Patents

Literature

46results about How to "Improve interlayer bond strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

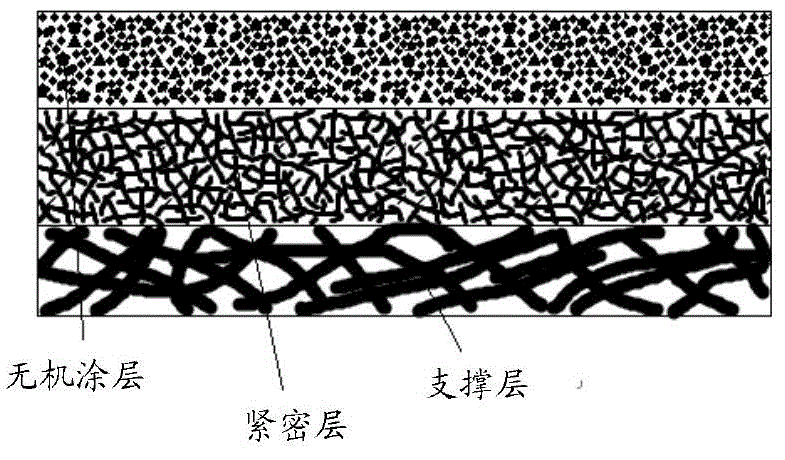

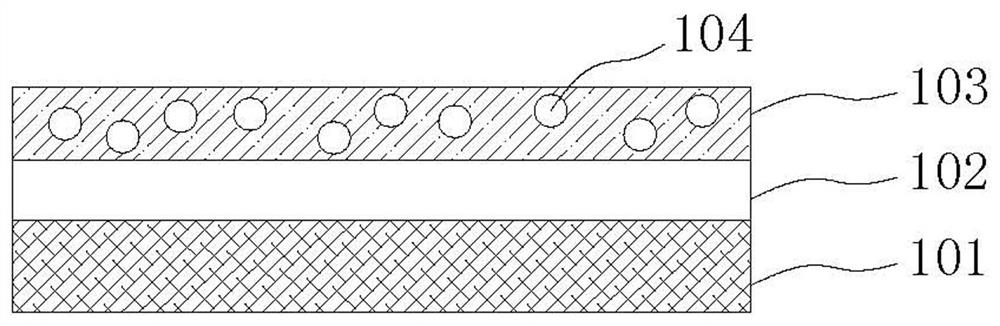

Lithium ion battery diaphragm, preparation method of lithium ion battery diaphragm and lithium ion battery

ActiveCN104157812ARequirements to ensure the strength of the diaphragmMeet the requirements of diaphragm strengthCell seperators/membranes/diaphragms/spacersSecondary cellsPorosityElectrical battery

The invention provides a lithium ion battery diaphragm, a preparation method of the lithium ion battery diaphragm and a lithium ion battery. The lithium ion battery diaphragm comprises a support layer, wherein either or both of a dense layer or an inorganic coating are compounded on the support layer; the average quantity of the lithium ion battery diaphragm is 8-25g / m<2>, the thickness is 15-60 mu m, the average aperture is 50-500nm, and the porosity is 78-82%. The lithium ion battery diaphragm provided by the invention is good in isolating property and excellent in electrolyte absorbing property, is further relatively high in tension strength, is capable of realizing high power capacity of a battery, and can meet the requirement of rapid large-current charge and discharge of the lithium ion battery.

Owner:SOUTH CHINA UNIV OF TECH

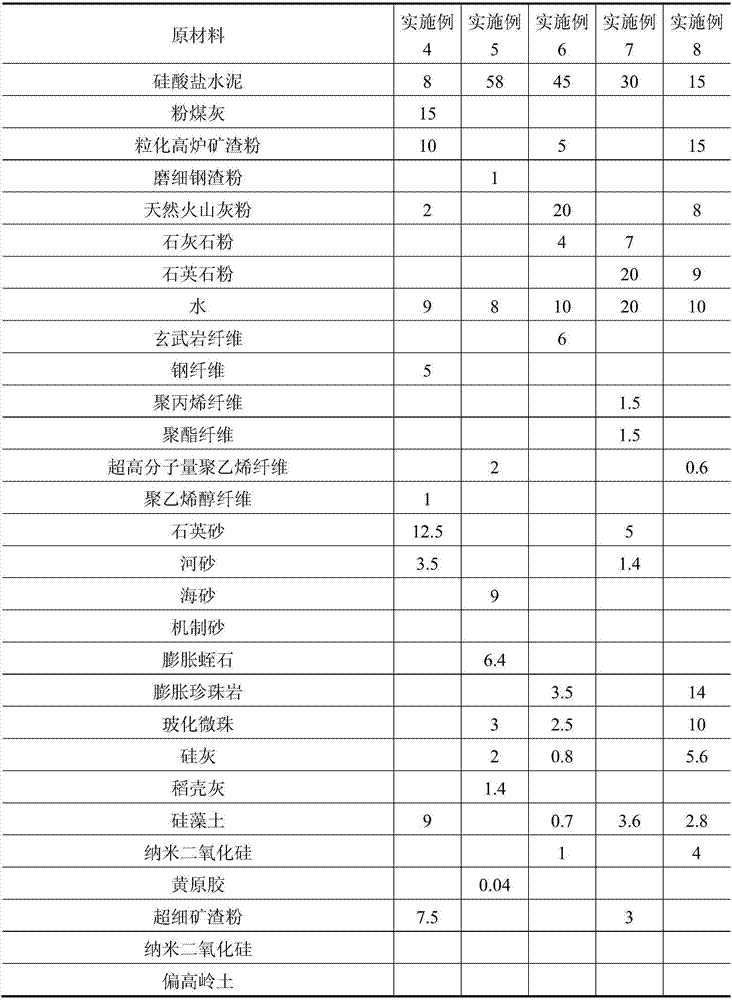

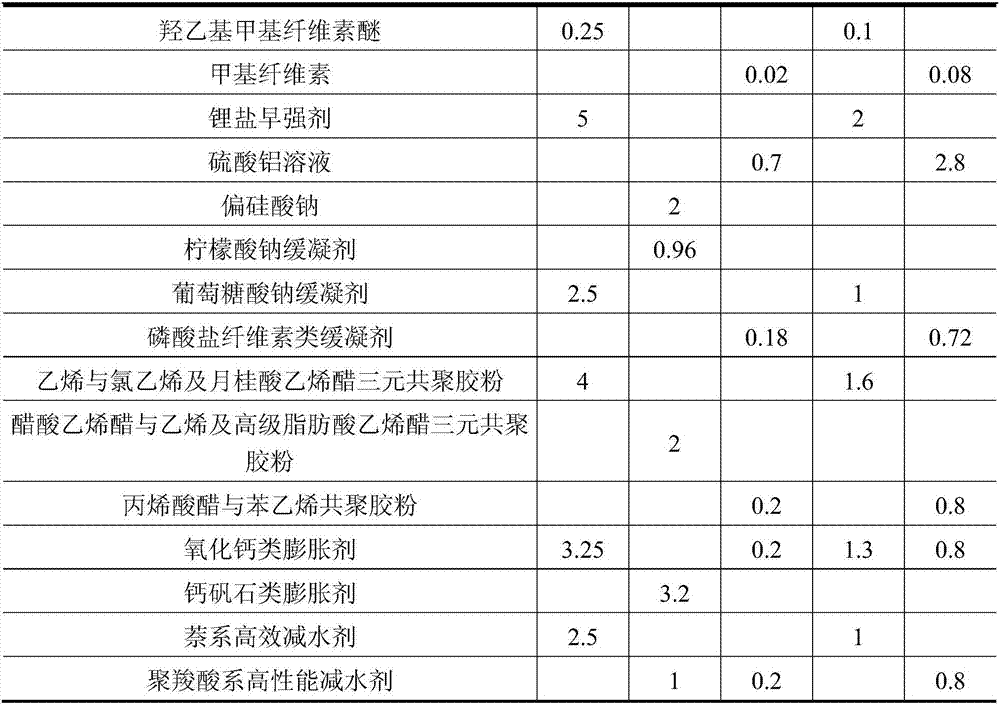

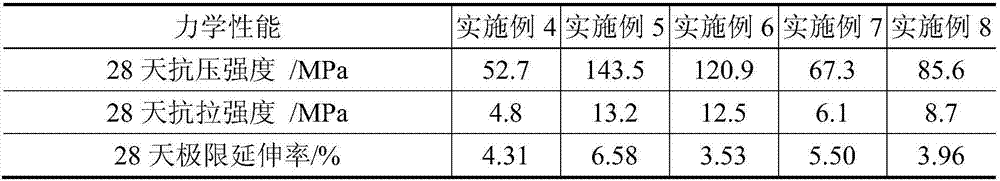

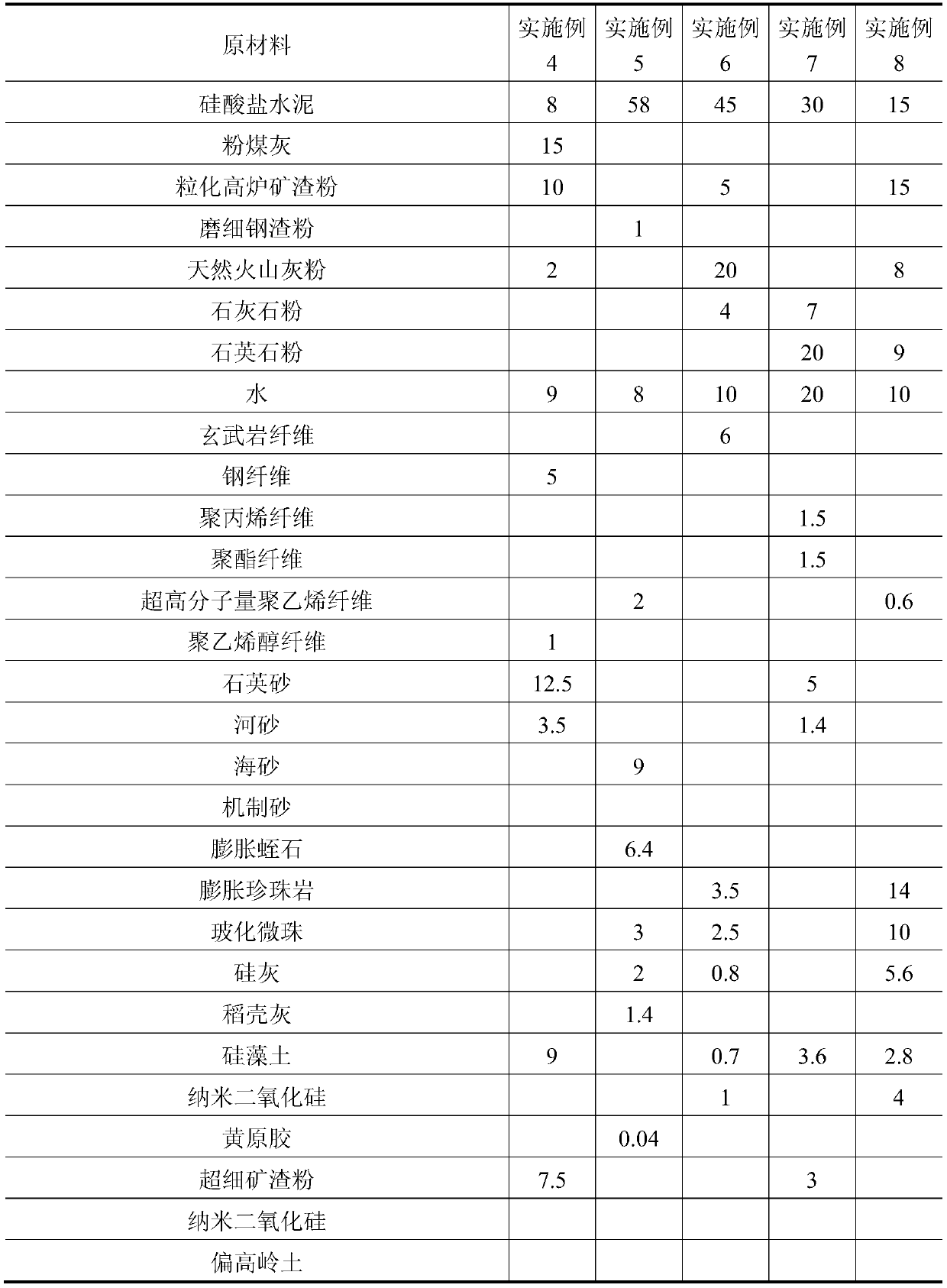

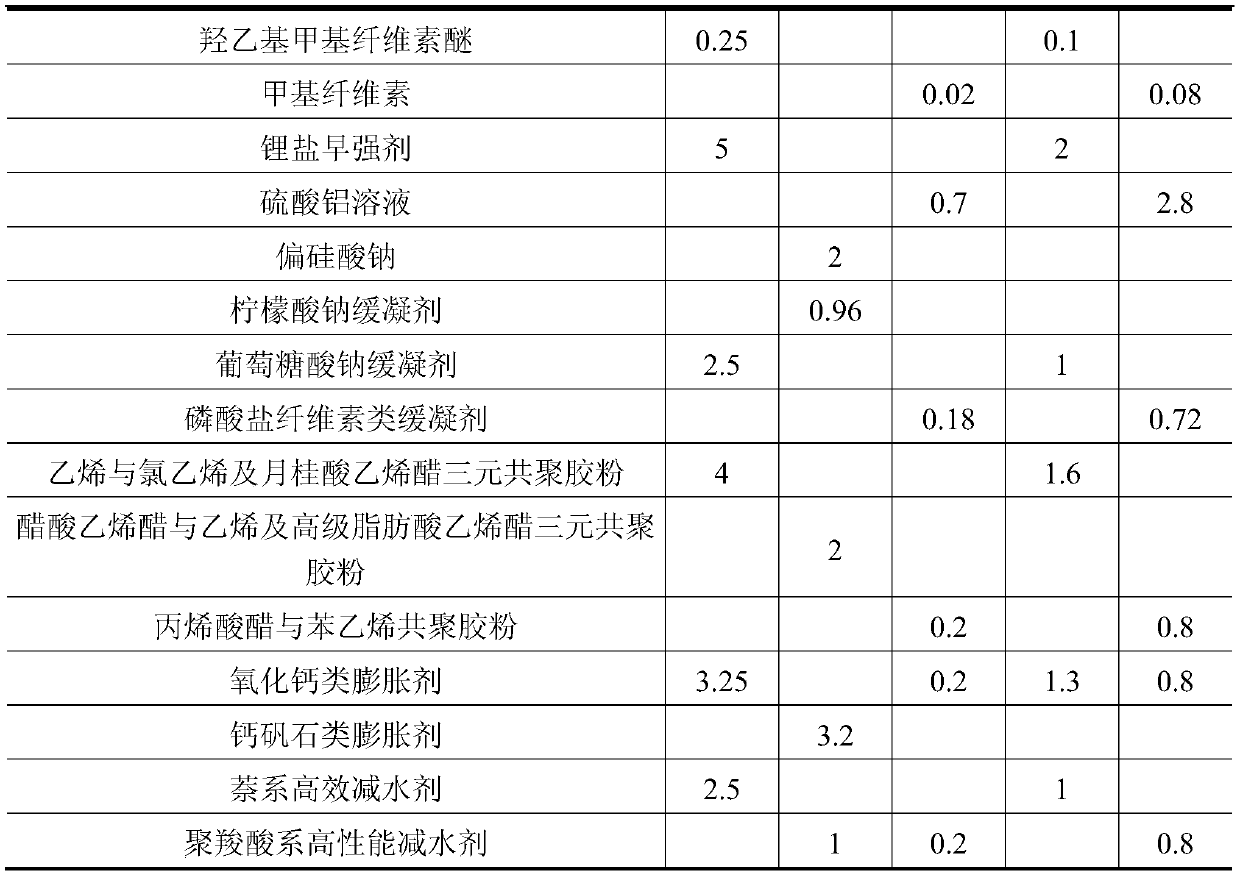

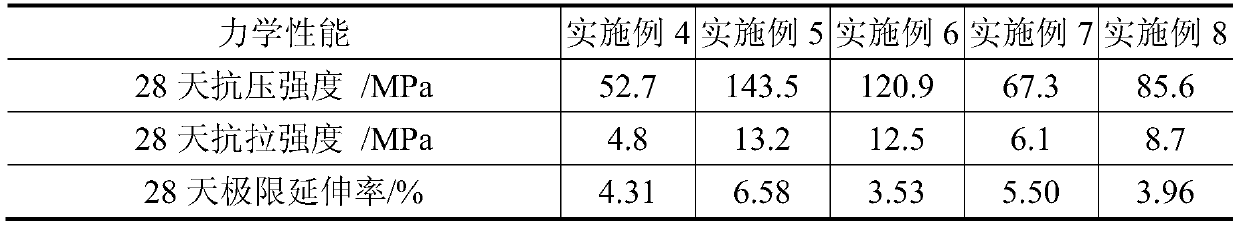

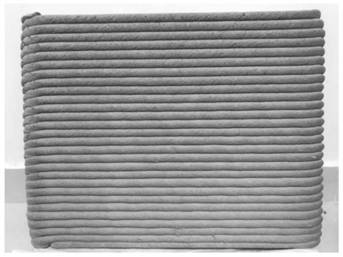

High-ductility fiber-enhanced cement based composite material used for 3D printing and preparation method of composite material

ActiveCN107500687AImprove performanceHigh compressive strengthAdditive manufacturing apparatusRebarWater reducer

The invention provides an additive composition used for a high-ductility fiber-enhanced cement based composite material. The additive composition comprises, by weight percentage, 20-85% of a rheological adjusting component, 2-30% of a setting and hardening adjusting component, 1-20% of an interlayer bonding strength adjusting component, 4-40% of a volume stabilizer, and 1-10% of a water reducer. The invention further provides a high-ductility fiber-enhanced cement based composite material based on the additive composition. Through optimal design of the additive composition and aggregate, the workability and the setting and hardening speed of a material is adjusted, and the printability, constructability, and the interlayer bonding strength of the high-ductility fiber-enhanced cement based composite material in 3D printing are improved. Compared with a 3D printing building material in the prior art, the composite material shows excellent whole performance. A component made from the composite material can meet the ductility of structural requirements without steel bars, thereby solving the problem that a component made from a 3D printing building material in the prior art is finally broken in a brittle failure manner.

Owner:万玉君

Thin film lamination-delamination process for fluoropolymers

InactiveUS6887334B2Improve interlayer bond strengthSimple and cost-effectiveLamination ancillary operationsDecorative surface effectsEngineeringFluoropolymer

A process for forming thin film laminations of thin fluoropolymer films to receiver sheets, more particularly, the production of very thin, transferable fluoropolymer films. A thin fluoropolymer base layer is applied onto a support layer, which may be a thicker film. The support layer / thin base layer is then laminated to a receiver sheet, followed by stripping away the support layer, leaving the base film on the receiver sheet.

Owner:HONEYWELL INT INC

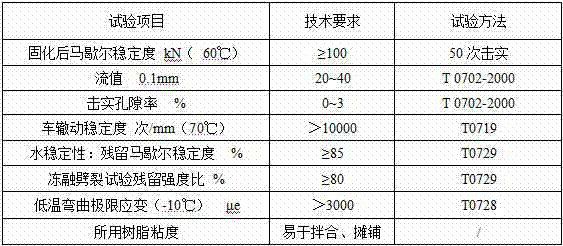

Steel bridge deck pavement cold mixing maintenance material and manufacturing method thereof

ActiveCN103114526AImprove bonding effectImprove interlayer bond strengthIn situ pavingsBridge structural detailsStructural engineeringResin bonding

The invention discloses a steel bridge deck pavement cold mixing maintenance material and a manufacturing method thereof. The maintenance material comprises a resin detritus waterproof layer, a resin bonding layer and a resin concrete pavement layer. The resin detritus waterproof layer is coated on a steel bridge panel required maintenance and is formed by solidifying resin and detritus spread on the surface of the resin. The resin bonding layer is coated on the resin detritus waterproof layer. The resin concrete pavement layer is coated on the resin bonding layer and is formed by solidifying the resin and aggregate in a mixed mode. According to the maintenance material, construction is convenient, influence on construction conditions by temperature is small, performance is excellent, maintenance time is short, production is convenient and rapid, construction period is short and influence on traffic is small.

Owner:江苏苏科建设项目管理有限公司

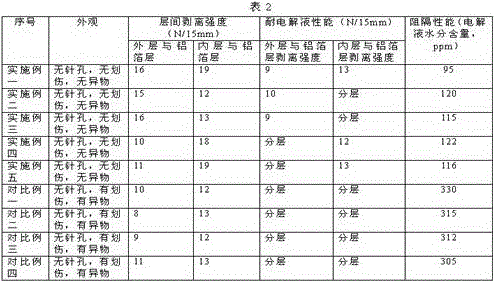

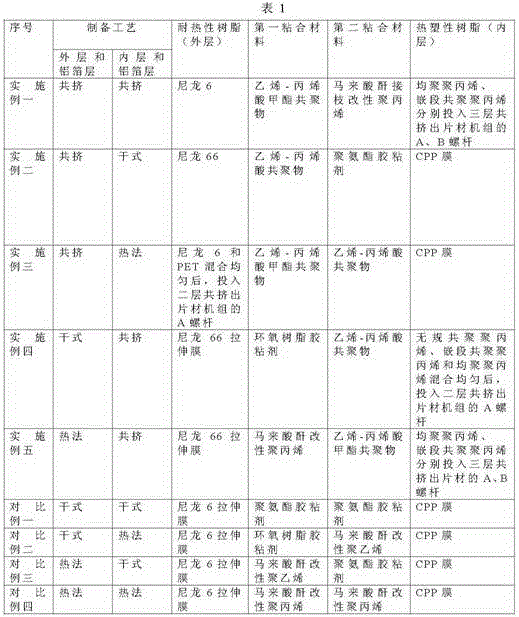

Preparing method for aluminum plastic film for lithium battery packaging

InactiveCN106808662AImprove bindingHigh bonding strengthSynthetic resin layered productsFlat articlesMolten stateMetallurgy

The invention discloses a preparing method for an aluminum plastic film for lithium battery packaging. The method comprises the following steps that firstly, an outer layer material and a first bonding material are added in a screw A and a screw B of a two-layer co-extrusion sheet unit and are melted and co-extruded in a screw extruder to be in tape casting to one side of aluminum foil to become a film; secondly, an inner layer material and a second bonding material are added in the screw A and the screw B of the two-layer co-extrusion sheet unit and are melted and co-extruded in the screw extruder to be in tape casting to the other side of the aluminum foil to become a film; and then the aluminum plastic film for lithium battery packaging can be obtained. The outer layer material or the inner layer material is melted and co-extruded to be in tape casting to the surface of the aluminum foil to become the film in the screw extruder melting, co-extrusion and tape casting manner; the outer layer material (or the inner layer material) in the molten state and the bonding material can seep into each other among the layers, and when the outer layer material (or the inner layer material) and the bonding material are in tape casting to the surface of the aluminum foil to be laminated, interlayer bonding is firmer, and the interlayer bonding strength is further improved.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Shrink film and cylindrical shrink label

InactiveUS20100279133A1Low specific gravityEasy to separateSynthetic resin layered productsLabelsPolyester resinPolypropylene

[Object] To provide a multilayer shrink film which is composed of different polymers, i.e., a polypropylene resin and an aromatic polyester resin and which does not suffer from delamination even in a center-sealed portion during shrinking process; and a cylindrical shrink label using the shrink film.[Solving Means] The shrink film has a multilayer structure including layers A, B, and C in the order of (layer A) / (layer B) / (layer C) without the interposition of any other layer, in which the layer A is a resin layer mainly containing a modified aromatic polyester resin; the layer B is an intermediate layer mainly containing an ethylene-vinyl acetate resin and having a vinyl acetate component content of 20 to 30 percent by weight; and the layer C is a resin layer mainly containing a polypropylene resin.

Owner:FUJI SEAL INTERNATIONAL INC

A high-ductility fiber-reinforced cement-based composite material for 3D printing and its preparation method

ActiveCN107500687BImprove performanceHigh compressive strengthAdditive manufacturing apparatusRebarWater reducer

Owner:万玉君

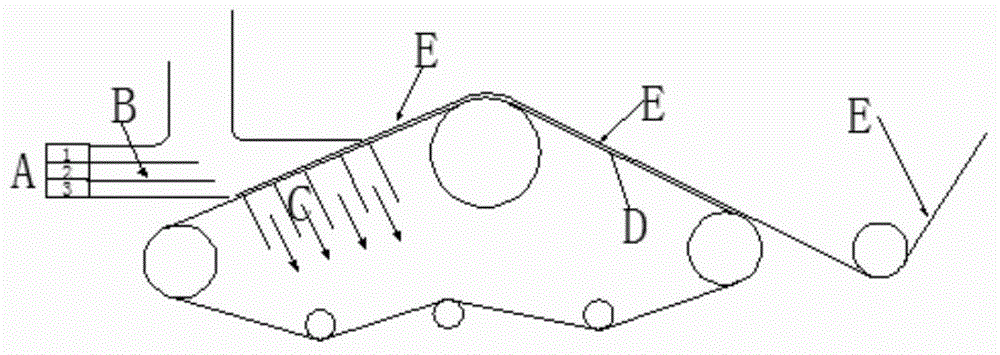

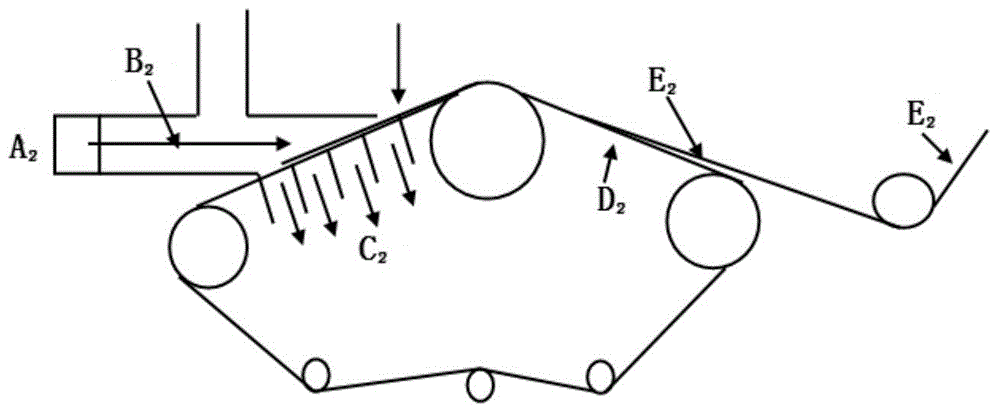

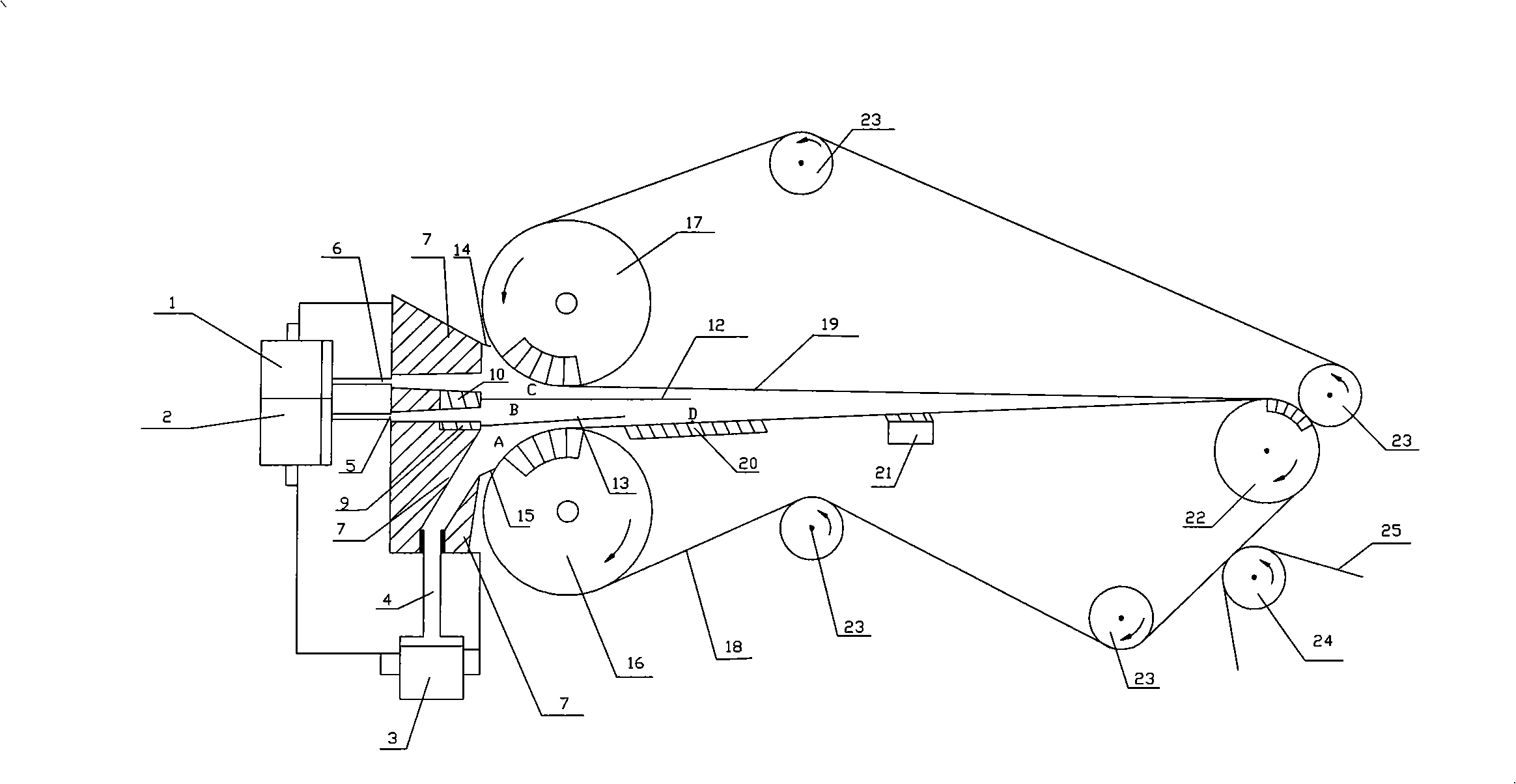

Multi-layer paper sheet gap former and method

InactiveCN101338530AReduce double-sidednessFast formingDryer sectionPress sectionPulp and paper industryEngineering

The invention discloses a device and method for forming multi-layer paper sheet sandwich net. An upper dehydration net and a lower dehydration net form upper and lower sandwich nets, the two nets between a vacuum forming roller and a vacuum breast roller are integrated to compose to a wedge-shaped opening for containing paper pulp; the wedge-shaped opening are divided into three parts by a long drift sheet and a short drift sheet from top to bottom, the long drift sheet is fixed on the main body of a multi-layer head box by a long drift sheet fixing support, the short drift sheet is fixed on the main body of the multi-layer head box by a short drift sheet fixing support. The method comprises that a lower layer A pulp flow enters into the dehydration wedge-shaped area for performing primary dehydration, then converges with a middle layer B pulp flow at initial end of dehydration sheets, the B pulp flow is evenly arranged above the A pulp flow, an upper layer C pulp flow enters into the dehydration wedge-shaped area for performing primary dehydration, but paper web is not formed yet, from the middle parts of the dehydration sheets, the A, B, C pulp flows are dehydrated together through the dehydration sheets and the vacuum dehydration tank, finally three layers of paper webs are formed. The invention has advantages of simple process, low energy consumption, less investment and compact structure.

Owner:SOUTH CHINA UNIV OF TECH

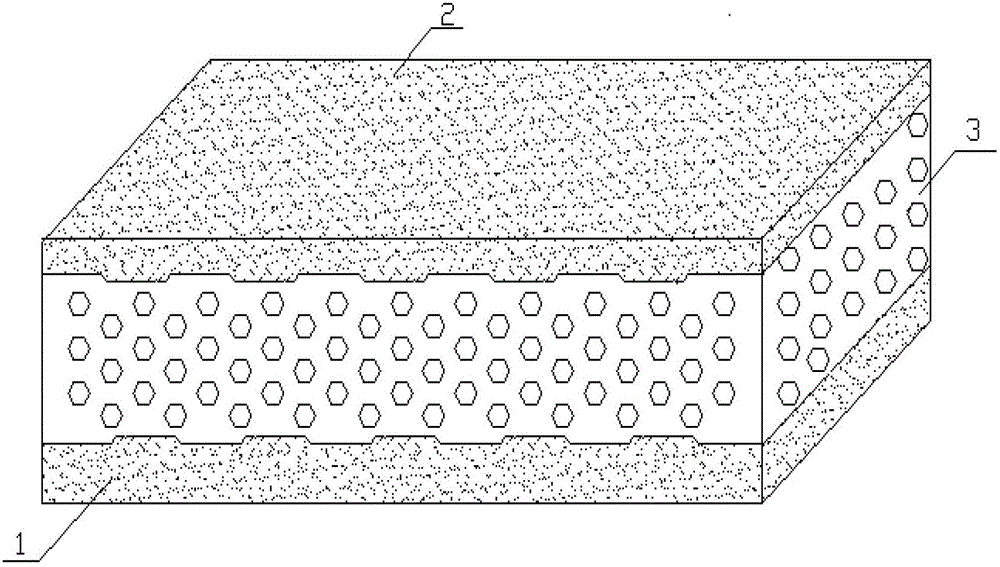

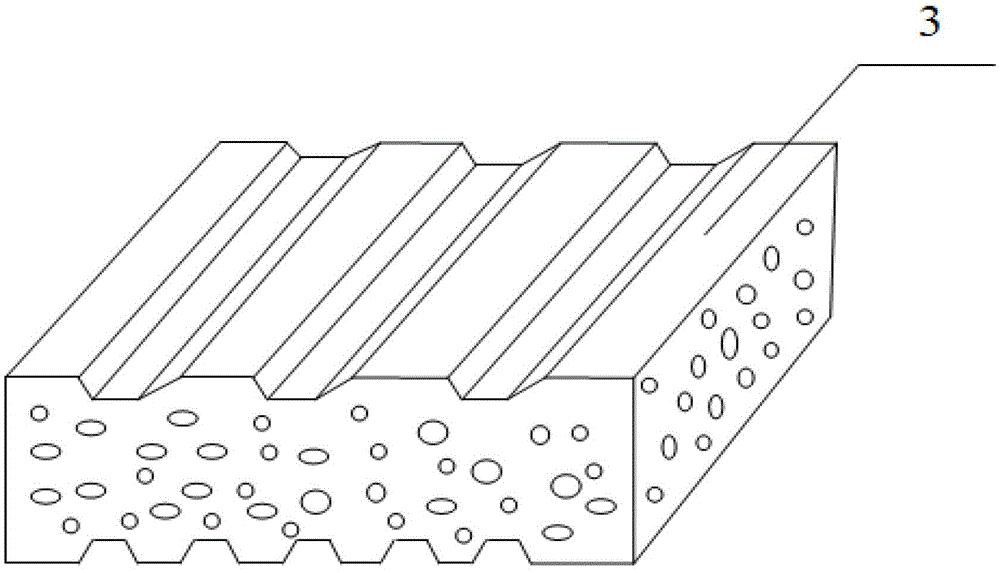

Foamed cement sandwich outer wall thermal insulation board

InactiveCN102747788AImprove interlayer bond strengthHigh strengthHeat proofingFire proofingCement boardEngineering

The invention discloses a foamed cement sandwich outer wall thermal insulation board which comprises an outer wall thermal insulation board core body; and outer guard boards provided with light cement plaster reinforcements are respectively embedded on the surfaces of the inner and outer sides of the outer wall thermal insulation board core body. The outer wall thermal insulation board core body is spliced with the outer guard boards through the occlusion of concave trapezoidal grooves and trapezoidal lug bosses. The outer wall thermal insulation board core body is a foamed cement board core body formed through foaming, and reinforcement meshes are sandwiched in the interlayers of the light cement plaster reinforcement outer guard boards. By adopting the double-layer sandwich occluded structure, the board is not only small in unit weight but also has great strength and better thermal insulation, fire prevention and heat insulation performances, and the board is simple in production process and low in manufacturing cost.

Owner:西安文昊新型建材有限公司

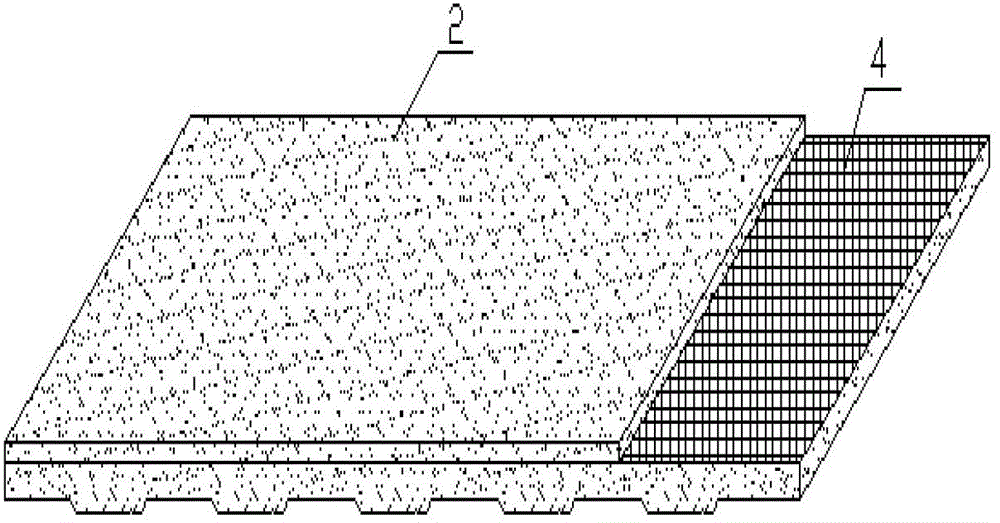

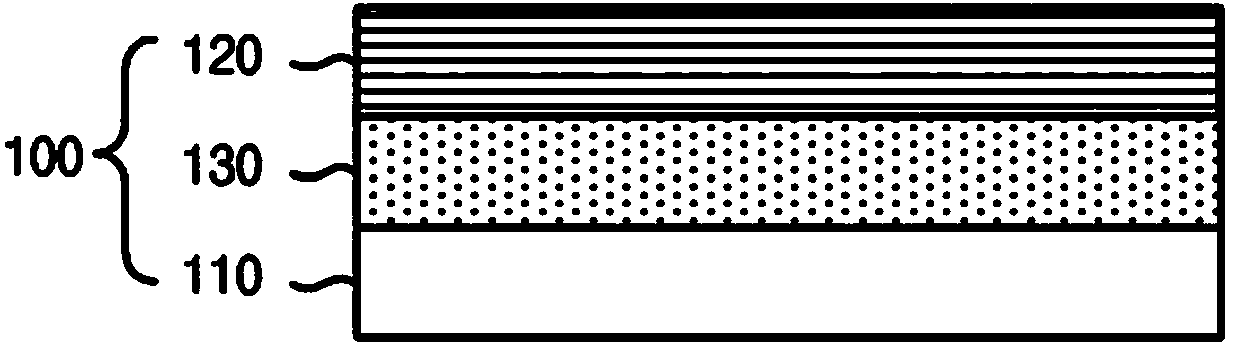

Solar cell backplane and solar cell module

InactiveCN104124300AHigh backplane strengthImprove interlayer bond strengthSynthetic resin layered productsPhotovoltaic energy generationBackplaneEngineering

The invention provides a solar cell backplane which comprises an enhancement layer, a matrix layer and a bonding layer which are successively stacked. The enhancement layer is a composite material which is formed by fabrics and a polymer. The invention also provides a solar cell module containing the backplane. The solar cell backplane provided by the invention has good strength.

Owner:BYD CO LTD

Manufacturing method of glass fiber continuous felt

The invention relates to a manufacturing method of a glass fiber continuous felt. The manufacturing method comprises the following steps of drawing out dried glass fiber proto-filaments through a creel to form proto-filament tows, enabling the proto-filament tows to penetrate through 6-12 pairs of swing arms, transversely throwing and laying the proto-filament tows onto a mesh belt through the swing arms in a reciprocating mode to form a felt blank, evenly scattering a bonding agent on the felt blank, curing the felt blank in a drying furnace, and flattening, trimming and taking up the felt blank to obtain the glass fiber continuous felt. The manufactured glass fiber continuous felt is even in forming and high in interlayer bonding strength and tensile failure strength, meanwhile has excellent high-temperature-resisting performance and can be widely applied to chemical plants, thermal power plants, cement plants, lime factories, coking plants, metallurgical plants, asphalt plants, paint spraying plants and high flues and hot air filtration of electric-arc furnaces, oil-fired boilers and incinerators, and the production efficiency is remarkably improved.

Owner:SHANDONG FIBERGLASS GRP

Refrigeration film, product comprising refrigeration film

ActiveCN111806020AIncrease polarityHigh surface energyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention relates to a refrigeration film. The refrigeration film comprises a base layer, and a reflective layer, an adhesive layer and a fluorine-containing film which are sequentially laminatedon the base layer, wherein the adhesive layer comprises a colloid and a functional additive distributed in the colloid; the colloid is made of an adhesive, a bonding substance in the adhesive is selected from a compound of which a molecular chain contains at least one of an ester group and a urethano group, the surface, used for being attached to the adhesive layer, of the fluorine-containing filmcontains a polar group, the adhesive layer is connected with the fluorine-containing film through a chemical bond, and the adhesive layer can emit heat through an atmospheric window in an infrared radiation mode. The invention also relates to a product comprising the refrigeration film. The refrigeration film is high in interlayer bonding strength, excellent in refrigeration effect and stable inperformance, the product using the refrigeration film has the excellent refrigeration effect, meanwhile, the glossiness of the product is low, and light pollution can be effectively reduced in the using process.

Owner:NINGBO RADI COOL ADVANCED ENERGY TECH CO LTD +1

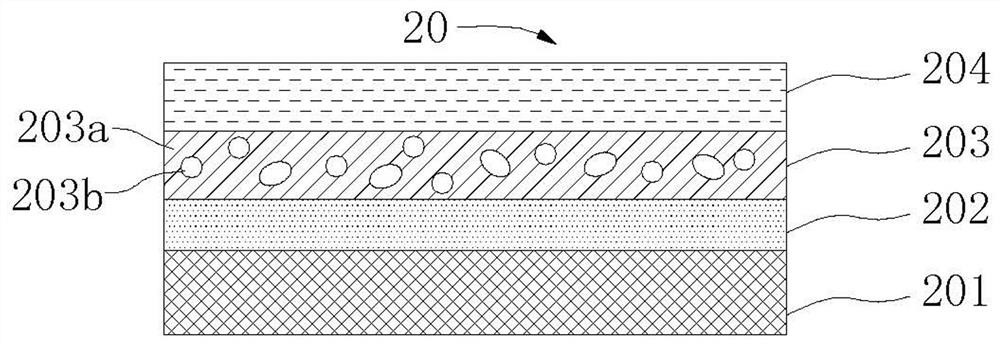

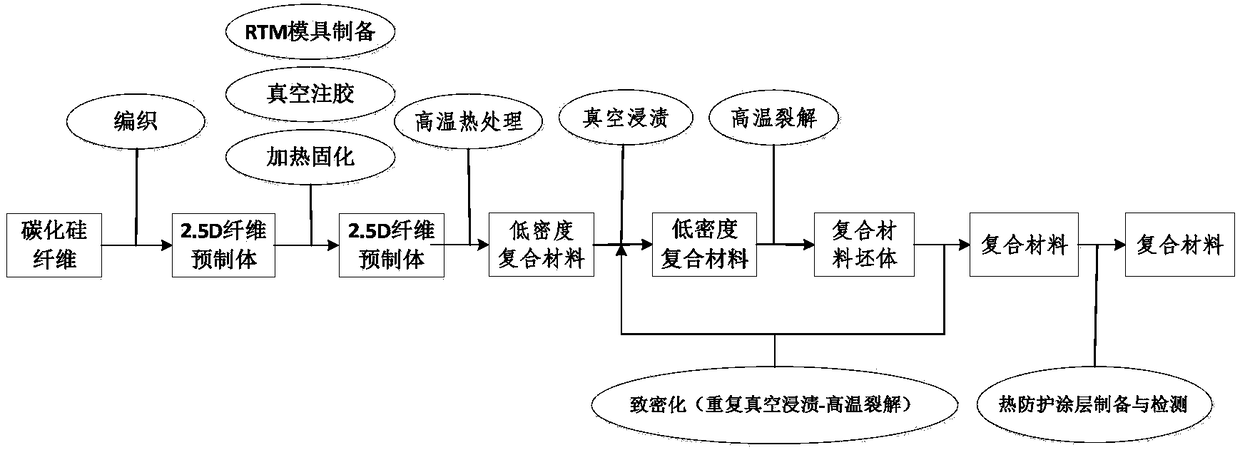

Preparation method of SiC/SiC composite material

InactiveCN109251050AExcellent interlayer bonding strength and toughnessMaterial support is goodBenzeneWeft yarn

The invention belongs to the technical field of composite material manufacturing, relates to a preparation method of a SiC / SiC composite material, and in particular, relates to a preparation method ofa high-density SiC / SiC composite material. The prepared SiC / SiC composite material adopts a 2.5D weaving mode, through interweaving of warp yarns, the disadvantage of poor interlayer performance of a2D weaving process is overcome, and at the same time, the disadvantage that a 3D weaving process has great difference between the weft direction mechanical property and the warp direction mechanicalproperty due to containing of no weft yarns is overcome, so that the SiC / SiC composite material has excellent interlayer bonding strength and toughness in both the warp direction and the weft direction, and better material support is provided for the design of SiC / SiC composite material components. In addition, the liquid polycarbosilane as an impregnant is used as a raw material for preparing a ceramic matrix in the early stage of preparation of the SiC / SiC composite material. Compared with a traditional polycarbosilane benzene based solution impregnant, the SiC / SiC composite material has theadvantages of high ceramic yield and is beneficial to shortening the development cycle of the material.

Owner:AVIC BASIC TECH RES INST

Lightweight high-ductility cement-based composite material capable of being used for 3D printing and preparation method thereof

ActiveCN112876165ASmall particle sizeLight weightAdditive manufacturing apparatusSolid waste managementManufactured materialSlurry

The invention discloses a lightweight high-ductility cement-based composite material capable of being used for 3D printing and a preparation method thereof. The cement-based composite material is prepared from the following components by weight: 300-400 parts of cement, 200-300 parts of fly ash, 100-200 parts of rice hull ash, 200-250 parts of light sand, 100-200 parts of glass beads, 12-18 parts of a high-efficiency water reducing agent, 10-20 parts of synthetic fiber and 160-200 parts of water. The specific preparation method comprises the following steps of: uniformly mixing and stirring 300-400 parts of cement, 200-300 parts of fly ash, 100-200 parts of rice hull ash, 200-250 parts of light sand and 100-200 parts of glass beads to obtain a dry material; pouring 12-18 parts of the high-efficiency water reducing agent into 160-200 parts of water, uniformly stirring the substances, adding the mixture into the dry material, and uniformly mixing and stirring the substances to obtain slurry; dispersing and scattering 10-20 parts of synthetic fibers into the slurry, and uniformly stirring the substances to obtain the lightweight high-ductility cement-based composite material capable of being used for 3D printing. The preparation method is simple, the variety of raw materials is few, the prepared cement-based composite material meets the printability requirement, and the constructability is improved due to the characteristics of light weight and high strength.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +2

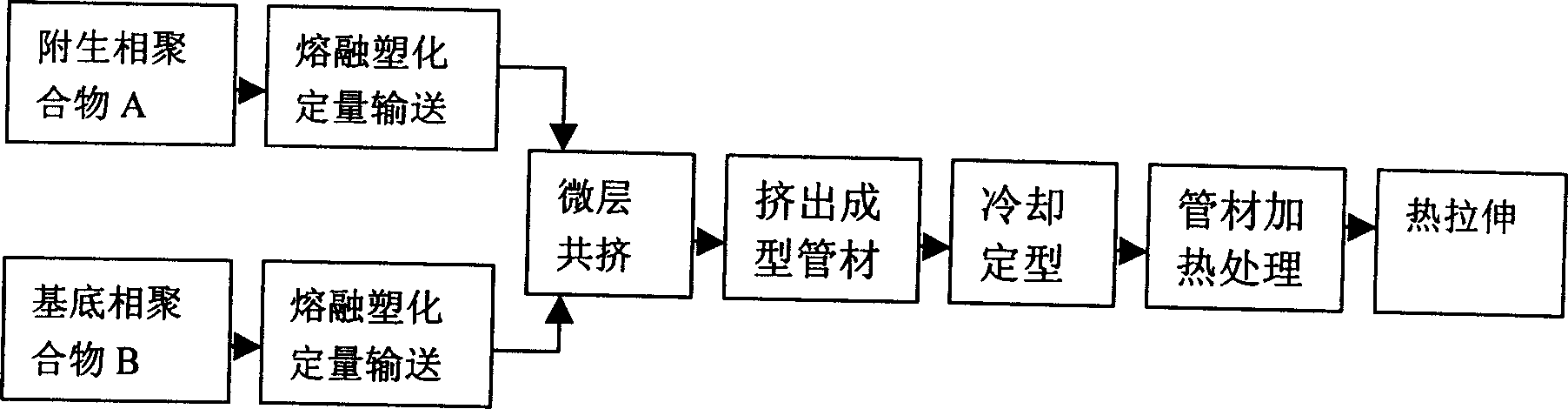

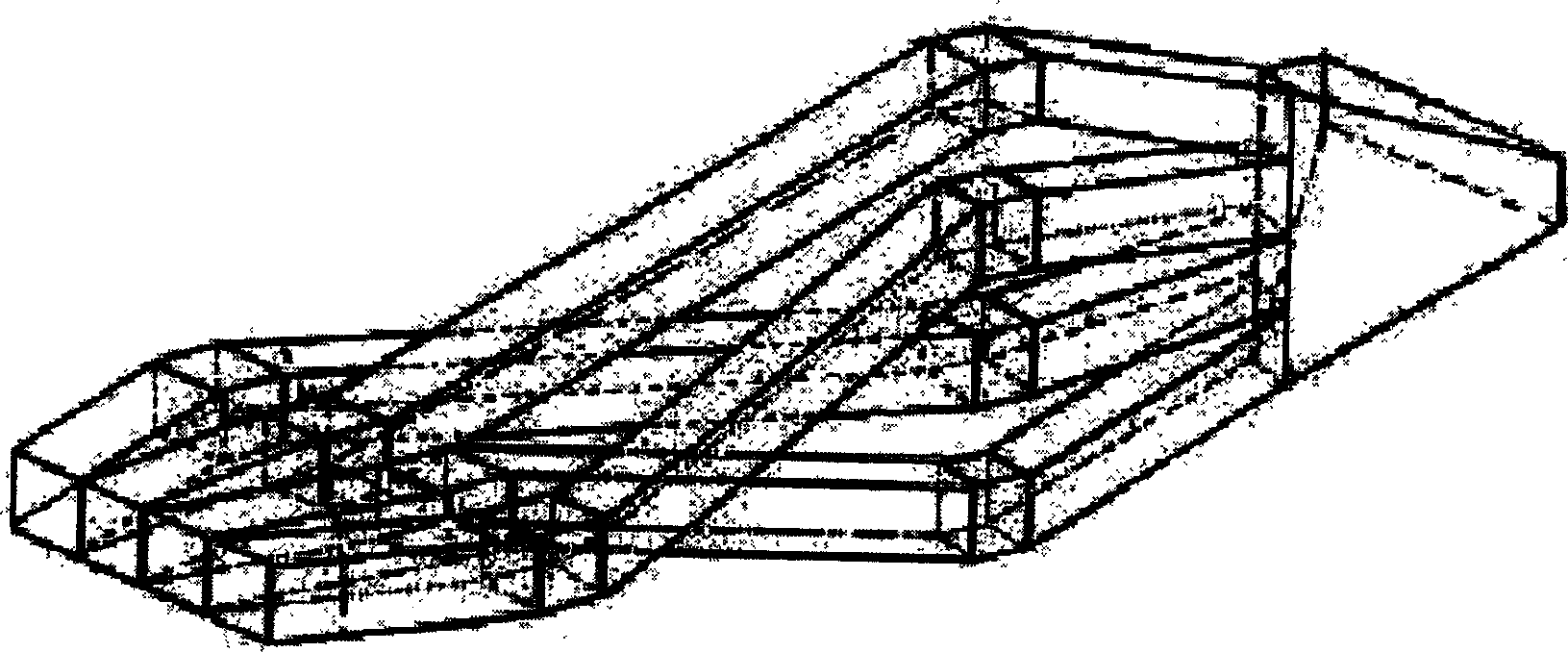

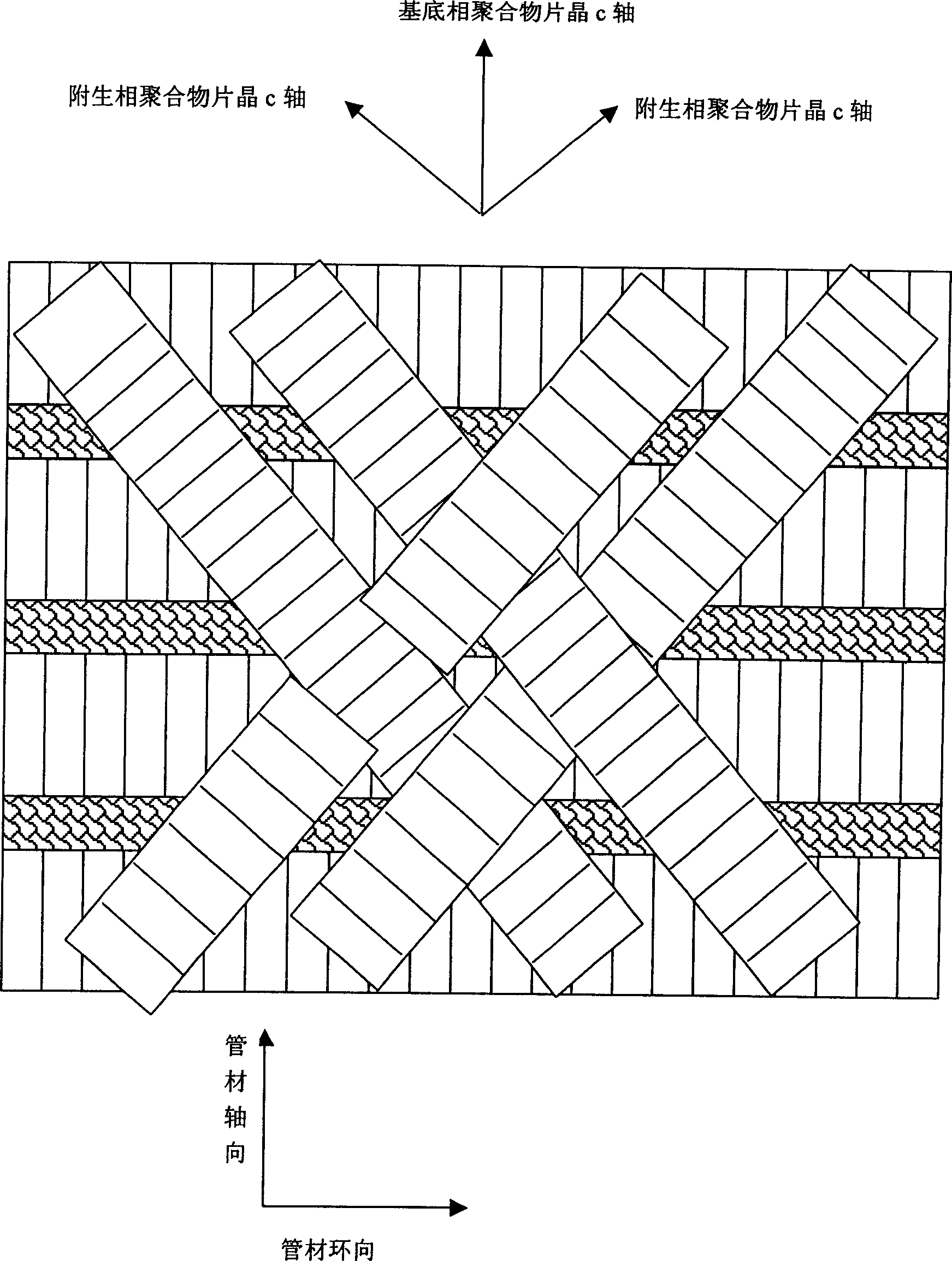

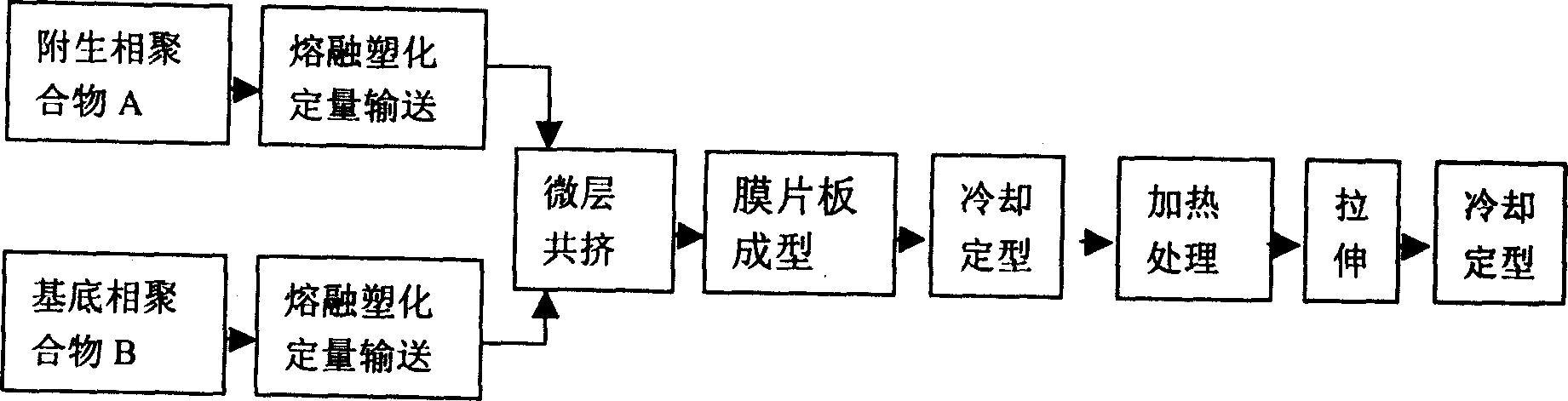

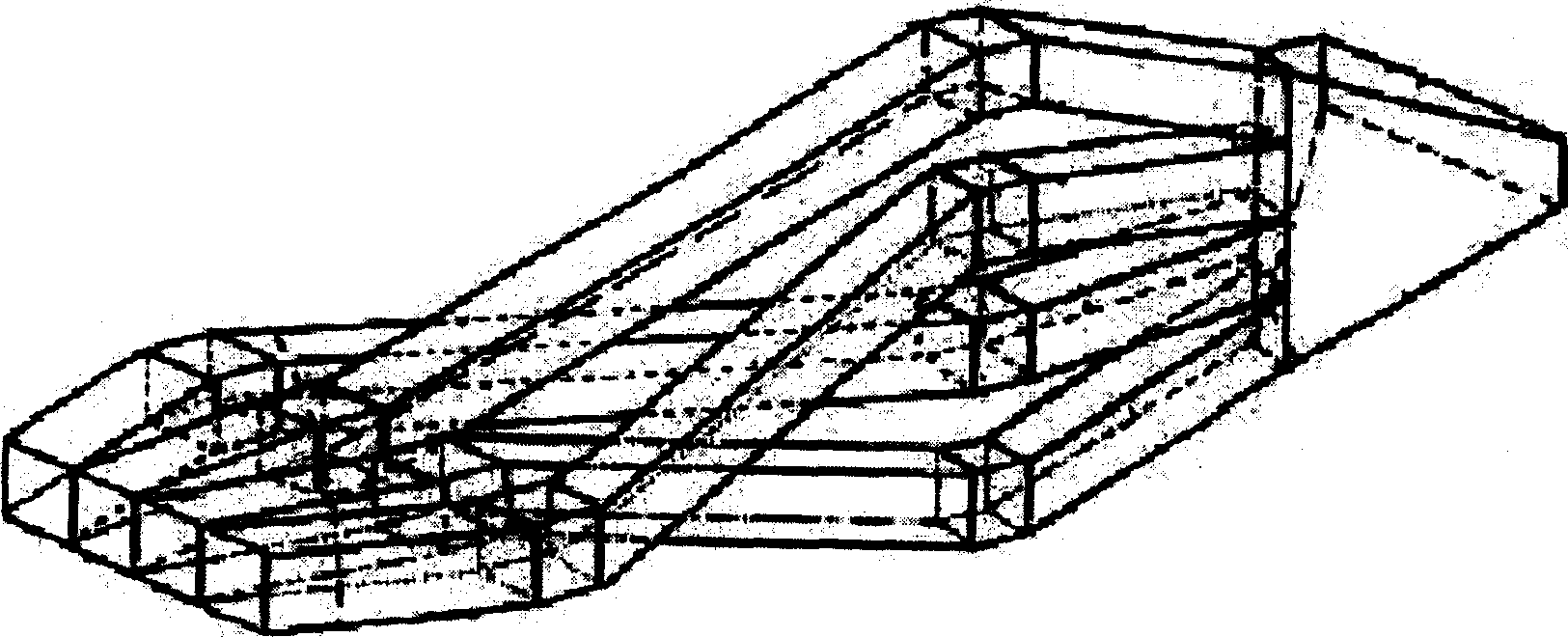

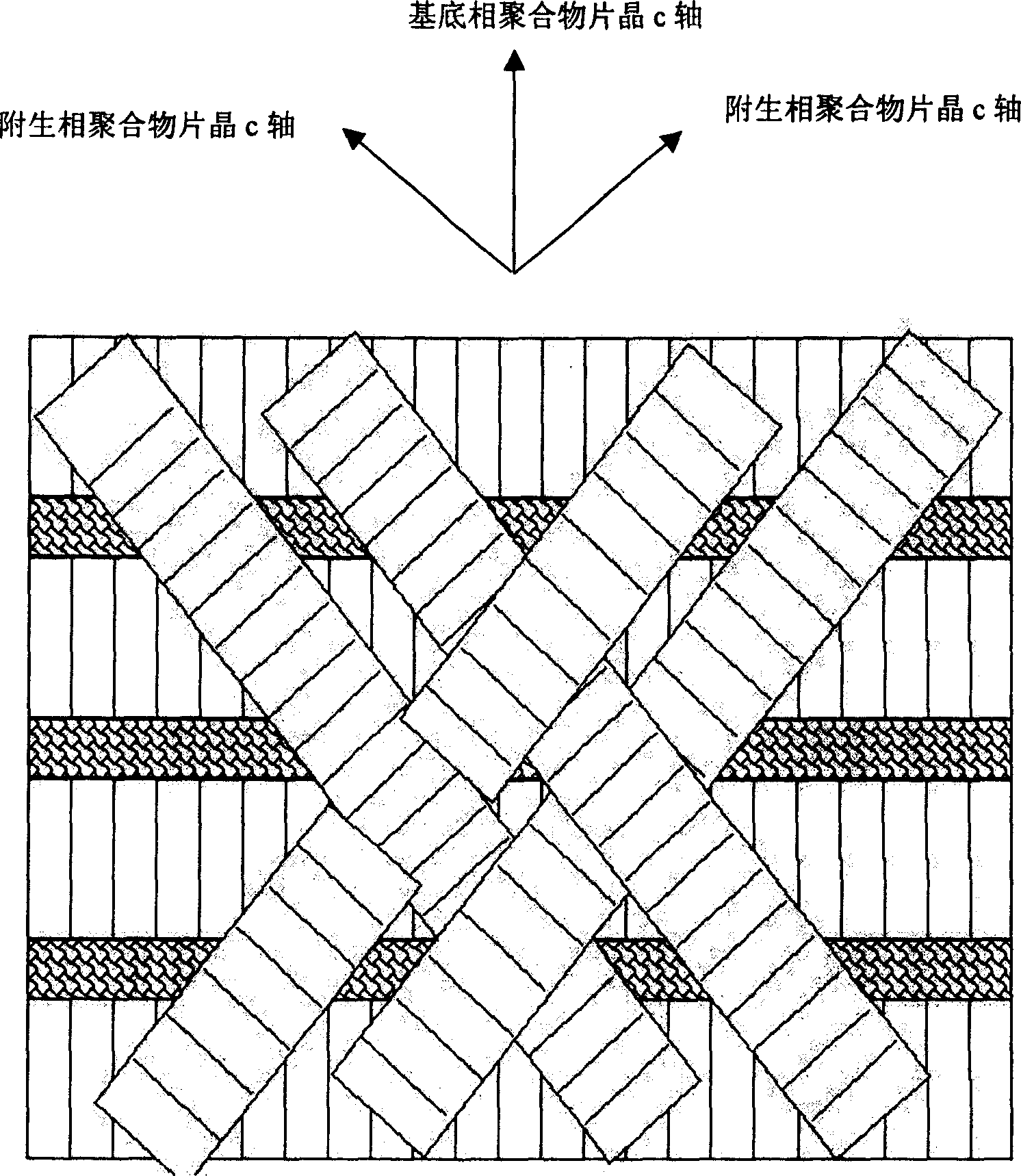

Multiplayer composite tube made from polymer possessing texture in nano layer and making method

InactiveCN1687626AHigh strengthHigh modulusRigid pipesTubular articlesPolymer scienceLayer thickness

The invention discloses the multi-layer polymer composite tubing with nanometer layer structure and its manufacturing method. The composite tubing is formed by the two polymers with non-parallel hetero crossed structure, which passes through the micro-layer coextrusion, the cooled forming, the heat processing and the heat pulling procedures. The c axis of the base polymer layer is along the axial of the tubing, and it accumulative layer thickness is 50-99%of the thickness of the tubing; the c axis of the agglomerative polymer crosses with the axis line of the tubing, and its accumulative thickness is 1-50% of that of the tubing, and the thickness of the single layer of the agglomerative polymer is 50-300 nanometers. The invention forms the reinforcing phase in the tubing in order to strengthen the intensity of the tubing and to improve the expansion of the tubing.

Owner:SICHUAN UNIV

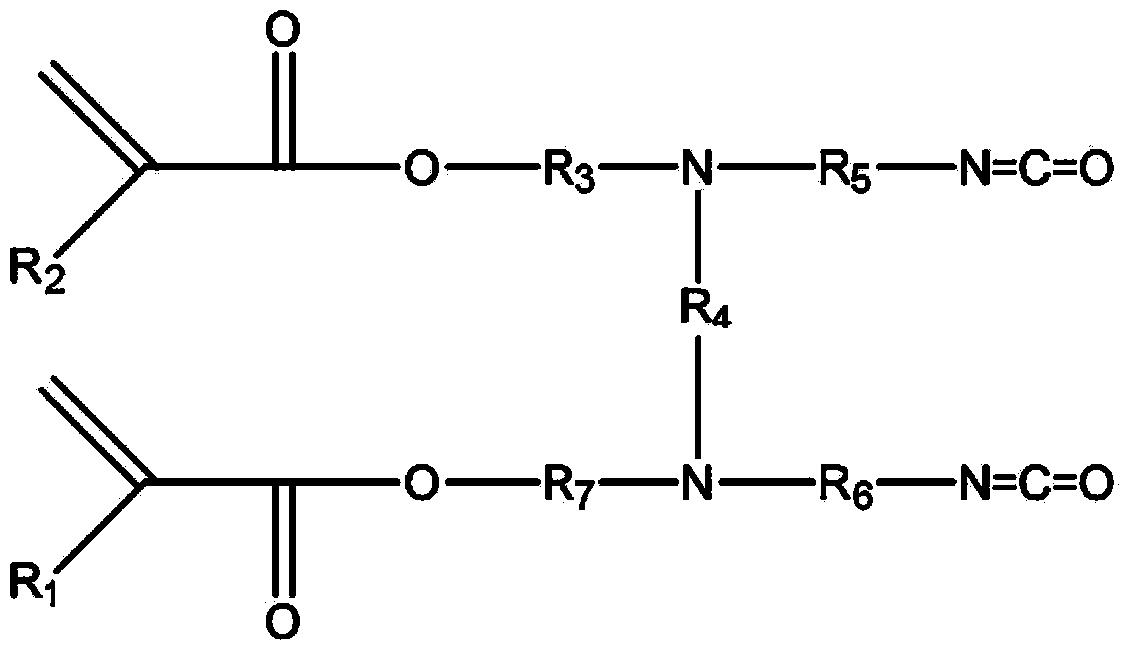

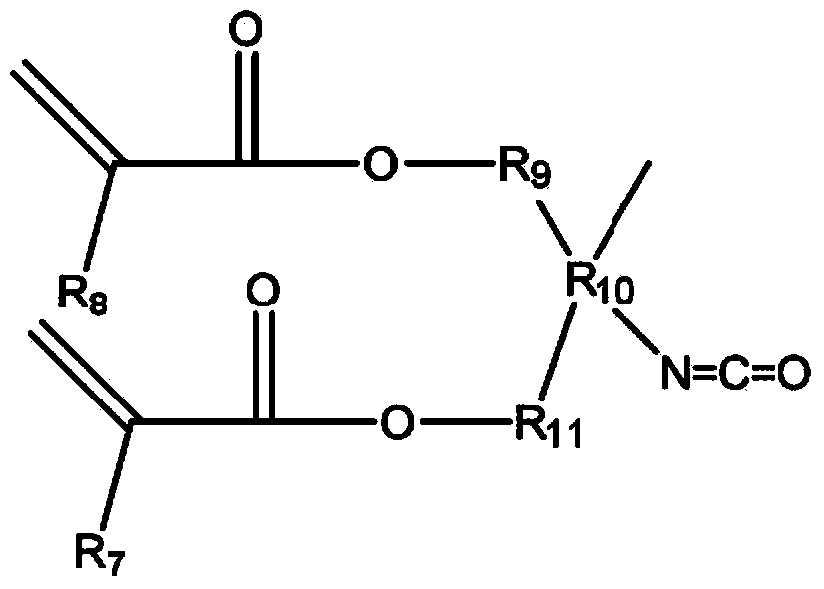

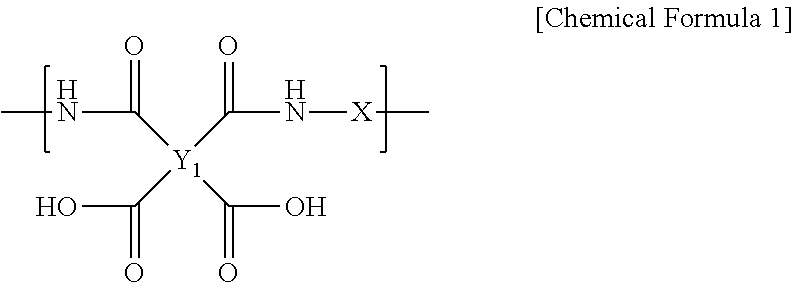

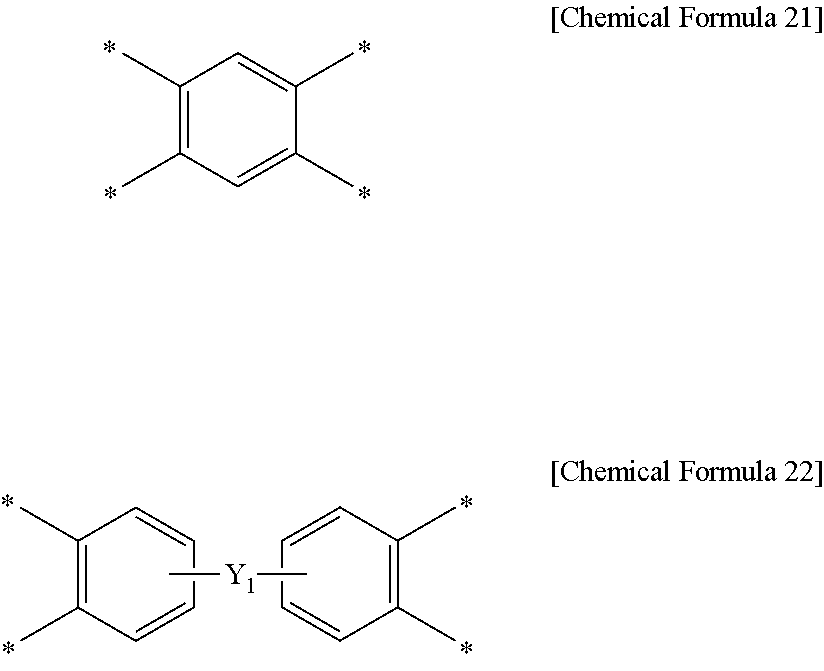

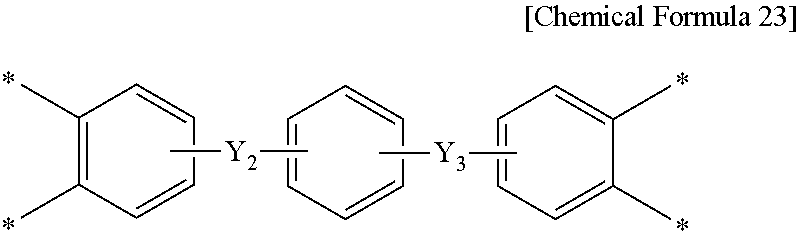

Composition for forming an alignment layer, and alignment layer and phase difference film manufactured using same

InactiveCN103857751AImprove interlayer bond strengthHigh bonding strength between layersPolarising elementsPhase differenceLiquid crystal

The present invention relates to a composition for forming an alignment layer and to an alignment layer manufactured using same. More particularly, the present invention relates to a composition for forming an alignment layer for aligning liquid crystal compounds. The composition includes an adhesion-reinforcing agent including an isocyanate group and a (meth)acrylate group at an end portion for forming a bond with a reactive group in the liquid crystal compound. While curing the composition for forming the alignment layer, a chemical bond may be formed with another layer formed at the side portion so as to manufacture a phase difference film having very strong interlayer adhesion.

Owner:DONGWOO FINE CHEM CO LTD

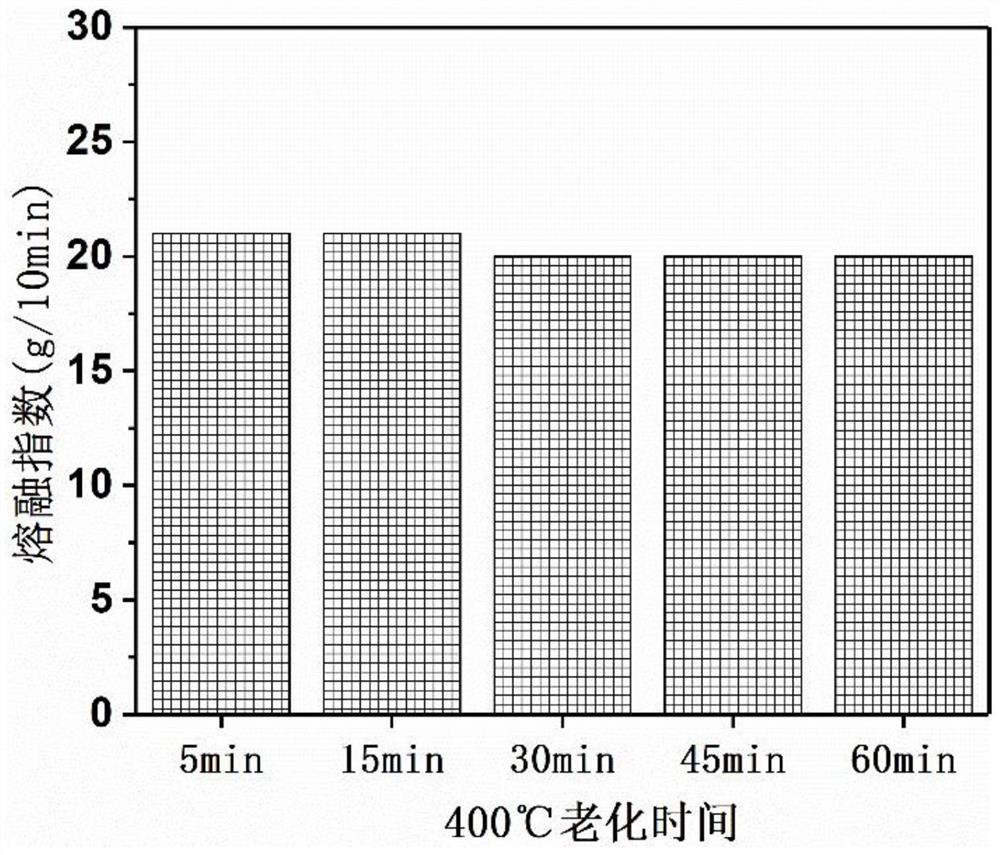

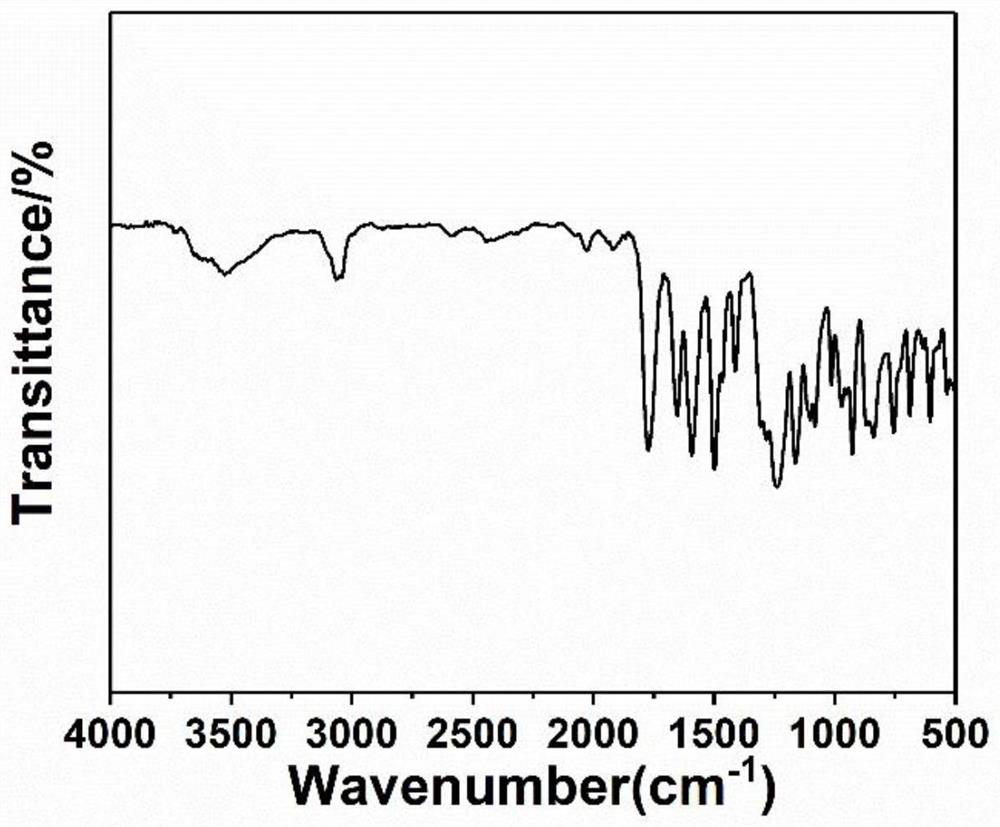

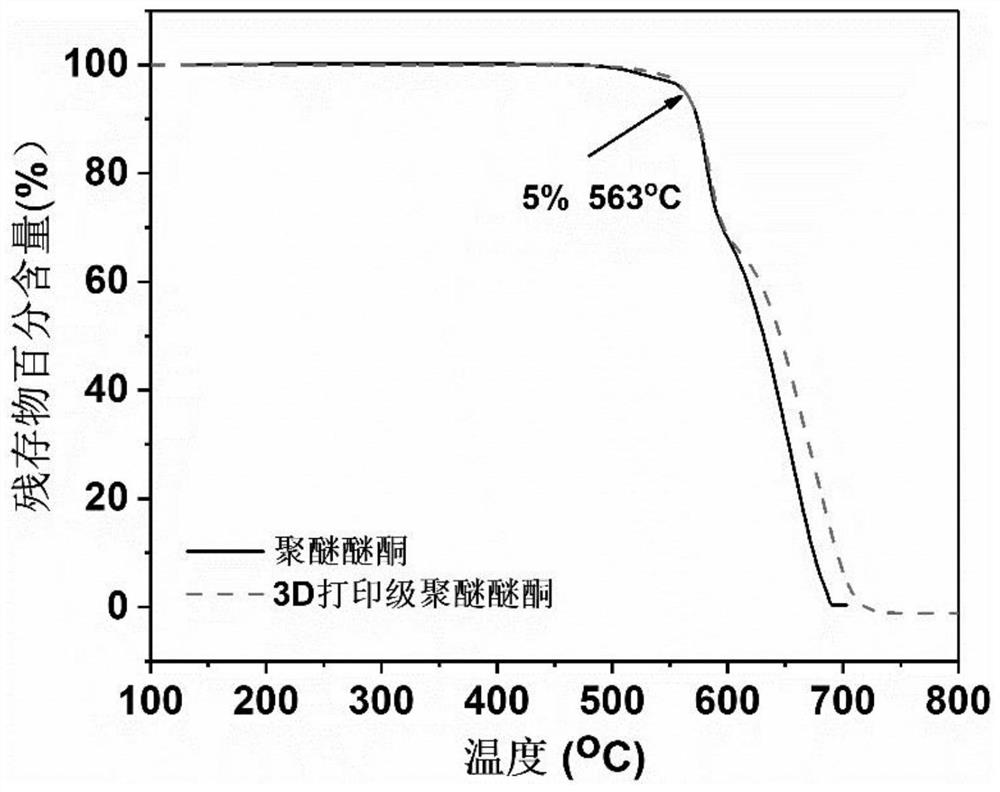

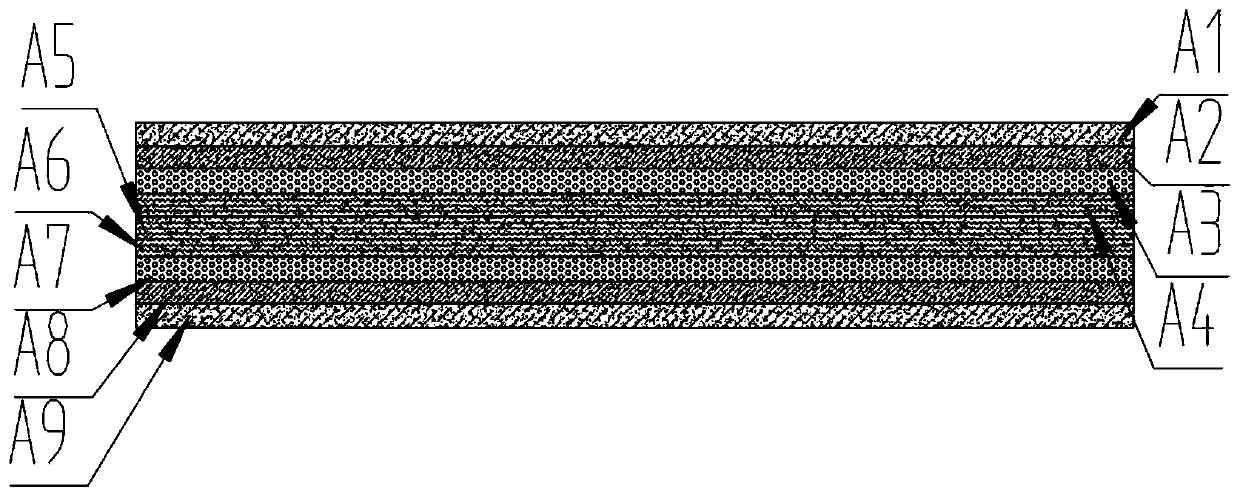

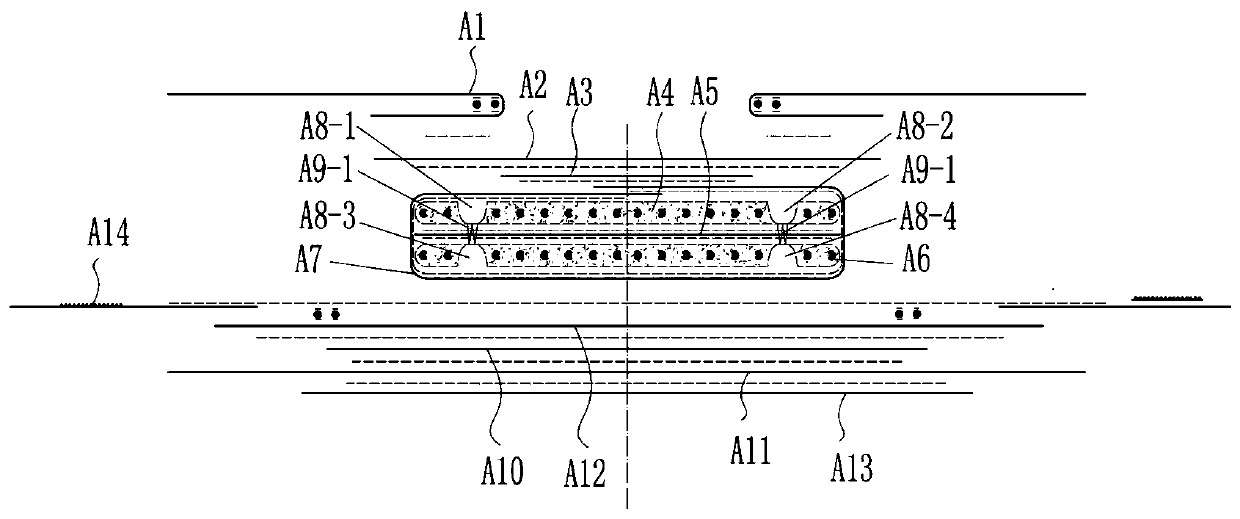

3D printing grade polyether-ether-ketone resin special material, preparation and application thereof, 3D printing interlayer reinforced polyether-ether-ketone alloy material and preparation thereof

ActiveCN113736044AImprove temperature resistanceImprove stabilityAdditive manufacturing apparatus3d printEndcapping

The invention provides a 3D printing grade polyether-ether-ketone resin special material, preparation and application thereof, a 3D printing interlayer reinforced polyether-ether-ketone alloy material and preparation thereof, and belongs to the technical field of 3D printing materials. According to the invention, 4-fluorodiphenyl sulfone with a higher temperature-resistant grade is used as an end-capping group, so that the polyether-ether-ketone resin has a very stable fluorine-containing end group, and polyether-ether-ketone can maintain good fluidity and stability under a higher-temperature processing condition, so that the requirement of 3D printing high-temperature processing is met. In addition, the special material is blended with an interlayer reinforced modifier, so that the prepared 3D printing interlayer reinforced polyether-ether-ketone alloy material keeps excellent mechanical properties of polyether-ether-ketone, and meanwhile, the interlayer bonding strength is greatly improved.

Owner:JILIN UNIV

Integrated self-adhesion composite core and preparation process thereof

InactiveCN110393638AImprove anti-pilling effectExcellent diversion and diffusionAbsorbent padsBaby linensSurface layerFluff pulp

The invention relates to an integrated self-adhesion composite core. The core comprises a composite surface layer, a high water absorption resin layer, an expansion supporting layer, a high water absorption resin layer and a composite bottom layer from top to bottom, wherein the composite surface layer consists of an upper surface layer and a lower surface layer; the composite bottom layer consists of an upper bottom layer and a lower bottom layer; each surface layer and each bottom layer are formed by hot-melt superfine short fibers and fluff pulp fibers; the expansion supporting layer consists of an upper supporting layer, a middle supporting layer and a lower supporting layer; and each supporting layer is formed by hot-melt long fibers and fluff pulp fibers. Through the thermal pressurewelding joint effect which is generated by respectively subjecting the hot-melt superfine short fibers and the hot-melt long fibers to hot melting, the layers are bonded and connected into a whole. Meanwhile, the high water absorption resin and the fluff pulp fibers are connected and fixed, so that the fixing effect on the high water absorption resin is realized, the effect that the composite core absorbs the core material without lumping and cotton breaking is realized, and the cost is greatly reduced.

Owner:佛山市合正新型材料有限公司

Flexible metal laminate

ActiveUS20160136933A1Low dielectric constantImprove interlayer bond strengthSynthetic resin layered productsRecord information storageThermosetting polymerThermoplastic polyimide

Disclosed herein is a flexible metal laminate including: a first thermosetting polyimide resin layer containing 5 wt % to 75 wt % of a fluorine-based resin; a second thermosetting polyimide resin layer formed on at least one surface of the first thermosetting polyimide resin layer, and containing 1 wt % or less of the fluorine-based resin; and a thermoplastic polyimide resin layer formed on one surface of the second thermosetting polyimide resin layer so as to face the first thermosetting polyimide resin layer, wherein the first thermosetting polyimide resin layer and the second thermosetting polyimide resin layer include the same thermosetting polyimide resin.

Owner:GUANGDONG SHENGYI SCI TECH

Multilayer polymer compound packaging material with with nano layer texture and its processing method

A packing multi-layer polymer container with nano-layer texture is prepared from two polymers able to generate non-parallel cross texture of heterophase epiphytic crystals through microlayer coextruding, cooling, heat treating and thermal stretching. Its advantages are high strength and ductility and very high isolating performance and corrosion resistance.

Owner:SICHUAN UNIV

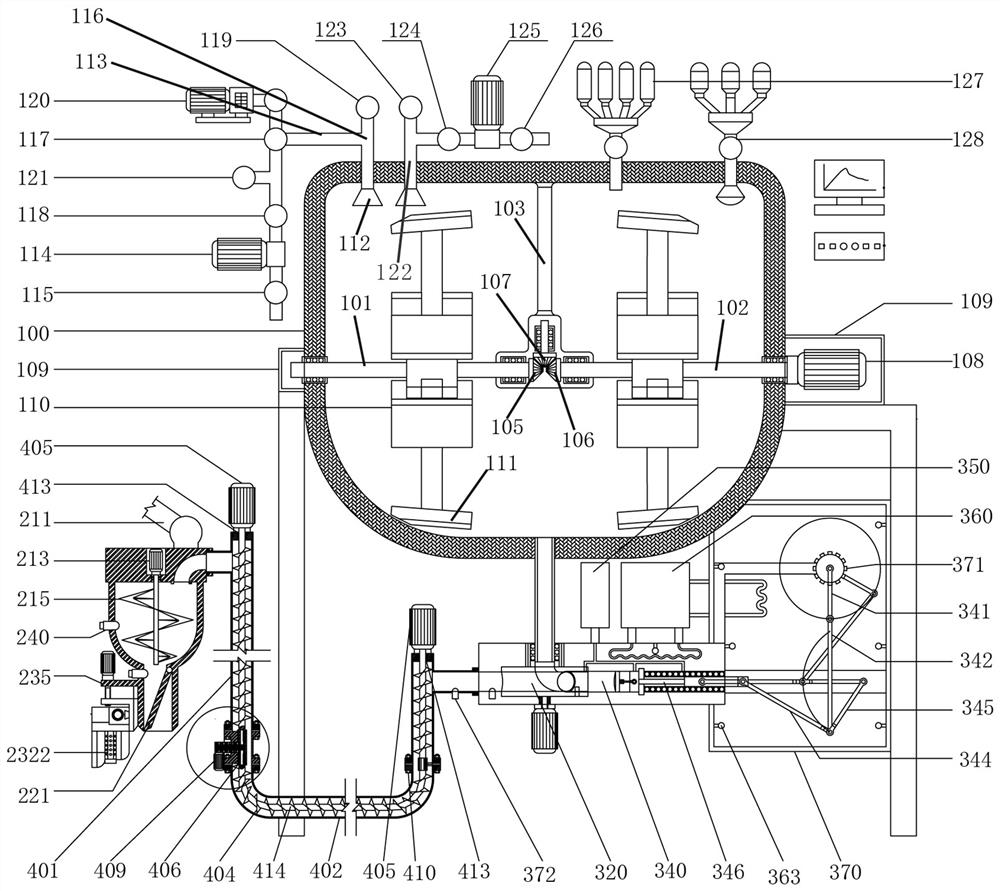

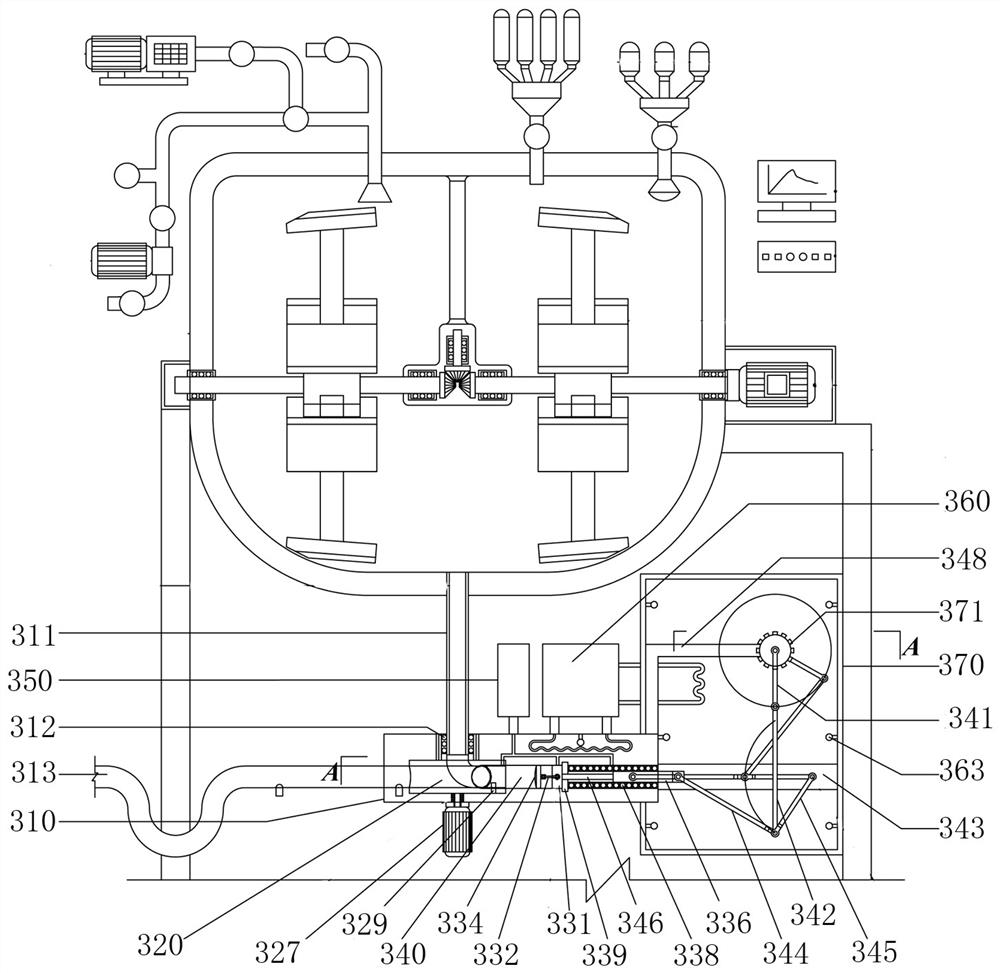

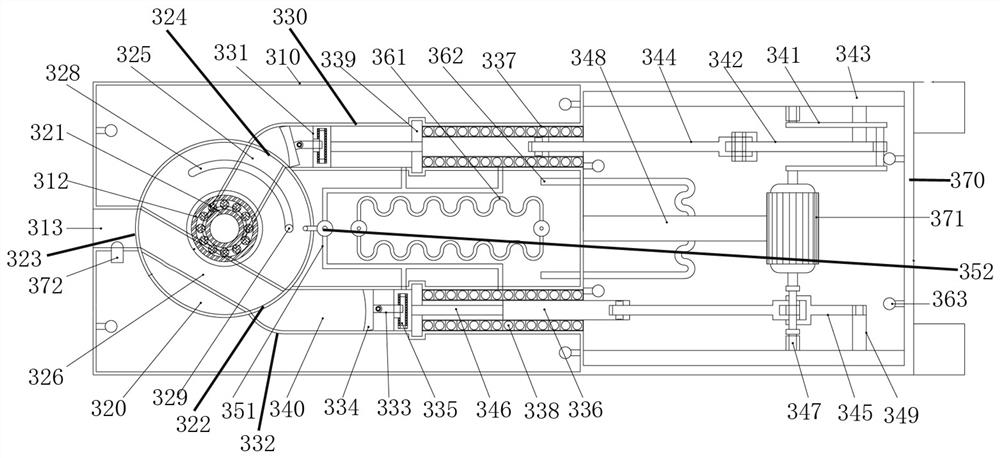

Feeding system for 3D printing of ultra-high performance concrete

PendingCN112829040AImprove homogeneityImprove compactnessAdditive manufacturing apparatusFeeding arrangmentsComputer printingStructural engineering

The invention belongs to the technical field of 3D printing of ultra-high performance concrete. A feeding system for 3D printing of ultra-high performance concrete comprises a stirring tank, a vacuumizing unit, a main stirring unit, a feeding unit, a conveying pump and a 3D printer nozzle, wherein the stirring tank is of a sealed structure and is supported by a main body rack; the vacuumizing unit is connected to the top of the stirring tank and is used for vacuumizing the stirring tank; the main stirring unit is used for stirring materials in the stirring tank; the feeding unit is arranged at the top of the stirring tank and is used for feeding the materials into the stirring tank; the feeding end of the conveying pump is connected with the bottom of the stirring tank through a material receiving pipe; and the discharging end of the conveying pump is connected with the 3D printer nozzle. The feeding system is reasonable in structural design, environmentally friendly, efficient, high in intelligent degree and green degree and more suitable for 3D printing of ultra-high performance concrete (UHPC).

Owner:ZHENGZHOU UNIV

Sandwich cured carbon felt

InactiveCN104339730ARaw materials are easy to getWide range of optionsLayered productsPolymer scienceHeat flow

The invention provides a sandwich cured carbon felt obtained by cross-bonding a layer of substrate carbon felt, a layer of a composite bonding agent, and another layer of substrate carbon felt. The composite bonding agent is a precursor. Through curing, carbonizing and high-temperature purification, a layer of compact heat-flow-resistant layer is obtained. Also, the heat-flow-resistant layer plays a role of bonding the substrate carbon felts on both sides into a whole. With the interaction of the substrate carbon felts and the composite bonding agent, a composite bonding strength is much higher than the peel strength of the carbon felt, such that the bonding strength of the heat-flow-resistant layer and the carbon felts is ensured, and a unified whole which is hard to separate or peel is formed. Also, the hardness and strength of the heat-flow-resistant layer is much better than those of traditional graphite paper. The sandwich cured carbon felt obtained with the preparation method has the capacity of blocking and resisting heat flows, and has supporting performance and overall strength better than those of traditional sandwich cured carbon felts and conventional cured carbon felts.

Owner:GANSU HAOSHI CARBON FIBER

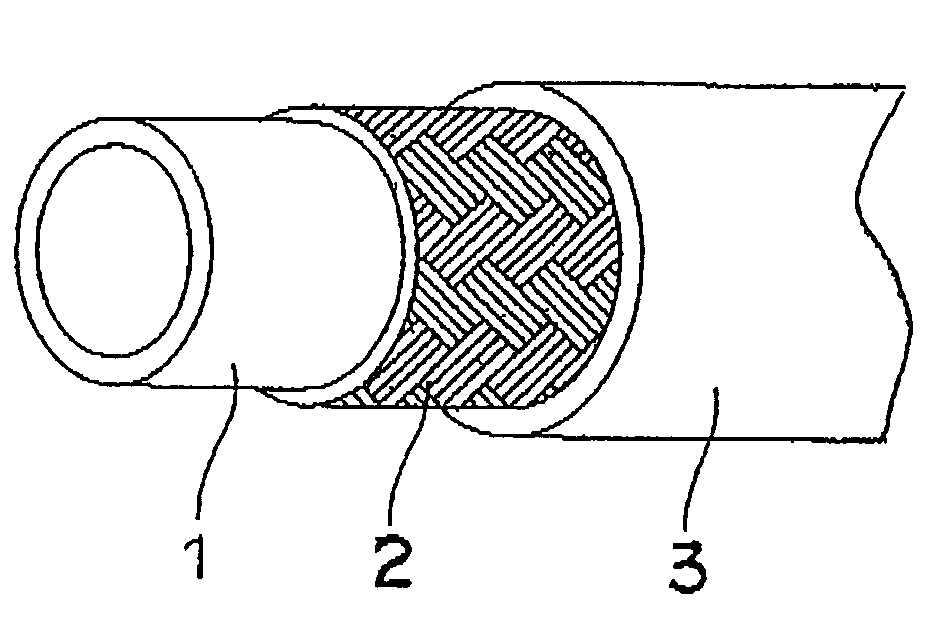

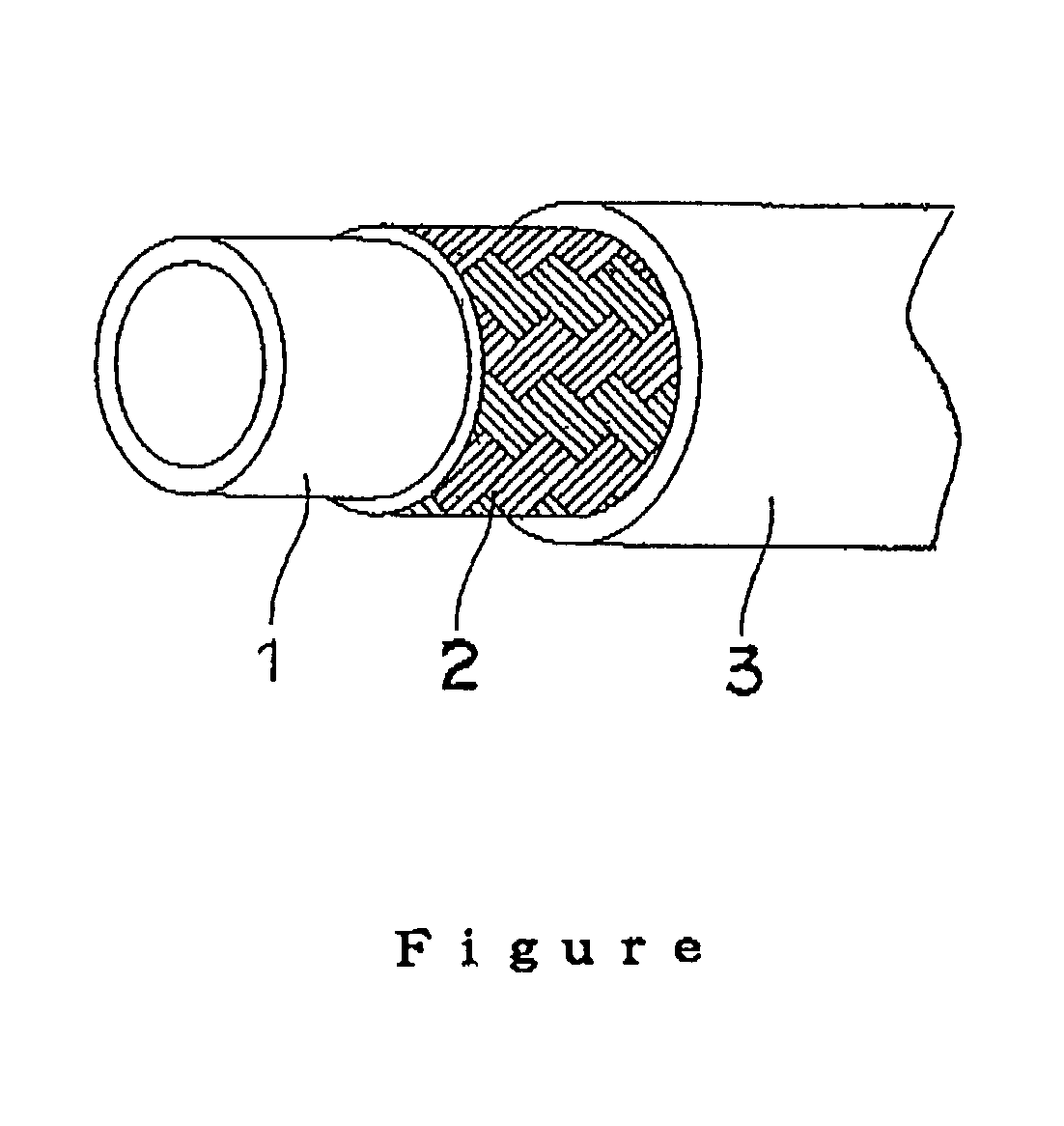

Vacuum brake hose

ActiveUS7497236B2Improve interlayer bond strengthLow costDetection of fluid at leakage pointLayered productsAdhesiveAcrylonitrile

A vacuum brake hose having excellent interlaminar bonding strength between a tubular inner layer and an outer layer, as well as available at low cost by mass production. The vacuum brake hose comprising the tubular inner layer formed by using acrylonitrile-butadiene rubber, a reinforcing fiber layer provided on an outer peripheral surface of the tubular inner layer and the outer layer formed on an outer peripheral surface of the reinforcing fiber layer by using chloroprene rubber, wherein the reinforcing fiber layer is impregnated with adhesive consisting essentially of components (A) to (C) and interlaminar bonding between the tubular inner layer and the outer layer is effected through the adhesive:(A) chloroprene rubber;(B) acrylonitrile-butadiene rubber; and(C) at least one filler of carbon black and a white filler.

Owner:SUMITOMO RIKO CO LTD

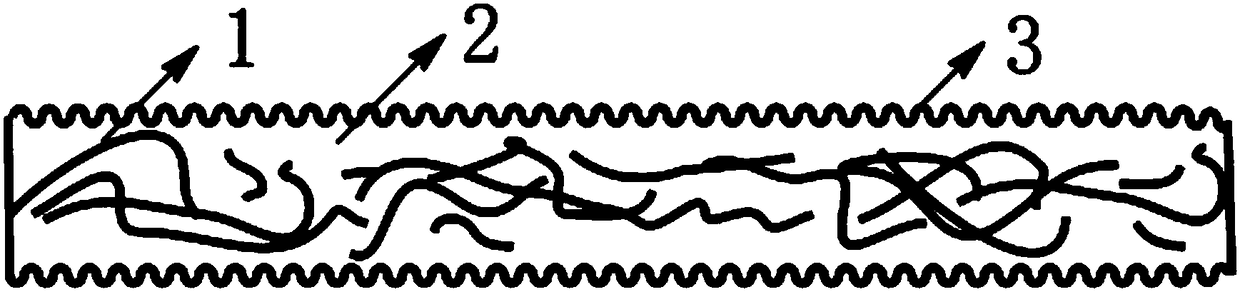

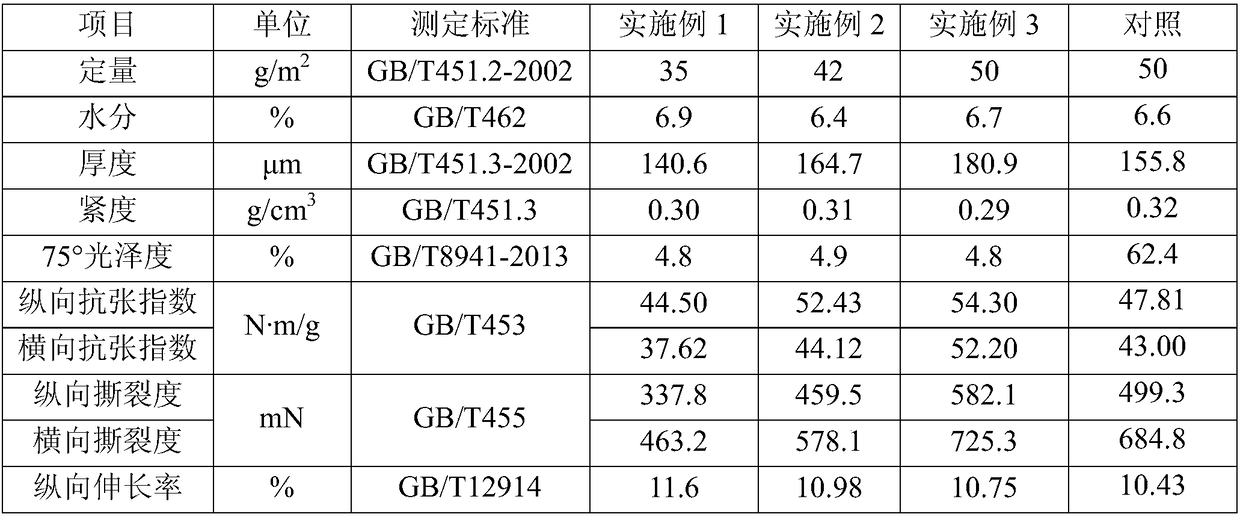

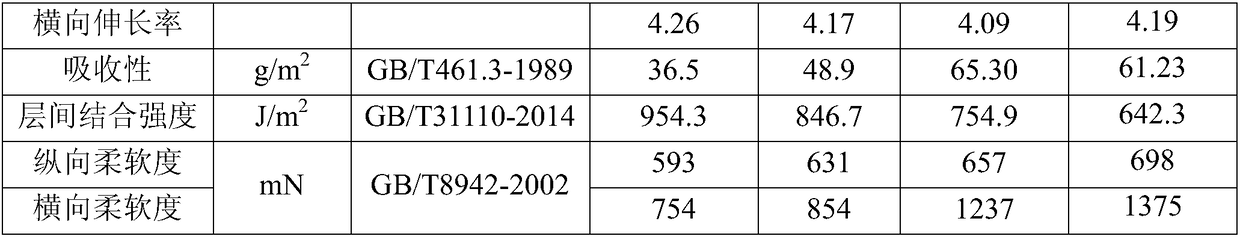

Matt textured paper with high layer-to-layer bonding strength and preparation method of paper

InactiveCN108411704AHigh whitenessGood physical strength indexDefoamers additionSpecial paperWater basedFiber

The invention discloses matt textured paper with high layer-to-layer bonding strength and a preparation method of the paper. The matt textured paper with the high layer-to-layer bonding strength comprises slurry and an auxiliary agent; the slurry comprises the following components in percentages by mass: 80-90% of bleached softwood pulp and 10-20% of bleached hardwood pulp; and the auxiliary agentcomprises the following components in percentages by mass based on absolutely dry slurry: 0.6-1.6% of a wet strength agent, 0.05-0.2% of a softening agent, 0.03-0.1% of a defoaming agent, and 1.0-1.5% of light calcium carbonate. The method disclosed by the invention adopts compounding of water-based self-matting polyurethane resin and synthetic latex for gum dipping in the process of preparing the textured paper, so that the paper has matt characteristic; and the polyurethane resin has a large number of polar amino groups, so that a large number of hydrogen bonds can be formed among fibers, the impregnated textured paper has stronger bonding force, so that the type of the textured paper is enriched, and an application range of the textured paper in interior decoration, wall decoration, gift packaging and other aspects is expanded.

Owner:SOUTH CHINA UNIV OF TECH

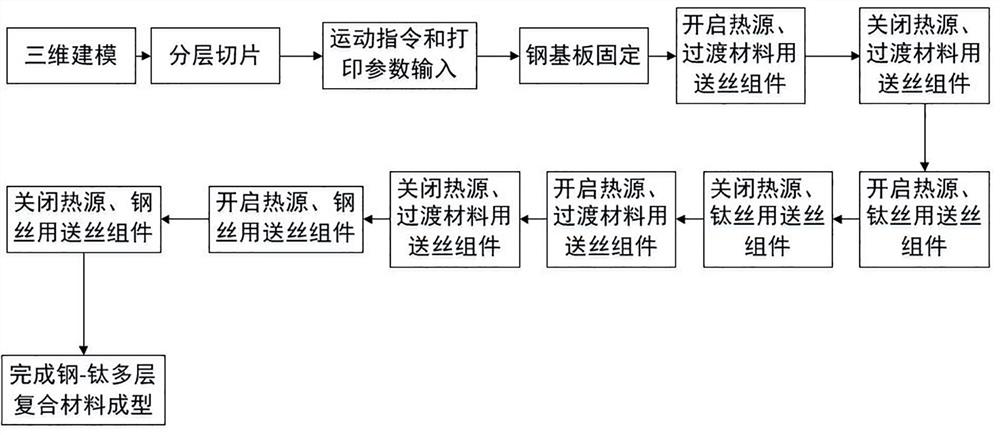

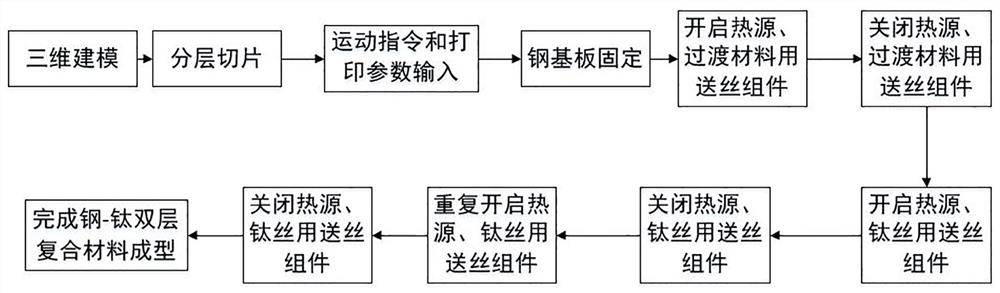

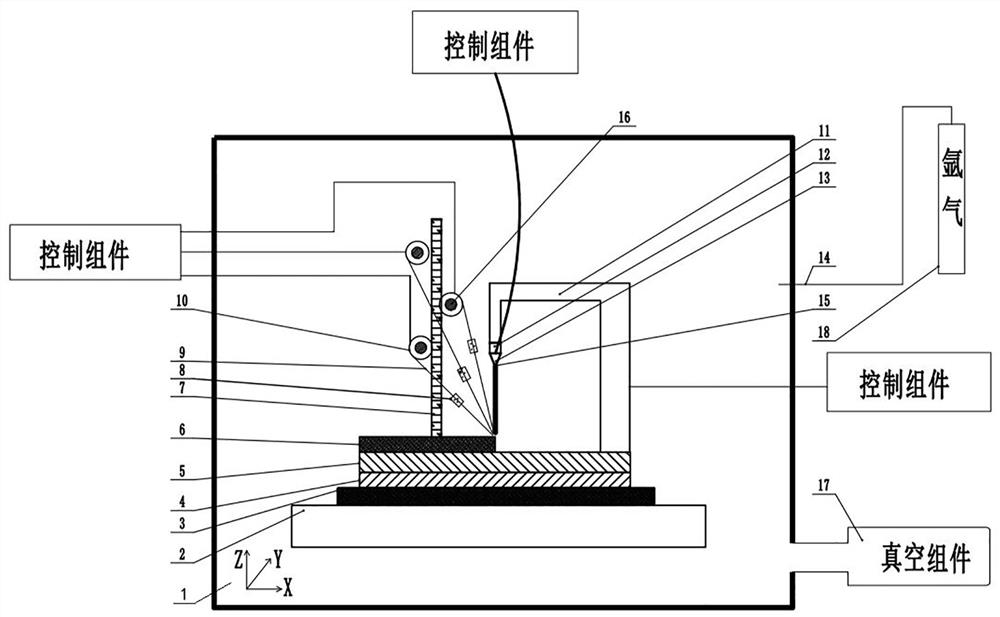

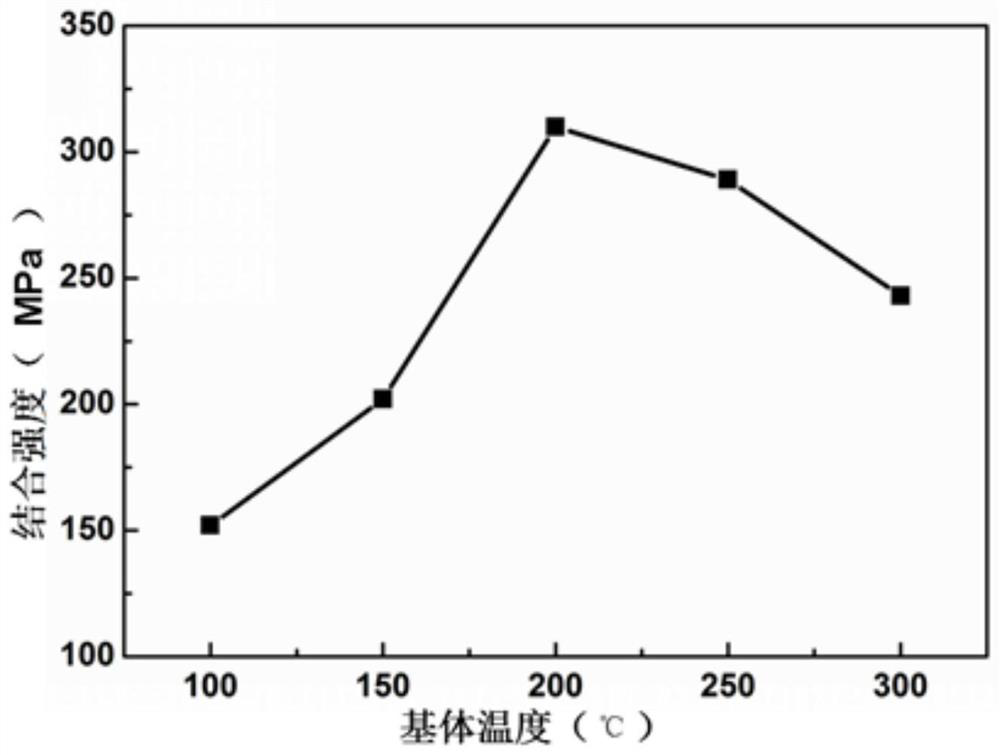

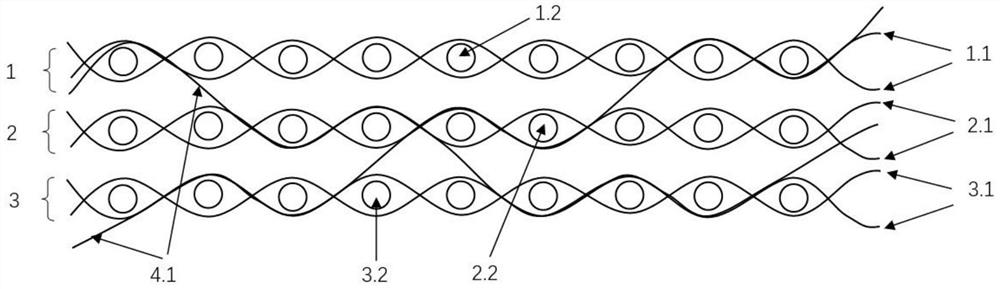

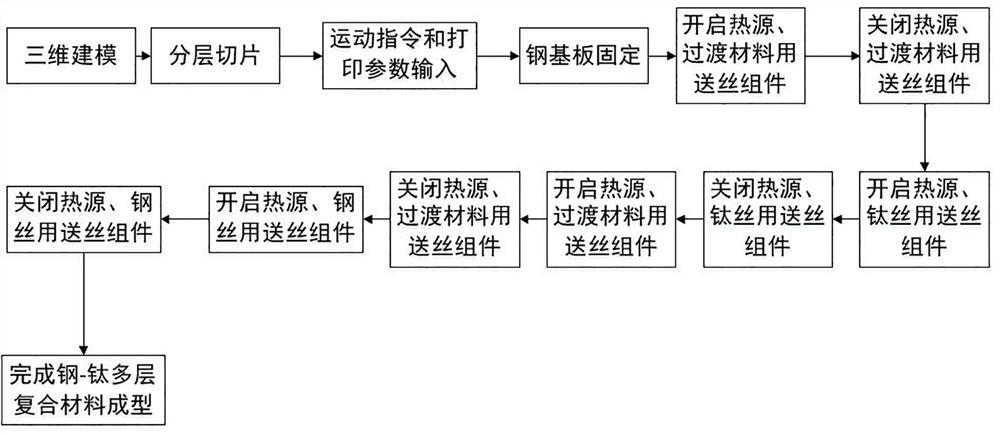

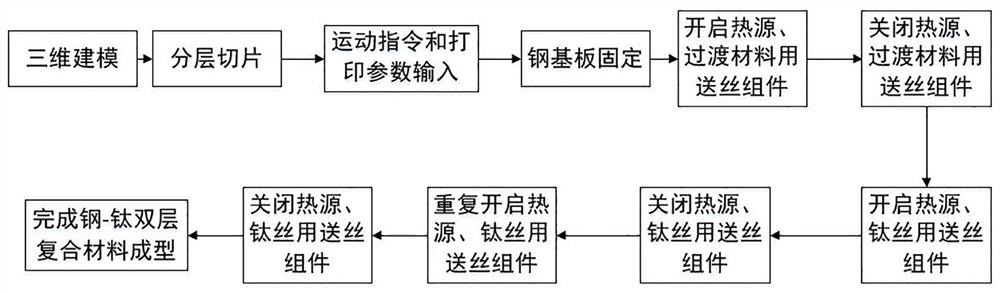

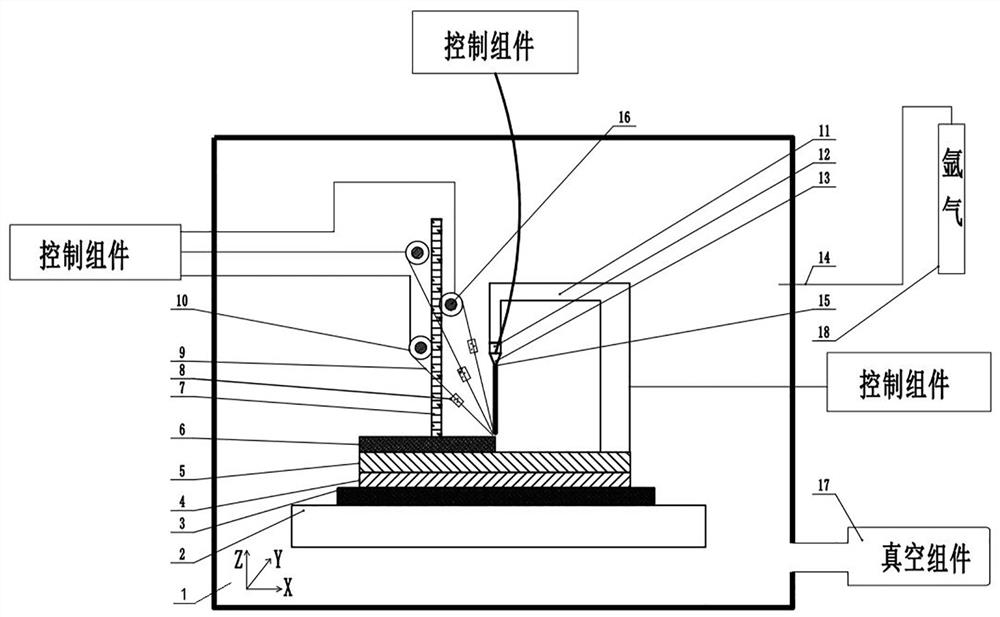

Steel-titanium composite material fuse high-efficiency additive manufacturing system and preparation method

ActiveCN111992719AUnrestricted structureAbandon pollutionAdditive manufacturing apparatusIncreasing energy efficiencyTitaniumAdditive layer manufacturing

The invention belongs to the technical field of fuse high-efficiency additive manufacturing, and discloses a steel-titanium composite material fuse high-efficiency additive manufacturing system and preparation method. The method comprises the following steps that firstly the three-dimensional modeling of a to-be-processed part of a composite material is carried out, the layered slicing is carriedout, printing parameters are adjusted through a control assembly, a to-be-processed steel substrate is fixed, a heat source and a wire feeding assembly for a transition material are started to complete one-layer fused deposition of a transition layer, then the heat source and the wire feeding assembly for a titanium wire are started to complete one-layer fused deposition of a titanium layer, the opening and closing of the wire feeding assembly for the transition material, the wire feeding assembly for the titanium wire and the wire feeding assembly for a steel wire are correspondingly adjustedaccording to the requirements of a to-be-processed part, and the fuse high-efficiency additive of the multi-layer steel-titanium composite material is completed. According to the steel-titanium composite material fuse high-efficiency additive manufacturing system and preparation method, the adopted technology is flexible in the technology, high in flexibility, short in period and friendly to theenvironment, and the prepared steel-titanium composite material can be steel-titanium double-layer composite or steel-titanium-steel-titanium multi-layer composite as well, and the number and mode ofcomposite layers are not limited.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Method for preparing magnesium-aluminum composite plate by radio frequency magnetic control

ActiveCN112663008AThickness is easy to controlAchieve metallurgical bondingVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringInlet valve

The invention belongs to the technical field of light alloys, and particularly relates to a method for preparing a magnesium-aluminum composite plate by radio frequency magnetic control. The method comprises the following steps that (1) a matrix is prepared, and specifically, the cleaned magnesium alloy matrix is placed into a sample feeding chamber of radio frequency magnetron sputtering equipment to be vacuumized; (2) pre-sputtering is conducted, and specifically, a magnesium target material and an aluminum target material in an sputtering cavity are subjected to pre-sputtering; (3) sample feeding is conducted, and specifically, the magnesium alloy matrix is fed to a sample table in the sputtering cavity; (4) cavity washing is conducted, specifically, an air inlet valve of the sputtering cavity is opened, and the flow rate of high-purity argon and the cleaning time are adjusted; (5) the matrix is heated, specifically, the magnesium alloy matrix is heated, and then a sample rotating table is adjusted to continuously rotate; (6) sputtering is conducted, and specifically, the magnesium target material and the aluminum target material are subjected to radio frequency magnetron sputtering; and (7) cold rolling is conducted, specifically, the sputtered aluminum single face is subjected to cold rolling treatment, and the magnesium-aluminum composite plate is obtained. The magnesium-aluminum composite plate prepared through the method is excellent in comprehensive performance, complete metallurgical bonding of a layer interface between magnesium and aluminum is achieved, and high bonding strength is achieved.

Owner:JIANGSU UNIV OF TECH

Thermoplastic composite fiber preform and forming method thereof

InactiveCN112877856AGuaranteed stabilityImprove interlayer bond strengthHeating/cooling textile fabricsMulti-ply fabricsPolymer scienceThermoplastic composites

A thermoplastic composite fiber preform and a forming method thereof are characterized in that a composite is formed by hot pressing of a fabric preform, and the fabric preform is fabric with a three-layer structure and formed by weaving warp yarn of four systems and weft yarn of three systems, wherein upper-layer warp yarn and upper-layer weft yarn are interwoven to form upper-layer fabric, inner-layer warp yarn and inner-layer weft yarn are interwoven to form inner-layer fabric, lower-layer warp yarn and lower-layer weft yarn are interwoven to form lower-layer fabric, and binding warp yarn is intermittently interwoven into the upper-layer fabric, the inner-layer fabric and the lower-layer fabric, so that the upper-layer fabric, the inner-layer fabric and the lower-layer fabric are tightly connected into a whole, the upper-layer fabric and the lower-layer fabric are reinforced fiber yarn braided fabric or the fabric formed by blending reinforced fiber yarn and polyphenylene sulfide yarn, the inner-layer fabric is polyphenylene sulfide yarn fabric, and the binding warp yarn is the reinforced fiber yarn. Through the layout design of the preform organization structure, reinforced fibers and matrix fibers, the design of the resin content and the resin distribution in a final product, and a resin flow path in a machining process is realized, and the preform-composite with large thickness and better impregnation can be obtained.

Owner:南京特塑复合材料有限公司

Production process of folding and explosion-resistant copper plate card

PendingCN114457623AImprove folding resistanceHigh bonding strength between layersNatural cellulose pulp/paperCoatings with pigmentsSodium phosphatesSizing

The invention discloses a production process of a folding-and-explosion-resistant chromo board, which comprises the following steps: taking cassava starch as a raw material, carrying out alkali treatment to obtain modified starch, mixing the modified starch with sodium hypochlorite, sodium tripolyphosphate, an ethylene-vinyl acetate copolymer and ground calcium carbonate, grinding, and sieving to obtain coated starch; then carrying out papermaking molding on the mixed paper pulp to obtain raw paper; sizing is conducted on the surface of the base paper through coating starch, then coating and calendering are conducted through a coating containing the coating starch, and the folding and explosion resistant chromo board is obtained. The obtained chromo board is good in folding resistance (the folding resistance is 15 times or above) and high in interlayer bonding strength (180 J / m < 2 > or above), the paper quality is improved, and the high-standard requirement for the chromo board is met.

Owner:SHANDONG BOHUI PAPER INDUSTRY CO LTD

Interlayer binding material for thin-layer pavement of cement pavement and preparation method of interlayer binding material

PendingCN114686165AImprove interlayer bond strengthHigh strengthNon-macromolecular adhesive additivesBituminous material adhesivesDefoaming AgentsFirming agent

The invention discloses an interlayer binding material for thin layer pavement of a cement pavement and a preparation method of the interlayer binding material. The interlayer binding material comprises 5-10 parts of water-borne epoxy resin, 10-20 parts of a water-borne epoxy curing agent, 70-85 parts of wheel-sticking-free emulsified asphalt, 0.1-0.5 part of a thickening agent and 0.5-1 part of a defoaming agent. During preparation, the waterborne epoxy resin, the waterborne epoxy curing agent, the non-sticking emulsified asphalt, the lauric acid and the ethylene oxide are uniformly mixed. The water-based epoxy modified emulsified asphalt is adopted as a binding material of the cement pavement, water-based epoxy resin can permeate into a cement base layer, the interlayer binding strength is improved, the composite drawing strength at 40 DEG C is larger than 0.4 MPa, a spatial three-dimensional network structure is formed in the asphalt after water-based epoxy is cured, the strength is high after film forming, blistering is not prone to occurring, and the water-based epoxy modified emulsified asphalt can be used as a binding material of the cement pavement. And wheel sticking is not generated when a construction vehicle paves the mixture.

Owner:南京兴佑交通科技有限公司

A high-efficiency additive manufacturing system and preparation method of steel-titanium composite fuse wire

ActiveCN111992719BUnrestricted structureLong cycleAdditive manufacturing apparatusIncreasing energy efficiencyTitaniumAdditive layer manufacturing

The invention belongs to the technical field of fuse high-efficiency additive manufacturing, and discloses a steel-titanium composite material fuse high-efficiency additive manufacturing system and preparation method. The method comprises the following steps that firstly the three-dimensional modeling of a to-be-processed part of a composite material is carried out, the layered slicing is carriedout, printing parameters are adjusted through a control assembly, a to-be-processed steel substrate is fixed, a heat source and a wire feeding assembly for a transition material are started to complete one-layer fused deposition of a transition layer, then the heat source and the wire feeding assembly for a titanium wire are started to complete one-layer fused deposition of a titanium layer, the opening and closing of the wire feeding assembly for the transition material, the wire feeding assembly for the titanium wire and the wire feeding assembly for a steel wire are correspondingly adjustedaccording to the requirements of a to-be-processed part, and the fuse high-efficiency additive of the multi-layer steel-titanium composite material is completed. According to the steel-titanium composite material fuse high-efficiency additive manufacturing system and preparation method, the adopted technology is flexible in the technology, high in flexibility, short in period and friendly to theenvironment, and the prepared steel-titanium composite material can be steel-titanium double-layer composite or steel-titanium-steel-titanium multi-layer composite as well, and the number and mode ofcomposite layers are not limited.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com