Integrated self-adhesion composite core and preparation process thereof

A composite core, self-bonding technology, applied in the fields of medical science, clothing, underwear, etc., can solve the problems of low utilization rate of superabsorbent resin, poor softness of absorbent core material, low water absorption rate, etc., and achieve interlayer bonding. High strength, good anti-pilling effect and excellent absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

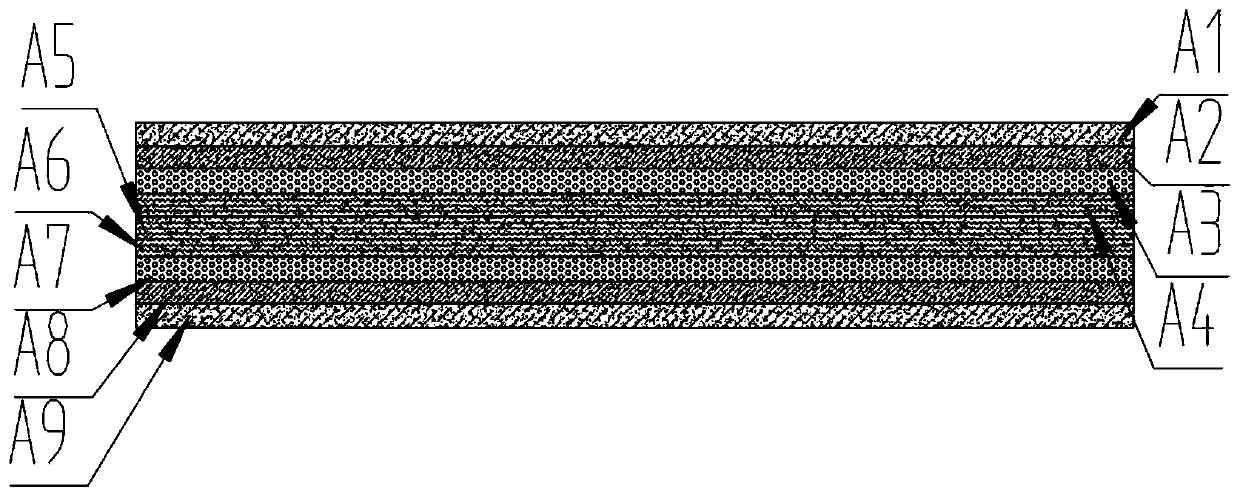

[0035] Such as figure 1 As shown, the integrally formed self-adhesive composite core includes from top to bottom: from top to bottom including upper surface layer A1, lower surface layer A2, super absorbent resin layer A3, upper support layer A4, middle support layer A5, lower support layer A6, the superabsorbent resin layer A7, the upper base layer A8 and the lower base layer constitute A9. in:

[0036] (1) Each surface layer and each bottom layer are formed by mixing hot-melt ultra-fine short fibers and fluff pulp fibers. The fiber denier of the hot-melt ultra-fine short fibers is 0.8-2.5dtex, and the fiber length is 0.5- 10mm. Preferably the fiber denier is 1.5 dtex and the fiber length is 5 mm.

[0037] In the implementation of this example, the square gram weight of the upper surface layer and the lower bottom layer is 10-25g / m 2 , the proportion of fluff pulp fiber is 50-65%, and the rest is the proportion of hot-melt ultra-fine short fibers, and the square gram weig...

Embodiment 2

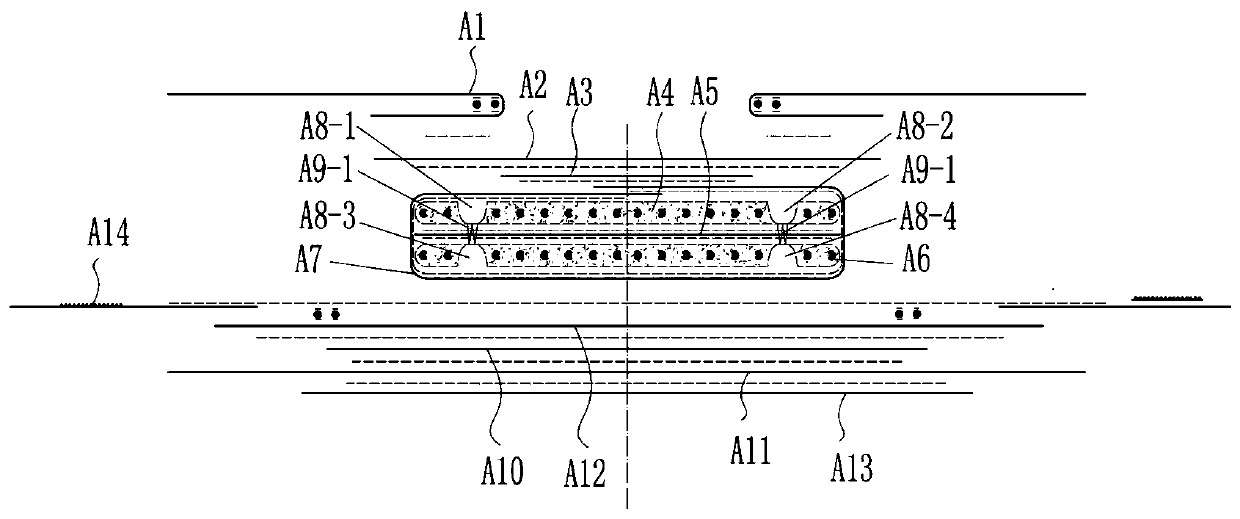

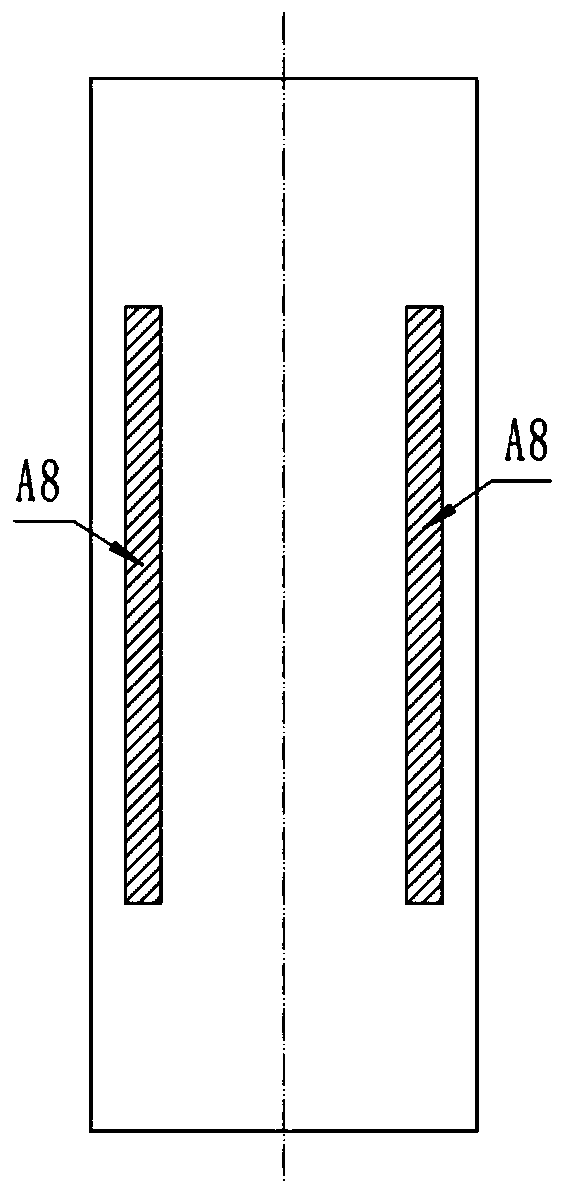

[0052] Such as figure 2 , image 3 As shown, this embodiment is a waist stick type hygroscopic product using an integrally formed self-adhesive composite core, which includes a liquid-impermeable side leakage prevention partition layer A1, a liquid-permeable top layer A2, a liquid-permeable flow guide Layer A3, integrally formed self-adhesive composite core, non-woven wrapping layer or dust-free paper wrapping layer A7, overlapping hollow area A8, thermal welding point A9 at the overlapping hollow area, liquid-tight bottom film A10, liquid-tight The bottom non-woven fabric A11, the elastic waist part A12, the front waist sticker A13, and the left and right waist stickers A14. The above layers of materials are bonded between layers by hot melt adhesive.

[0053] The integrally formed self-adhesive composite core of the present embodiment comprises an upper layer hollow absorbent core A4 and a lower layer hollow absorbent core A6, wherein the upper layer hollow absorbent core...

Embodiment 3

[0057] as attached Figure 5 As shown, the difference between this example and Example 2 is that on the basis of the implementation of Example 2, the front end and rear end of the integrally formed self-adhesive composite core are respectively provided with transverse hollow areas C15 and The transverse hollow area C16 makes the integrally formed self-adhesive composite core of this embodiment have a more excellent function of preventing front and rear leakage.

[0058] The shape of the transverse hollow area C15 and the transverse hollow area C16 in this embodiment can be crescent-shaped or linear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com