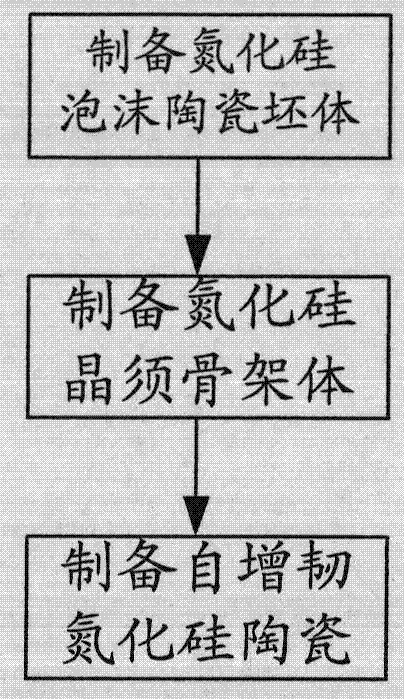

Method for preparing self-toughening silicon nitride ceramics

A technology of tough silicon nitride ceramics and tough silicon nitride, which is applied in the field of preparing self-toughened silicon nitride ceramics, can solve the problems of poor toughening effect and small aspect ratio of crystal grains, and achieve surface tension reduction and finished products High rate, good toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Preparation of silicon nitride foam ceramic body

[0045] Weigh 40g of silicon nitride powder, add 2.4g of sintering aids (0.8g of aluminum oxide and 1.6g of yttrium oxide), 0.4g of dispersant, 3.2g of molding solidification medium, 6g of carboxymethylcellulose (CMC) solution ( Carboxymethylcellulose (CMC) aqueous solution concentration is 4%) and 0.8g foaming agent, add 60g deionized water to form a mixture, utilize concentrated ammonia water to adjust the pH value of the mixture to 10, and make a slurry after ball milling for 12h; The slurry after ball milling was continued to be stirred at high speed for 20 minutes to foam, then an appropriate amount of initiator and catalyst was added, stirred for 5 minutes, injection molded, solidified and formed, and then the green body was dried (in the air) and debinding (burned out organic matter).

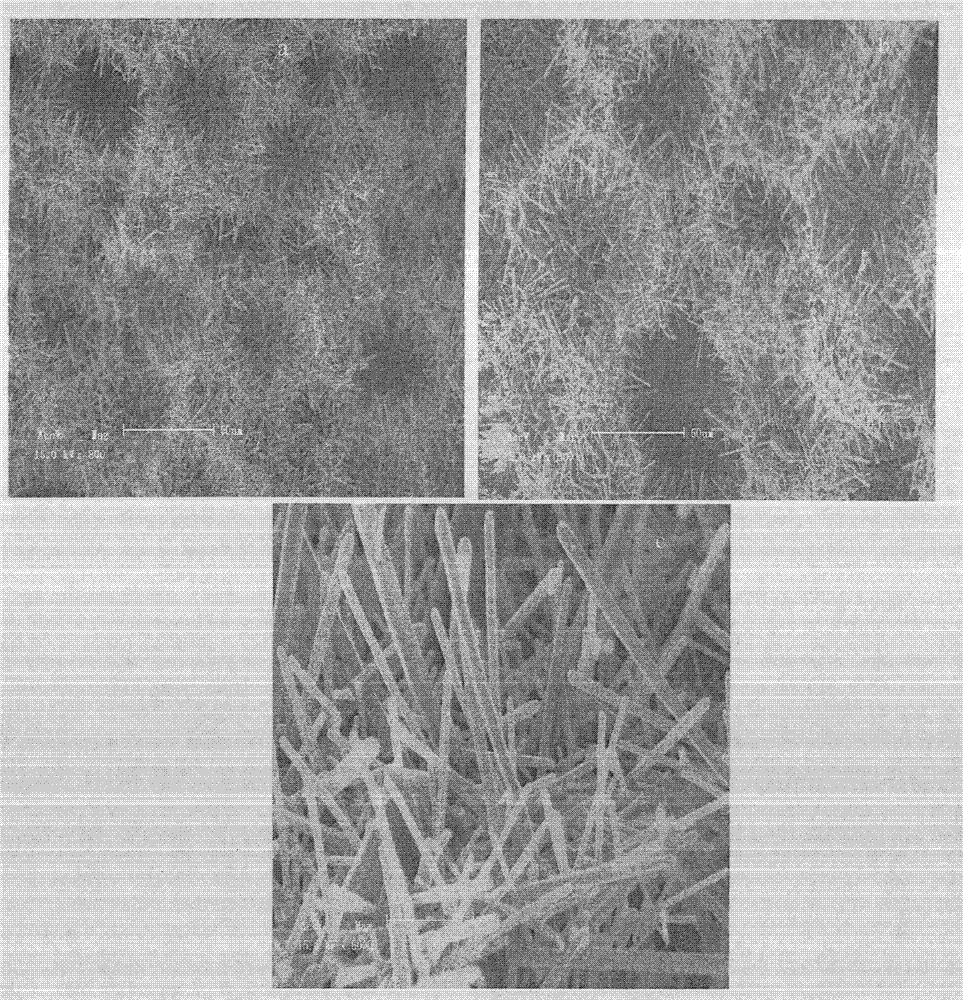

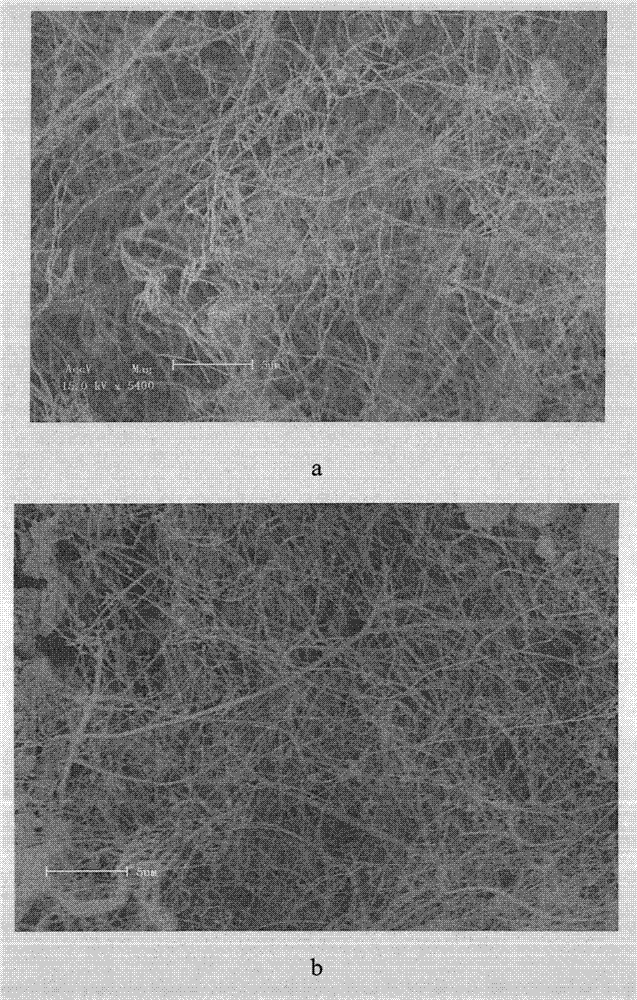

[0046] (2) Preparation of silicon nitride whisker framework

[0047] During the sintering process, the heating rate below 80...

Embodiment 2

[0055] (1) Preparation of silicon nitride foam ceramic body

[0056] Weigh 40g of silicon nitride powder, add 2.4g of sintering aids (0.8g of alumina and 1.6g of yttrium oxide), 0.4g of dispersant, 3.2g of forming and curing medium, and add 4g of carboxymethylcellulose (CMC) solution (the concentration of carboxymethyl cellulose (CMC) solution is 3%) and 0.8g foaming agent, add 60g deionized water to form a mixture, utilize concentrated ammonia water to adjust the pH of the mixture to be 10, and make a slurry after ball milling for 12h ; The slurry after ball milling continues to be stirred at high speed for 20 minutes to foam, and an appropriate amount of initiator and catalyst is added, stirred for 5 minutes, injection molded, solidified and formed, and then the green body is dried (in the air) and debinding (burning out organic matter).

[0057] (2) Preparation of silicon nitride whisker framework

[0058] During the sintering process, the heating rate below 800°C is 15°C / ...

Embodiment 3

[0066] (1) Preparation of silicon nitride foam ceramic body

[0067] Weigh 40g of silicon nitride powder, add 2.4g of sintering aids (0.8g of alumina and 1.6g of yttrium oxide), 0.4g of dispersant, 3.2g of forming and curing medium, and add 8g of carboxymethylcellulose (CMC) solution (the concentration of carboxymethyl cellulose (CMC) solution is 3%) and 0.8g foaming agent, add 60g deionized water to form a mixture, utilize concentrated ammonia water to adjust the pH of the mixture to be 10, and make a slurry after ball milling for 12h The slurry after ball milling continues to be stirred at high speed for 20 minutes to foam, add an appropriate amount of initiator and catalyst, stir for 5 minutes, injection mold, solidify and form, and then dry the green body (in the air) and debinding (burn out organic matter)

[0068] (2) Preparation of silicon nitride whisker framework

[0069] During the sintering process, the heating rate below 800°C is 15°C / min, and the atmosphere is va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com