Patents

Literature

264 results about "Superhydrophilicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

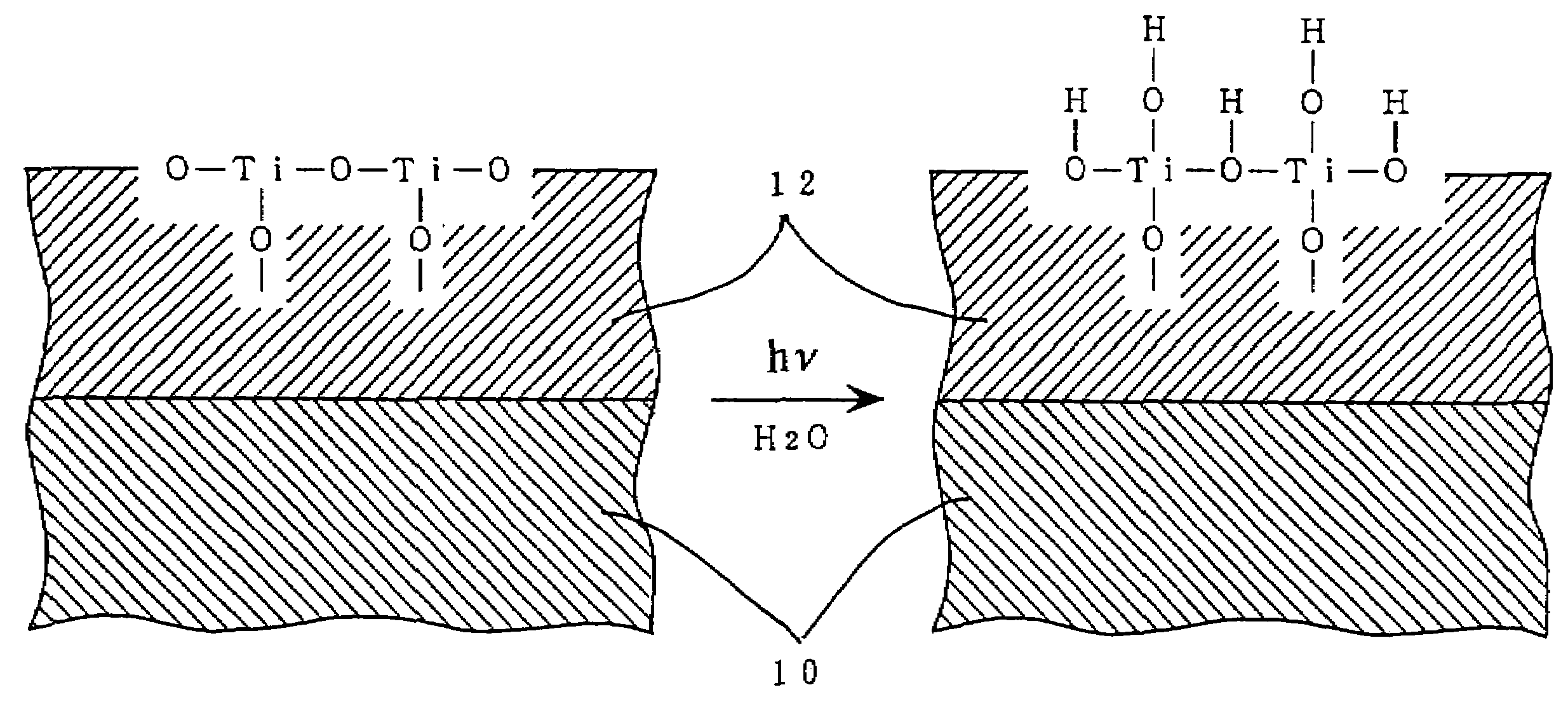

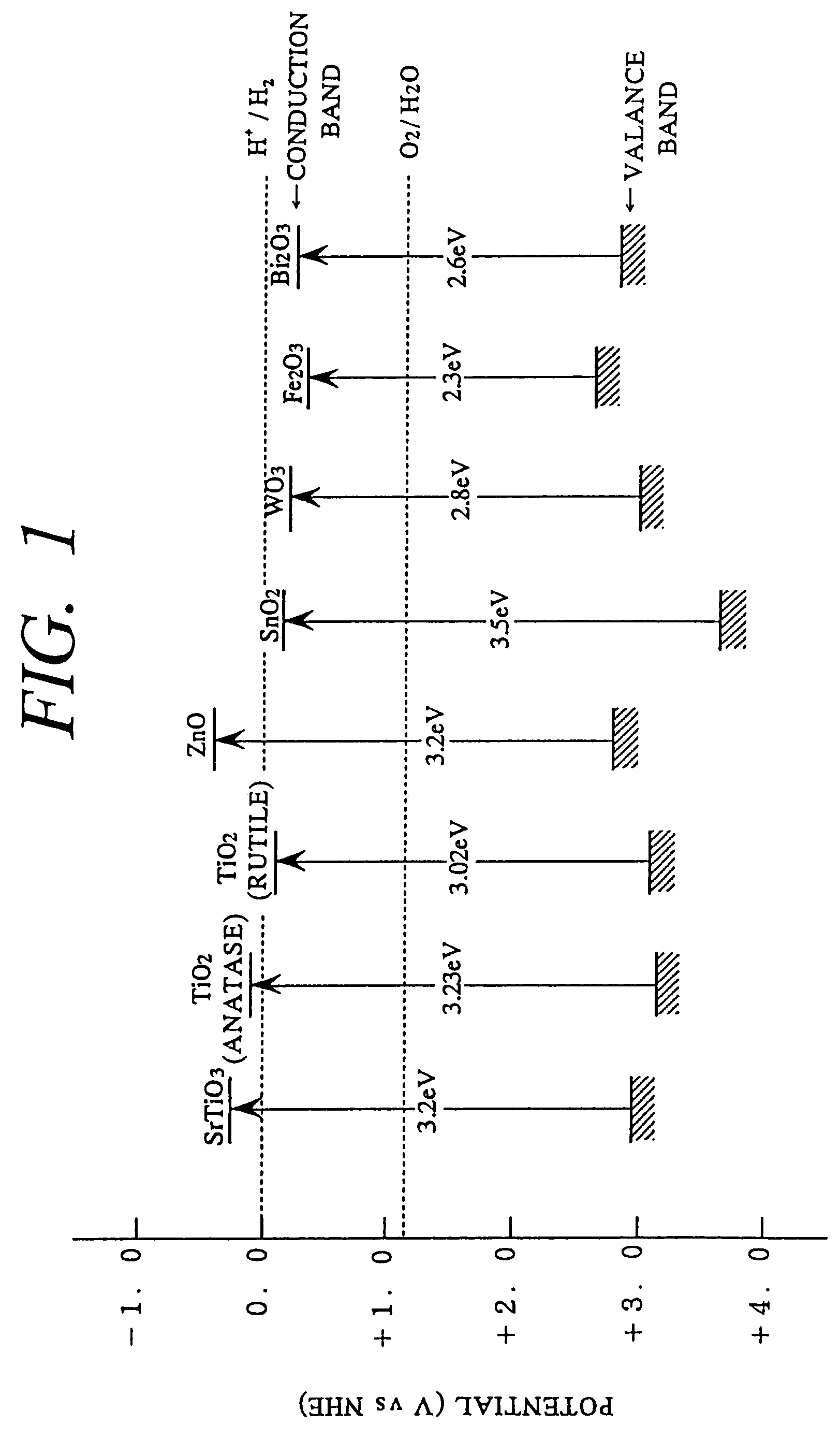

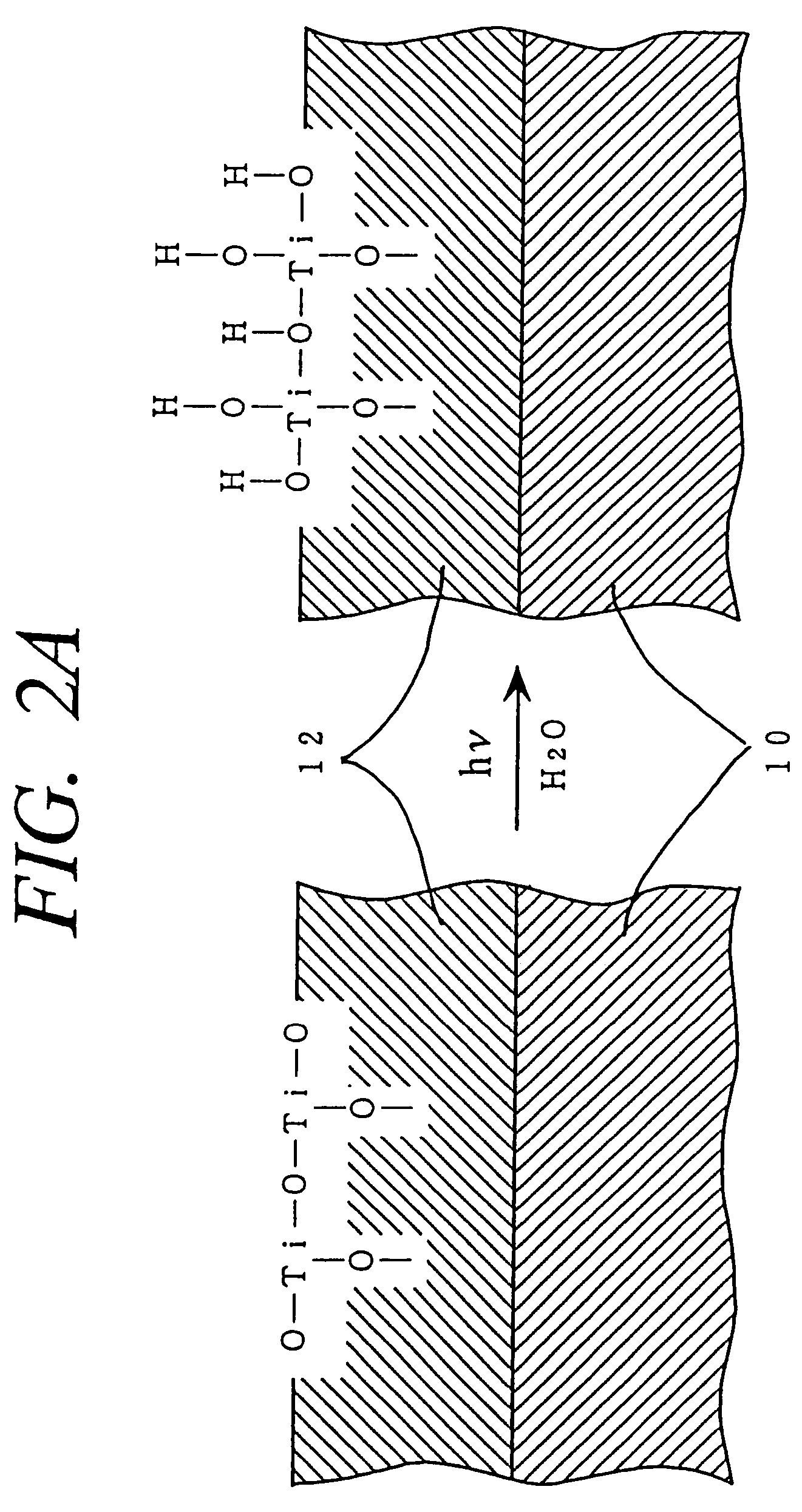

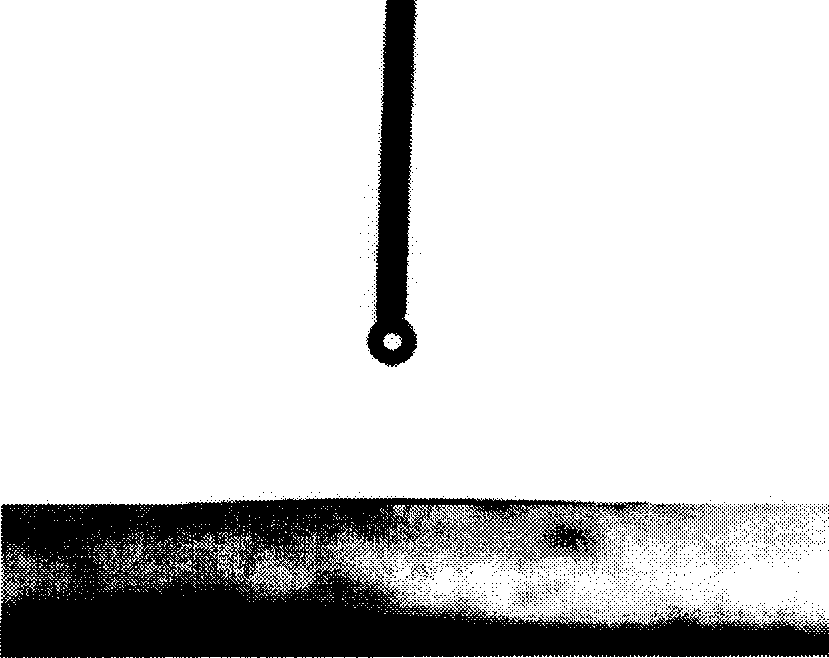

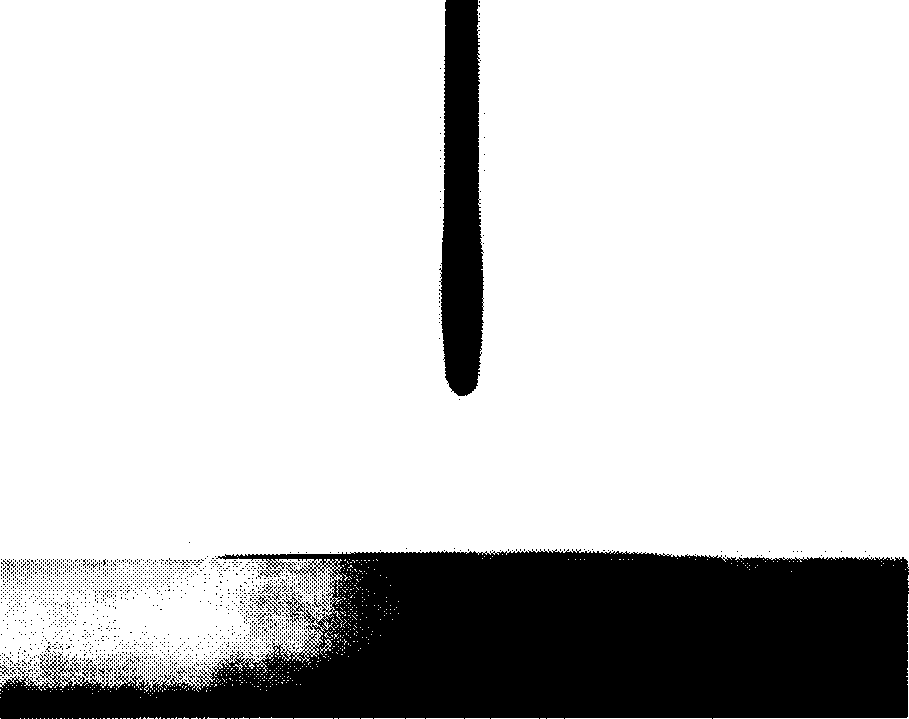

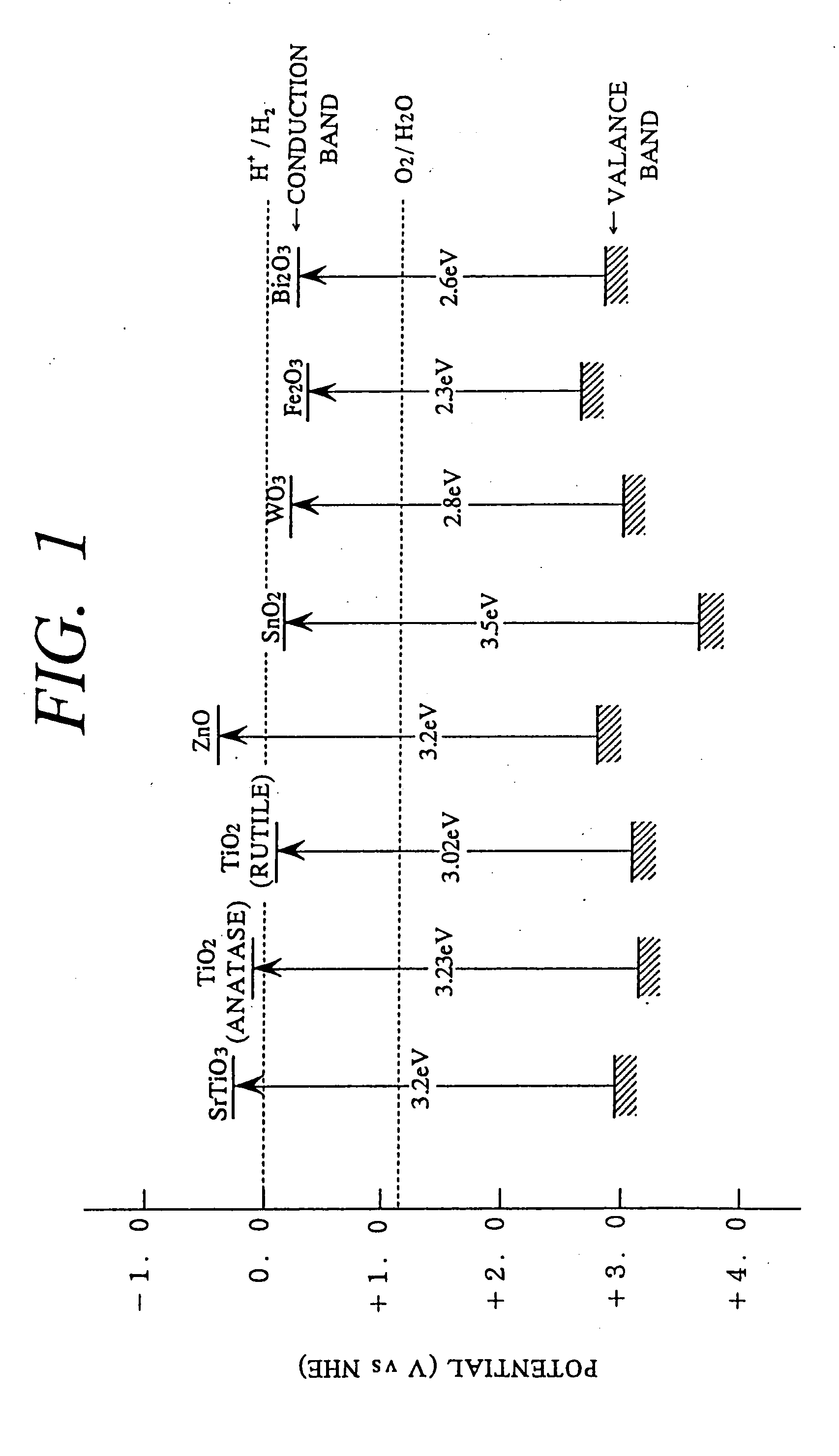

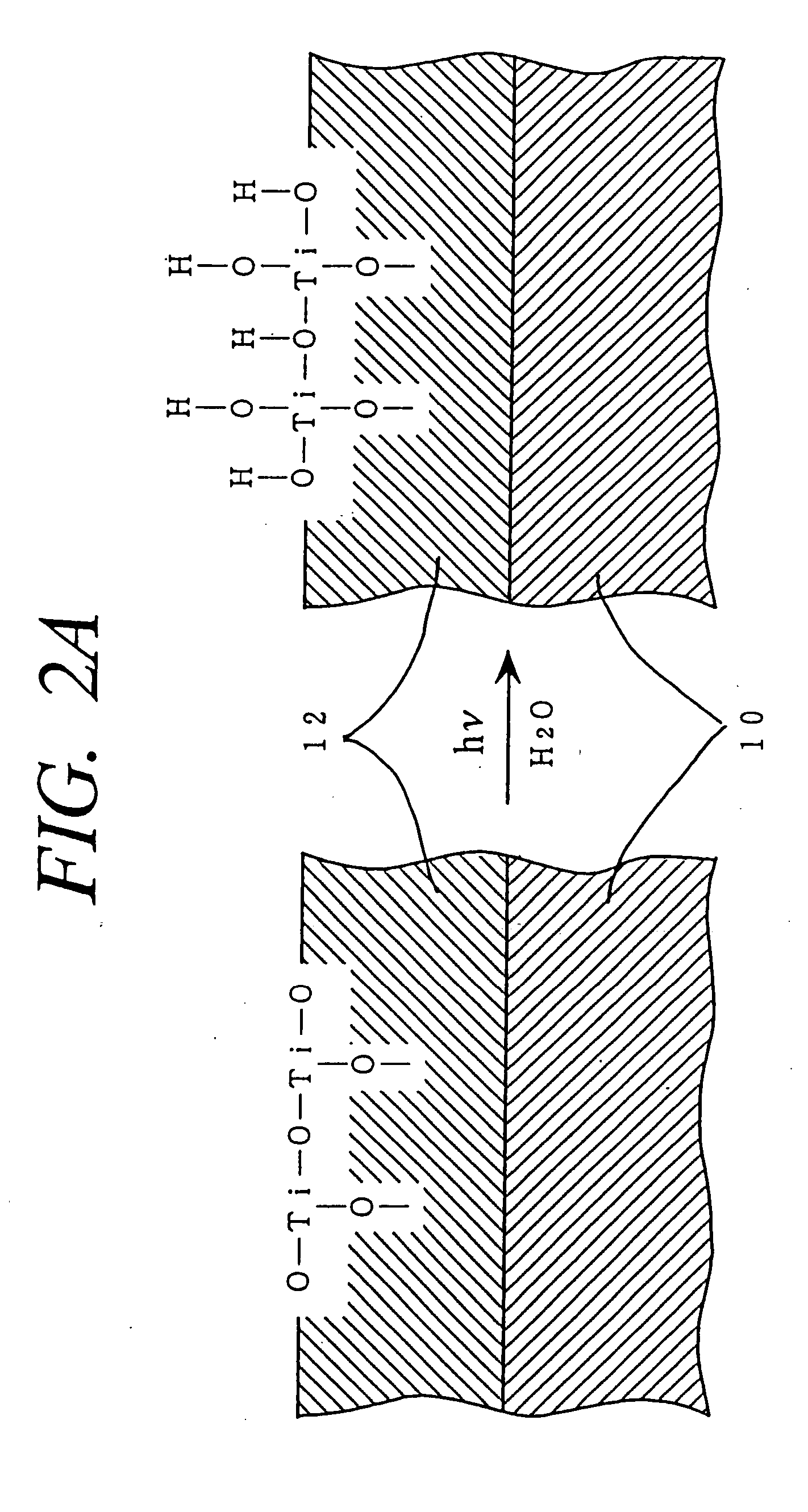

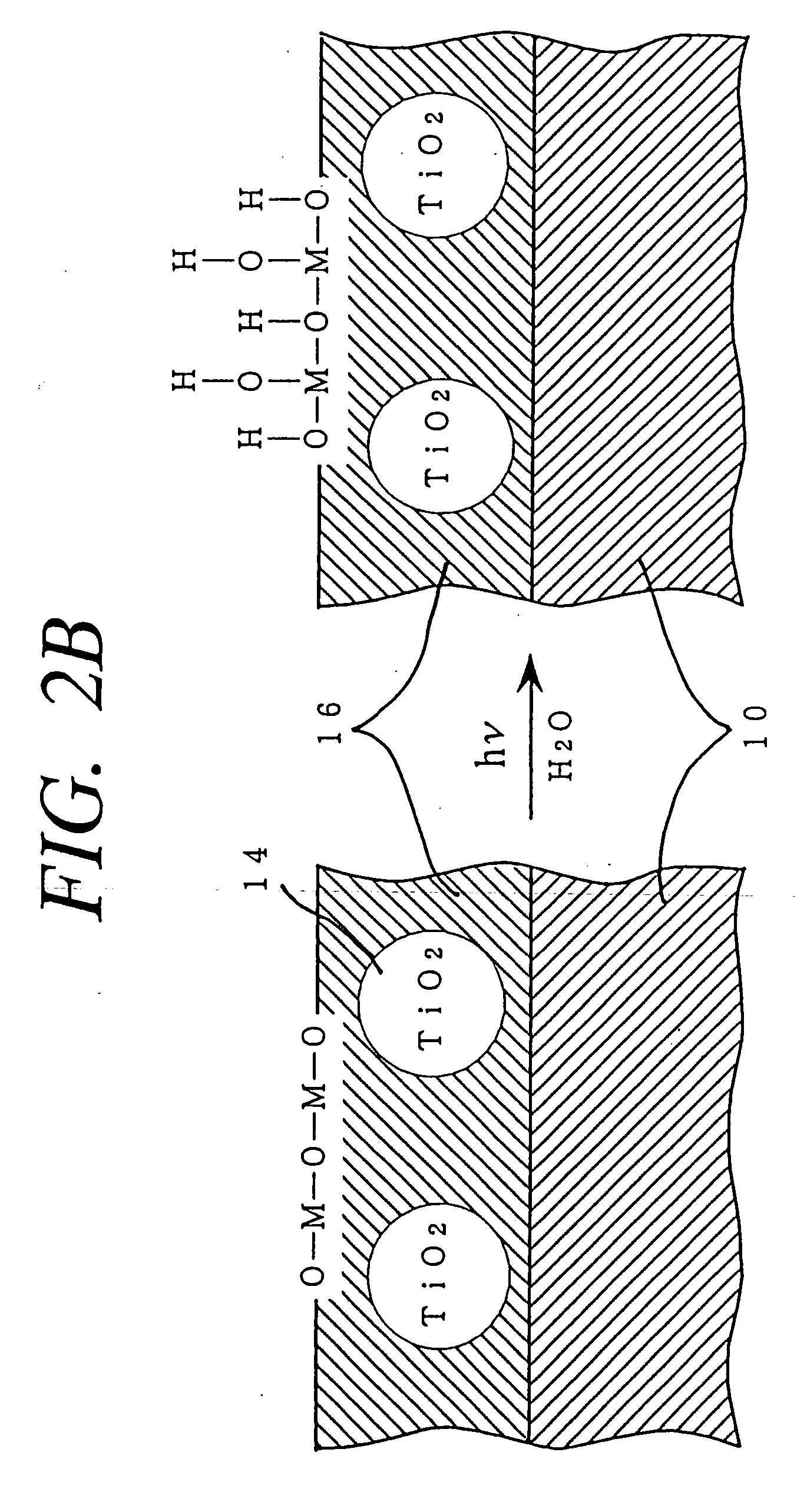

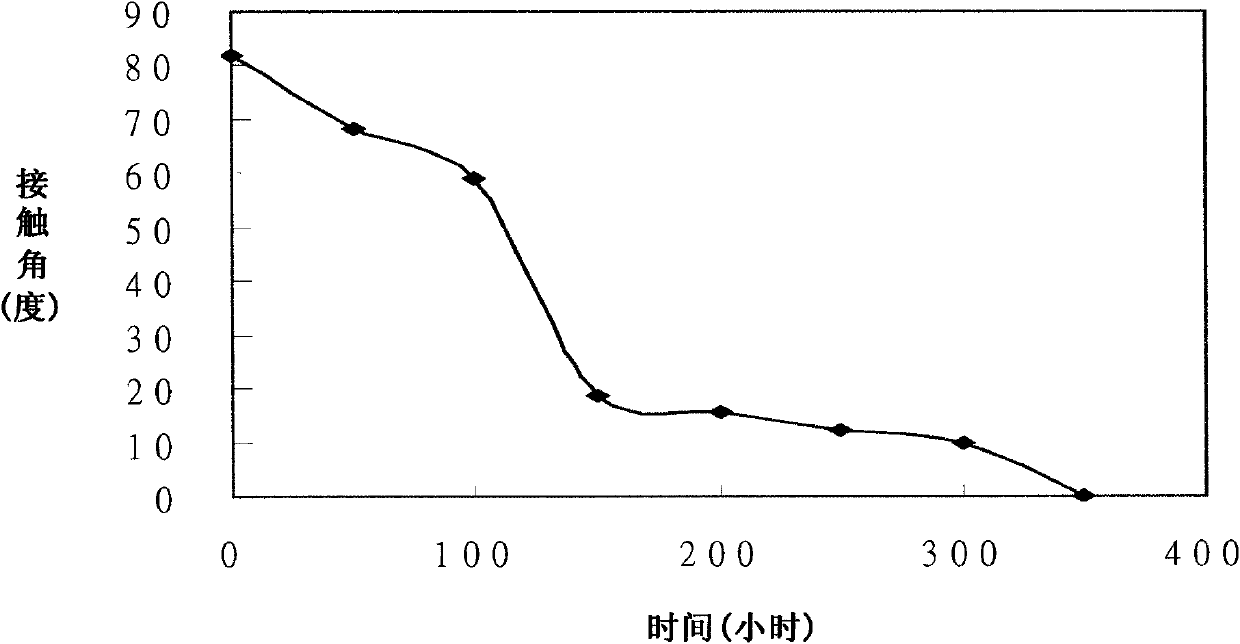

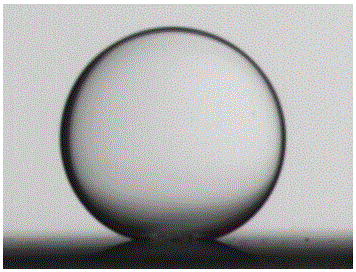

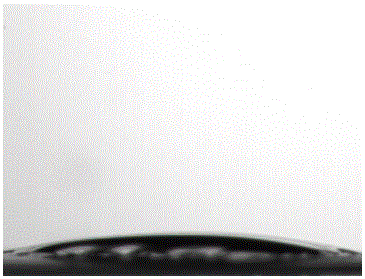

Superhydrophilicity refers to the phenomenon of excess hydrophilicity, or attraction to water; in superhydrophilic materials, the contact angle of water is equal to zero degrees. This effect was discovered in 1995 by the Research Institute of Toto Ltd. for titanium dioxide irradiated by sunlight. Under light irradiation, water dropped onto titanium dioxide forms no contact angle (almost 0 degrees).

Method for photocatalytically rendering a surface of a substrate superhydrophilic, a substrate with superhydrophilic photocatalytic surface, and method of making thereof

A method of preventing or reducing fogging of a surface of a composite when subjected to humid conditions includes providing a composite with a surface. The composite includes a substrate and a photocatalytic surface layer. The photocatalytic surface layer includes a photocatalyst. The method further includes subjecting the photocatalyst to photoexcitation to render the surface of the composite hydrophilic, wherein, after the photoexcitation, the surface of the composite has a water wettability of less than 10° in terms of the contact angle with water. The method further includes subjecting the composite to humidity that is sufficient to induce fogging of the substrate if the photocatalytic surface layer were absent.

Owner:TOTO LTD

Superhydrophilic and Superhydrophobic Powder Coated Fabric

InactiveUS20090042469A1Fibre treatmentSynthetic resin layered productsSuperhydrophobeSelf-assembled monolayer

Superhydrophilic and superhydrophobic fabrics are taught having a superhydrophilic or superhydrophobic powder disposed on the fabric. The superhydrophilic powder has at least one material of sodium borosilicate glass and porous diatomaceous earth. The powder material has a contiguous interpenetrating structure with a plurality of spaced apart nanostructured surface features. The superhydrophilic powder is switched to superhydrophobic by adding at least one superhydrophobic material of perfluorinated organics, fluorinated organics, and self-assembled monolayers.

Owner:UT BATTELLE LLC

Application of super hydrophilicity and/or super lipophilicity nano pore material

Owner:INST OF CHEM CHINESE ACAD OF SCI

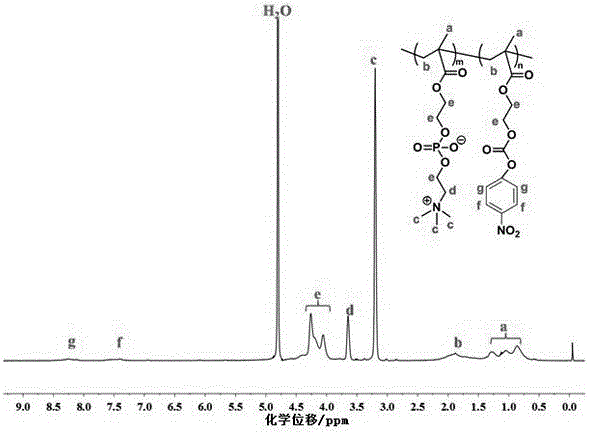

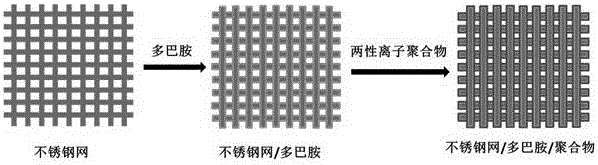

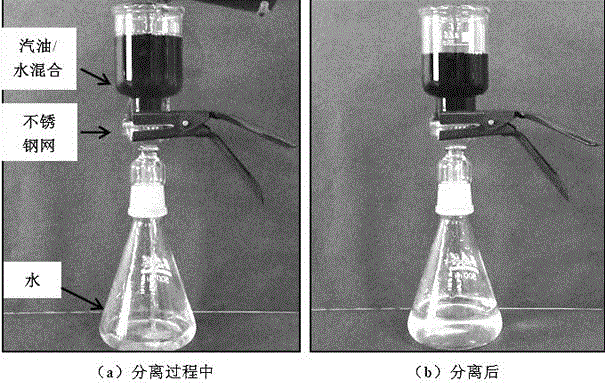

Method for preparing hydrophilic/oleophobic oil-water separation stainless steel net films

ActiveCN105964014AHigh strengthCorrosion resistantMembranesSemi-permeable membranesDip-coatingPollution

The invention relates to a method for preparing hydrophilic / oleophobic oil-water separation stainless steel net films. Stainless steel nets are used as bases. The method includes constructing a poly-dopamine medium layer on the surface of each stainless steel net in dip-coating or spraying modes; dipping the stainless steel nets with the poly-dopamine medium layers in zwitter-ionic polymers with active ester groups; or spraying the zwitter-ionic polymers with the active ester groups on the surfaces and meshes of the stainless steel nets with the poly-dopamine medium layers; carrying out amidation coupling reaction on the zwitter-ionic polymers and each poly-dopamine medium layer to form a stable hydrophilic polymer film on the surface and the meshes of the corresponding stainless steel net. The method has the advantages that the hydrophilic / oleophobic oil-water separation stainless steel net films prepared by the aid of the method are super-hydrophilic and are high in water flux, stable in structural performance and high in anti-pollution capacity; the method has a broad application prospect in the aspects of recycling marine oil slick, removing water from crude oil, treating oily sewage and the like.

Owner:NORTHWEST UNIV

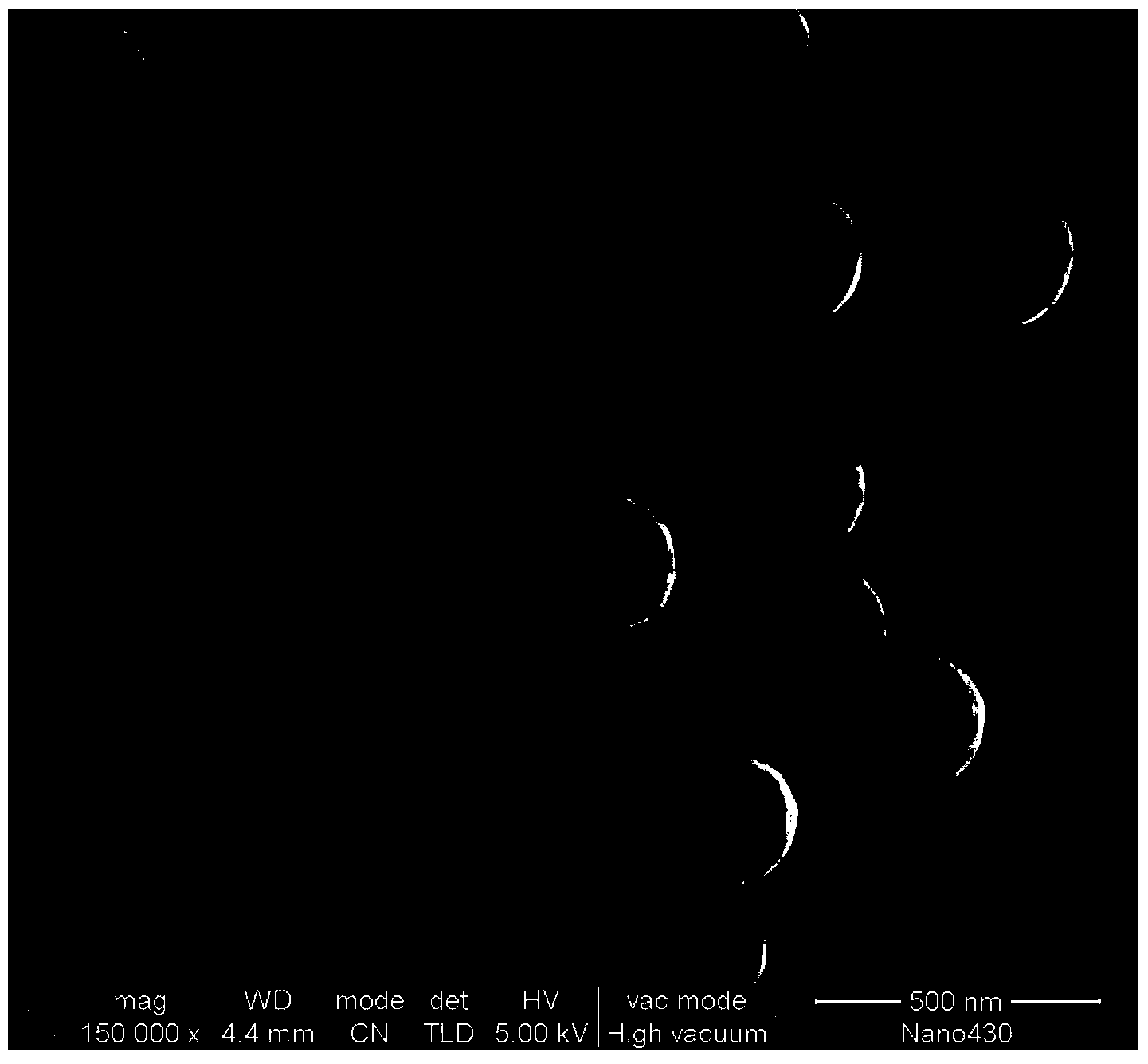

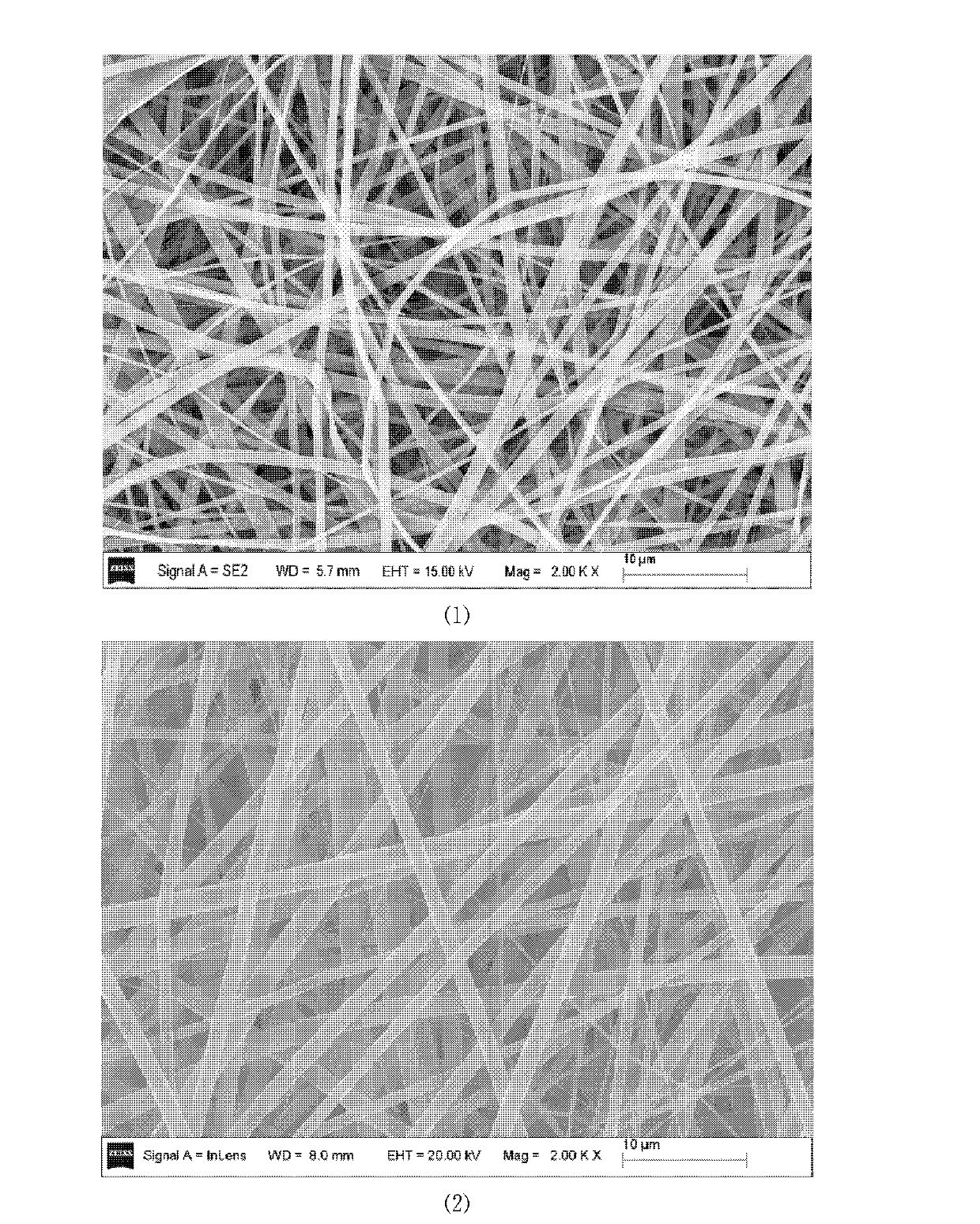

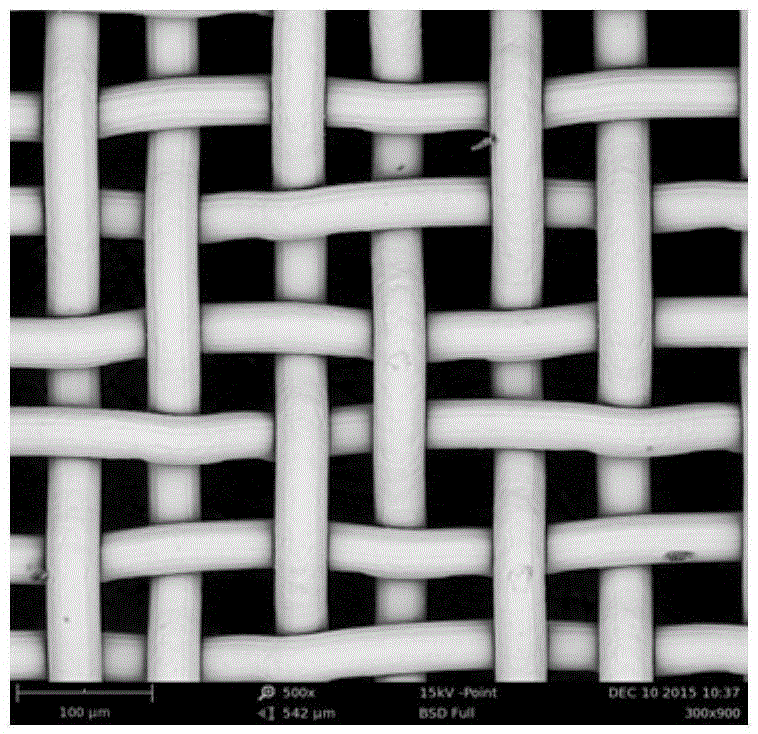

Super-hydrophilic and underwater super-oleophobic oil-water separation mesh film and preparation method thereof

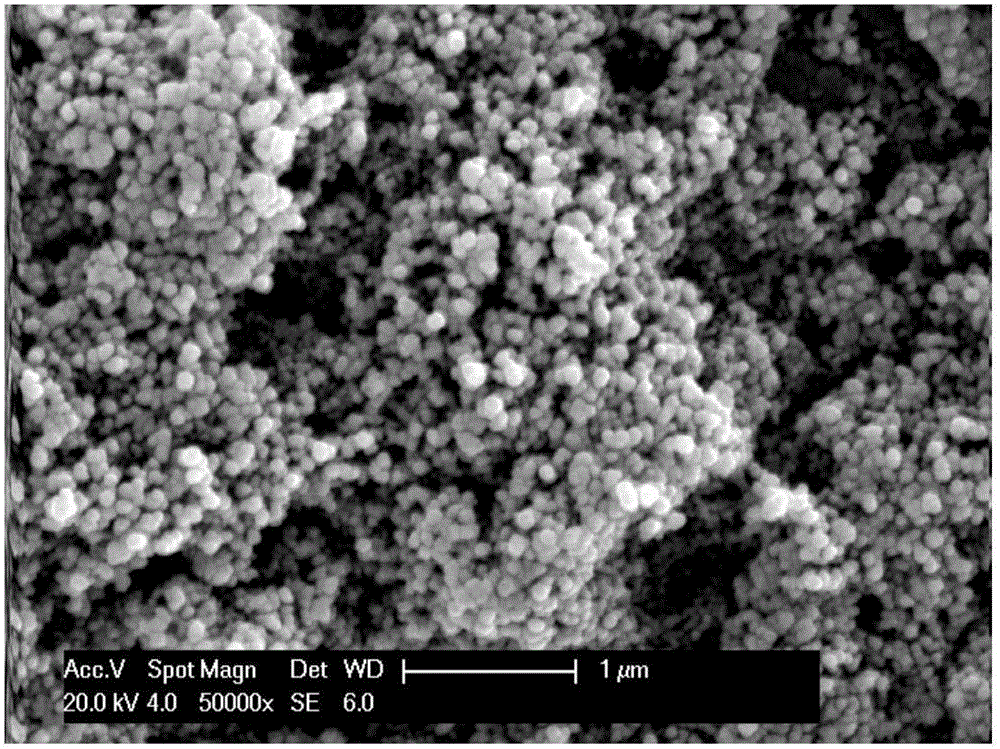

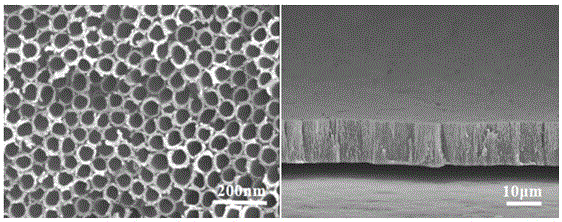

InactiveCN103893999AHas super oleophobic propertiesLow costLiquid separationMicro nanoPolymer science

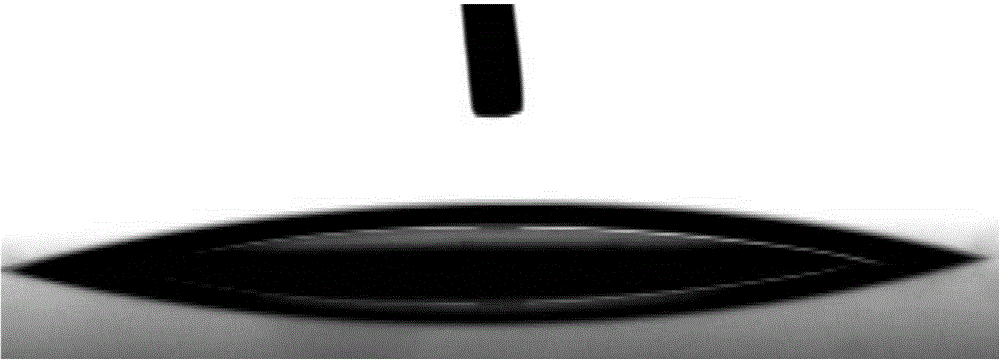

The invention discloses a super-hydrophilic and underwater super-oleophobic oil-water separation mesh film and a preparation method thereof. The method comprises the following steps: ultrasonically cleaning a fabric silk screen and airing at normal temperature; preparing polymer emulsion particle microspheres of which the particle size distribution is 100-500nm and the surface is rich in carboxyl salt by adopting an emulsion polymerization, and preparing nano-silica sol by adopting a sol-gel method; preparing hydrophilic emulsion particles and the nano sol into a mixed solution and performing uniformly ultrasonic dispersion; immersing the silk screen into the mixed solution, vertically lifting up, or directly spraying by adopting a high-pressure spray gun, and drying to obtain the super-hydrophilic and underwater super-oleophobic oil-water separation mesh film. The surface of the oil-water separation mesh film has a spherical rough micro-nano binary structure, contact angles with water and oil in air are 0 degree, and the oil-water separation mesh film has the super hydrophilicity. A contact angle with oil drops under water is larger than 150 degrees, and the oil-water separation mesh film has low adhesion properties on the oil drops. The mesh film can be applied to separating oil water mixtures and treating oily sewage.

Owner:SOUTH CHINA UNIV OF TECH

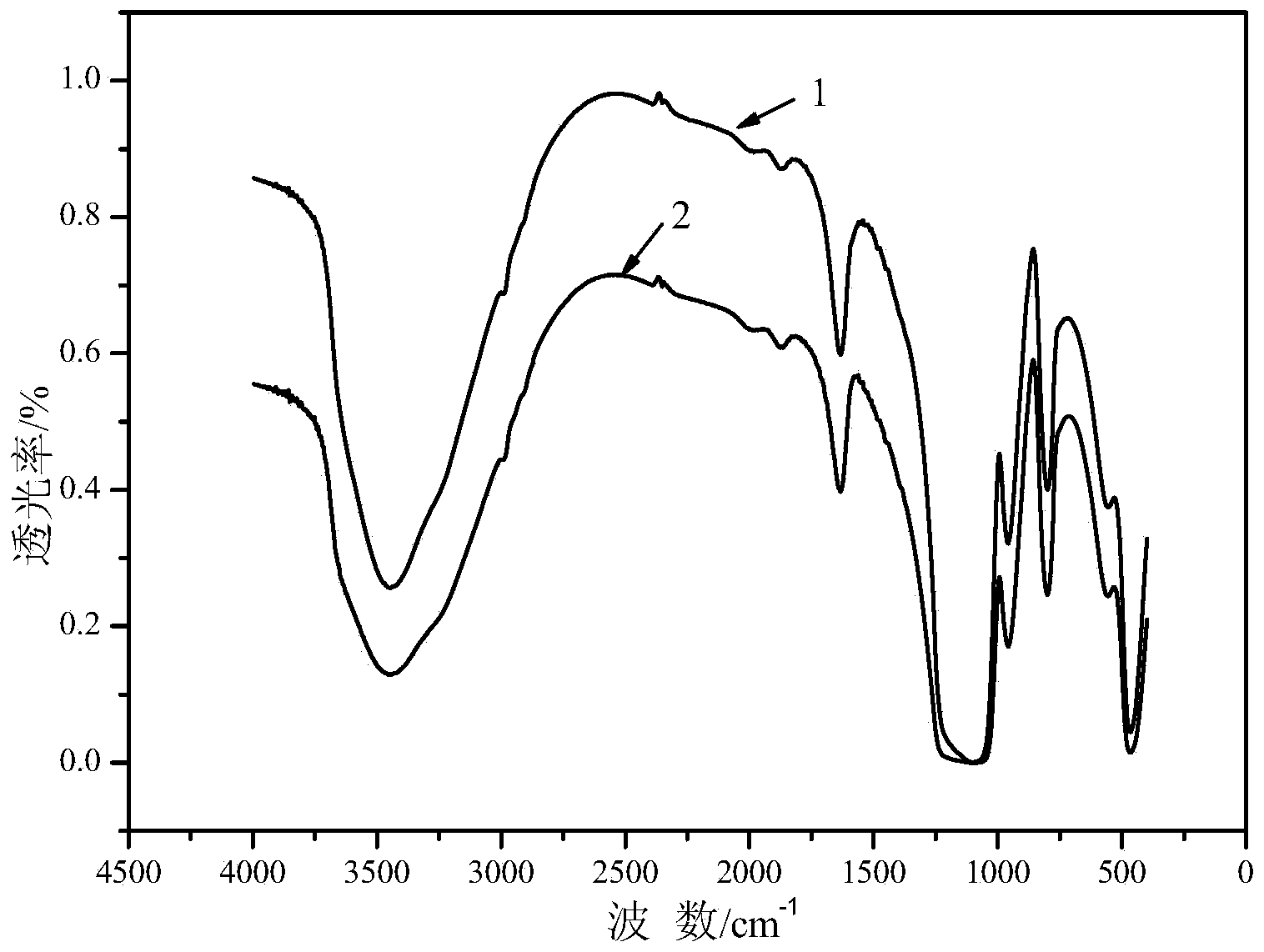

Preparation method for super-hydrophobic and super-hydrophilic electrostatic spinning nanofiber composite membranes

InactiveCN102605554AEasy to prepareSpinning process is stableFibre typesNon-woven fabricsFiberNanofiber

A preparation method for super-hydrophobic and super-hydrophilic electrostatic spinning nanofiber composite membranes belongs to the field of the nanofiber composite membranes. For the method, the raw materials are easy to obtain, the process is simple, and the operation is convenient and quick. In the method, the electrostatic spinning technology is mainly adopted to prepare the polymer nanofiber composite membranes, different solvents and different treatment methods are adopted, the nanofiber composite membranes are super-hydrophobic or super-hydrophilic, and the mechanical property is improved. The preparation method is simple, the spinning process is stable, the fiber is small in diameter and light in weight, no pollution is caused, and the preparation method is widely applied to the fields of filter materials, construction paint, mineral floatation and the like.

Owner:BEIJING UNIV OF CHEM TECH

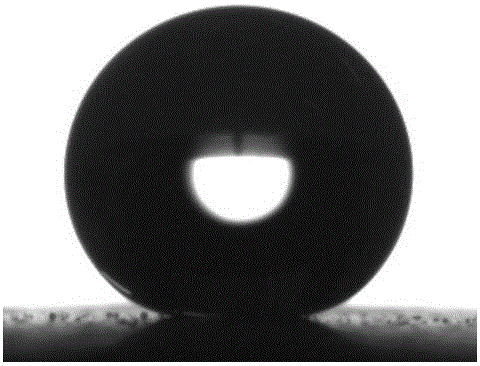

Super-hydrophilic particle hybridized super-hydrophobic coating and preparation method thereof

The invention relates to a super-hydrophilic particle hybridized super-hydrophobic coating and a preparation method thereof. A substrate is ultrasonically cleaned through acetone, absolute ethyl alcohol and deionized water in sequence for 15 min, and oil stain and dust on the surface are removed; then, absolute ethyl alcohol is used for elution, and cold-blast air is used for drying for use. Nanometer SiO2 sol is subjected to fluoroalkyl silane modification, a super-hydrophobic coating spraying solution is obtained, a super-hydrophilic monodisperse sphere type nanometer SiO2 solution, silica powder and glass beads are added into the super-hydrophobic coating spraying solution, stirred to be uniform and sprayed on the substrate, and after solidification, the super-hydrophilic particle hybridized super-hydrophobic coating is obtained. The coating has the low adhesion and super-hydrophobicity, and the condensation and dewfall efficiency and the dewdrop adsorption amount are remarkably high compared with a super-hydrophobic coating. The preparation technology is simple, no pollution is caused, operation is easy, the apparent mass is good, the cost is low, and wide application prospect and huge market benefits are achieved on the aspects of heat exchangers, water collection, seawater desalination and the like.

Owner:SOUTHEAST UNIV

Preparation method of superhydrophilic/superhydrophobic composite nanofiltration membrane

ActiveCN104759214ARealize roughness controlAchieving cut-off separationSemi-permeable membranesPolyelectrolyteOrganic solvent

The invention relates to a preparation method of a superhydrophilic / superhydrophobic composite nanofiltration membrane, belonging to the technical field of membrane separation. The preparation method comprises the following steps: putting a pretreated base membrane in a polycation electrolyte solution, washing with water, putting in a polyanion electrolyte solution, washing with water, and alternately assembling many times to form a predissociation layer; putting the membrane containing the predissociation layer in a soluble calcium salt polycation electrolyte solution, taking out, washing with water, putting in a soluble-silicate-containing polyanion electrolyte solution, taking out, washing with water, and repeating many times to obtain a polyelectrolyte / calcium silicate hydrate superhydrophilic composite nanofiltration membrane; and putting the superhydrophilic membrane in a fluorosilane ethanol water solution, immersing for 40-90 minutes, flushing with deionized water, and drying and solidifying in a drying oven. The superhydrophilic nanofiltration membrane can implement entrapping separation on the water-soluble dye molecules, and the superhydrophobic nanofiltration membrane can implement entrapping separation on organic solvent dye molecules.

Owner:陕西禹慧智通环保科技有限公司

UV cured super-hydrophilic and underwater super-oleophobic oil-water separation membrane, its preparation method and application thereof

InactiveCN103357276AGood hydrophilic effectGood anti-oil adhesion effectSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPhotoinitiatorSol-gel

The invention discloses a UV cured super-hydrophilic and underwater super-oleophobic oil-water separation membrane, its preparation method and an application thereof. The preparation method comprises the following steps: carrying out ultrasonic cleaning on a fabric silk screen; preparing nano sol by a sol-gel method, mixing 10-50 parts of a single-function UV cured oligomer, 60-80 parts of a bi-functional UV cured oligomer, 10-20 parts of multifunctional UV cured oligomer, 200-500 parts of silica sol, 1-5 parts of a waterborne photoinitiator and 1-5 parts of an emulsifier, and uniformly dispersing; coating a mixed liquor on the surface of a membrane by a dip-coating or spray process, drying, and carrying out UV curing to obtain a product. The surface of the oil-water separation membrane has a hydrophilic polymer molecular brush structure based on the micro-nano dual structure. The contact angle of the membrane to water and oil is 0 degree in the air, and the membrane has super-hydrophilicity. The contact angle of the membrane to oil drops is greater than 150 degrees underwater, and the membrane has low adherence to oil drops. The membrane provided by the invention can be used in separation of an oil-water mixture and treatment of oily sewage.

Owner:SOUTH CHINA UNIV OF TECH

Method for photocatalytically rendering a surface of a substrate superhydrophilic, a substrate with superhydrophilic photocatalytic surface, and method of making thereof

InactiveUS20050019700A1Radiation applicationsPhotomechanical apparatusSurface layerMaterials science

A method of preventing or reducing fogging of a surface of a composite when subjected to humid conditions includes providing a composite with a surface. The composite includes a substrate and a photocatalytic surface layer. The photocatalytic surface layer includes a photocatalyst. The method further includes subjecting the photocatalyst to photoexcitation to render the surface of the composite hydrophilic, wherein, after the photoexcitation, the surface of the composite has a water wettability of less than 10° in terms of the contact angle with water. The method further includes subjecting the composite to humidity that is sufficient to induce fogging of the substrate if the photocatalytic surface layer were absent.

Owner:TOTO LTD

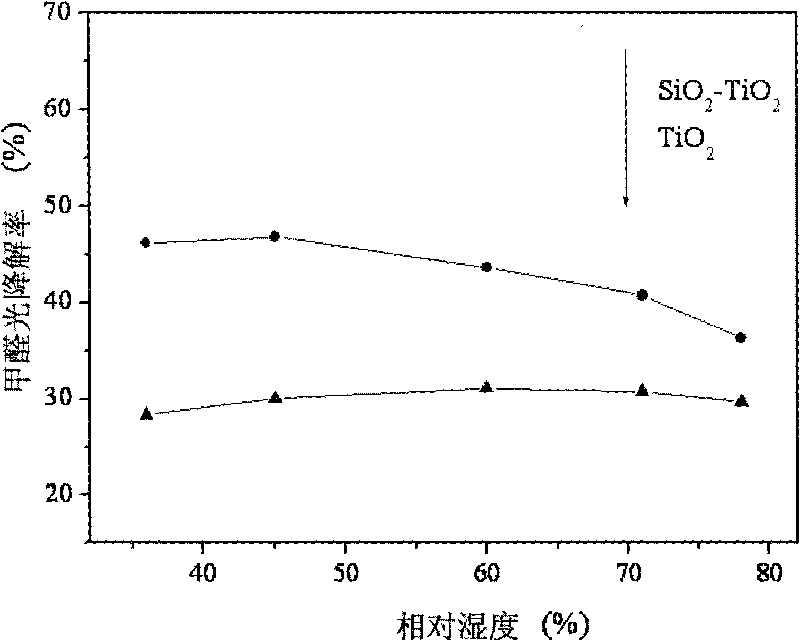

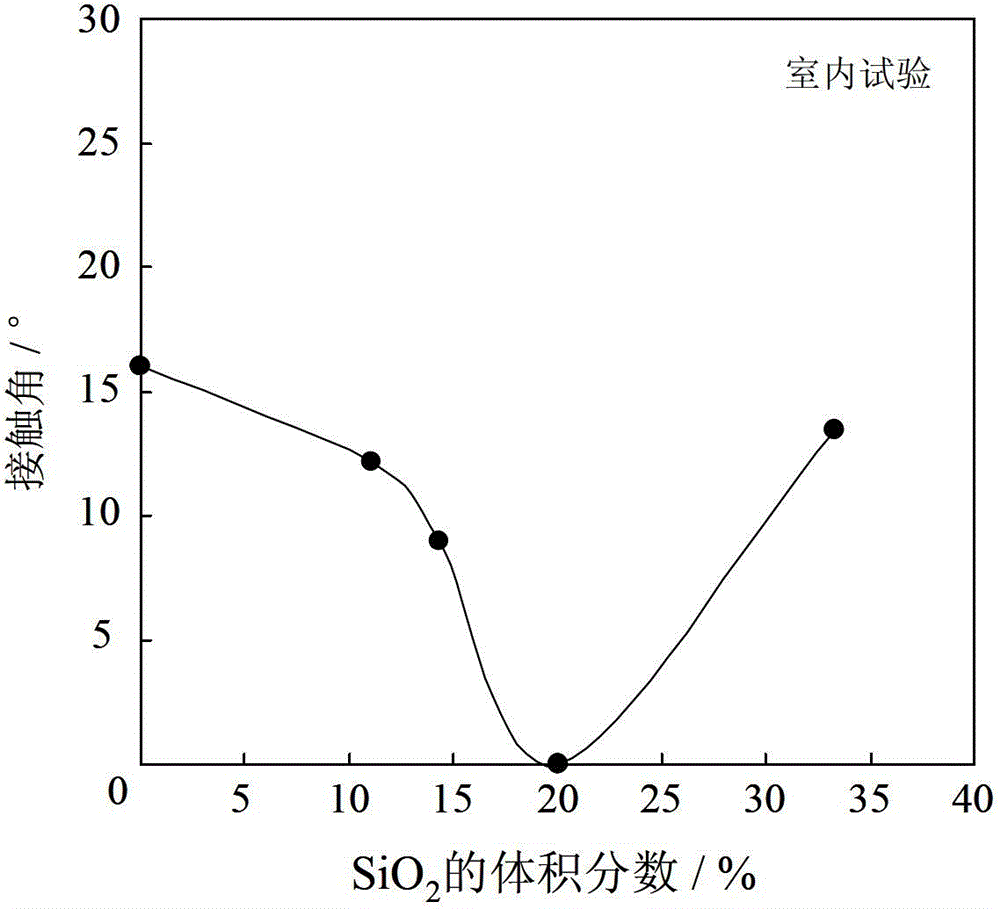

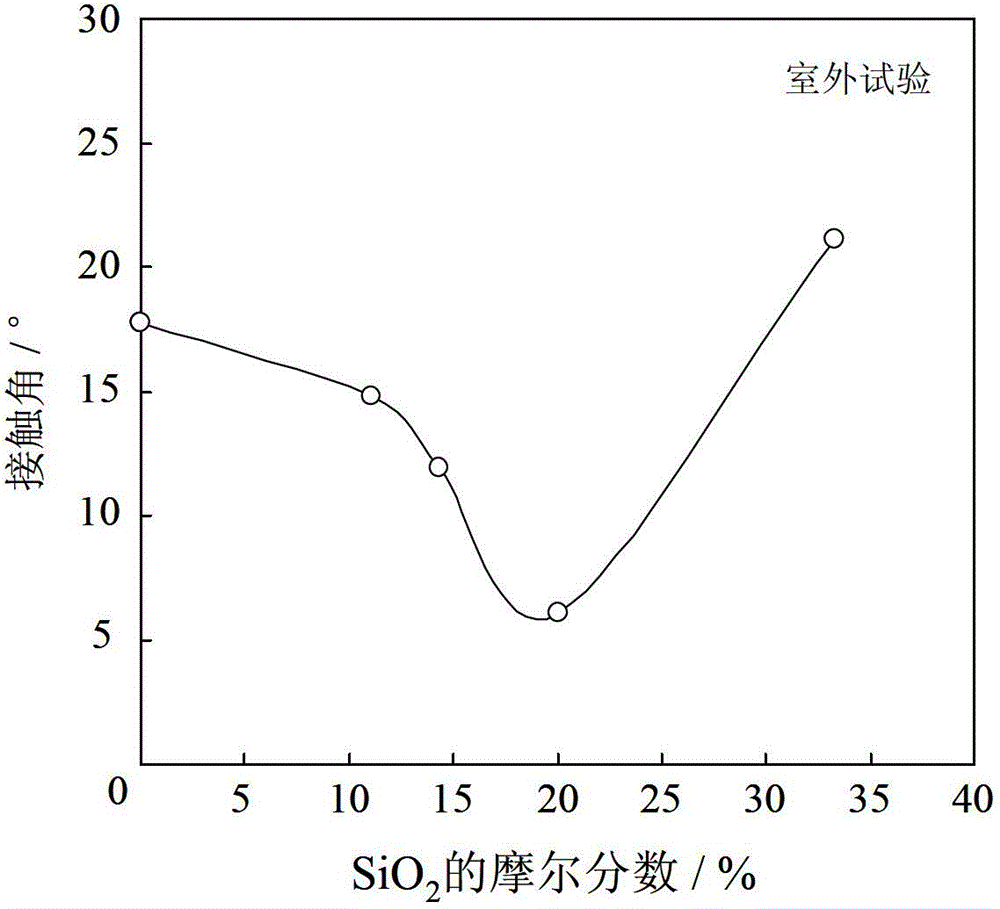

Preparation method of ultra-hydrophilic transparent SiO2/TiO2 antifog film

InactiveCN103771721APossess super hydrophilic propertiesHigh light transmittanceSilicic acidSilicon oxide

The invention provides a preparation method of ultra-hydrophilic transparent SiO2 / TiO2 antifog film. The preparation method employs a sol-gel method, and comprises the following steps: preparing a nanometer SiO2 sol by using ethyl orthosilicate as raw material; preparing a nanometer TiO2 sol using tetrabutyl titanate as raw material; preparing a SiO2 / TiO2 sol by mixing SiO2 sol and TiO2 sol according to a ratio; preparing films of different layers by coating a pretreated glass base material with the SiO2 / TiO2 sol by using a spin coating mode; and then placing the material in a muffle furnace for annealing. The invention has the advantages of simple equipment and low cost, and the SiO2 / TiO2 film has super hydrophilicity and high light transmittance under visible light, and can be used for building glass, wind screen glass, bathroom glass and various antifog occasions.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

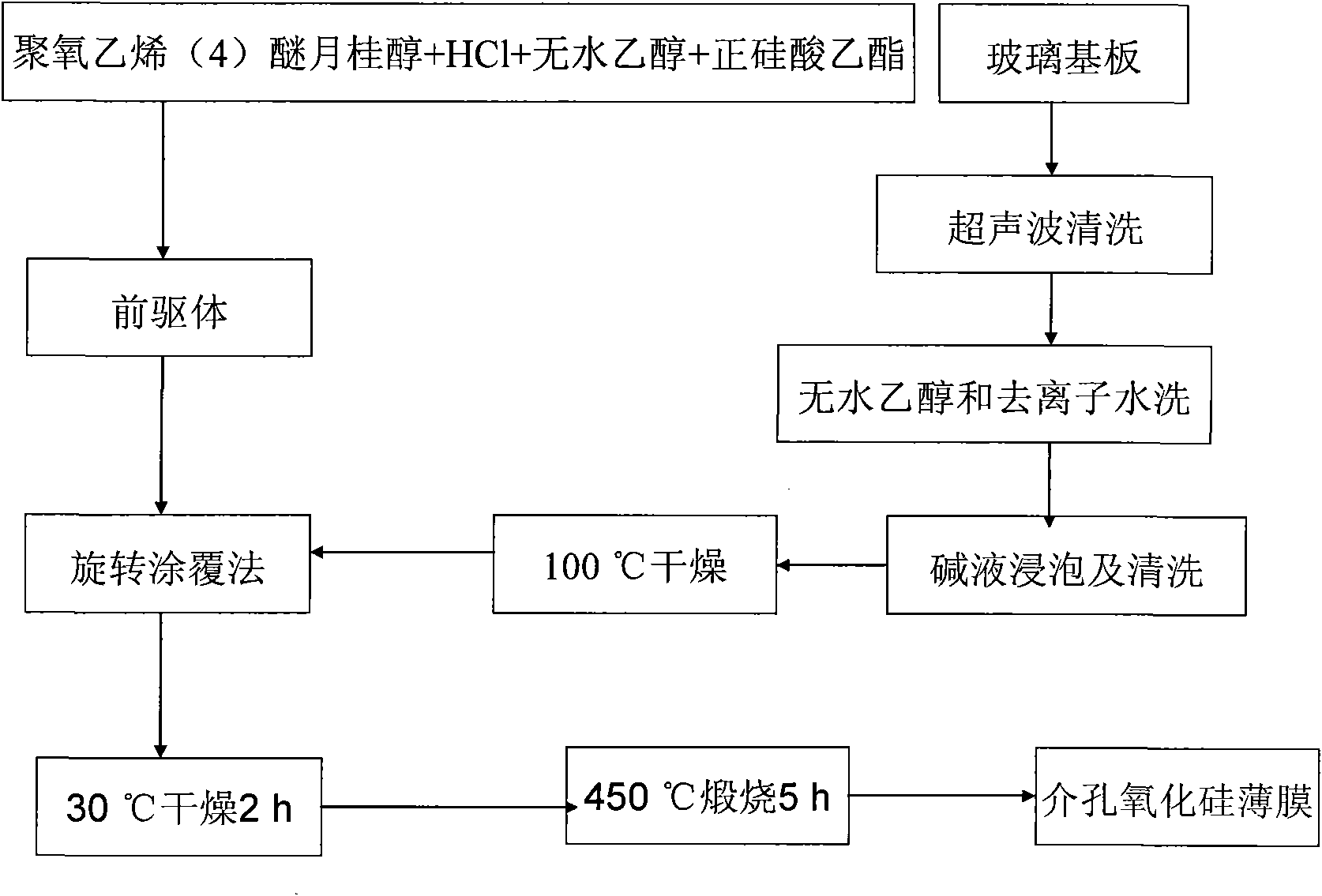

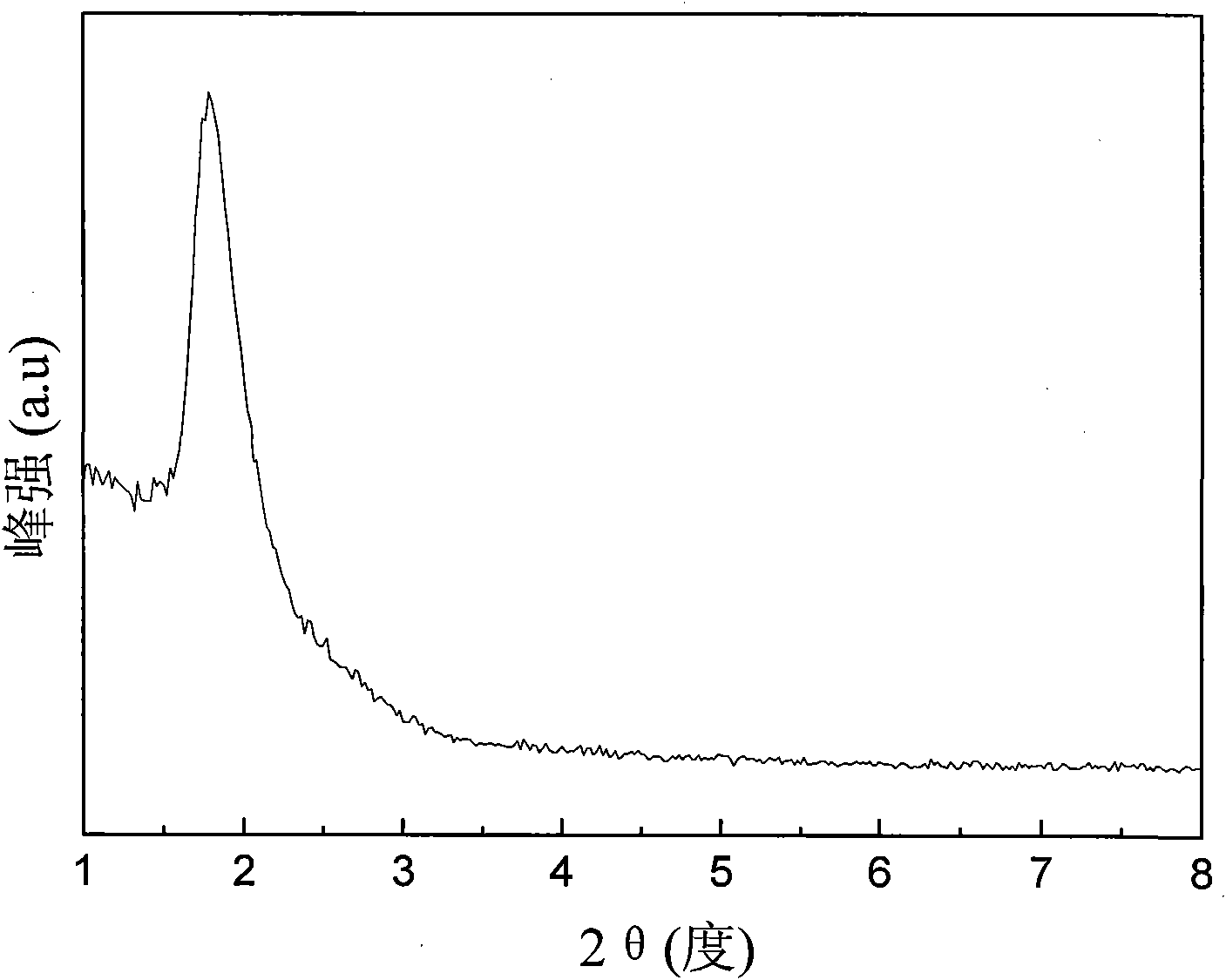

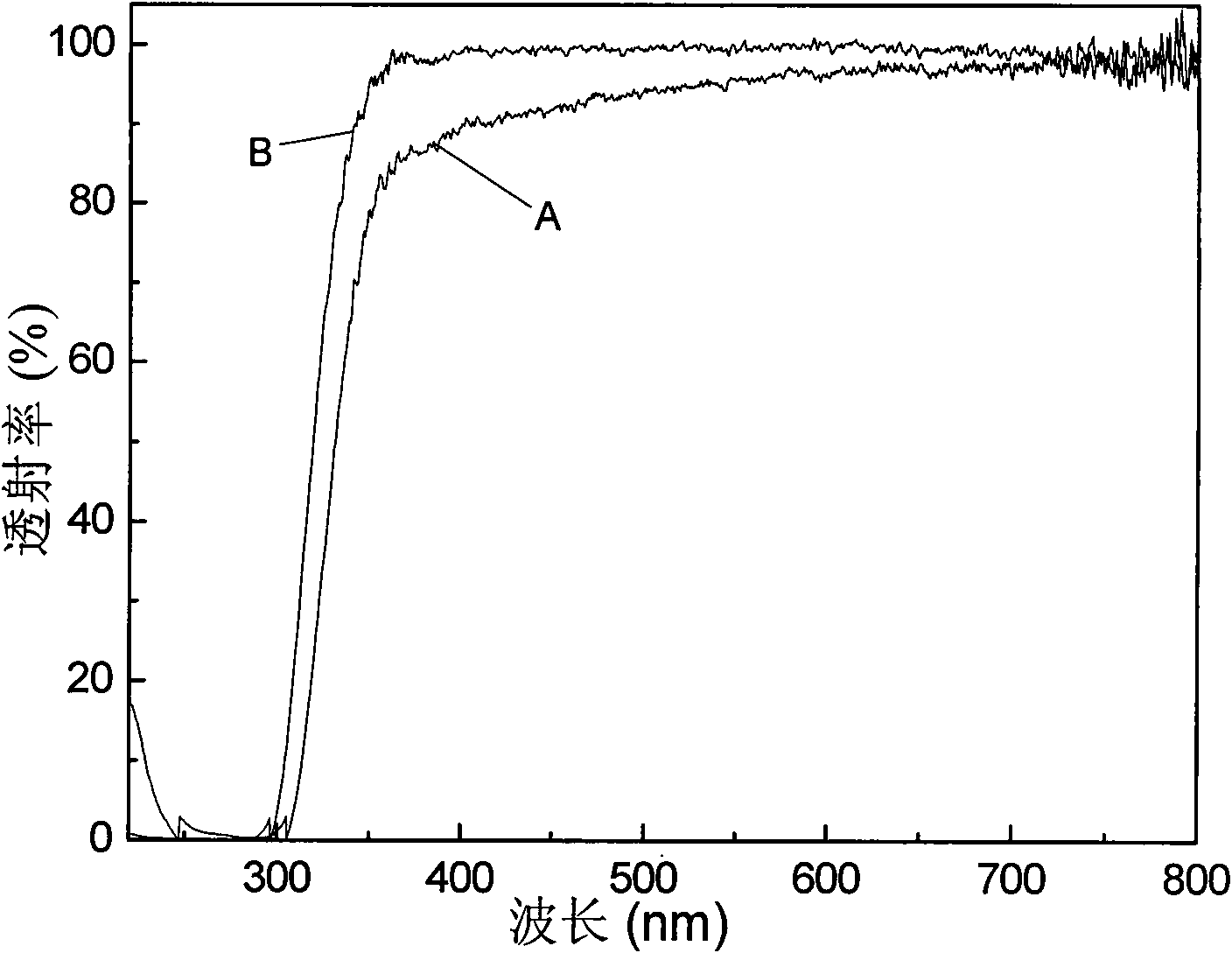

Preparation method of super-hydrophilic mesoporous silicon oxide films

The invention discloses a preparation method of super-hydrophilic mesoporous silicon oxide films. The method employs a sol-gel technique, utilizes ethyl orthosilicate as a silicon source and utilizespolyoxyethylene (4) laurinol as a template agent so as to prepare the mesoporous silicon oxide films on the surface of a glass substrate by a rotary coating method. The wrapping angle between the filmand water is 0 DEG, and the film is super-hydrophilic. The film formed on the glass has the advantages of high luminousness, no color, transparency, stability, evenness and wear resistance; and the surface of the film is easy to wash after being polluted by dust. The method has the advantages of simple operation, short period and low cost and can be widely used on the substrates of glass curtainwalls, bathroom mirrors, automobile windshields, rearview mirrors and the like which need self-cleaning antifog treatment.

Owner:KAYMAO TECH SHENZHEN

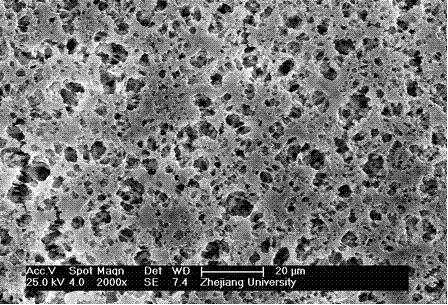

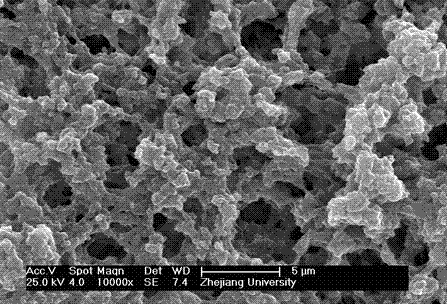

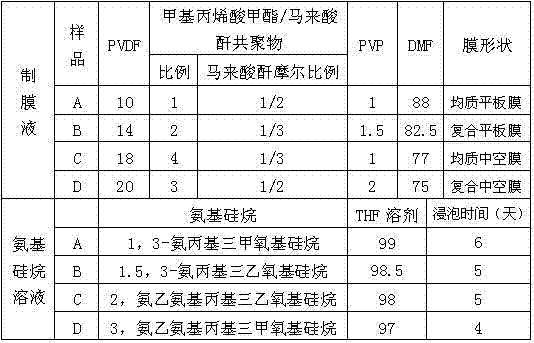

Method for preparing super-hydrophilic polyvinylidene fluoride membrane

ActiveCN102240510AImprove mechanical propertiesImprove heat resistanceSemi-permeable membranesSilanesAcquired membrane

The invention discloses a method for preparing a super-hydrophilic polyvinylidene fluoride membrane. The method comprises the following steps: 1) mixing polyvinylidene fluoride, a copolymer containing maleic anhydride, a solvent and an aperture regulator, and then performing vacuum de-foaming to obtain a membrane preparing solution; 2) performing phase inversion on the acquired membrane in the presence of alcohol used as a coagulating bath to obtain a polyvinylidene fluoride membrane; and 3) soaking the obtained polyvinylidene fluoride membrane in an amino silane solution for a period of timeto obtain the super-hydrophilic polyvinylidene fluoride membrane. The super-hydrophilic polyvinylidene fluoride membrane prepared by using the method has the advantages that the preparation cost is low, the process is simple, the super-hydrophilic property of the membrane is more stable because of an organic inorganic hybridized membrane surface, and the membrane has better mechanical property and thermal property because of the use of the hybridized materials.

Owner:ZHEJIANG UNIV

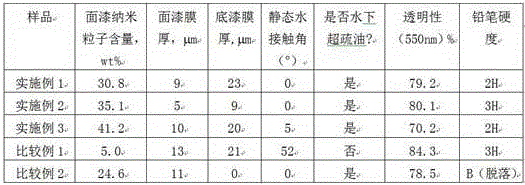

Superhydrophilic/underwater superoleophobic coating material and preparation method thereof

ActiveCN106634275AImprove mechanical propertiesHigh transparencyAntifouling/underwater paintsPretreated surfacesNano structuringAcrylic resin

The invention relates to a superhydrophilic / underwater superoleophobic coating material and a preparation method thereof. The coating material is composed of a primer layer and a finish coat layer, wherein the primer layer is mainly composed of a hydroxy acrylic resin and a curing agent thereof; the finish coat layer is composed of polyvinyl alcohol and nanoparticles; and the curing agent in the primer can produce chemical crosslinking reaction with the polyvinyl alcohol. The preparation method comprises the following steps: applying the primer layer on the substrate surface; applying the finish coat layer, and precrosslinking by drying at room temperature or low temperature to initiate the chemical bonding between the primer layer finish coat layer; soaking the coating in a crosslinking agent water solution for some time; and taking the coating out of the crosslinking agent water solution, and sufficiently curing the primer layer by drying at room temperature or high-heat treatment. The coating material obtained by the method has a gradient micro / nano structure surface, and has the advantages of outstanding superhydrophilicity and underwater superoleophobicity, high binding force with the substrate and favorable transparency. The coating material can be used as an antifogging coating, and can also be used as a self-cleaning antifouling coating on the surface of an underwater facility.

Owner:FUDAN UNIV

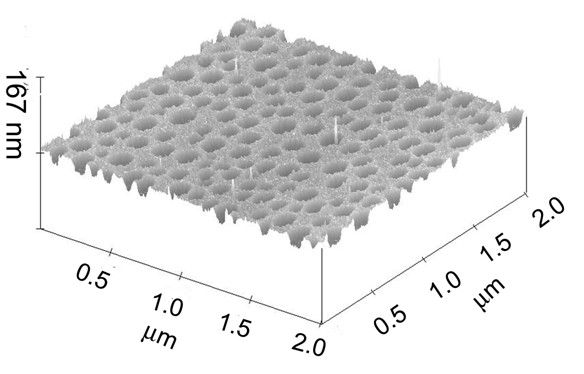

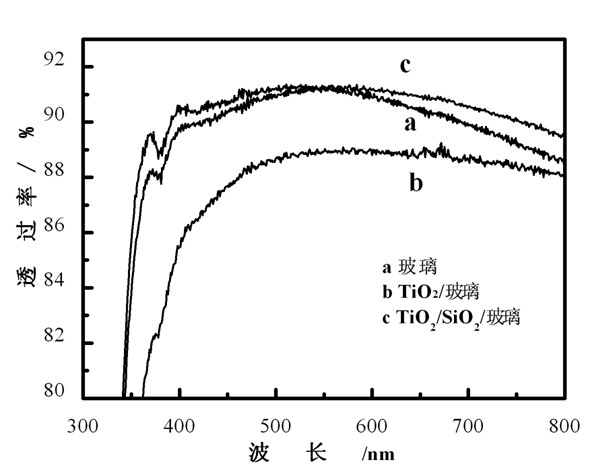

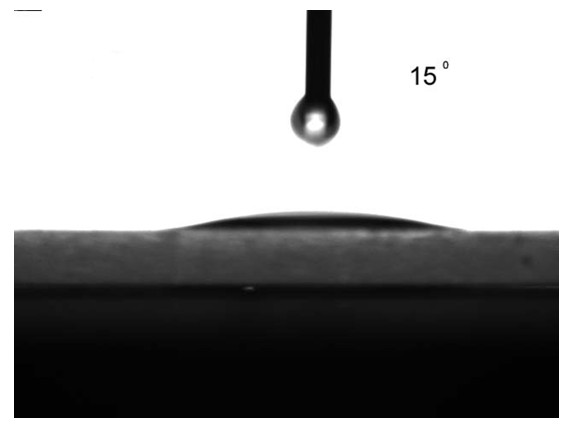

Preparation method of superhydrophilic TiO2/SiO2 porous bilaminar membrane

ActiveCN102432196AImprove transmittanceGood anti-fog performanceOther chemical processesPolyethylene glycolEngineering

The invention which provides a preparation method of a superhydrophilic TiO2 / SiO2 porous bilaminar membrane which has a high transmittance and can perform the superhydrophilicity under visible light belongs to the technical field of nanomaterials. The method comprises the following steps: 1, carrying out spin coating on a glass substrate with an SiO2 sol, drying, carrying out spin coating with a mixed solution of polyethylene glycol 2000 and TiO2, and drying the glass substrate in a drying box for 20-40min at 80-120DEG C; 2, heating the dried glass substrate in a muffle furnace to 450-550DEG C according to a heating rate of 2-3DEG C / min, and annealing for 2-3h; and 3, naturally cooling to room temperature after completing the anneal to obtain the superhydrophilic TiO2 / SiO2 porous bilaminar membrane. The prepared superhydrophilic TiO2 / SiO2 porous bilaminar membrane of the invention, which has a highly ordered porous structure and a high transmittance, can perform the superhydrophilicity under visible light and has a good antifog effect, can be applied to various antifog occasions of building glass, automobile rearview windows, windscreens, bathroom glass and the like.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Method for improving surface hydrophilicity of medical titanium or titanium alloy

InactiveCN101880874AImprove surface hydrophilicityImprove bindingMetallic material coating processesUltravioletSodium titanate

The invention relates to a method for improving the surface hydrophilicity of medical titanium or a titanium alloy, which is characterized by comprising the following steps of: placing the titanium or the titanium alloy in 1.0-5.0 M of NaOH solution and then treating 12-24 hours at 60-80 DEG C to form a nano porous sodium titanate gel layer on the surface; and then soaking the alkali liquor-treated sample in 0.1 M of diluted hydrochloric acid for 12 hours at the room temperature to transform the nano porous sodium titanate gel layer into a nano porous titanium oxide gel layer. The titanium oxide gel layer can be crystallized by thermally treating 0.5-2.0 hours at 500-600 DEG C. After a nano porous titanium oxide film is irradiated for 3-4 hours by ultraviolet rays (the wavelength is 253 nm) or is treated for 2-4 minutes by atmosphere plasmas, the superhydrophilicity can be obtained, and the high hydrophilicity of the superhydrophilic sample can be maintained after the superhydrophilic sample is preserved in deionized water. When used for improving the surface hydrophilicity of the medical titanium or the titanium alloy, the method has the characteristics of simple and easy feasibility, stable process, reliable performance, firm combination of a titanium dioxide layer, suitability for various titanium alloys and the like.

Owner:XI AN JIAOTONG UNIV

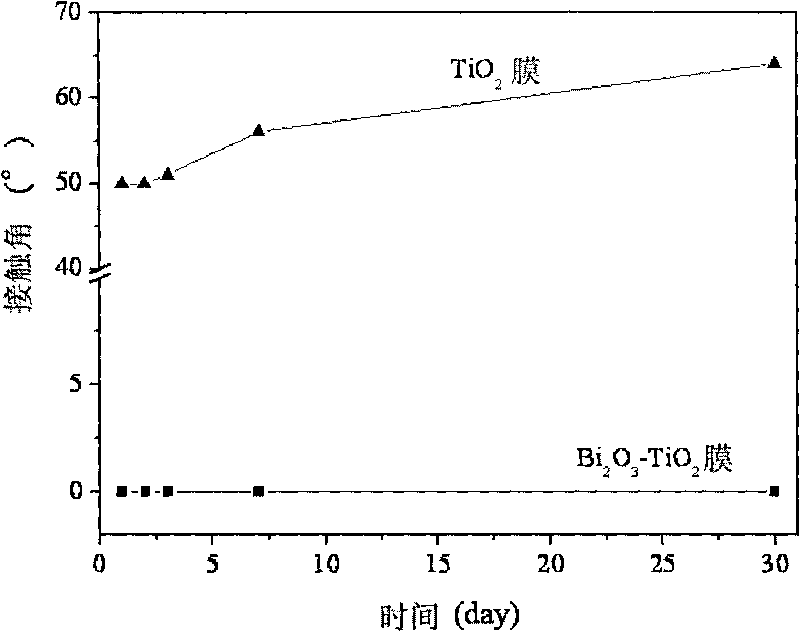

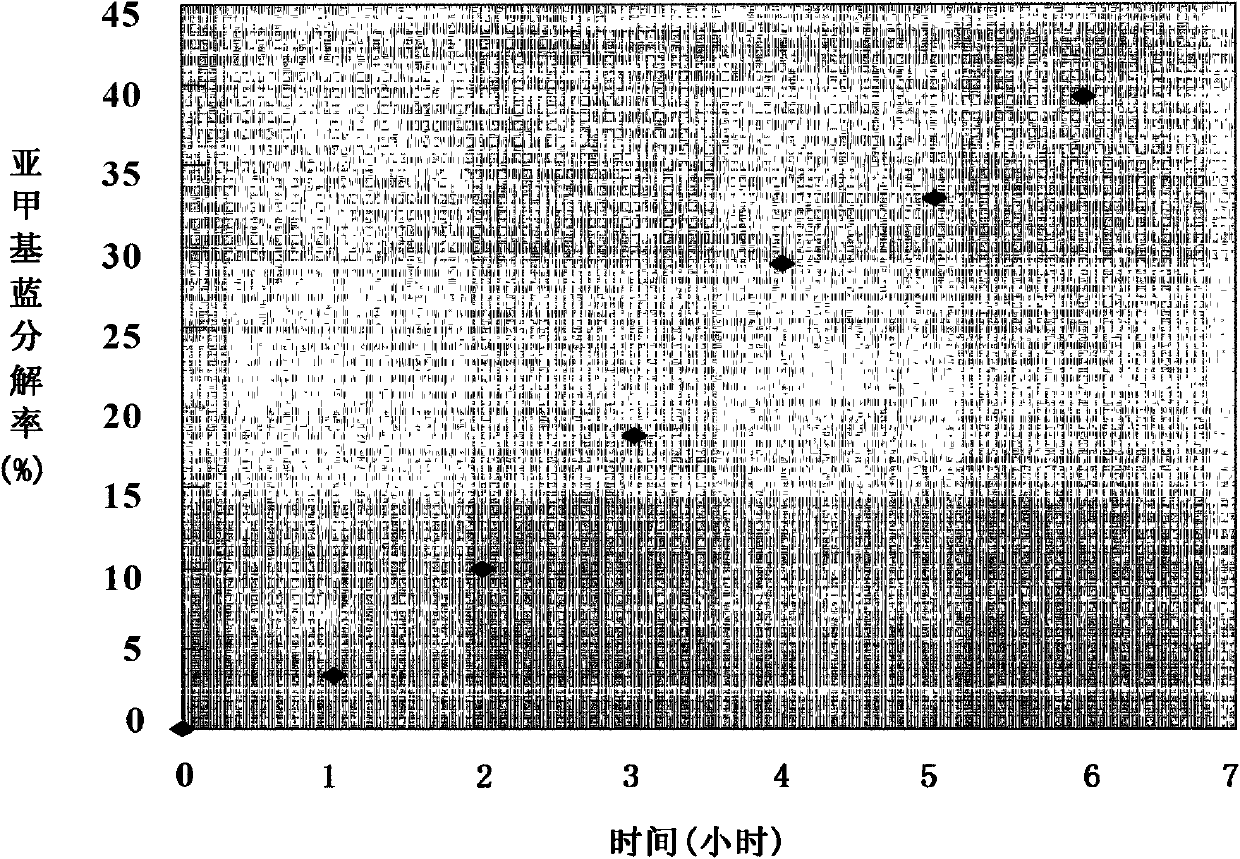

Superhydrophilic nano titanium dioxide photocatalysis composite membrane as well as preparation method and application thereof

InactiveCN101757900AHas visible light catalytic activitySave energyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsParticulatesSilicon dioxide

The invention discloses a superhydrophilic nano titanium dioxide photocatalysis composite membrane as well as a preparation method and application thereof. The superhydrophilic nano titanium dioxide photocatalysis composite membrane comprises nanosize titanium dioxide sol and a submicron particle; and the particle is selected from one or more of the following compounds: silicon dioxide, bismuth oxide, active carbon, zinc oxide and iron oxide. The composite membrane can also maintain superhydrophilic performance for a long time without illumination and improves the efficiency of air purification processing by changing a common hydrophilic titanium dioxide membrane into the superhydrophilic membrane. The photocatalysis membrane can be widely applied to the technical field of air purification processing.

Owner:SOUTHEAST UNIV

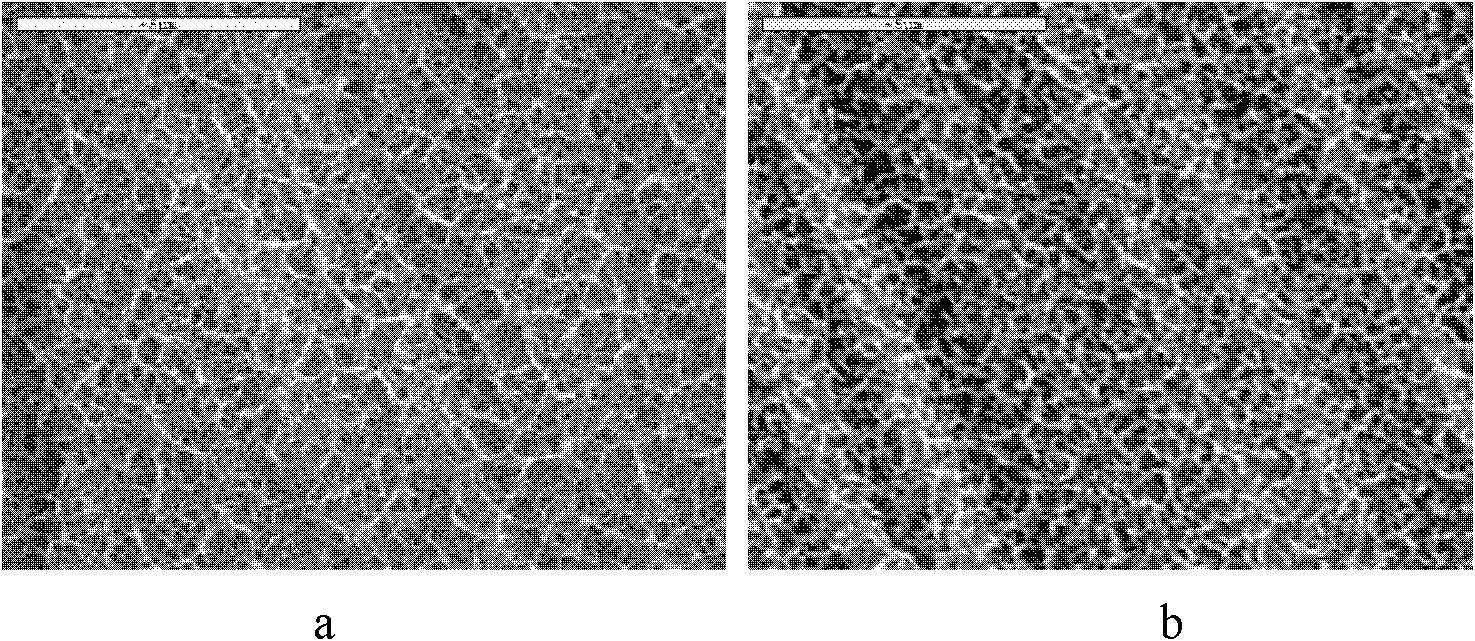

Method for preparing self-cleaning antifogging coating film

ActiveCN102718410AImprove photocatalytic activityImprove superhydrophilicityComposite filmThin membrane

The invention discloses a method for preparing self-cleaning antifogging coating film and belongs to the technical field of films. The method includes: subjecting a disperse system of tetrabutyl titanate to hydrothermal treatment to obtain TiO2 nano particle suspension; and dispersing SiO2 sol into the TiO2 suspension to obtain a TiO2 / SiO2 composite film by means of the dip-coating technique. The TiO2 particles are adhered and attached to the surface of a glass substrate by amorphous SiO2. Proper roughness factors are jointly provided by the TiO2 particles and continuous nano pore passages distributed in the film, and the apparent contact angle of water on the surface can be effectively decreased. The wettability of water on the surface of the film is further improved by a great quantity of OH groups carried by the amorphous SiO2, so that the super-hydrophilcity of the film can still be maintained after long-time outdoor placement.

Owner:佛山市南牧新材料有限公司

Photocatalyst coating liquid, photocatalyst film and photocatalyst member

InactiveUS20060162617A1Good photo-catalytic functionIncreased durabilityPigmenting treatmentOrganic-compounds/hydrides/coordination-complexes catalystsColloidal silicaTotal solid content

The present invention relates to a photocatalyst coating liquid capable of forming on an organic substrate a photocatalyst film that is excellent in photocatalytic functions such as super-hydrophilic nature and the performance of maintaining super-hydrophilic nature in a dark place and that has excellent durability, the photocatalyst coating liquid being excellent in stability, and a photocatalyst film formed therefrom, and there are provided a photocatalyst coating liquid comprising (A) titanium oxide fine particles formed of anatase type crystal, (B) colloidal silica and (C) a binder formed of a hydrolysis-condensate of a titanium alkoxide, and having, based on the total solid content, a component (A) content of 5 to 50 mass %, a component (B) content, as a solid content, of 25 to 75 mass % and a component (C) content, as a TiO2 slid content, of 10 to 55 mass %, and a photocatalyst film formed from the above coating liquid.

Owner:UBE NITTO KASEI CO LTD

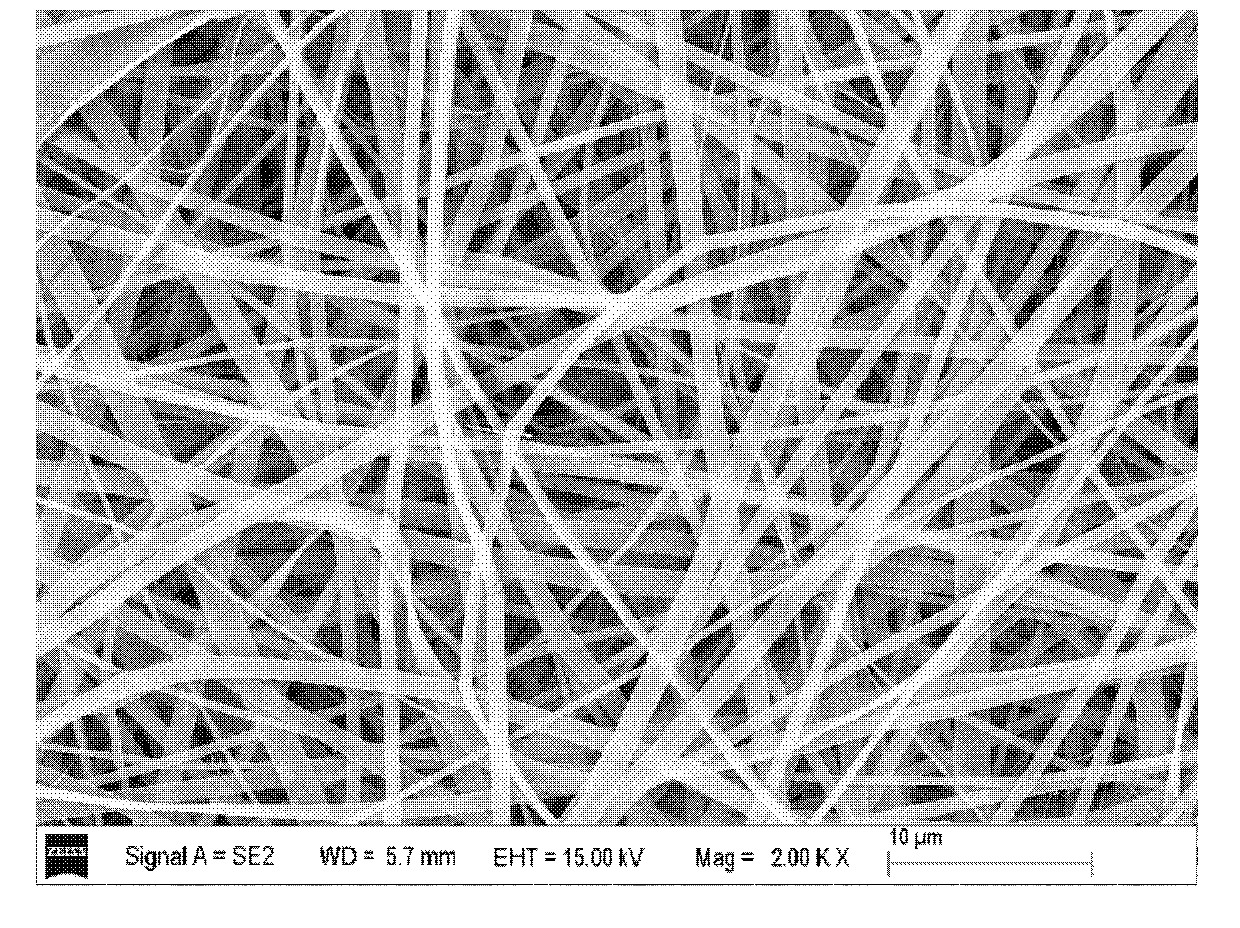

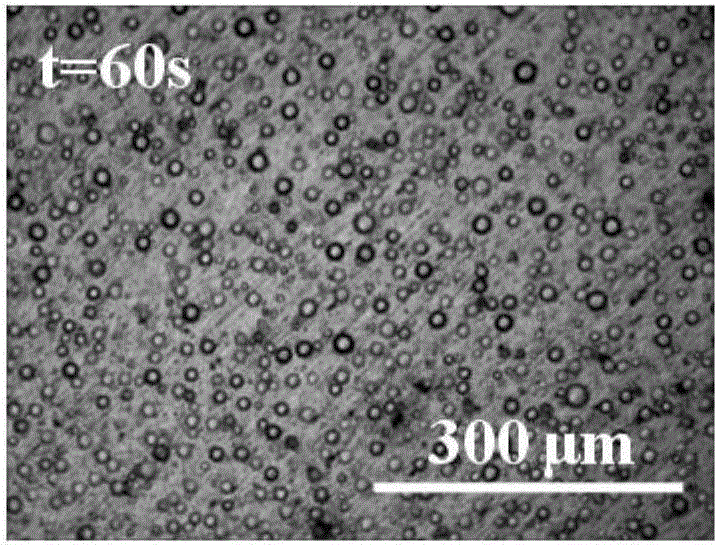

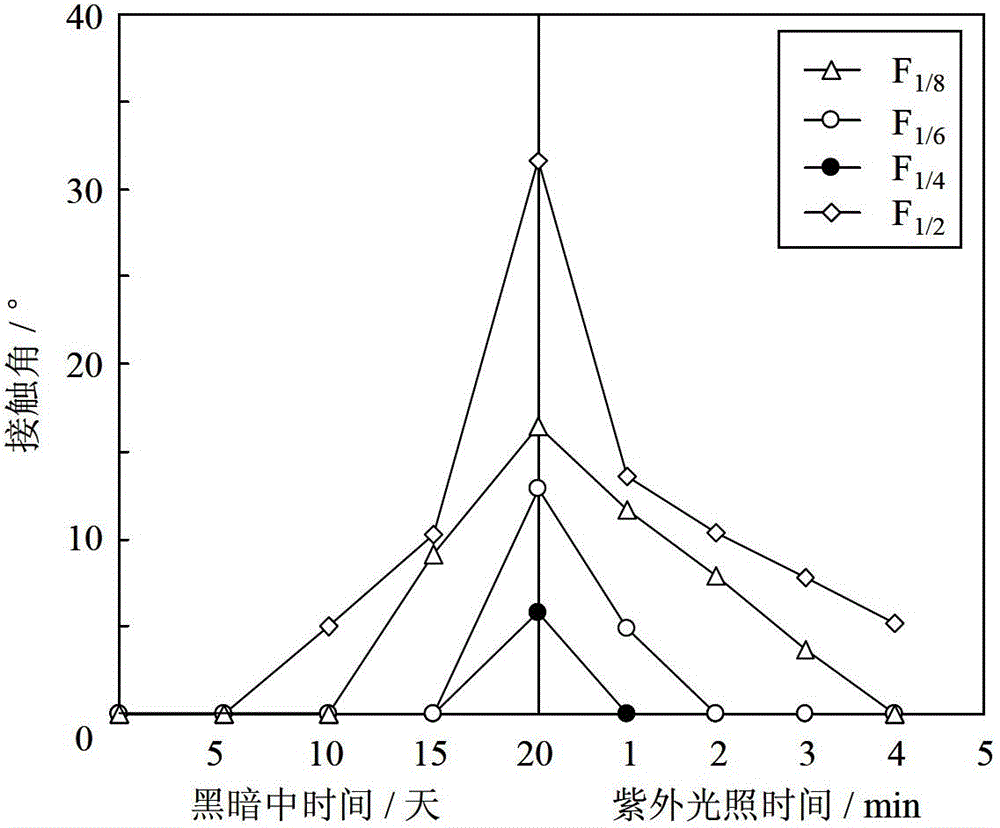

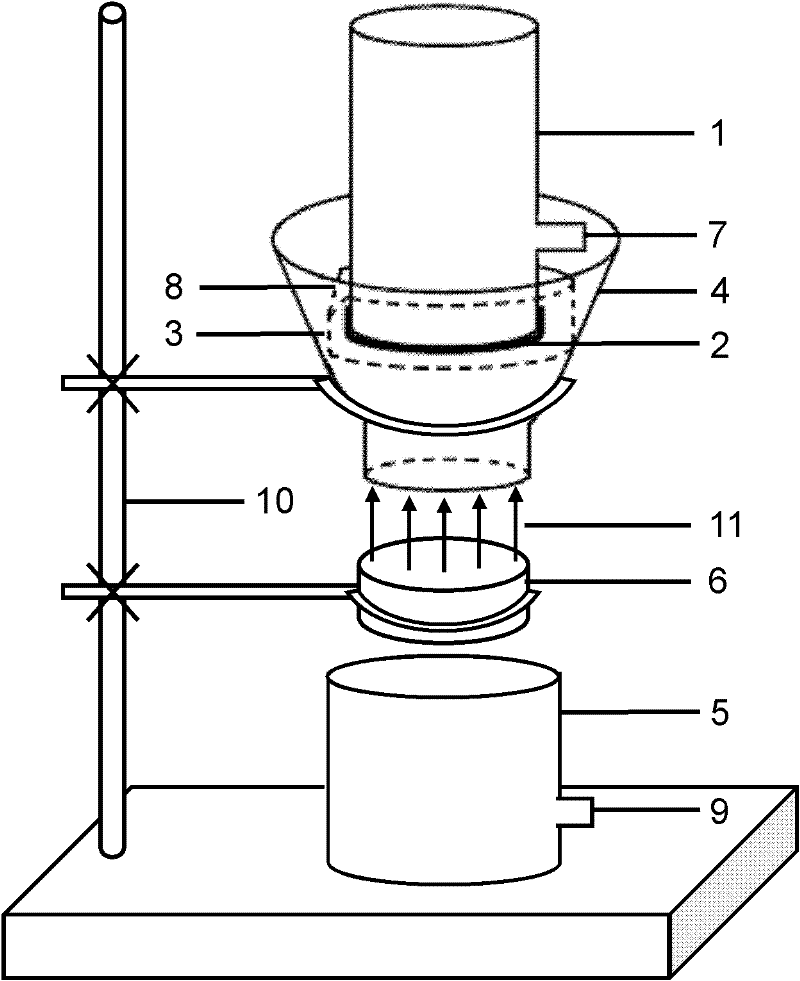

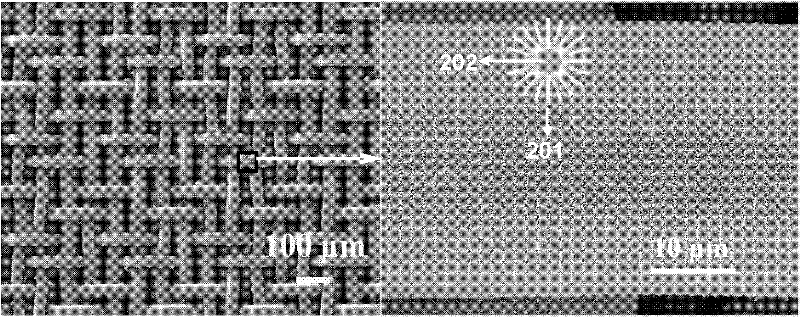

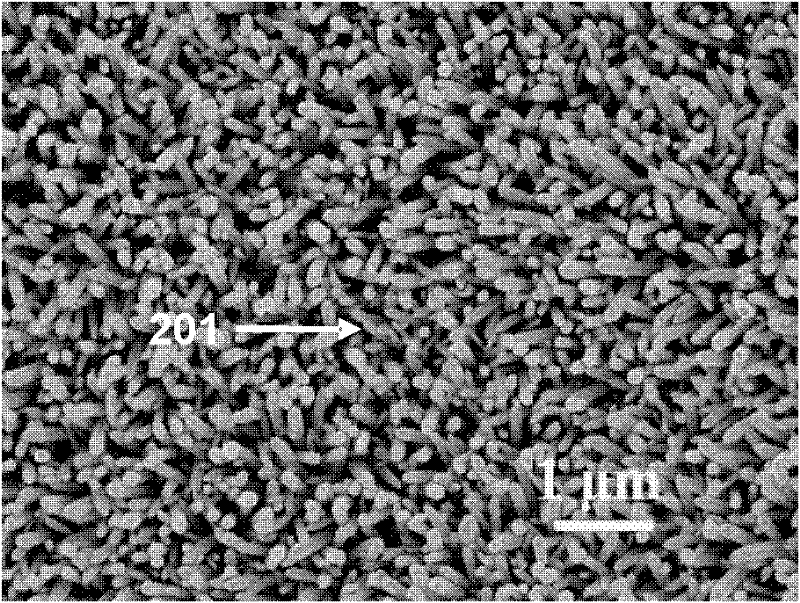

Hierarchical micro-nanostructure omentum based light-operated oil-water separator and its application method

InactiveCN102380230AWith underwater super oleophobic propertiesWith underwater self-cleaning propertiesEnergy based chemical/physical/physico-chemical processesLiquid separationUltraviolet lightsOil water

The invention brings forward a hierarchical micro-nanostructure omentum based light-operated oil-water separator and its application method. The oil-water separator comprises an oil-water separator with the hierarchical micro-nanostructure omentum, a constant water surface device, a drainage device, a water gathering device and a light source device. The oil-water separator with the hierarchical micro-nanostructure omentum is composed of an oil-water mixed liquid gathering device and the hierarchical micro-nanostructure omentum, which is made from a pore structured fabric net substrate material with a microstructure and a nanorods array structured material layer which is perpendicular to the surface of the pore structured fabric net substrate material. The hierarchical micro-nanostructureomentum can have superhydrophobicity after dark storage and can have superhydrophilicity by ultraviolet light. The hierarchical micro-nanostructure omentum based light-operated oil-water separator isstable, highly efficient and environmentally friendly. With the application of the light-operated oil-water separator for oil-water separation control, light-operated water can penetrate through the omentum instead of oil. In addition, the light-operated oil-water separator can be repeatedly used.

Owner:BEIHANG UNIV

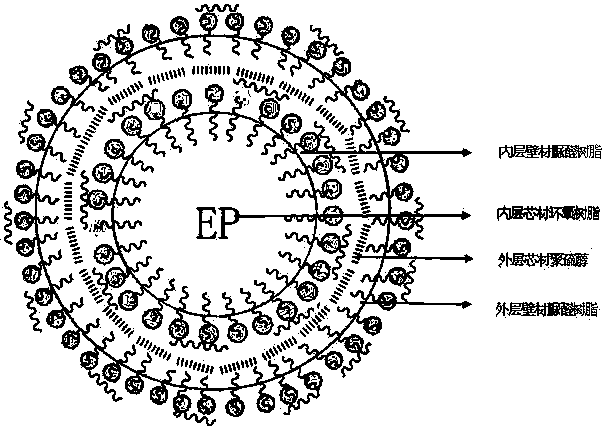

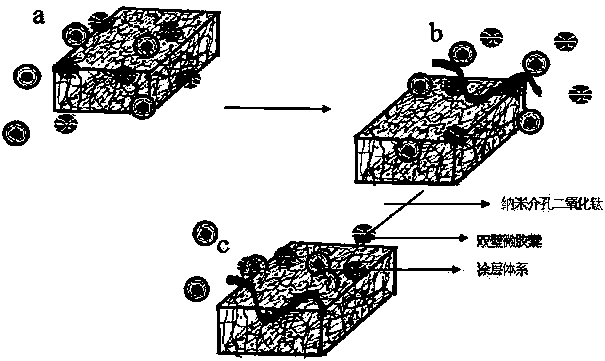

Preparation method of anticorrosive coating capable of self-repairing rapidly at room temperature

ActiveCN103788815AAvoid randomness of contactAutomatic active healingAnti-corrosive paintsMicroballoon preparationPtru catalystCrazing

The invention discloses a preparation method of an anticorrosive coating capable of self-repairing rapidly at room temperature, relating to a preparation method of an anticorrosive coating. According to the method, urea resin is taken as a wall material. A microcapsule repairing agent is high in coating rate and high in possibility of contact with a catalyst. A polythiol curing agent is taken as an outer layer core material, so that the effect of rapidly repairing cracks at room temperature can be achieved. By applying nano titanium dioxide with special photocatalytic performance, super hydrophobicity and ultraviolet ray shielding performance to the coating and keeping the nano titanium dioxide in a nanoscale state in the coating, the defects of poor weather resistance, easiness in staining and the like of an existing coating can be overcome, and the siphon action on micro cracks is improved since the nano titanium dioxide is porous. By adding self-repairing microcapsules into a mesoporous molecular sieve and a double-wall sandwich structure, the self-repairing performance of the coating is remarkably improved, the self-repairing time is shortened, and excellent corrosion resistance is realized.

Owner:SHENYANG SHUNFENG NEW MATERIAL CO LTD

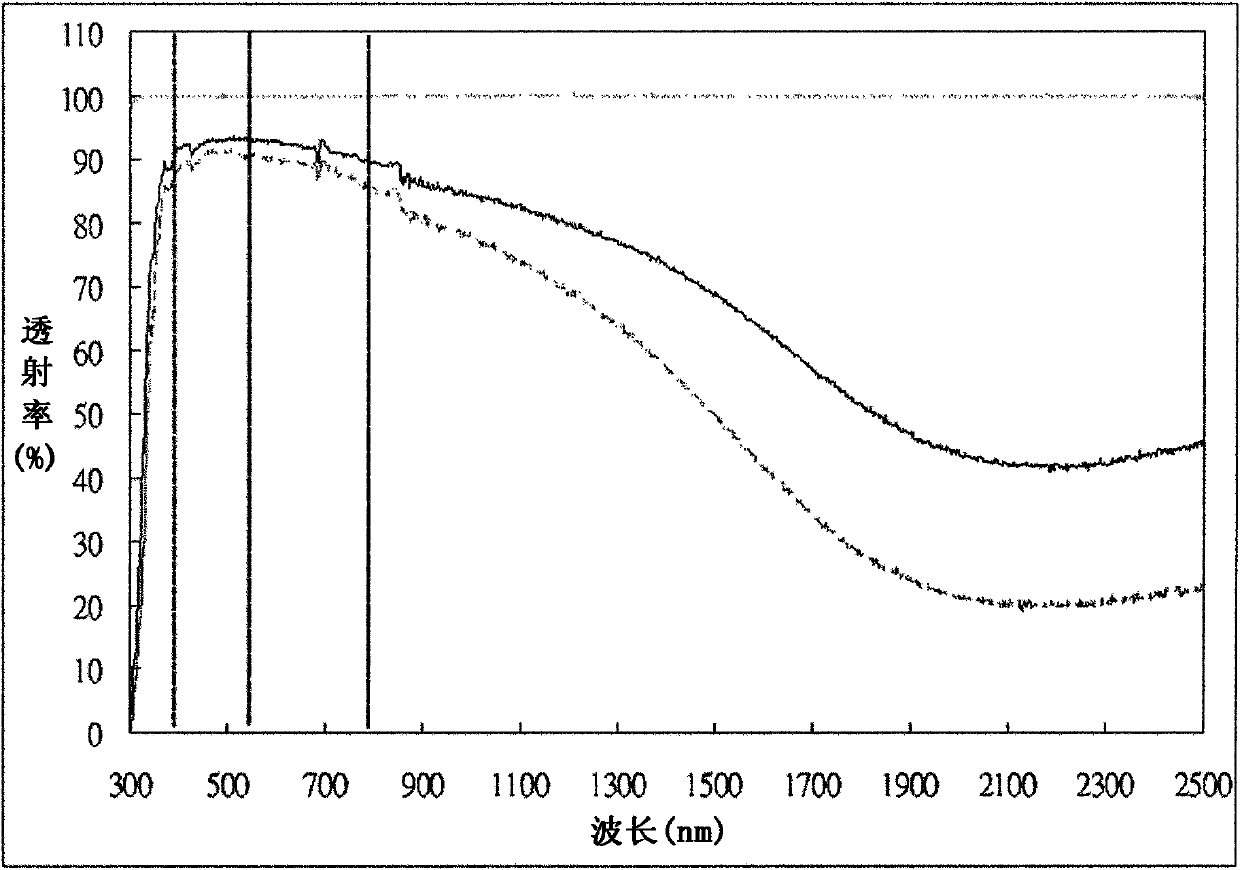

Coating composition and usage thereof

ActiveCN102167954AEffective blockingEffective reflectionClimate change adaptationChemical industryInfraredEngineering

Owner:ETERNAL MATERIALS CO LTD

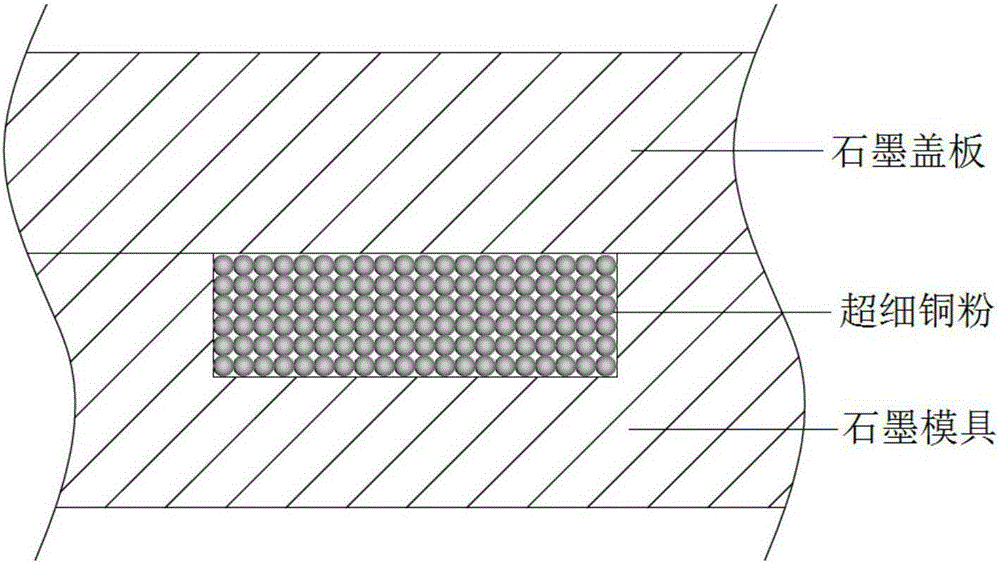

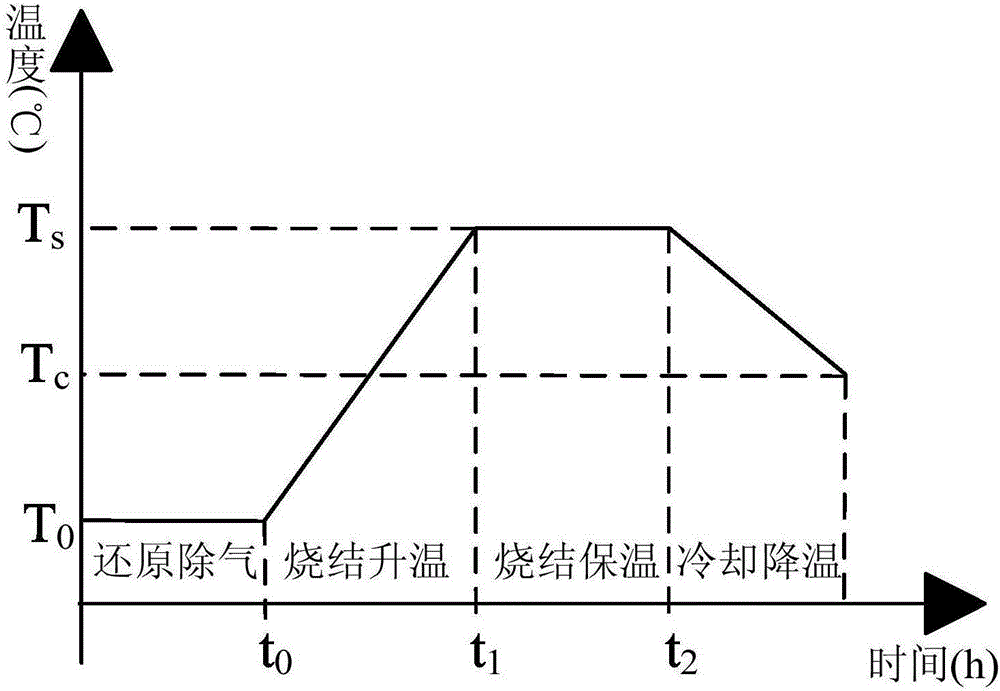

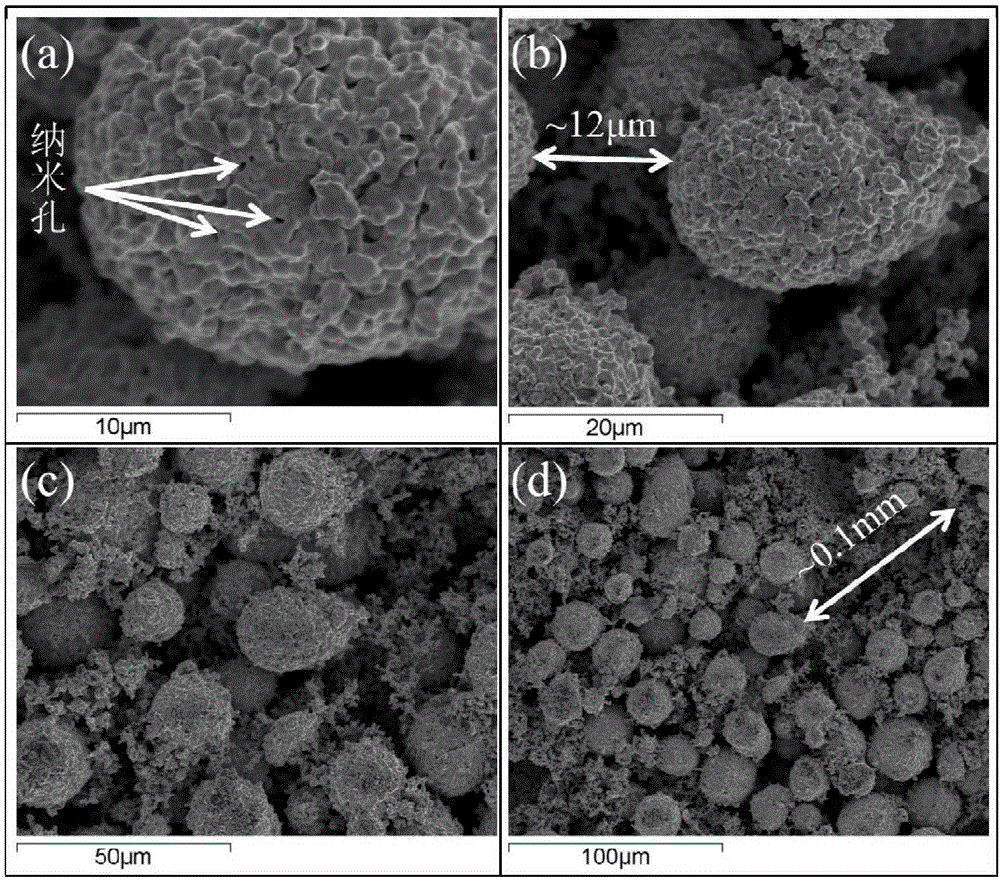

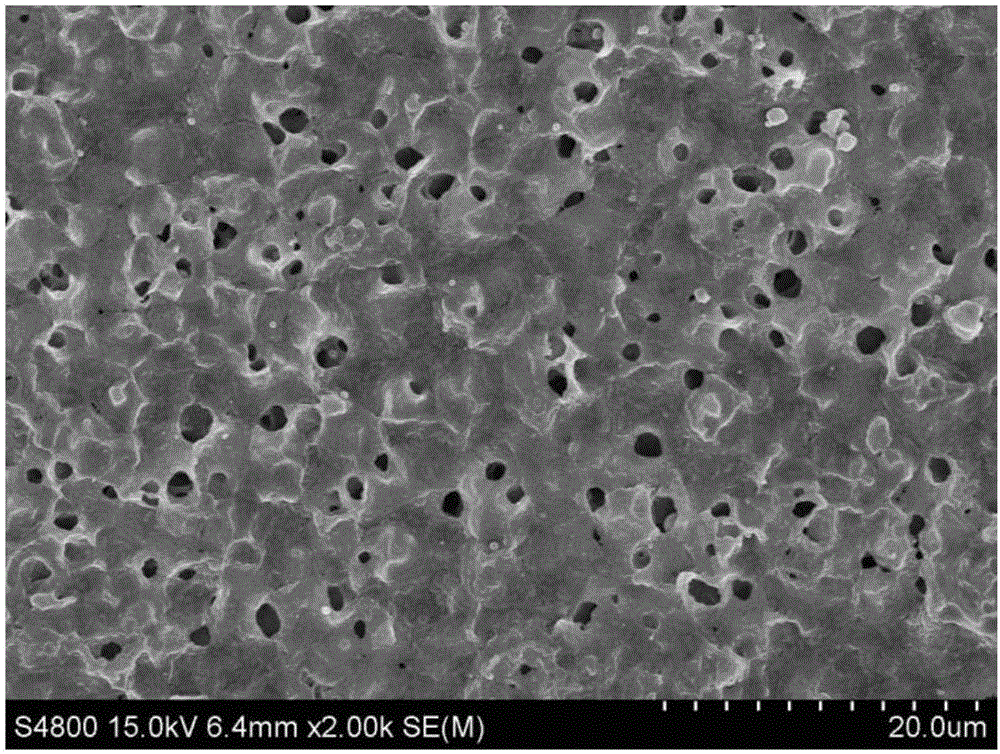

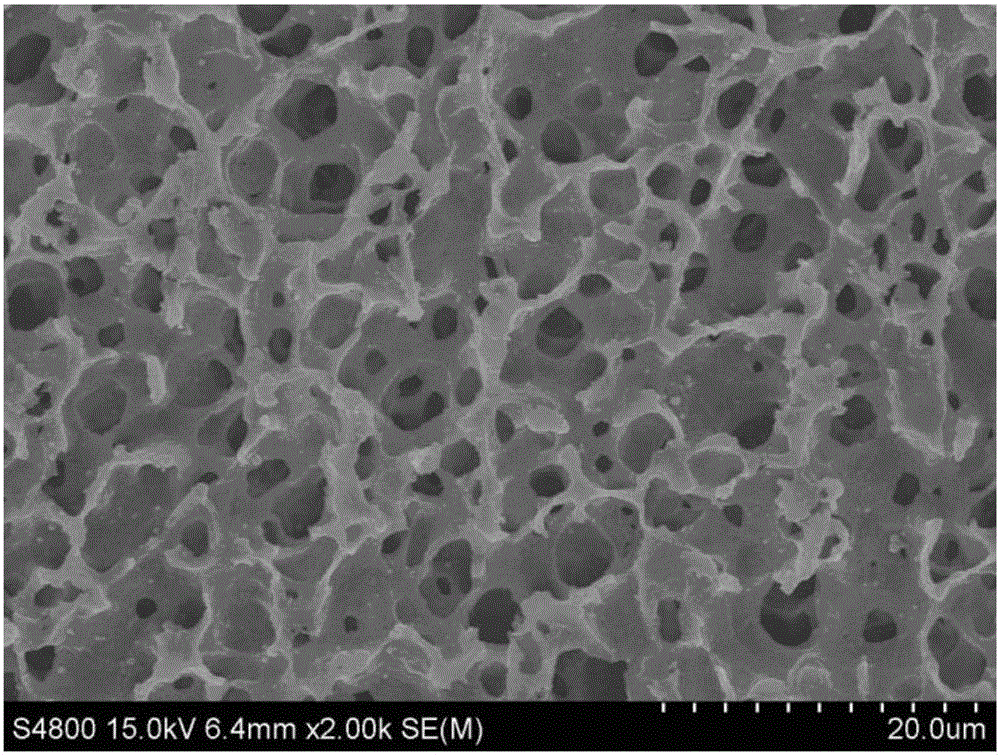

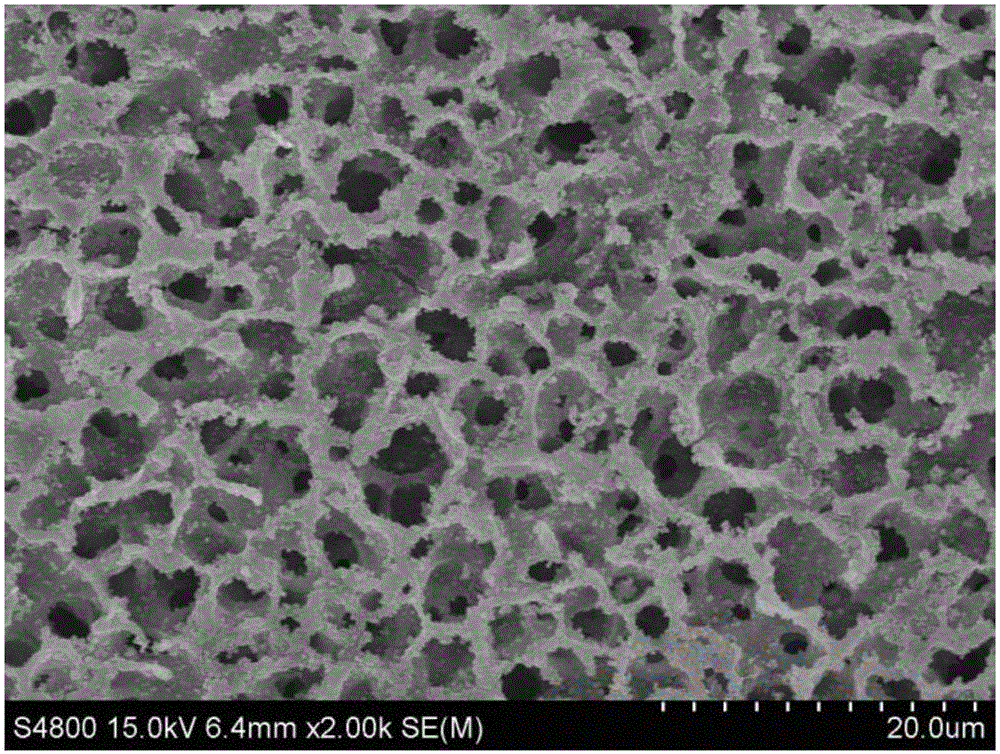

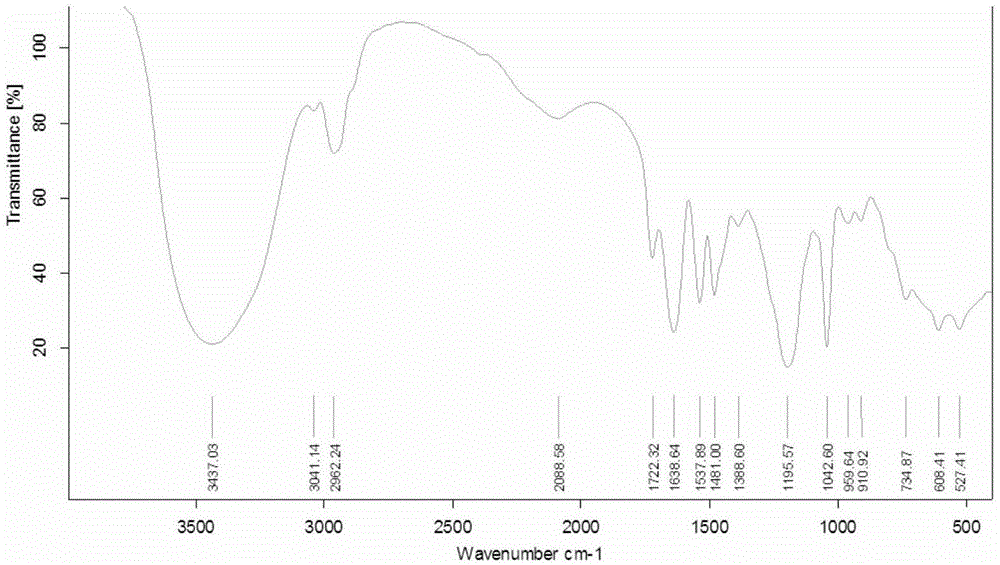

Preparation method for scale-adjustable nano porous metal material

The invention discloses a preparation method for a scale-adjustable nano porous metal material and belongs to the field of porous material preparation. A pore-forming material is added to superfine metal powder, compression molding of the superfine metal powder is conducted, and then the superfine metal powder is sintered in a vacuum sintering furnace to obtain the porous material. The interior of the porous material contains multiple pore scales of nano-micron-milli, and the dual-adjustment of the inside pore scale of the porous material and the surface roughness scale of a metallic matrix can be achieved by controlling the parameters such as the grain size of the metal powder, the content and grain size of the pore-forming material, the sintering temperature and the holding time and the follow-up treatment process, so that the porous material has super hydrophilicity, and the efficiency of boiling heat transferring is significantly improved. The preparation method for the scale-adjustable nano porous metal material is low in cost, easy to operate and reliable in technology; the product can be used for a wick of a heat pipe, the evaporating surface of an evaporator and other boiling phase-changing heat transferring devices, so that the preparation method for the scale-adjustable nano porous metal material has good application prospects.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

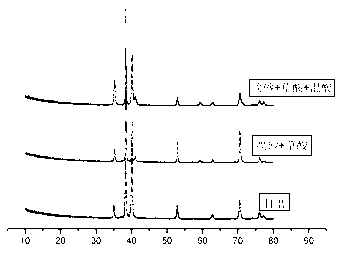

Method for preparing super-hydrophilic structure on red copper surface and red copper micro-heat tube manufactured by using same

ActiveCN103556193AImprove stabilityImprove the bonding strength of the interfaceIndirect heat exchangersHeat transfer modificationMicro nanoCopper

The invention discloses a method for preparing a super-hydrophilic structure on a red copper surface and a red copper micro-heat tube manufactured by using the method. The method for preparing the red copper super-hydrophilic structure comprises the following four steps: preparing electrolyte, performing red copper surface pretreatment, constructing a micro-nano rough structure in an electrochemical deposition mode, and sintering. The contact angle of the super-hydrophilic structure prepared by using the method and water is 5-0 degree, and moreover the super-hydrophilic structure has good stability and high boundary binding strength, and can be used as a super-hydrophilic layer to be applied to the red copper micro-heat tube. Due to the good super-hydrophilic property, the heat conduction coefficient of the red copper micro-heat tube and the capillary force of the super-hydrophilic layer are greatly improved. By adopting the method, the conventional difficult problem in machining the red copper micro-heat tube is solved, and the method is simple and easy to control in process, low in cost and applicable to popularization.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of compound material with super-hydrophilic polyvinylidene fluoride@dopamine@silicon dioxide

InactiveCN106178986AImprove hydrophilicitySimple methodMembranesSemi-permeable membranesEmulsionPolyvinylidene difluoride

The invention provides a preparation method of a compound material with super-hydrophilic polyvinylidene fluoride@dopamine@silicon dioxide. The preparation method comprises the following steps of: (1) preparing a polyvinylidene fluoride membrane; (2) preparing a polyvinylidene fluoride@dopamine membrane; (3) preparing the compound material with the super-hydrophilic polyvinylidene fluoride, the dopamine and the silicon dioxide. The compound material prepared by the invention is good in mechanical property and stable in structure, simultaneously has super-hydrophilic property and can be used for emulsion separation.

Owner:JIANGSU UNIV

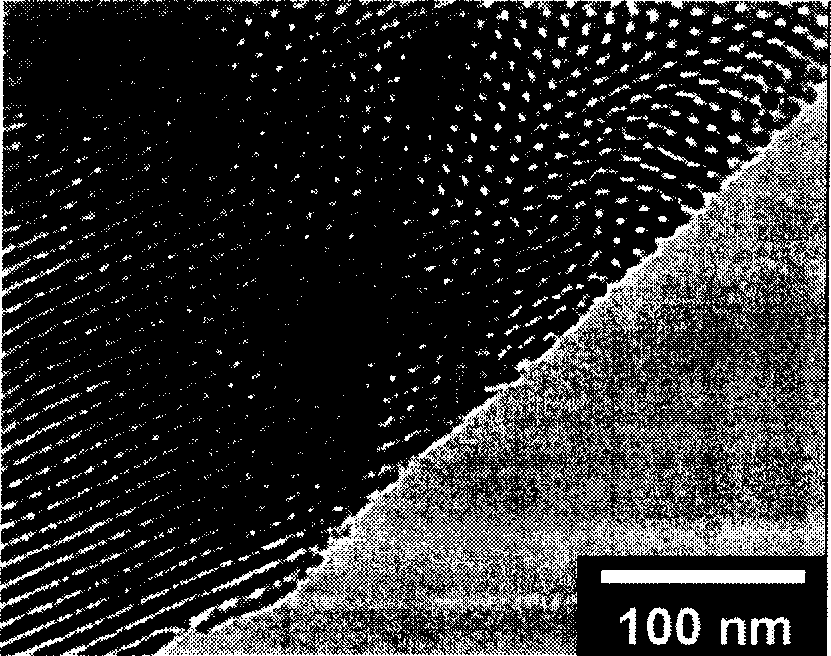

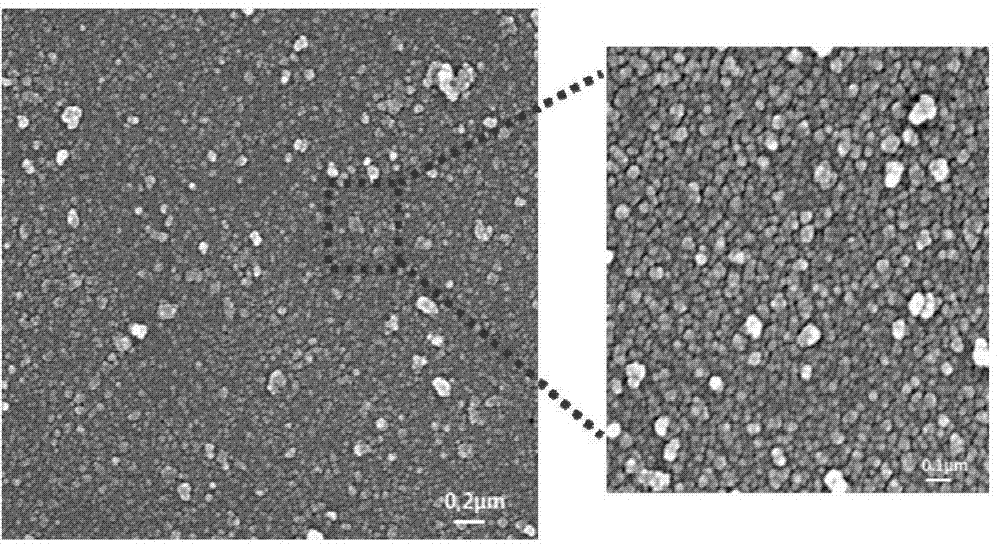

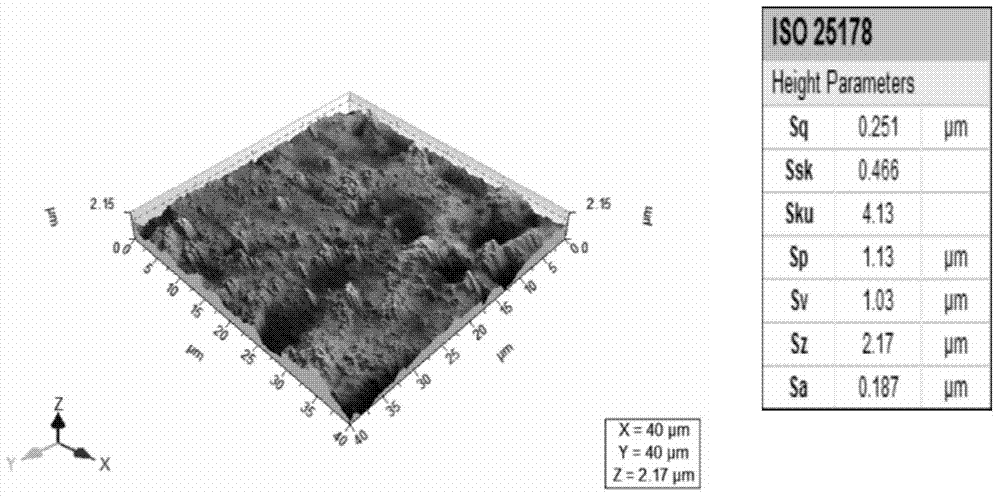

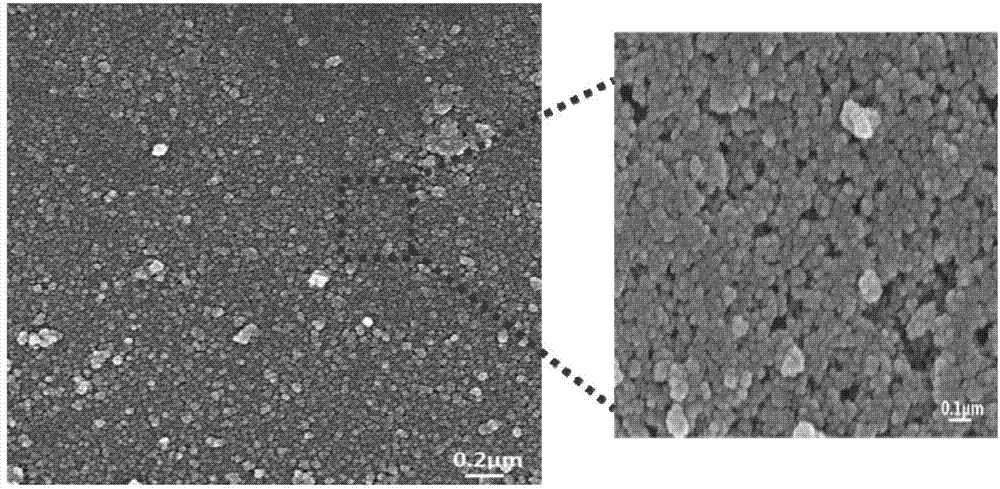

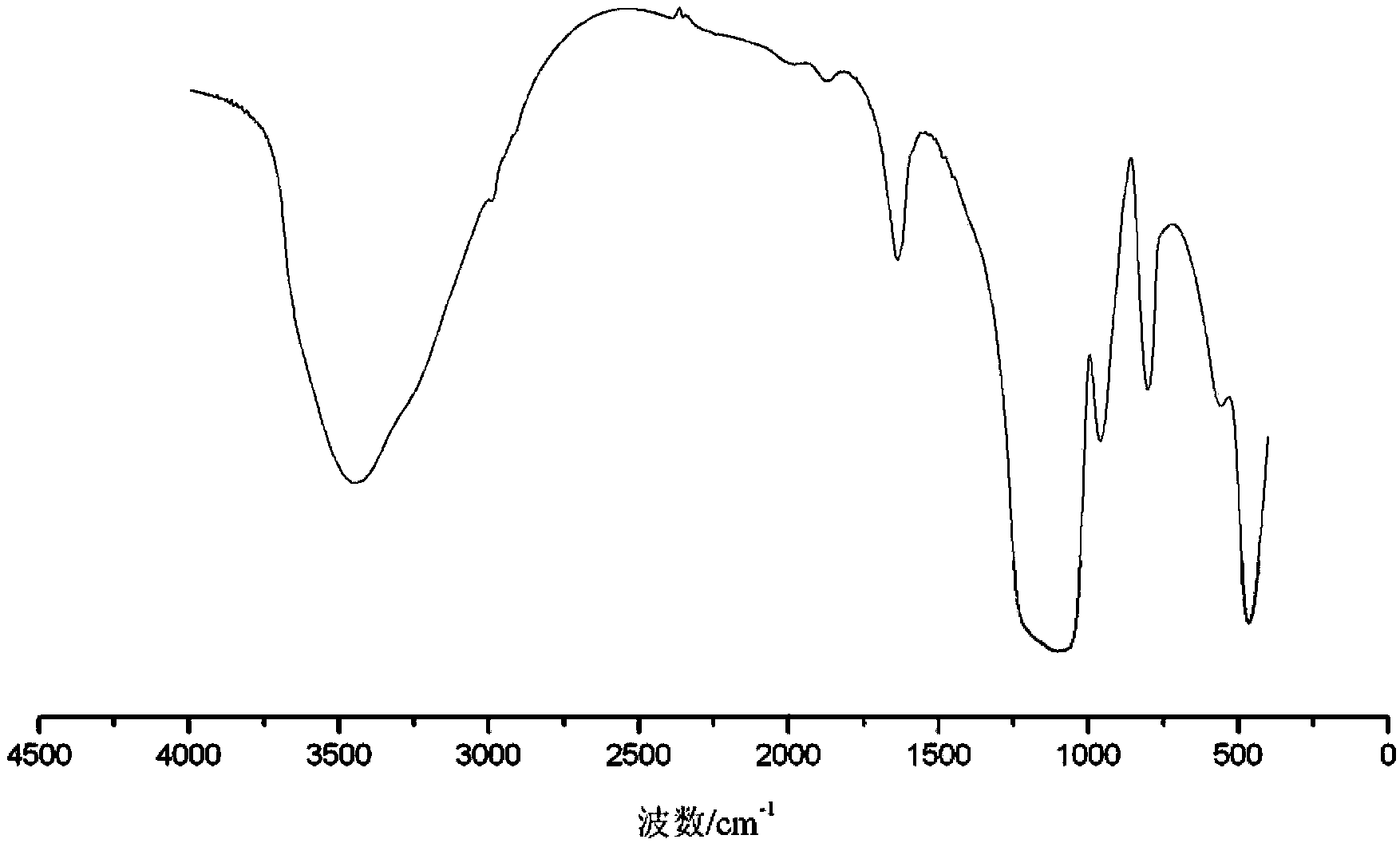

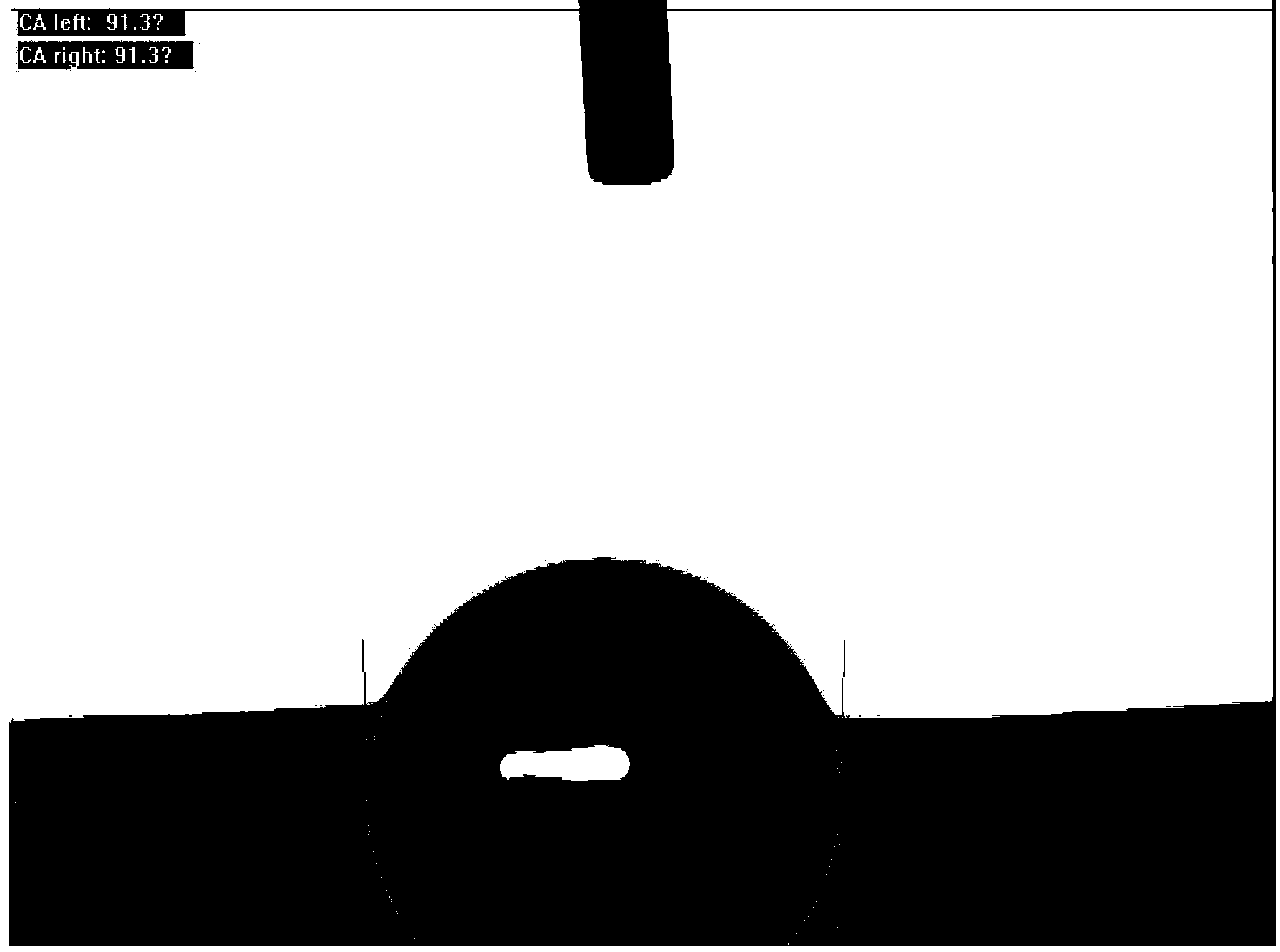

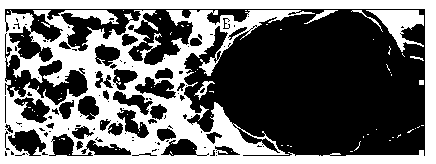

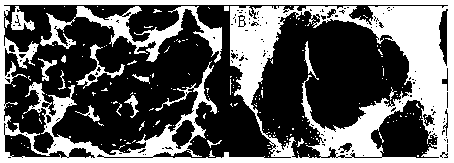

Preparation method of titanium implant surface with micro-nano composite structure

The invention provides a preparation method of a titanium implant surface with a micro-nano composite structure. The preparation method comprises the following steps: (1) performing blast sanding and ultrasonic processing on a smooth implant surface, then washing with water, and drying; (2) processing the implant surface in an oxalic acid solution for 30-240 min, then washing with water, and drying, wherein the concentration of the oxalic acid solution is 30% to saturation; and (3) taking a mixed acid solution of H2SO4 with the concentration of 98% and H2O2 with the concentration of 30% for processing, and then washing with water to obtain the titanium implant surface with the micro-nano composite structure. According to the preparation method of the titanium implant surface with the micro-nano composite structure, disclosed by the invention, the implant surface with the micro-nano composite structure is obtained by performing a secondary etching on a micron-structure surface processed by sand blast and oxalic acid, and compared to the micron-structure surface, titanium implant surface is provided with a microstructure with more levels, which is capable of providing more comprehensive environment signals for cell growth and tissue regeneration; and the titanium implant surface with the micro-nano composite structure has super-hydrophilicity and the protein adsorption capability is remarkably enhanced, which are of a great significance to further improving the surface biological activity of implants.

Owner:ZHEJIANG UNIV

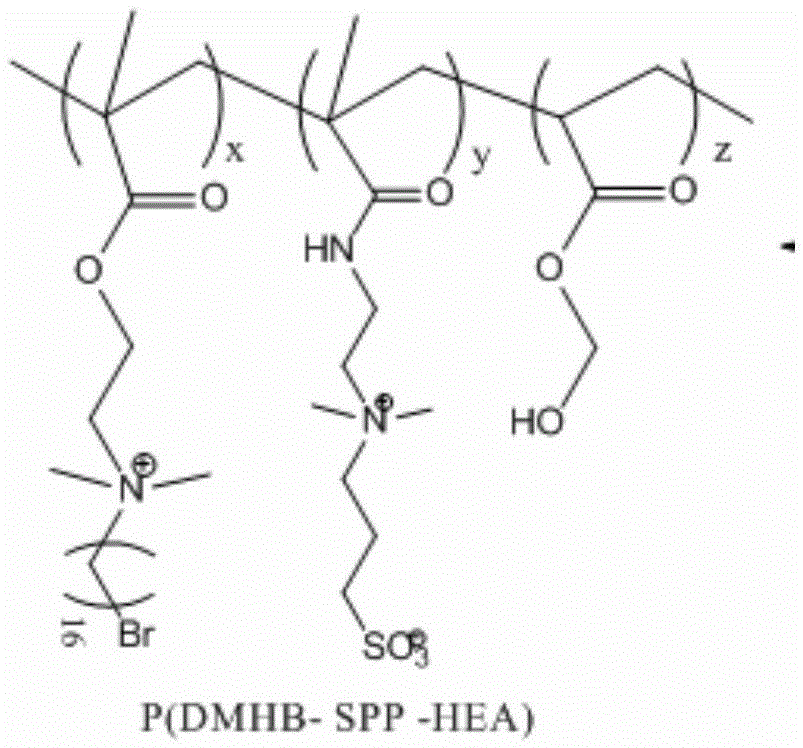

Super-hydrophilic oil water separation net film with antifouling and antibacterial functions and preparation as well as application thereof

InactiveCN105413236ANo health hazardWill not cause secondary pollutionFatty/oily/floating substances removal devicesNon-miscible liquid separationBetaineMolecular adsorption

The invention discloses a super-hydrophilic oil water separation net film with antifouling and antibacterial functions and preparation as well as application thereof. The net film is provided with a special three-layer structure, and is formed by a water-sensitive agent bottom layer, a crosslinking agent interlayer and a super-hydrophilic ternary polymer surface layer; a super-hydrophilic ternary polymer at the outermost layer is obtained by polymerizing three monomers of HEA, SPP and DMHB through a water solution, and adopted raw materials and a reaction system (water) are environment-friendly, cannot cause secondary pollution, and also cannot infect the health of an operator. In the super-hydrophilic ternary polymer, long carbon chain quaternary ammonium salt groups of the DMHB exist and can effectively kill bacteria, and meanwhile SPP glycine betaine groups simultaneously having positive and negative charges also exist and can effectively prevent molecular adsorption of protein and the like. The net film is stable in film layer structure, can better keep super hydrophilicity and antifouling and antibacterial properties, and can be applied to treatment of oily wastewater.

Owner:SOUTH CHINA UNIV OF TECH

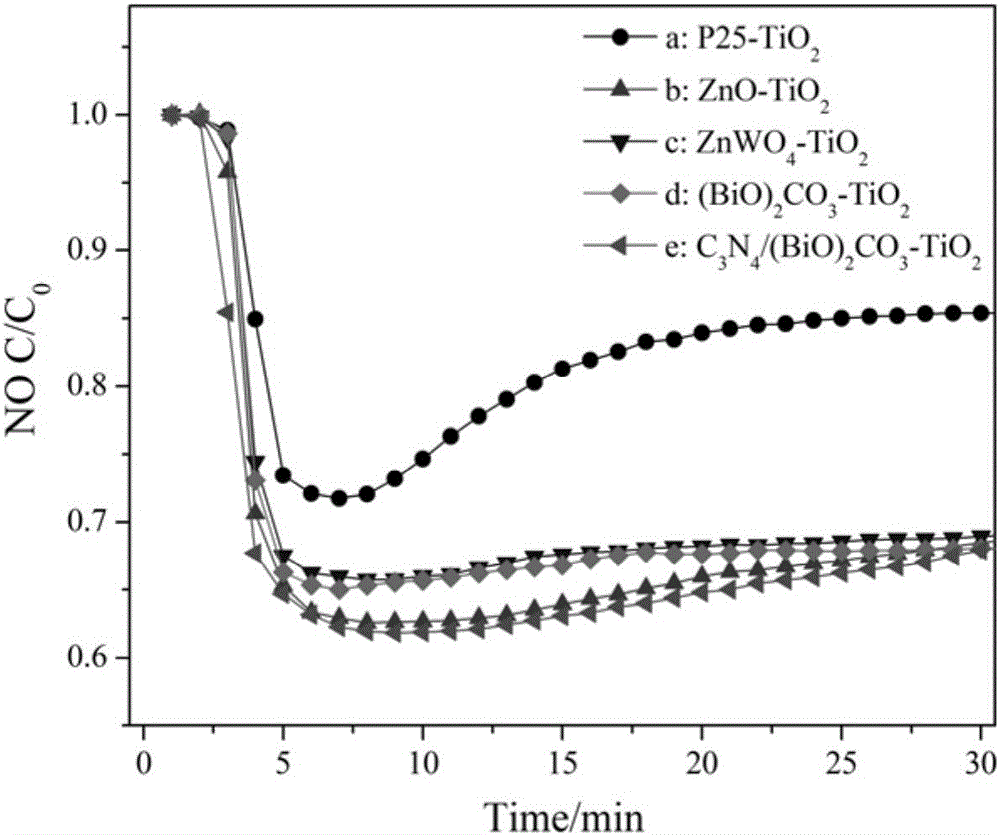

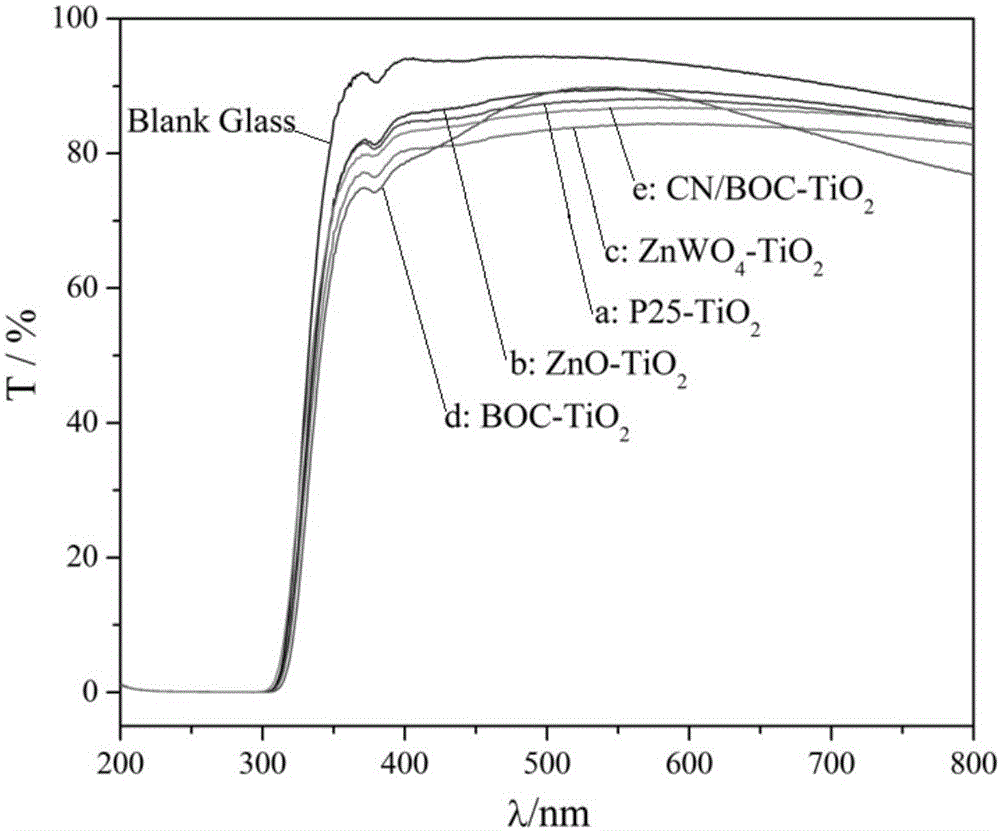

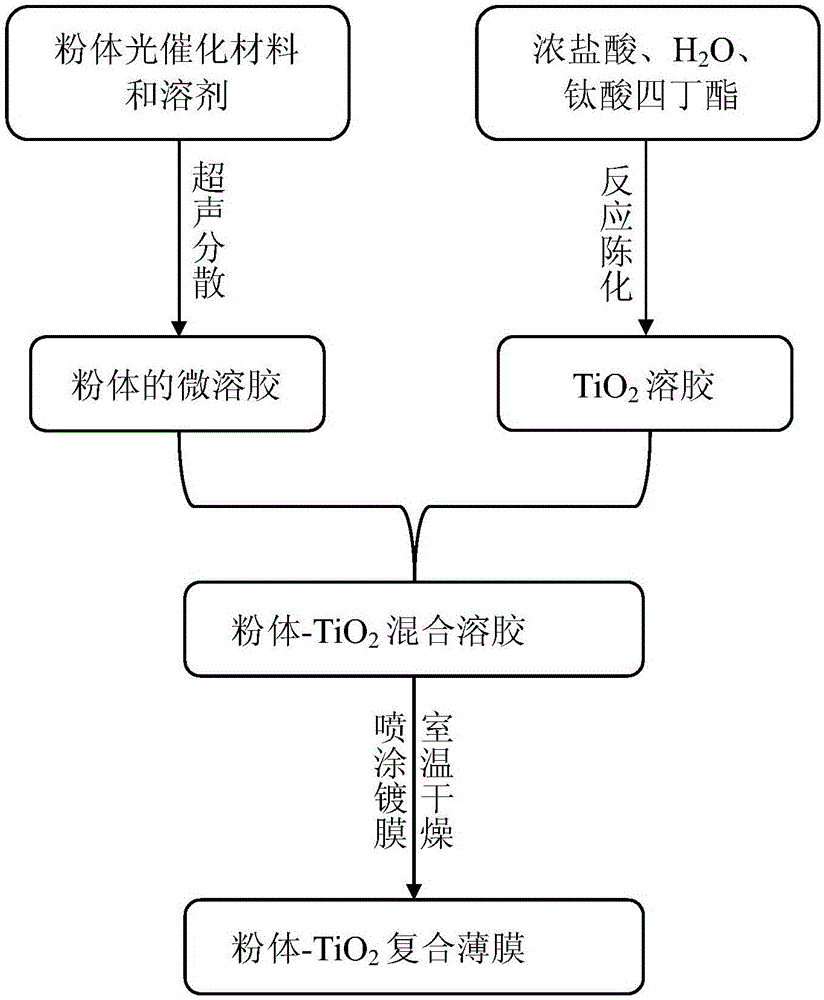

Method for preparing powder-TiO2 photoinduced super-hydrophilic composite film at low temperature

ActiveCN105771952AGood light-induced superhydrophilicitySolve application difficultiesCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsIce waterComposite film

The invention provides a method for preparing a powder-TiO2 photoinduced super-hydrophilic composite film at a low temperature. Under the condition of ice-water bath, hydrochloric acid, H2O and tetrabutyl titanate are mixed in the volume ratio of (0.6-1.3):100:10 and react under stirring for 2h, aging is performed at the room temperature, and TiO2 sol is obtained; a powder photocatalytic material is added into solvent and subjected to ultrasonic dispersion to be uniform, and micro-sol made from the powder material is obtained; the TiO2 sol is mixed with the micro-sol made from powder photocatalytic material, and powder-TiO2 mixed sol is obtained after uniform dispersion; the powder-TiO2 mixed sol is sprayed for coating a carrier substrate at 80 DEG C, film coating is performed with a spraying method, and then drying at the room temperature is performed. The powder-TiO2 composite film prepared with the method is prevented from powder separation after being dried, and has good adhesive force; the film shows a good photoinduced super-hydrophilic property, and the light transmittance is relatively high; the film coating method has the advantages of simple operation, mild technological conditions, and relatively low cost, thereby facilitating industrial production and application.

Owner:INST OF EARTH ENVIRONMENT CHINESE ACAD OF SCI

Nanocrystalline metal oxide array with under-oil super-hydrophobicity and super-hydrophilicity reversible transition function and preparation method thereof

ActiveCN105887158ABroaden the application scope of intelligent transformationElectrolytic inorganic material coatingSurface reaction electrolytic coatingPhoto irradiationUltraviolet lights

The invention discloses a nanocrystalline metal oxide array with an under-oil super-hydrophobicity and super-hydrophilicity reversible transition function and a preparation method thereof. The static contact angle under the oil phase is larger than 150 degrees after the nanocrystalline metal oxide array is subjected to thermal treatment at the temperature ranging from 120 DEG C to 350 DEG C for 1 h to 4 h, and the nanocrystalline metal oxide array has super-hydrophobicity performance; the static contact angle of water under the oil phase is smaller than 10 degrees after the nanocrystalline metal oxide array is irradiated under ultraviolet light for 1 h to 2 h, the nanocrystalline metal oxide array has super-hydrophilicity performance, and the conversion from super-hydrophobicity to super-hydrophilicity is achieved; and after heating recovery is conducted for 1.5 h to 3 h at the temperature ranging from 100 DEG C to 150 DEG C, the static contact angle of water under the oil phase recovers to 150 degrees or above, the nanocrystalline metal oxide array has super-hydrophobicity performance, and the reversible conversion from super-hydrophilicity to super-hydrophobicity is achieved. According to the method, the nanocrystalline metal oxide array is prepared through an existing mature and simple method and is subjected to the processes of thermal treatment, ultraviolet irradiation and heating recovery, the function of reversible conversion from super-hydrophobicity to super-hydrophilicity under different oil phase complex environments is achieved, and therefore the application range of nanotube array intelligent conversion is widened, and important application prospects are achieved.

Owner:HARBIN INST OF TECH

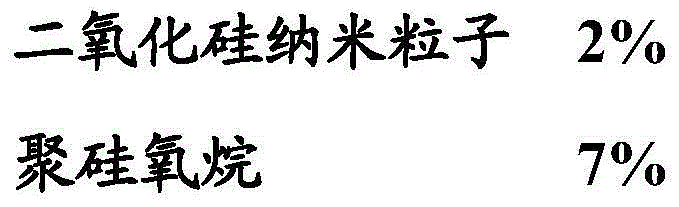

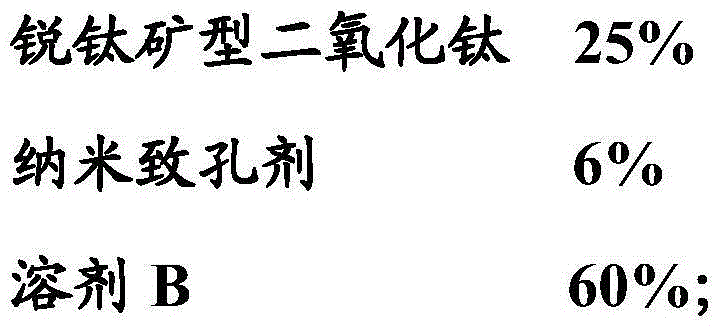

Novel preparation method of nanometer self-cleaning glass

The invention provides a novel preparation method of nanometer self-cleaning glass with low refractive index. The preparation method comprises the following steps: 1) uniformly spraying a nanometer self-cleaning paint onto the surface of glass; 2) drying the self-cleaning glass obtained from the step 1) under the normal temperature or heating condition so as to obtain self-cleaning glass with a nanometer self-cleaning film; and 3) spraying a solvent A onto the surface of the self-cleaning glass obtained from the step 2), standing, removing the nano-pore-forming agent-dissolved solvent A, and drying to form a nanometer concave-convex structure on the film. The self-cleaning glass prepared by the method has raised self-cleaning ability and high light transmittance, also has enhanced super-hydrophilic property and antifogging property, and has wider applicability.

Owner:江纳股份公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com