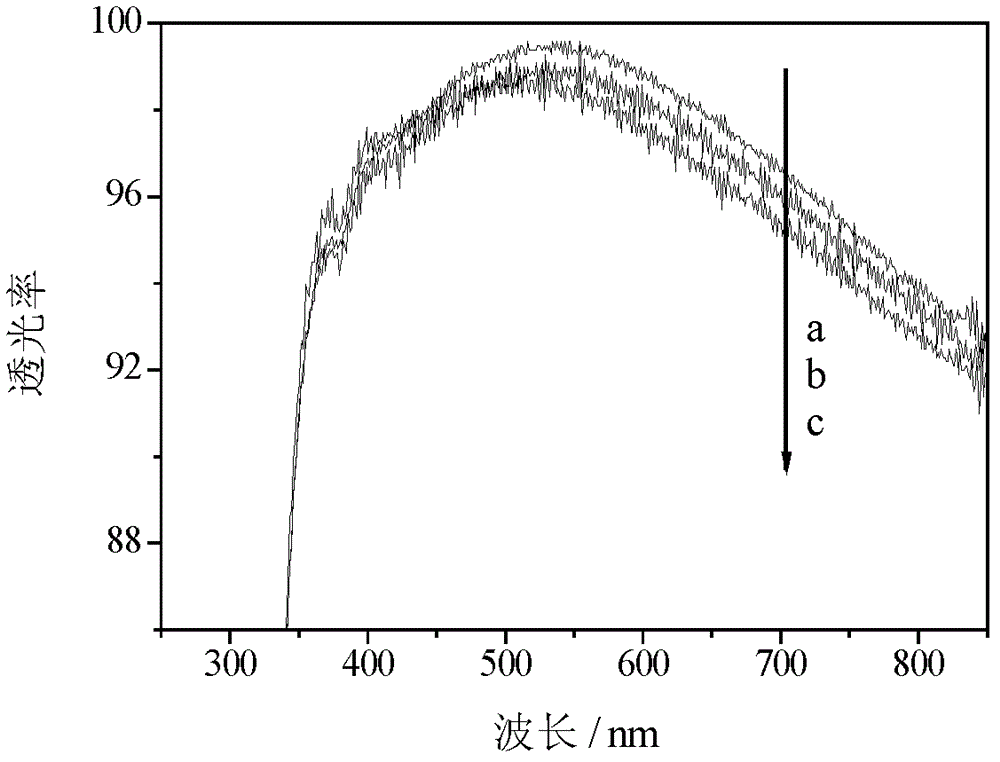

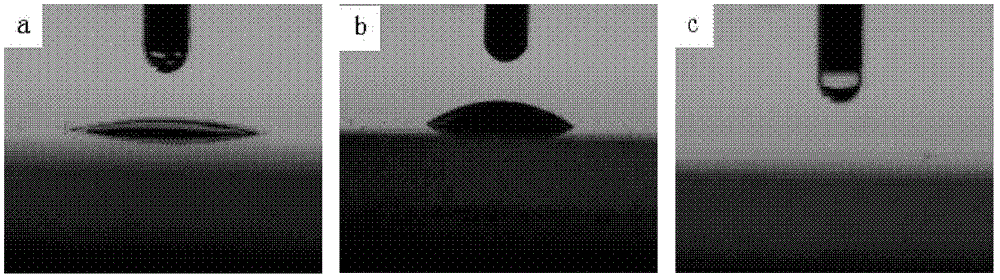

Embodiment 1

[0035] Wear-resistant super-hydrophilic anti-reflection coating: five layers of SiO with a particle size of 10-20nm 2 Nano particle composition, its preparation method comprises the following steps:

[0036] (1) Add 3mL of ammonia water and 100mL of absolute ethanol into the Erlenmeyer flask at room temperature and stir for 10 minutes, then stir at 60°C for 2 minutes, add 2mL of tetraethyl orthosilicate (TEOS) dropwise under stirring, and stir vigorously at 60°C for 10 minutes Hours, a translucent suspension was obtained containing SiO particles with a particle size of 10-20 nm. 2 Spherical small particle suspension, and dilute it with water into a suspension with a mass fraction of 0.1% to 1% for later use;

[0037] (2) Immerse the ordinary glass sheet into the newly prepared Pirhana solution (the H concentration is about 98%) 2 SO 4 with a mass concentration of about 30% H 2 o 2 5 to 20 minutes in the mixed solution mixed with a volume ratio of 7:3), take it out, wash i...

Embodiment 2

[0043] Wear-resistant super-hydrophilic anti-reflective coating: composed of six layers of SiO with a particle size of 20-30nm 2 Nano particle composition, its preparation method comprises the following steps:

[0044] (1) Add 4mL of ammonia water and 100mL of absolute ethanol into the Erlenmeyer flask at room temperature and stir for 10 minutes, then stir at 60°C for 2 minutes, add 2mL of tetraethyl orthosilicate (TEOS) dropwise under stirring, and continue stirring at 60°C for 12 Hours, a translucent suspension was obtained containing SiO particles with a particle size of 20-30 nm. 2 Spherical small particle suspension, and dilute it with water into a suspension with a mass fraction of 0.1% to 1% for later use;

[0045] (2) Immerse the ordinary glass sheet into the newly prepared Pirhana solution (the H concentration is about 98%) 2 SO 4 with a mass concentration of about 30% H 2 o 2 5 to 20 minutes in the mixed solution mixed with a volume ratio of 7:3), take it out, w...

Embodiment 3

[0051] Wear-resistant super-hydrophilic anti-reflection coating: composed of seven layers of SiO with a particle size of 30-40nm 2 Nano particle composition, its preparation method comprises the following steps:

[0052] (1) Add 4mL of ammonia water and 100mL of absolute ethanol into the Erlenmeyer flask at room temperature and stir for 10 minutes, then stir at 60°C for 5 minutes, add 3mL tetraethyl orthosilicate (TEOS) dropwise under stirring, and continue stirring at 60°C for 10 minutes Hours, a translucent suspension was obtained containing SiO particles with a particle size of 30-40 nm. 2 Spherical small particle suspension, and dilute it with water into a suspension with a mass fraction of 0.1% to 1% for later use;

[0053] (2) Immerse the ordinary glass sheet into the newly prepared Pirhana solution (the H concentration is about 98%) 2 SO 4 with a mass concentration of about 30% H 2 o 2 5 to 20 minutes in the mixed solution mixed with a volume ratio of 7:3), take it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com