Super-hydrophilic oil water separation net film with antifouling and antibacterial functions and preparation as well as application thereof

An oil-water separation omentum membrane, super-hydrophilic technology, applied in immiscible liquid separation, liquid separation, separation methods, etc. The effect of anti-protein adsorption performance and strong bactericidal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

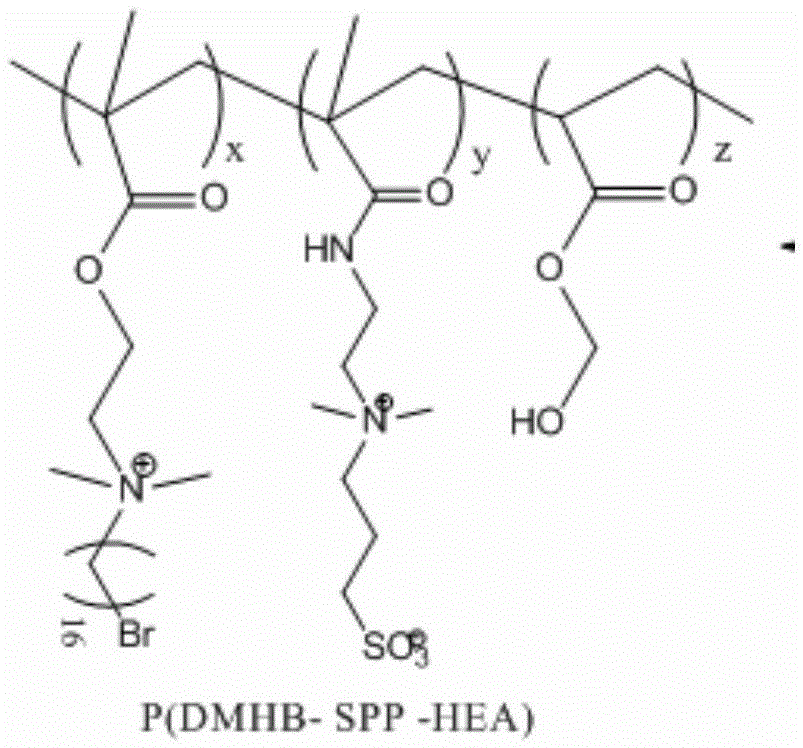

[0051] 1. Preparation of super-hydrophilic terpolymer: weigh 10 grams of reactive monomer with a mass ratio of HEA / SPP / DMHB = 10 / 85 / 5, put it into a 250mL three-necked reaction flask, add 80 grams of deionized water and pass Magnetic stirring to completely dissolve the monomer, pass in N 2 Air protection, after activation for 1h, start to add the initiator solution (0.1g AIBA dissolved in 10g deionized water), and control the reaction temperature at 85℃. After 8h reaction, a superhydrophilic terpolymer solution is obtained. Stand by at room temperature.

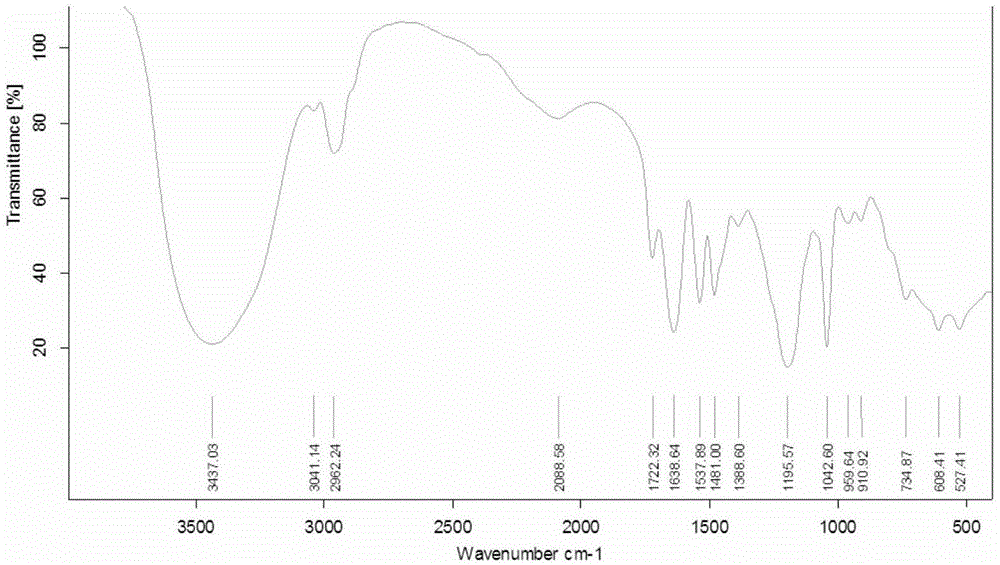

[0052] The structure of the synthesized super-hydrophilic copolymer was tested with the SpectrumRX infrared tester from PerkinElmer, USA. figure 2 The infrared spectrum is visible, at 3400cm -1 There is a strong absorption peak, which is the absorption peak of HEA hydroxyl OH, 1040cm -1 And 1190cm -1 The strong absorption peak at SPP sulfo SO 3 The stretching vibration peak, 1720cm -1 O-C=O stretching vibration peak of HEA and D...

Embodiment 2

[0064] 1. Preparation of super-hydrophilic terpolymer: Weigh 10 grams of reactive monomer whose mass ratio is HEA / SPP / DMHB=5 / 90 / 5, put it into a 250mL three-necked reaction flask, add 80 grams of deionized water and pass Magnetic stirring to completely dissolve the monomer, pass in N 2 Atmosphere protection, 4h after activation, start to add initiator solution (0.05g AIBA dissolved in 10g deionized water), and control the reaction temperature at 90℃. After 6h reaction, a super-hydrophilic terpolymer solution is obtained. Stand by at room temperature.

[0065] The structure of the synthesized super-hydrophilic copolymer was tested with the SpectrumRX infrared tester from PerkinElmer, USA. figure 1 Similar to the infrared spectrum figure 2 similar.

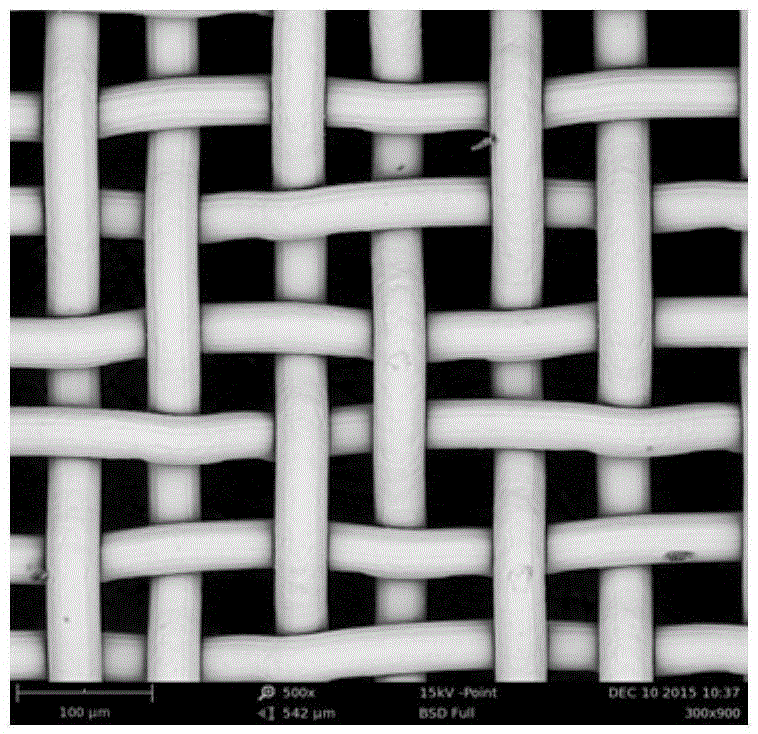

[0066] 2. A piece of 100-mesh copper wire mesh with a diameter of 5 cm was immersed in distilled water, ethanol or acetone, and distilled water in order, respectively, and ultrasonically cleaned at 150w and 40Khz for 10 minutes, and the...

Embodiment 3

[0077] 1. Preparation of super-hydrophilic terpolymer: Weigh 20 grams of reactive monomer with a mass ratio of HEA / SPP / DMHB = 5 / 85 / 10, put it into a 250mL three-necked reaction flask, add 70 grams of deionized water and pass Magnetic stirring to completely dissolve the monomer, pass in N 2 Air protection, after activation for 2h, start to add the initiator solution (0.1g AIBA dissolved in 10g deionized water), and control the reaction temperature at 75℃. After reacting for 12h, a super-hydrophilic terpolymer solution is obtained. Stand by at room temperature.

[0078] The structure of the synthesized super-hydrophilic copolymer was tested with the SpectrumRX infrared tester from PerkinElmer, USA. figure 1 Similar to the infrared spectrum figure 2 similar.

[0079] 2. A piece of 200-mesh non-woven fabric with a diameter of 5 cm was immersed in distilled water, ethanol or acetone, and distilled water in order, respectively, and ultrasonically cleaned at 150w and 40Khz for 10 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com