Patents

Literature

119results about How to "Not easy to pill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cotton fibers with antibacterial and insect-resisting effects and production method of cotton fibers

InactiveCN104278359AEasy to cleanNot easy to fluffConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsCnidium monnieriFatty alcohol

The invention discloses cotton fibers with antibacterial and insect-resisting effects. The cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 21-24 parts of cotton fibers, 10-12 parts of apocynum venetum fibers, 6-8 parts of silk fibers, 7-9 parts of cashmere fibers, 9-11 parts of pineapple fibers, 4-7 parts of polypropylene fibers, 6-8 parts of taxus chinensis superfine micro-powder, 3-5 parts of ailanthus altissima leaf extracted powder, 1-3 parts of zeolite powder, 1.1-2.3 parts of chitosan, 0.5-0.7 part of magnesium nitride, 0.8-1.4 parts of N,N-dicyanoethylaniline, 5-7 parts of sulfonated castor oil, 15-18 parts of fatty alcohol alkoxy ether, 1-2 parts of mashed garlic, 1.3-2.5 parts of cnidium monnieri cuss, 2.1-3.6 parts of coptis chinensis, 90-95 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 95-100 parts of 1-butyl-3-methylimidazolium acetate, 3-6 parts of an addition agent and a proper amount of water. According to the cotton fibers, the taxus chinensis superfine micro-powder is added into raw materials by adopting an ultrasonic technology and a prepared cotton textile has a very good health effect and a useful pain-relieving effect on tumor patients and female symptoms; furthermore, the other active ingredients are added so that the good clothes properties of sweat absorption, breathability, softness, allergy prevention, easiness of washing, low probability of fuzzing and balling up and the like of natural cotton fibers are maintained, and the cotton fibers have good antibacterial and insect-resisting functions, a good electromagnetic radiation shielding function and the like.

Owner:ANHUI SWAN TECH IND GRP

Three-effect liquid laundry detergent composition and preparation method thereof

ActiveCN103242973AIncrease polarityImprove adsorption capacityAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsLiquid laundry detergentSilicone oil

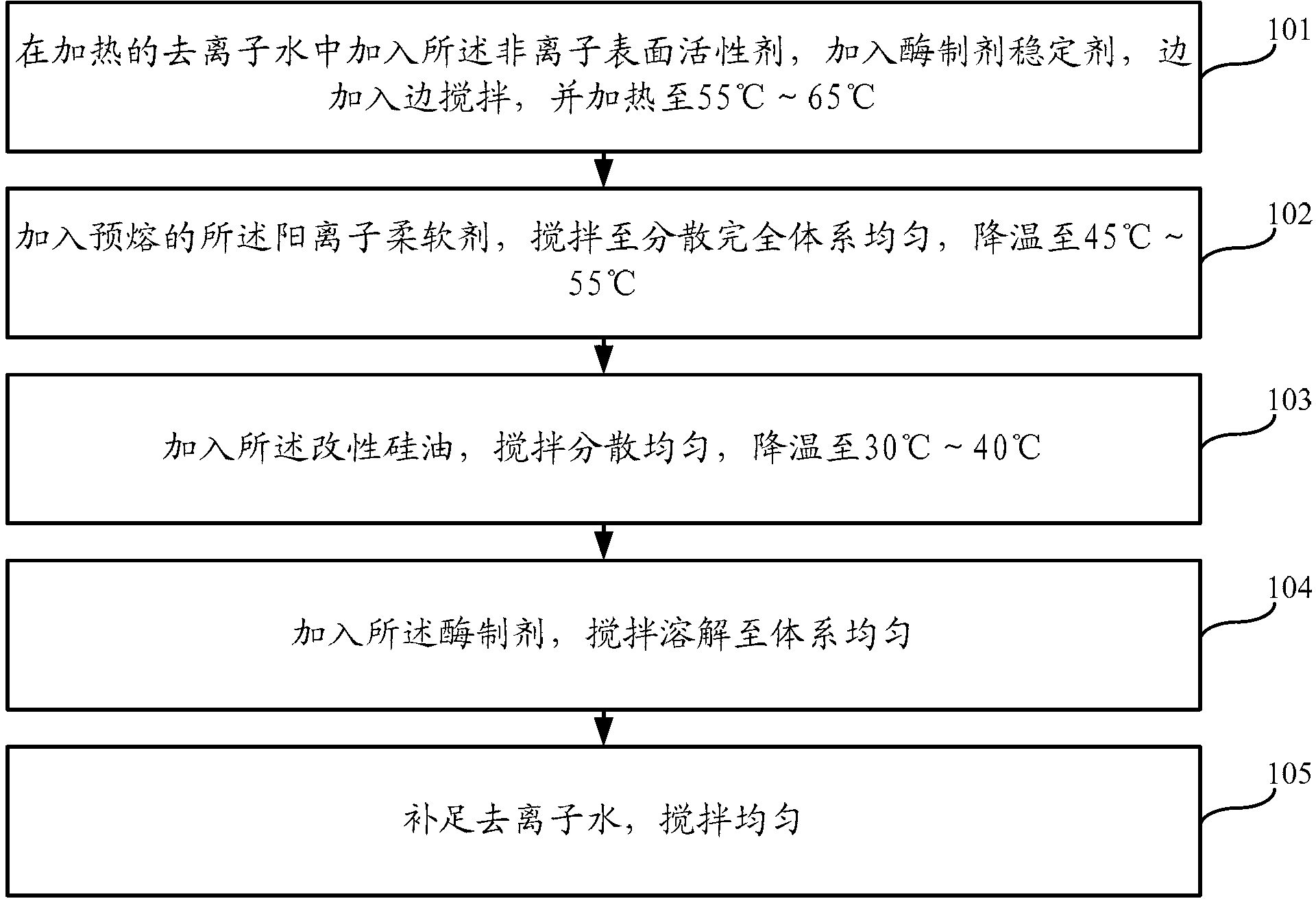

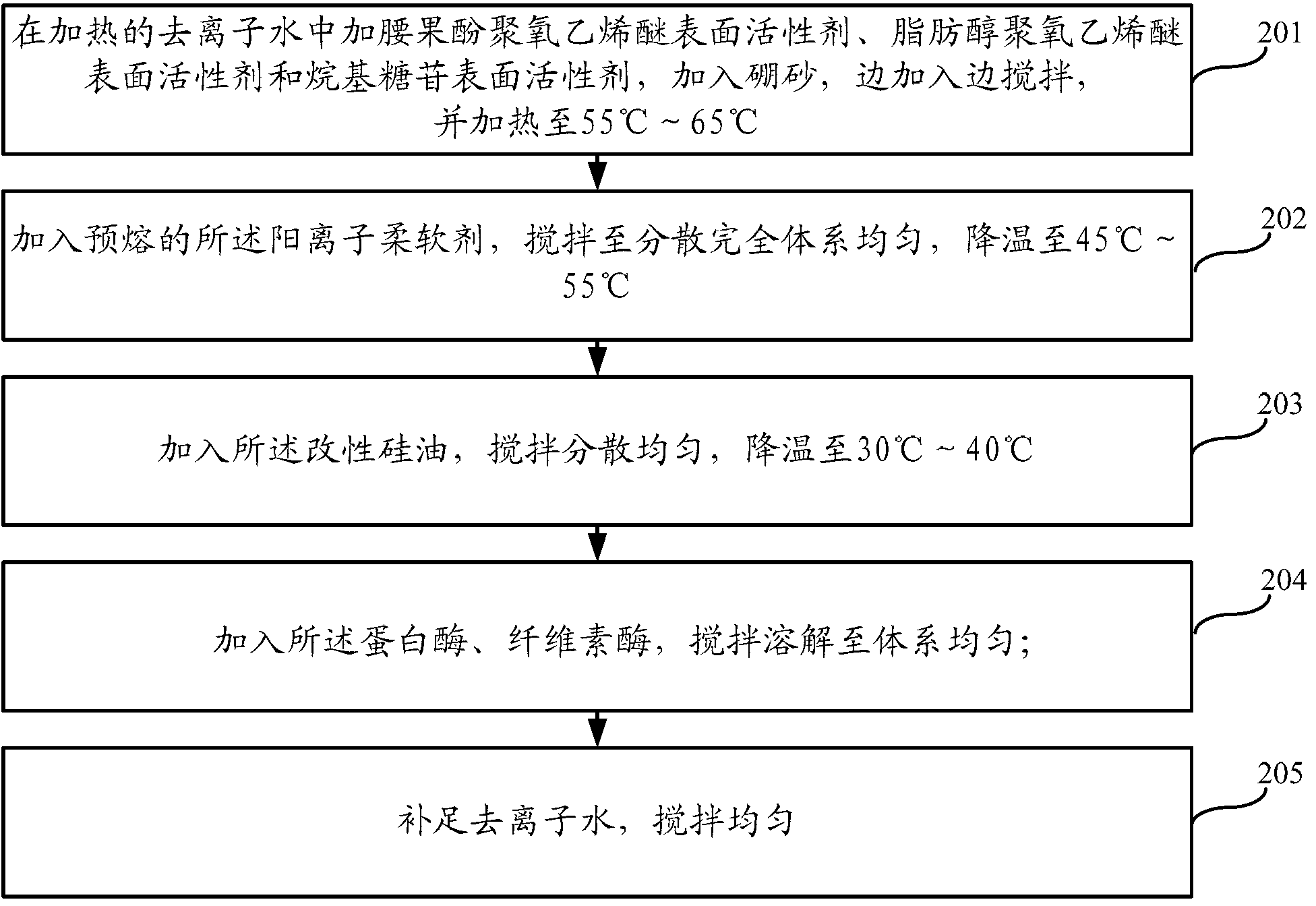

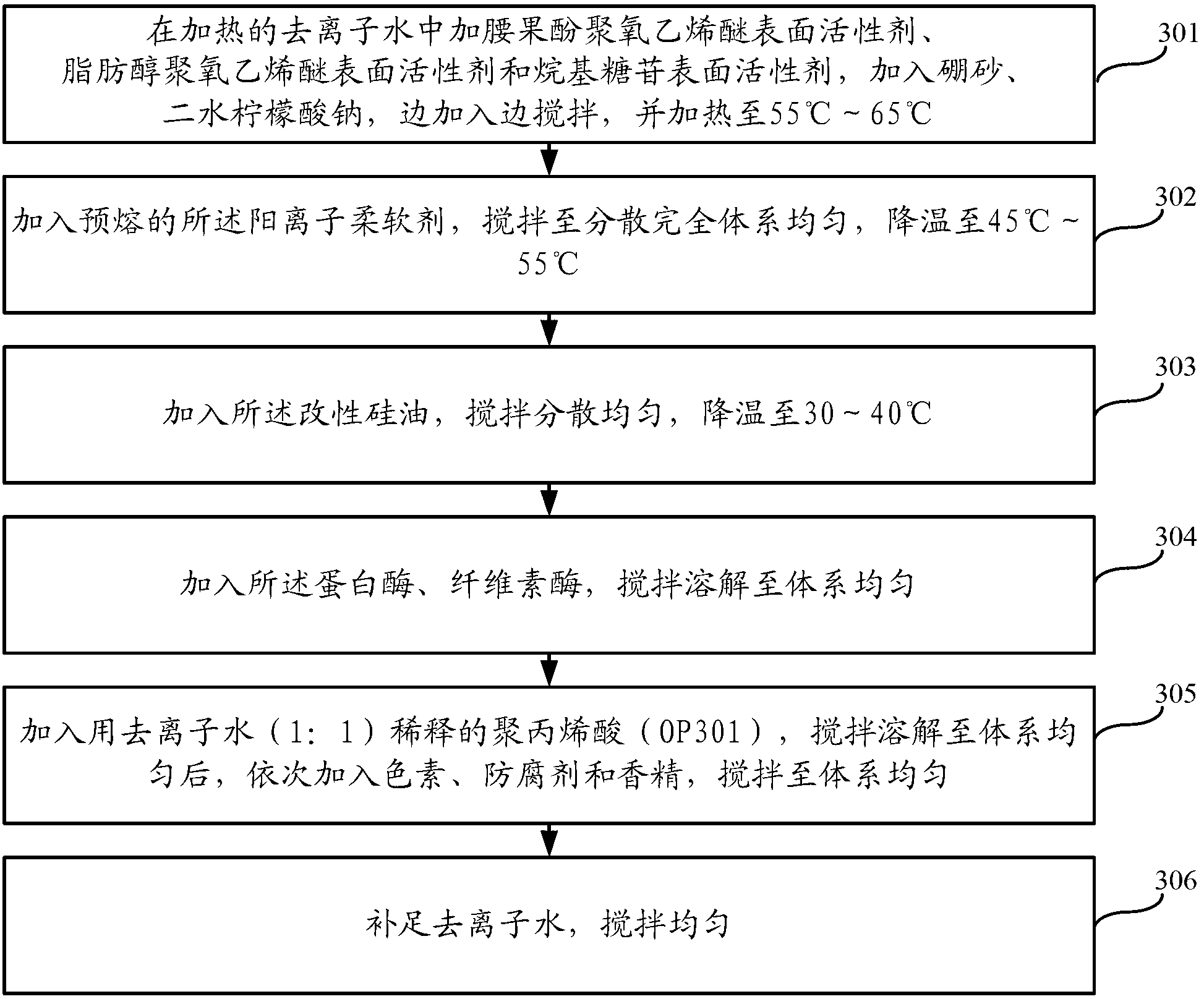

The invention relates to the field of detergents and particularly relates to a three-effect liquid laundry detergent composition and a preparation method thereof. The three-effect liquid laundry detergent composition has the three effects of washing, softness and puffiness and comprises the following components: 0.02-15% of cationic softener, 0.01-10% of modified silicon oil, 2-50% of nonionic surfactant, 0.02-6% of enzymic preparation and 0.01-12% of enzymic preparation stabilizer. The preparation method comprises the following steps of: adding the nonionic surfactant into the heated deionized water, adding the enzymic preparation stabilizer, stirring while adding, and heating the mixture to 55-65 DEG C; adding the pre-molten cationic softener, stirring until the pre-molten cationic softener is completely dispersed and the system is uniform, and cooling to 45-55 DEG C; adding the modified silicon oil, stirring and uniformly dispersing, and cooling to 30-40 DEG C; adding the enzymic preparation, stirring to dissolve the enzymic preparation until the system is uniform; and complementing the deionized water, and uniformly stirring the mixture.

Owner:纳爱斯成都有限责任公司

Plant functional polyester filament and preparation method thereof

InactiveCN110863252AHigh mechanical strengthImprove wear resistanceMonocomponent polyesters artificial filamentSynthetic polymer filament chemical after-treatmentPolyesterFiber

The invention discloses a plant functional polyester filament and a preparation method thereof. The plant functional polyester filament comprises 0.1-1.5% of plant extract. The preparation method includes a step of plant functional polyester master batch preparation, and the step of plant functional polyester master batch preparation includes: slicing PET, heating to melt, adding an antioxidant and a dispersing agent, and stirring; then, adding a protecting agent and the plant extract, and mixing at a high speed; finally, adding a modifying agent, well mixing to obtain a mixture, and extrudingfor granulation. The plant functional polyester filament integrates high mechanical strength of polyester fibers and the anti-mite and antibacterial performance of the plant extract and has advantages of antibacterial and deodorizing effects, high wear resistance, high elasticity, comfort in hand feeling and less proneness to pilling and fouling.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Light fabric and production method thereof

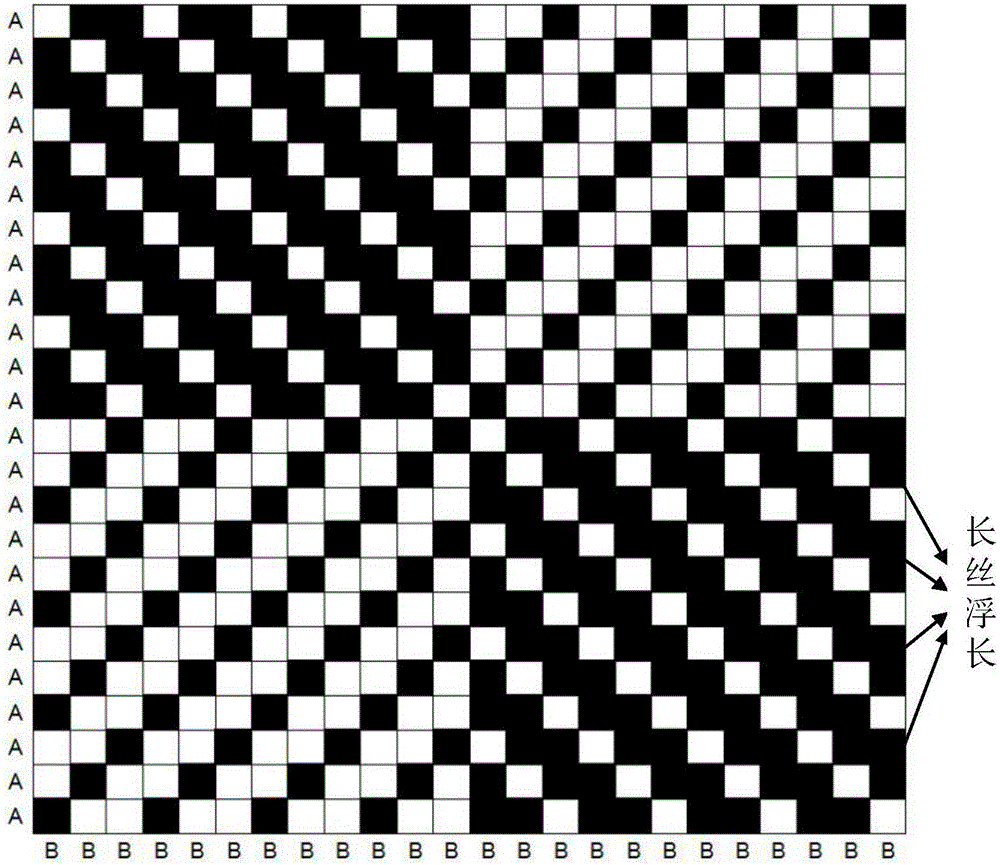

The invention discloses a light fabric and a production method thereof. The light fabric consists of long terylene fiber or long nylon fiber with the fineness between 10 and 40 deniers, wherein the monofilament fineness of the long terylene fiber or the long nylon fiber is between 0.2 and 6 deniers. The production method of the light fabric comprises the steps of material selecting, warping, starching, warp rebeaming, weaving and post-finishing processing to finally obtain finished products. The fabric produced by the invention has the characteristics of light weight, softness, good downproofness, snagging resistance and the like, is difficult to generate pilling, has simple processing process and stable quality and is applicable to light sport suit and high-grade down coat.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

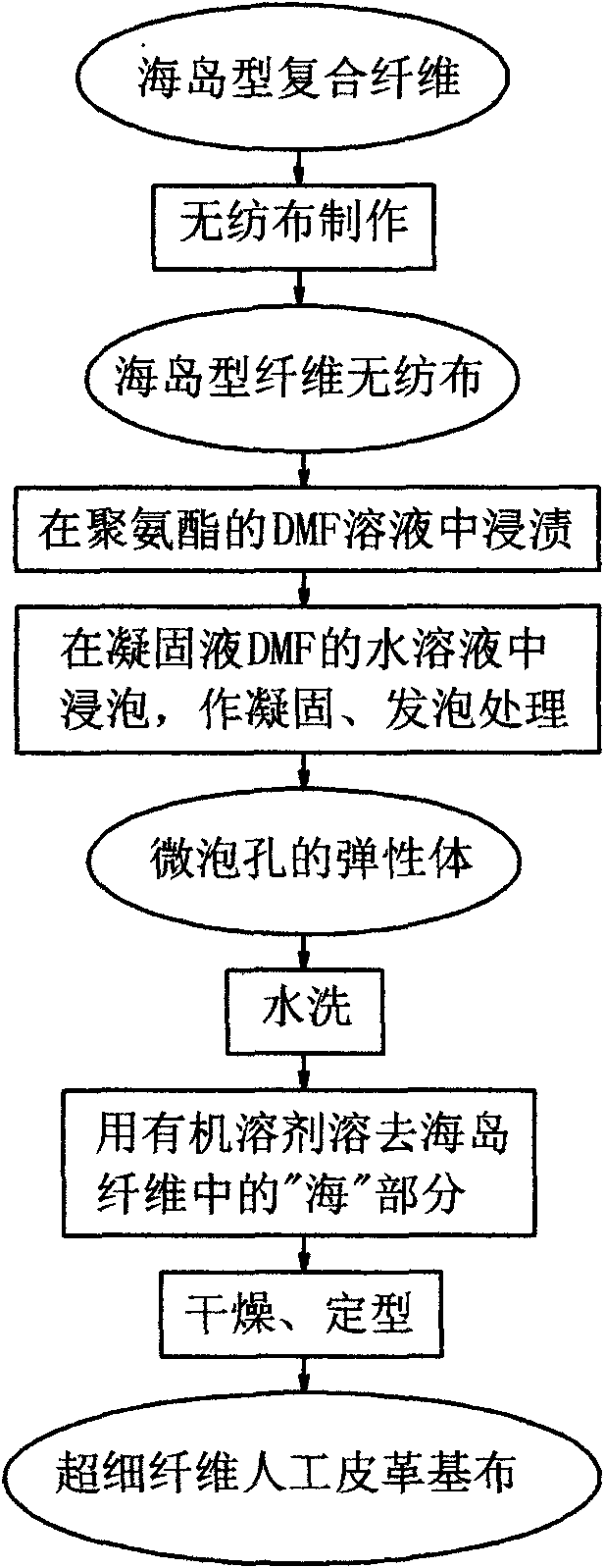

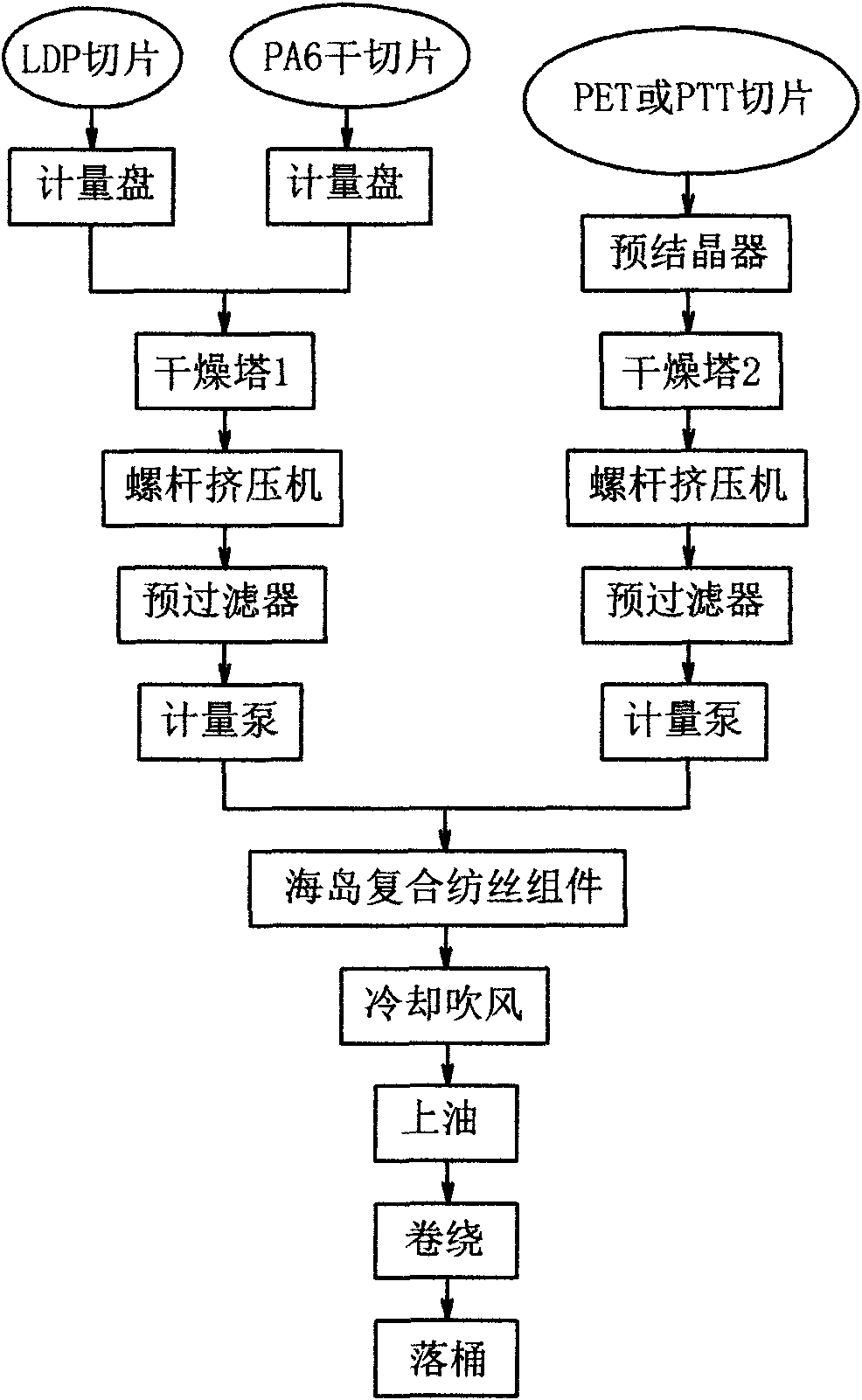

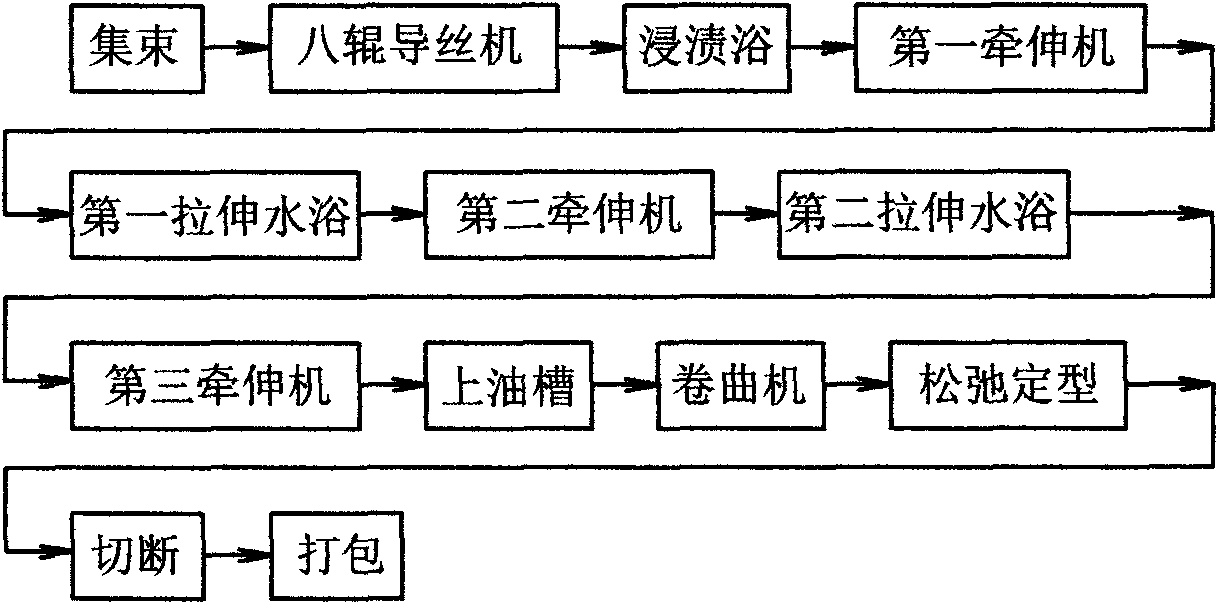

Method for preparing composite superfine fiber artificial leather base fabric

ActiveCN102168345ARaise the ratioUniform lengthMelt spinning methodsNon-woven fabricsElastomerOrganic solvent

The invention discloses a method for preparing a composite superfine fiber artificial leather base fabric, which comprises the following steps of: (1) impregnating sea island composite type fiber nonwoven fabric in a DMF (dimethyl formamide) solution of polyurethane; (2) preparing micropore-containing elastomer by carrying out solidification and foaming treatment in an aqueous solution of solidified solution DMF; (3) washing with water; (4) removing a 'sea' part in sea island type fiber by an organic solvent; and (5) drying and shaping, wherein the sea island composite fiber nonwoven fabric is prepared from the sea island type fiber which is prepared by double-screw sea island-type composite spinning equipment, and marine facies components adopt a blend of PE (polyurethane) and PA (polyamide) the blending proportion of which is 45:55 to 55:45. The marine facies in the sea island type fiber also contain fixed amount of non-figured sea island fiber, so the proportion of comprehensive island components is prominently enhanced, the PE which needs to be extracted is reduced correspondingly, and the density and the physical properties of the prepared superfine fiber base fabric are enhanced.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD +1

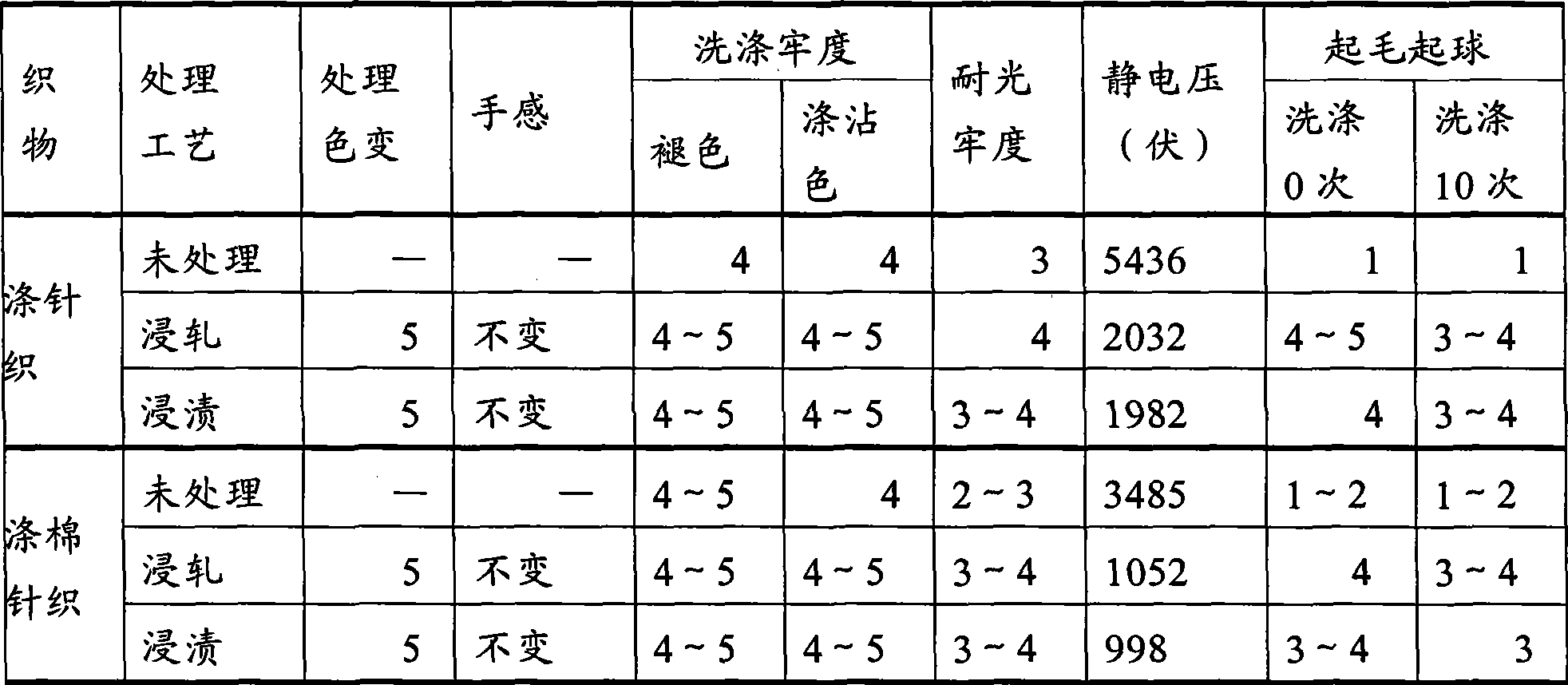

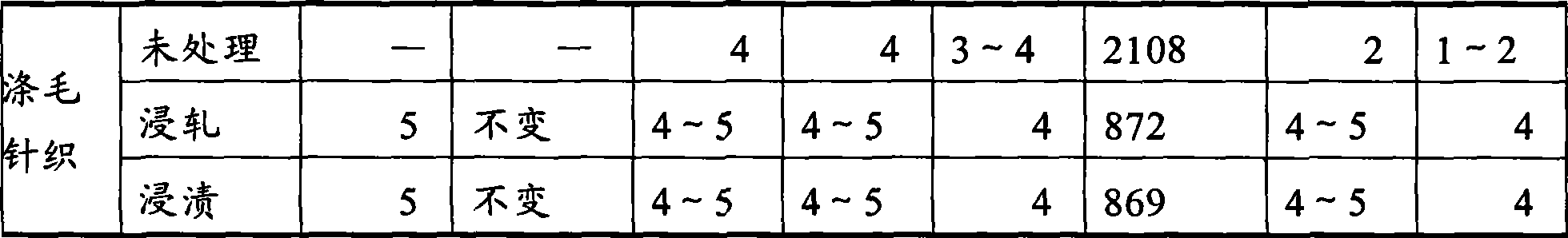

Anti-fuzzing and anti-pilling finishing agent for fabric

The invention relates to an auxiliary agent in the printing and dyeing industry, in particular to a surface finishing auxiliary agent for fabric. An anti-pilling finishing agent for the fabric is nonionic macromolecular polymer, and is characterized in that the anti-pilling finishing agent for the fabric is formed by copolymerizing 10 to 20 portions of high-hydro silicone oil, 30 to 50 portions of polyurethane prepolymer and 30 to 50 portions of polypropylene ester copolymer under the conditions of catalyst and heating; and the portion is weight portion. The fabric anti-pilling finishing agent is suitable for various fibers and fabrics; and in particular, polyester fabric treated by the anti-pilling finishing agent has basically unchanged tone and handfeel, improves the fastness to washing and light fastness, greatly improves the antistatic performance, has certain dust resistance and obviously improves the anti-pilling performance.

Owner:上海德桑精细化工有限公司

Antistatic cotton-polyester blend clothing material

InactiveCN1811034AHigh cotton contentImprove breathabilityOther chemical processesWoven fabricsPolyesterFiber

The antistatic cotton-polyester blend clothing material contains cotton of 21*21 count in 50-70 wt%, chemical fiber of 127*66 or 45 / 2*21 count in 29-49 wt% and conducting fiber of 130*66 count in 1 wt%. It has high cotton content and embedded conducting fiber resulting in excellent antistatic effect, high permeability from proper cotton / polyester ratio, certain brightness, high stiffness, high color fastness and fire retarding function, and can meet the requirement of antistatic clothing for workers in petrochemical and other industry.

Owner:YI HE STOCK

Wool product for preventing electric radiation and manufacturing technology thereof

PendingCN107237038AGood anti-electron radiation effectPromote absorptionWeft knittingBiochemical treatment with enzymes/microorganismsYarnPolyester

The invention provides a wool product for preventing electric radiation. The wool product comprises 10-20% of wool fiber, 30-40% of modified polyester fiber, 25-35% of silver-coated filament and 15-35% of bamboo pulp fiber, wherein the silver-coated filament is coated with the modified polyester fiber to form core spun yarn, the core spun yarn, the wool fiber and the bamboo pulp fiber are blended to form fabric with a function of preventing the electric radiation. Through the coordination of a manufacturing technology, the wool product which has a high electromagnetic shielding effect, comfortable in handfeel, is suitable for being worn can be obtained.

Owner:JIAXING ZHULANG CLOTHING CO LTD

Comfortable anti-flaming fabric and manufacturing method thereof

InactiveCN106592064AFlame retardant permanentComfortable foreverHeat resistant fibresHeating/cooling textile fabricsEngineeringFire resistance

The invention discloses a comfortable anti-flaming fabric. The comfortable anti-flaming fabric is characterized by being formed by vertically interweaving first yarns and second yarns, wherein the first yarns are made from staple fibers with anti-flaming property; the second yarns are made from anti-flaming filament yarns; after the fabric is padded, a firm fibroin sericin film is formed on the surface. The comfortable anti-flaming fabric has the advantage that the fire resistance and the comfort property are effectively combined so that the fabric has permanent flame retardance, wet-absorbing and breathable properties, skin-friendly and smooth properties, anti-pilling property, shrink-proof and anti-wrinkle properties, and the like.

Owner:北京邦维普泰防护纺织有限公司

Spinning process of polyester fleece knitted fabric

The invention provides a spinning process of polyester fleece knitted fabric. The spinning process mainly uses polyester filaments and polyester staple fibers as the raw materials to prepare the weft-knitted fabric. The spinning process includes: preprocessing gray fabric; dyeing and printing; softening and pre-forming; napping; carding; shearing; turning naps into granular naps; performing kinetic energy finishing; performing finished-product forming. The polyester fleece knitted fabric spun by the spinning process is soft and fluffy in touch, breathable and warm-keeping, less prone to pilling and fading, excellent in water resistance, oil resistance and fouling resistance and durable in flame retardance and can still have excellent three proofing and flame retardance after being washed at normal temperature.

Owner:森宝(福建)纺织科技发展有限公司

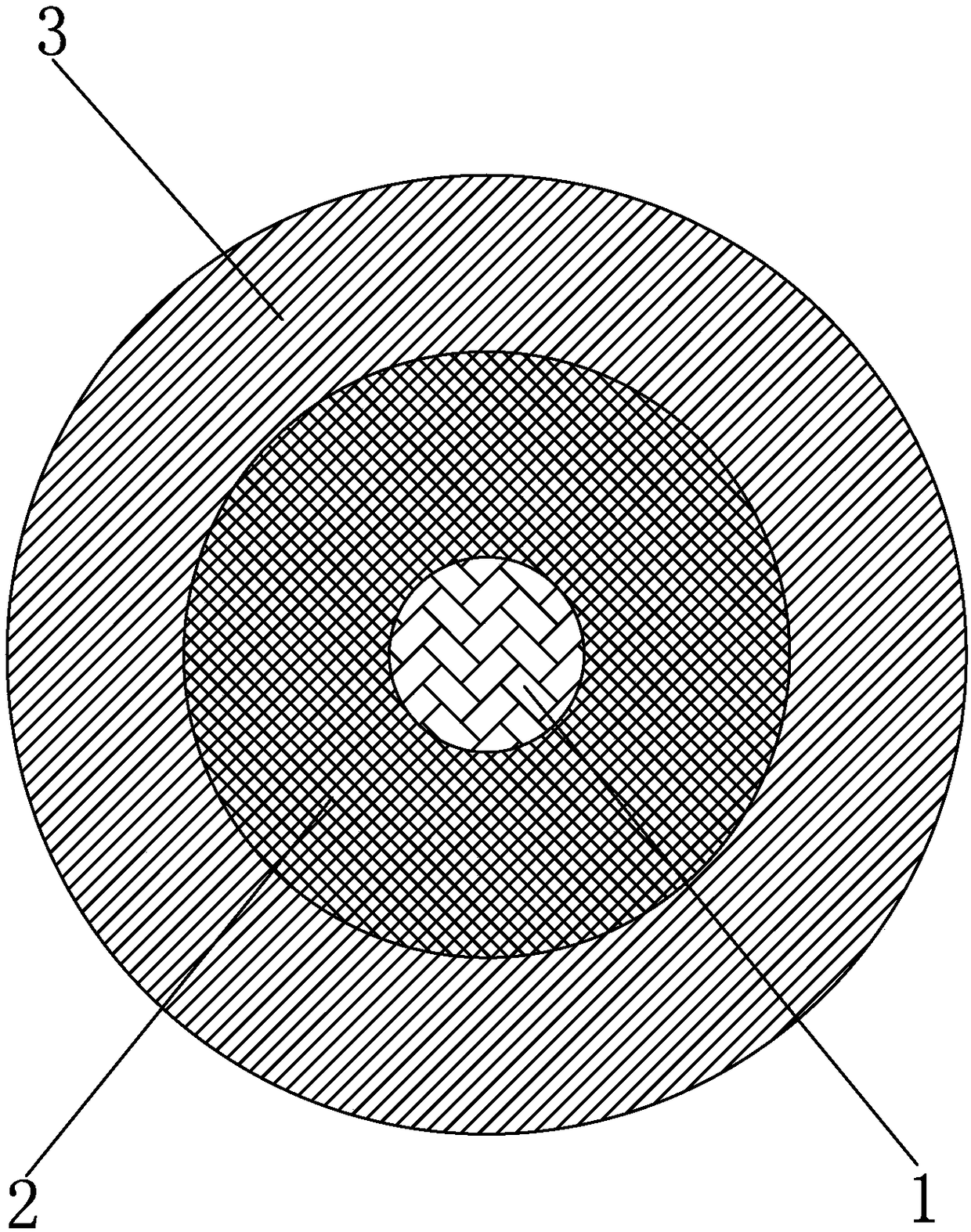

Shrink-proof wool core-spun yarn

The invention discloses a shrink-proof wool core-spun yarn, comprising: a core thread and a covering yarn; the core thread is a polyester thread, the covering yarn is a wool blended yarn made by twisting multiple wool fibers, cotton fibers and bamboo fibers, the wool blended yarn covers the polyester yarn, the wool fibers are special-shaped wool fibers having triangular cross section, and the cotton fibers are special-shaped cotton fibers having Y-shaped cross section. In this way, by covering the polyester core thread by using the wool blended yarn as the covering yarn with the wool blended yarn made by twisting the special-shaped wool fibers, the special-shaped cotton fibers and the bamboo fibers, the wool core-spun yarn is made which has excellent shrink-proof performance, good surface gloss, good softness and is resistant to picking and pilling.

Owner:SUZHOU WEIJIE TEXTILE

Production and pretreatment process for yarn-dyed fabrics

InactiveCN106521767AGood hygroscopicityImprove breathabilitySucessive textile treatmentsTwo or more solvent application treatmentYarnProcess engineering

The invention discloses a production and pretreatment process for yarn-dyed fabrics. The production process includes the steps: taking 36-branch cotton-wool blended yarns as raw materials; dyeing; warping; starching filaments; combining warps of warp beams to prepare beams for weaving; leasing; drafting; weaving; coldly stacking; steaming and cleaning; singeing and half mercerizing. The cotton-wool yarn-dyed fabrics woven by the process have functions of cotton fabrics and wool fabrics, better moisture absorption and air permeability and wide selling market, are not easy to crinkle, deform and pill, smooth, exquisite and comfortable in hand feeling and soft in texture, a user feels comfortable when wearing clothes prepared by the fabrics, and wearability of the fabrics is greatly improved. According to the process, the pretreatment process is added before the fabrics are printed and dyed, coldly stacking liquid and steam cleaning liquid are reasonably matched, so that the treated fabrics are better in functionality, and requirements of following processes can be effectively met.

Owner:江苏银桥纺织科技有限公司

Processing process of lustrous trilobal profiled polyester pre-oriented color yarn

InactiveCN102704018AFeel goodNot easy to pillFilament forming substance formingNew-spun product collectionYarnMasterbatch

The invention relates to a processing process of lustrous trilobal profiled polyester pre-oriented color yarn. The pre-oriented color yarn processing process comprises the following steps of: drying large lustrous PET (polyester) chips in a drying machine; adding the dried large lustrous PET chips and coloring masterbatch into a screw extruder for heating and melting; filtering heated and molten melt through a CPF (catalyzed particulate filtering) double-cylinder melt filter; adding the filtered melt into a spinning manifold for distributing and preserving heat; metering the heated and molten melt through a metering pump of the spinning manifold, and pressing the melt into a spinneret plate, wherein the ejection hole of the spinneret plate is in the shape of Y; ejecting the melt through the spinneret plate to form melt thin flows, and performing air cooling by means of an air cooling device; and oiling after cooling; and winding the oiled yarns through a winding head. According to the pre-oriented color yarn processing process, the product quality is improved by optimizing the process, and the products have stable tension, high profile degree and high color fastness in the post-processing process.

Owner:NINGBO HUAXING SCI & TECH

Spunlaced nonwoven fabric production technology and application thereof

InactiveCN110983627ASolve the phenomenon of easy fluffingFlat surfaceNon-woven fabricsPolymer scienceEngineering

The invention relates to the technical field of nonwoven fabrics, in particular to a spunlaced nonwoven fabric production technology and an application thereof. The spunlaced nonwoven fabric production technology comprises processes of opening and mixing, carding to form webs, cross lapping, drafting, pre-wetting, spunlace reinforcement and the like. By regulating type, proportion, denier, pre-wetting treatment process parameters and reinforcement treatment process parameters of fibrous materials, the spunlaced nonwoven fabric production technology relieves the phenomenon of pilling of nonwoven fabric prepared by an existing spunlace method, prepared nonwoven fabric products have flat surfaces, touch soft and are not prone to pilling, the strength of low-gram-weight nonwoven fabric products is improved, so that the pull rate of products is up to 95% or above, and the products can be applied to medical and sanitary products.

Owner:钱天宇 +1

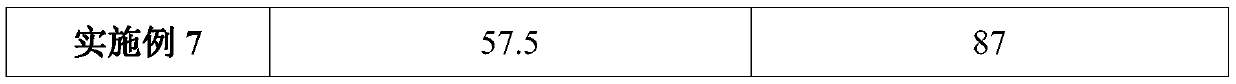

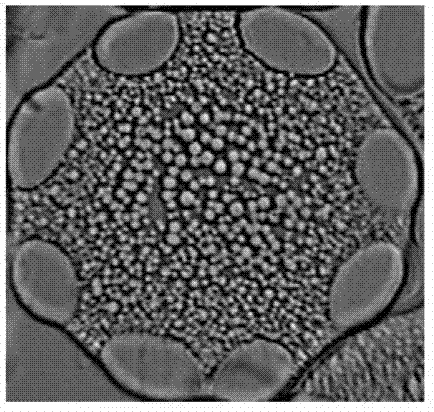

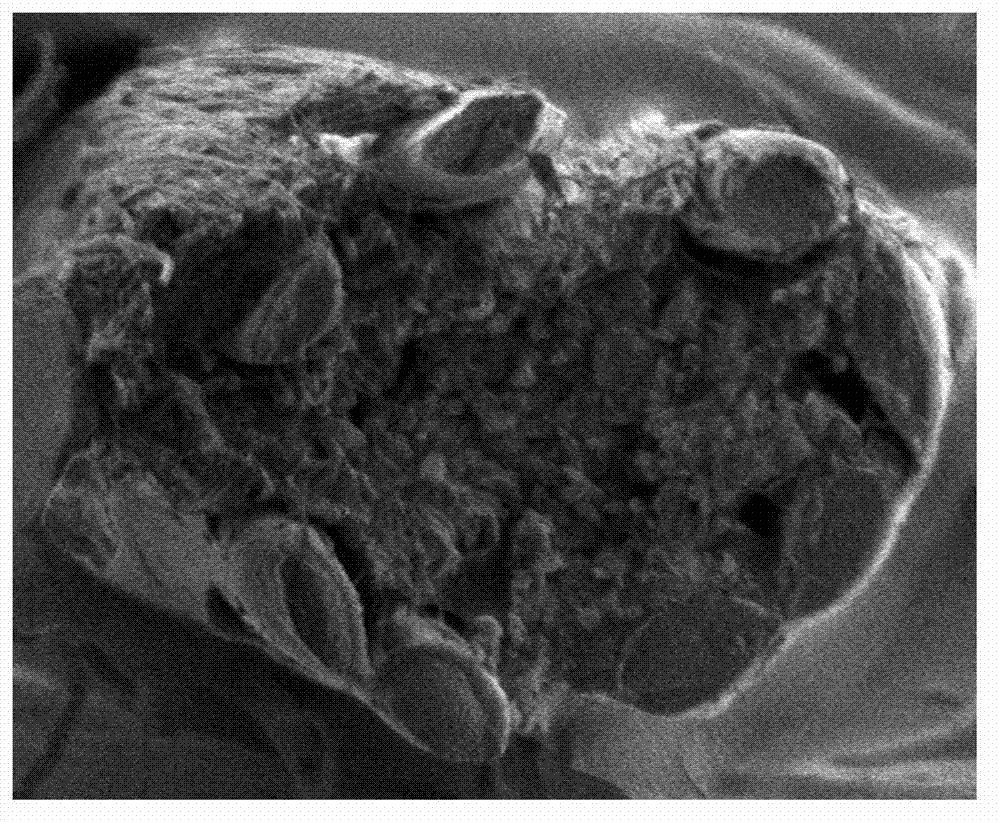

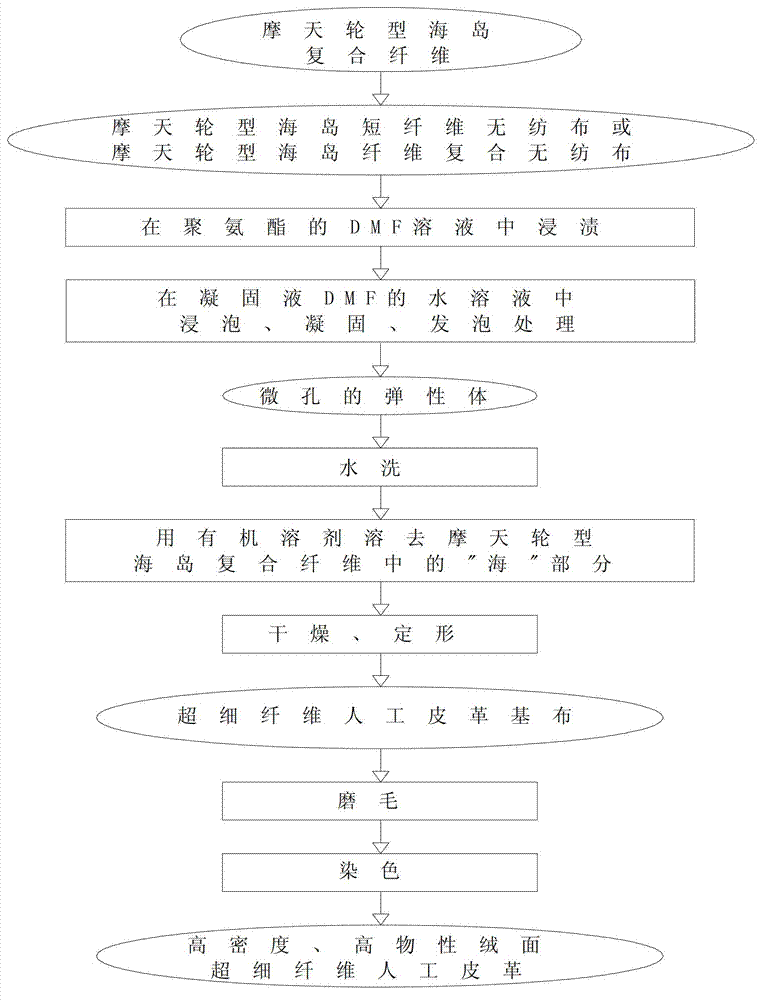

Preparation method of high-density and high-physical-property suede superfine fiber artificial leathers

InactiveCN103114458ARaise the ratioUniform lengthLamination ancillary operationsSynthetic resin layered productsDimethyl formamideWoven fabric

The invention discloses a preparation method of high-density and high-physical-property suede superfine fiber artificial leathers, which comprises the following steps: 1, preparing a ferris wheel type superfine fiber non-woven fabric from ferris wheel type sea island composite fibers; 2, soaking the non-woven fabric in a polyurethane DMF (dimethyl formamide) solution; 3, carrying out solidification and foaming processing on the non-woven fabric so as to prepare an elastomer with micro-foamed holes; 4; carrying out water washing on the elastomer; 5, removing a LDPE (low-density polyethylene) part through dissolving by using an organic solvent; 6, drying and formalizing the obtained product so as to obtain a high-density and high-physical-property suede superfine fiber artificial leather based fabric; and 7, carrying out peached finish and dyeing processing on the fabric. The ferris wheel type superfine fiber non-woven fabric can be a non-woven fabric prepared through short fiber needling, and also can be a superfine fiber non-woven fabric covered with ferris wheel type sea island filament woven mesh cloth. Because the proportion of the island phase of the ferris wheel type sea island composite fiber is as high as 70%, PE phases required to be extracted are correspondingly reduced. Naps of a fixed island fiber part are uniform in length and distribution, and can be prepared into high-strength and high-physical-property high-grade suede superfine fiber artificial leathers.

Owner:JIAXING UNIV

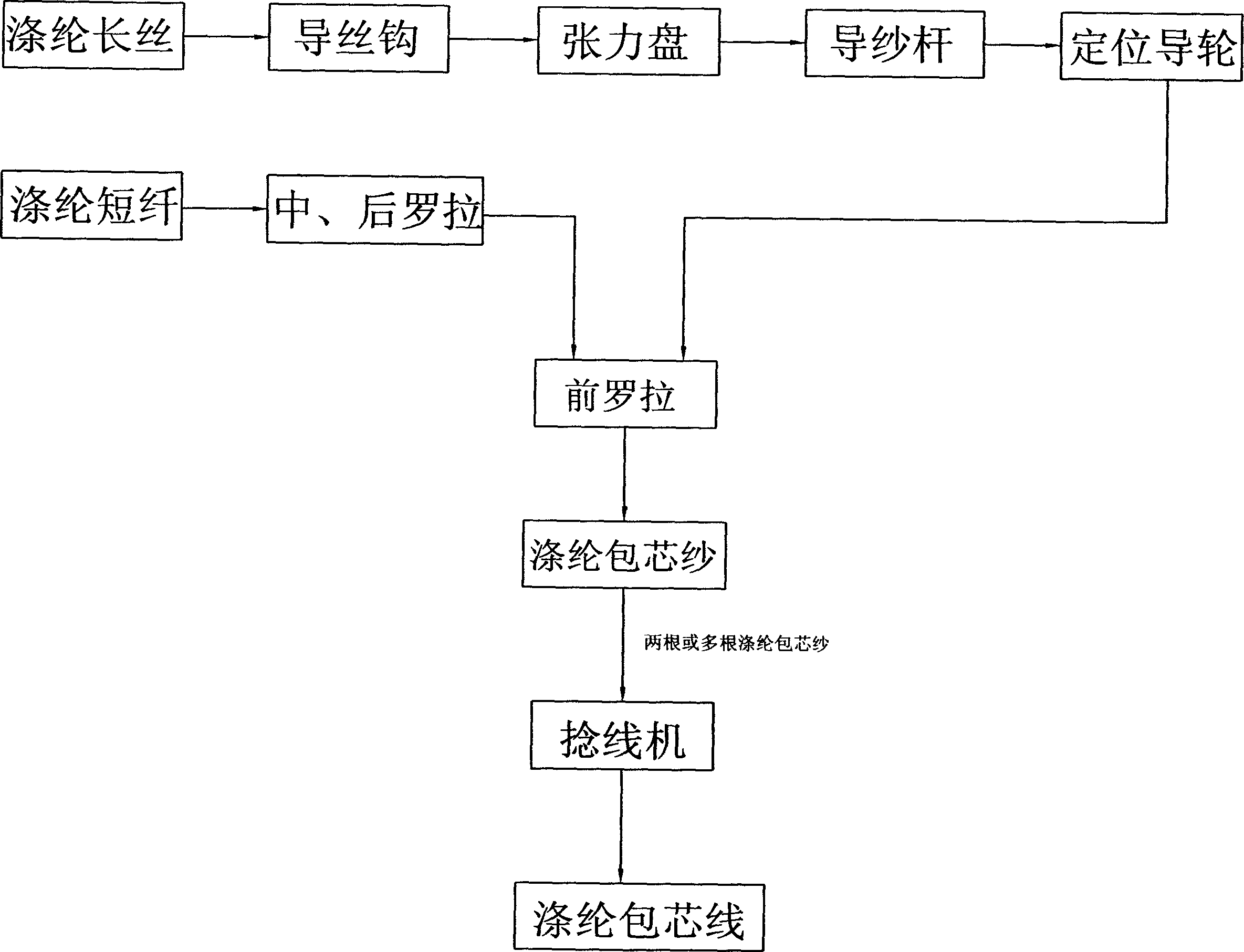

Terylene wrapped core wire and fabrication method

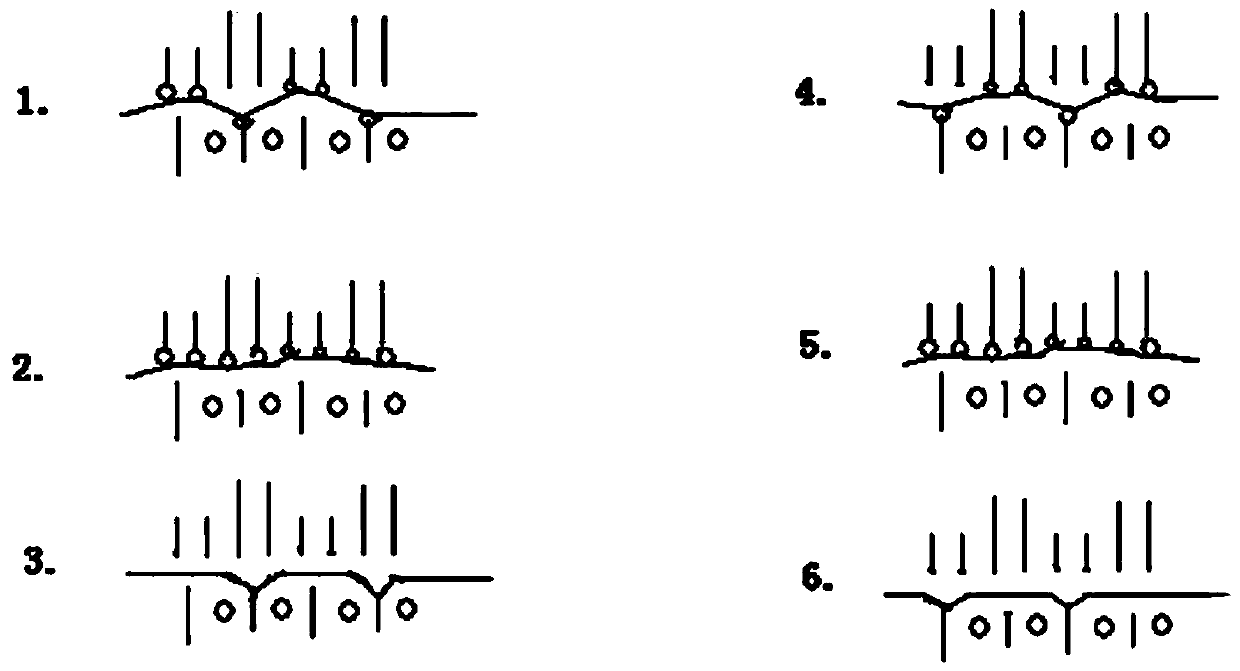

This invention discloses a terylene core-spun thread twisted by two or many terylene core-spun yarns composed of terylene long silk wrapped by terylene short fibers, the process method is as follow: 1) the processed long silks and the short fibers after middle and rear roller drawing are fed into a front roller. 2) the short fibers wrap the long silks in the front roller to become the terylene core-spun yarn to be output from the roller clamp, 3) two or many terylene core-sun yarns are twisted to terylene core-spun threads. The long silk tension is stabilized and controlled by godet hook and a tension disk then to be fed into the front roller after positioning by the carrier rod and the locationing guide wheel.

Owner:CHUNYAN TEXTILE GUANGDONG

Woolen sweater

InactiveCN102845849ADoes not generate static electricityHigh affinityGarmentsArtifical filament manufactureFiberHuman body

The invention discloses a woolen sweater. The woolen sweater is manufactured by blending the following components in parts by weight: 60-70 parts of wool, 5-10 parts of cashmere, 10-20 parts of artificial cotton, 10-20 parts of soybean protein fiber and 5-10 parts of composite seaweed carbon fibers. The woolen sweater is manufactured by blending the soybean protein fibers and the composite seaweed carbon fibers, is of friendliness with the skin of a human body, contains various amino acids required by the human body, and has excellent healthcare functions; and the composite seaweed carbon fiber has a function of absorbing far infrared ray, and the far infrared ray not only has an excellent heating function, but also can activate cells to discharge old or dead cells or to apply regeneration capability to old or dead cells so as to be capable of reinforcing energy of the cells, functions of the cells, activities of the cells and the like. The woolen sweater disclosed by the invention utilizes the artificial cotton so as to be smooth relative to fluffs and to be unlikely to pill, and the artificial cotton has excellent heat and electricity conductivity and does not generate static electricity so that the whole woolen sweater is unlikely to generate static electricity.

Owner:KUNSHAN CITY ZHOUSHI FEIHUANG GARMENT FACTORY

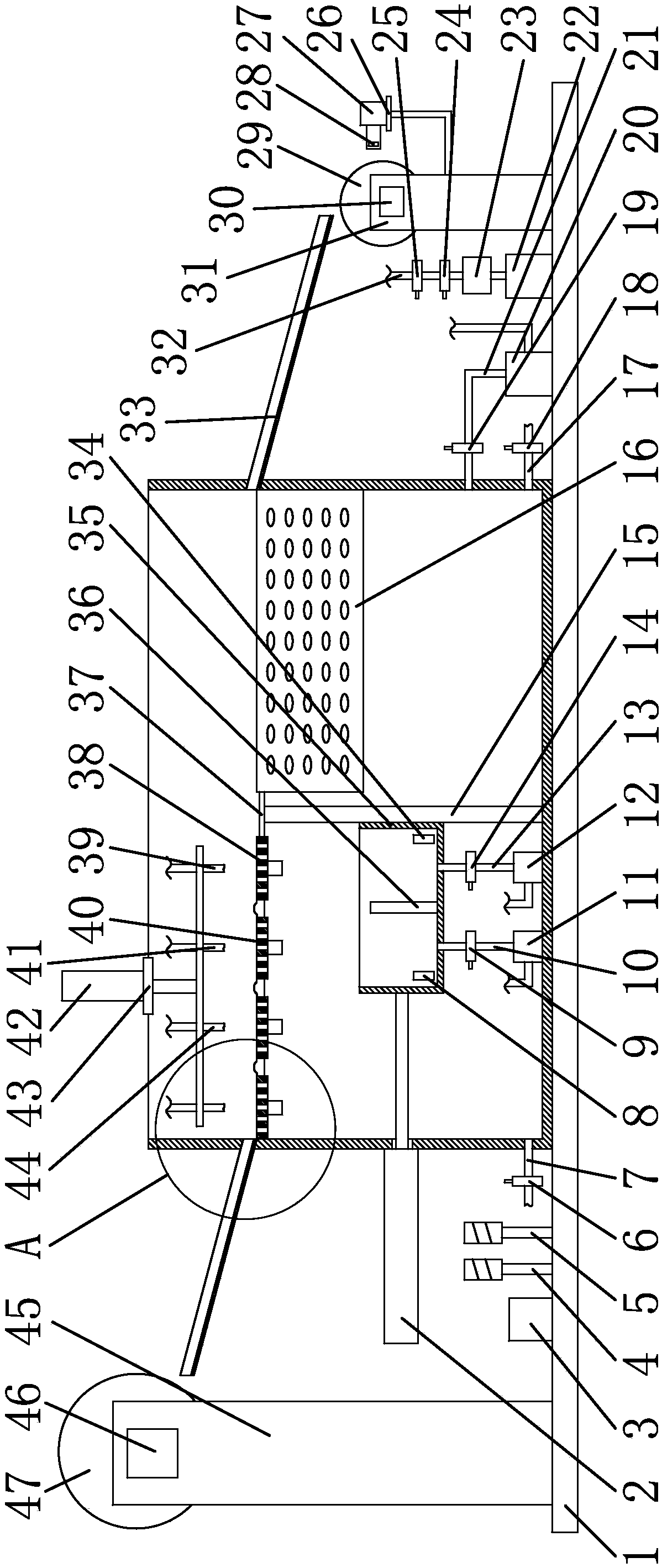

Manufacturing process of profiled, hollow, three-dimensional crimp and acrylic fibers and application thereof and dyeing and finishing process of fabric

InactiveCN105839206AReduce rigiditySoft and smoothHollow filament manufactureFilament/thread formingPolymer scienceAcrylic fibre

The invention discloses manufacturing process of profiled, hollow, three-dimensional crimp and acrylic fibers and application thereof and dyeing and finishing process of fabric and comprises the process of fiber spinning, the manufacturing process of home textile fabric by utilizing acrylic fibers as weft filaments and the process of dyeing and finishing the above fabric. The profiled, hollow, three-dimensional crimp and acrylic fibers manufactured by the invention are adopted so that rigidity of fibers is reduced and fibers feel smooth and soft. Hydrophilic groups are introduced into fibrous macromolecules such that material contact angles are reduced. Moisture makes the fiber surface wet and spreads at a quicker pace. Multiple capillaries are formed between the hollow structure of fibers and fiber assemblies of fabric so that an excellent moisture conducting system is formed and moisture conducting performance of the fabric is markedly improved. The hollow structure of fibers helps loosen fiber assemblies and contains more still air so that a unique heat preservation system is formed. Heat preservation performance of the fabric is markedly enhanced so that the fabric has the heat preservation performance and is more light-weighted.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Production technology of wool cotton dyed yarn fabric

InactiveCN104894727AEffective combinationGood hygroscopicityFibre treatmentWarping machinesYarnMoisture absorption

The invention discloses a production technology of a wool cotton dyed yarn fabric. Raw materials of the wool cotton dyed yarn fabric comprise wool cotton blended yarns of 40 counts. The production method of the wool cotton dyed yarn fabric is that cotton and wool are spun and then made into the fabric through dyeing, beaming, filament sizing, re-beaming, sectional beaming, drafting and weaving. The production technology of the wool cotton dyed yarn fabric provided by the invention is advantageous in that the wool cotton dyed yarn fabric produced in the invention effectively combines functions of a cotton fabric and a wool fabric, has better moisture absorption and air permeability, will not get wrinkled, deformed or pilling easily, feels smooth, fine and comfortable, has a soft texture, can be worn comfortably, greatly increases wearability, and has a wider sales market.

Owner:NANTONG YUEDA KNITTING GARMENT

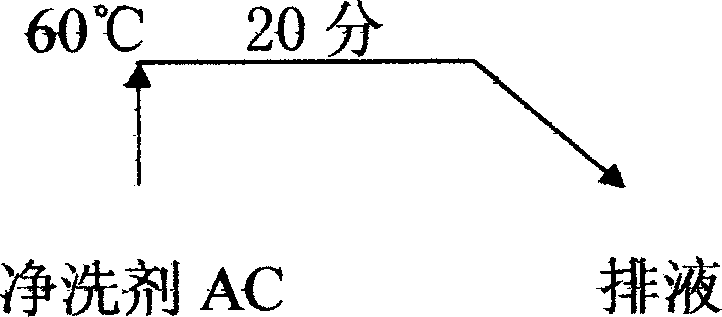

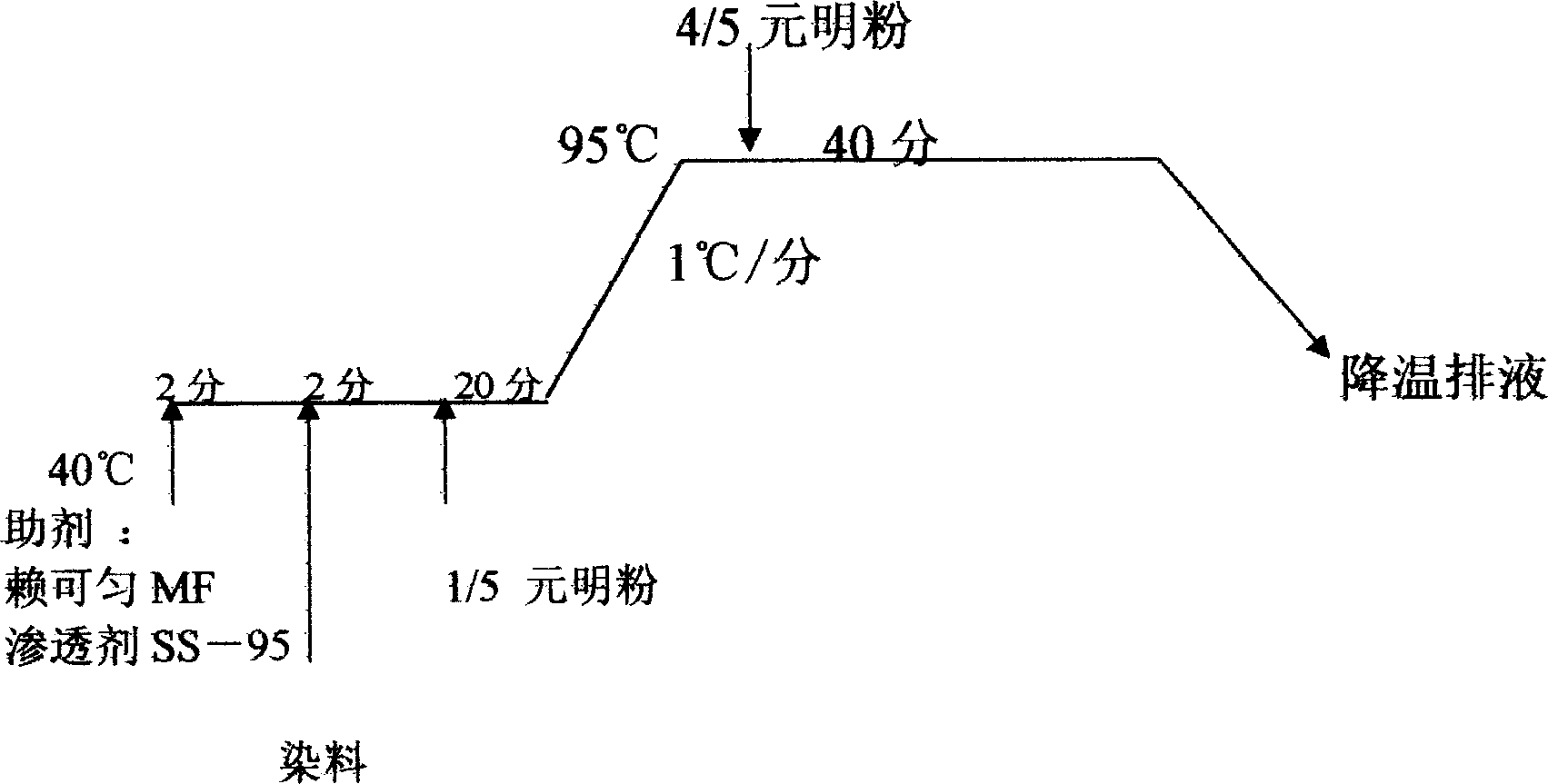

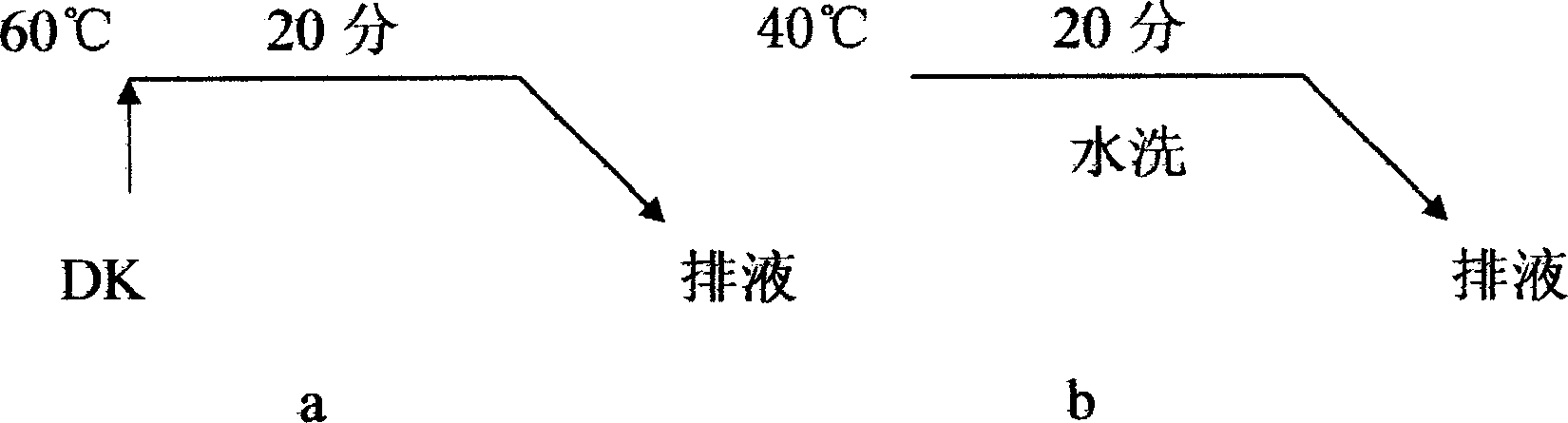

Manufacturing process of sanding cashmere sweater

The invention relates to a sand washing cashmere sweater making technology that contains the following steps: dying process: taking pre-processing, dying, adding assistant agent under 40 degree centigrade, whisking for 2 minutes, adding dye 20 minutes, heating at the speed of 1 degree centigrade per minutes, dying for 30 minutes at 95 degree centigrade, discharging; sand washing technology: dipping in positive ion and leavening agent for 25-35 minutes at 40 degree centigrade, sand washing for 15-20 minutes; inching, and adding floating stone, washing, softening, evaporating, drying. The invention has the advantages of unease balling up, strong wear resistance, etc.

Owner:INNER MONGOLIA KINGDEER CASHMERE

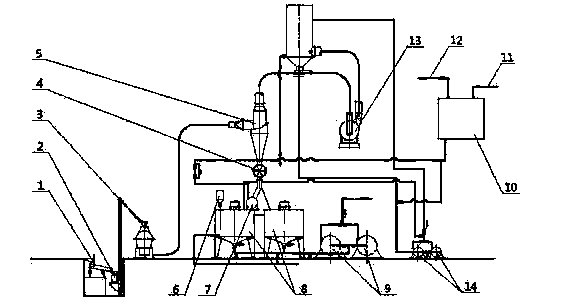

Energy saving type primary crushing apparatus

InactiveCN103418476ANot easy to pillReduce consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsThermal waterMagnet

The invention relates to an energy saving type primary crushing apparatus, which comprises a vibration sieve, a permanent magnet cylinder, a crushing device, a cyclone separator, an air closing device, a powder enzyme cylinder, an auger conveyor, a stirring tank, a powder slurry pump, an evaporator, a hot water tank, a fan and other components, and is characterized in that the vibration sieve is connected with the permanent magnet cylinder, the permanent magnet cylinder is connected with the crushing device, the crushing device is connected with the cyclone separator, the cyclone separator is communicated with the stirring tank through the air closing device and the auger conveyor, the stirring tank is further provided with the powder enzyme cylinder, and is connected with the powder slurry pump, and a steam circulation system is further arranged, comprises the evaporator, the hot water tank and the fan, and is provided for providing steam and hot water for the part of the equipment. The energy saving type crushing apparatus has advantages of energy saving, consumption reduction, good crushing quality, high cooking efficiency and the like.

Owner:乳山市日晟机械制造有限公司

Plant vehicle carpet and preparation method thereof

InactiveCN110901488AHigh mechanical strengthHigh strengthVehicle arrangementsBiotechnologyEngineering

The invention discloses a plant functional vehicle carpet and a preparation method thereof. The plant functional vehicle carpet contains plant functional polyester fibers, wherein the plant functionalpolyester fiber contains 0.1 to 1.5 percent of plant extract; wherein the plant extract is one or a combination of more of mint, valerian, lavender, wormwood and seaweed; the plant functional vehiclecarpet surface layer and the lining layer are both made of plant functional polyester fibers. The plant functional polyester filament yarn has high mechanical strength of the polyester fiber and miteand bacterium inhibiting performance of the plant extract, is good in bacterium inhibiting, deodorizing and abrasion resisting performance, has high elasticity, is not prone to pilling and contamination, does not carry static electricity or be stained with dust, and solves the problem that an existing carpet is not easy to clean. The carpet surface layer is soft and comfortable, the substrate layer is good in wear resistance, skid resistance and supporting effect, edge curling is not likely to happen, and practicability is higher.

Owner:QINGDAO YIJIAN BIOTECH CO LTD

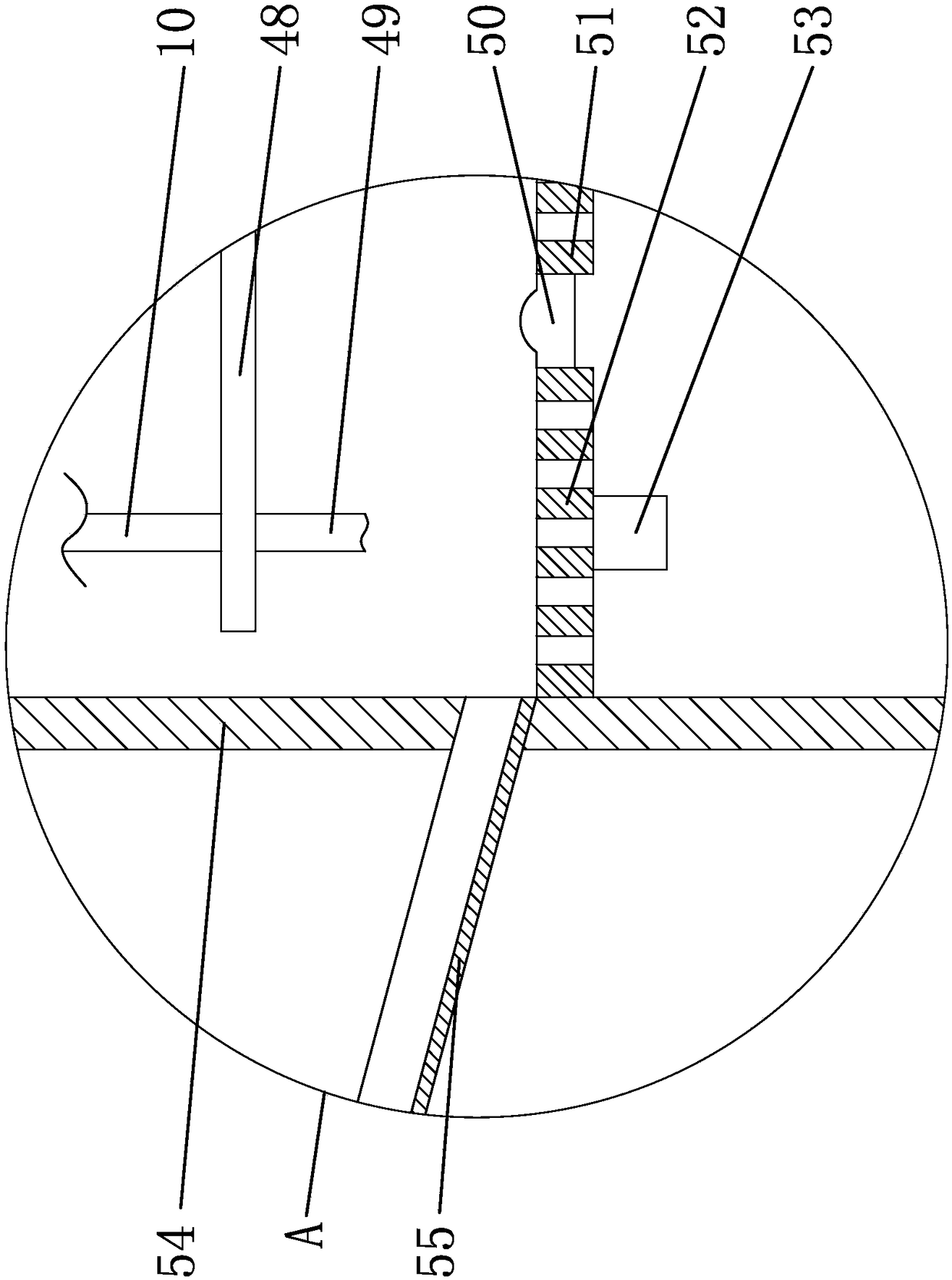

Nano antibacterial vortex spinning yarns and production technology thereof

InactiveCN108442005ASoft textureImprove comfortContinuous wound-up machinesOpen-end spinning machinesEngineeringAbnormal shaped

The invention discloses nano antibacterial vortex spinning yarns and a production technology thereof. Each nano antibacterial vortex spinning yarn comprises a yarn body, wherein the yarn body is of acore spun yarn structure and comprises core yarns and wrapping yarns; the wrapping yarns are wrapped outside the core yarns; the core yarns comprise irregular-cross-section polyester filaments, and tencil fibers and silver fibers which are located outside the irregular-cross-section polyester filaments; the surfaces of the irregular-cross-section polyester filaments are coated with a nano titaniumdioxide photocatalyst; the wrapping yarns are prepared from natural plant fibers formed by mixing soybean protein fibers and bamboo fibers. The nano antibacterial vortex spinning yarns disclosed by the invention have a soft texture, do not easily balling up and have good skin-friendly performance and air permeability; the irregular-cross-section polyester filaments are adopted and the wet permeability is good; the nano titanium dioxide photocatalyst and the silver fibers are matched so that the antibacterial performance is good; the soybean protein fibers and the bamboo fibers are provided with irregular grooves in the longitudinal direction and are matched with the irregular-cross-section polyester filaments to form a heat-dissipation and wet-conduction groove with a stereoscopic structure, so that bacterium breeding can be avoided.

Owner:SUZHOU CITY XINGJINGZE FIBER TECH CO LTD

Bamboo fiber sock and yarn forming process thereof

InactiveCN102534904ARetain breathabilityRetain antimicrobial propertiesPanty-hoseYarnYarnTextile technology

The invention discloses a bamboo fiber sock and a yarn forming process of the bamboo fiber sock, and belongs to the technical field of the bamboo fiber textile technology. Main yarns of the bamboo fiber sock are 100 percent of bamboo fiber yarns, in addition, double-yarn splicing is carried out after the single-yarn twisting, and the bamboo fiber yarns are prepared through seven steps: loosening, combing, drawing, roving, spinning, dying and spooling. The bamboo fiber sock has high bamboo fiber content, the special functions of ventilation performance, antibacterial performance, deodorization performance and the like of the bamboo fiber are preserved for the maximum degree. In addition, the bamboo fiber sock has the advantages that the pilling is not easy to occur, the intensity is good, the color is vivid, the color difference is small, and the like.

Owner:安吉县上墅针织厂

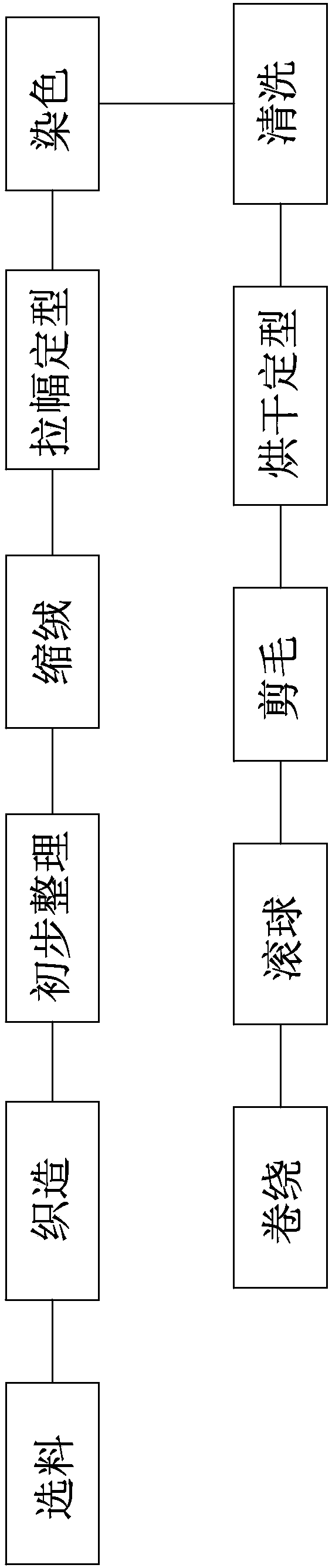

Production process of antibacterial, anti-pilling, anti-wrinkle and wear-resistant wool fabric

InactiveCN108221125AEasy to shapeAvoid deformationTextile treatment machine arrangementsStretchingPolyesterYarn

The invention provides a production process of antibacterial, anti-pilling, anti-wrinkle and wear-resistant wool fabric with an aim to solve technical problems that an existing production process is simple in process and rough in workmanship, fabric is poor in shaping, prone to deformation, free of effects of being skin-friendly, warm-keeping and non-stimulating, incapable of preventing moths, easy to pill and wrinkle, non wear-resistant, poor in function and the like. The production process includes the steps of S1, material selection, namely putting, by weight, wool fiber, cashmere fiber andpolyester fiber into a fiber mixer to obtain blended fiber, and then combing the blended fiber and making the combed blended fiber into wool tops; S2, weaving, namely making the wool tops combed in the S1 into yarn via pre-spinning, spinning, spooling, plying, double-twisting and yarn steaming and respectively taking the yarn used as warp and weft into a rapier loom for weaving to obtain the woolgray fabric. The production process has the advantage of strong functions.

Owner:孙艳

Process for producing novel antibacterial thermal home textile yarns

InactiveCN108193336ASkin-friendly and comfortableImprove yarn strengthCarbon fibresBiochemical fibre treatmentCardingCarbon fibers

The invention discloses a method for spinning and weaving novel antibacterial thermal home textile yarns. The novel antibacterial thermal home textile yarns comprise, by weight, 35%-65% of coffee carbon fibers, 15%-25% of modal fibers and 15%-25% of PTT (polytrimethylene terephthalate) fibers. The coffee carbon fibers, the modal fibers and the PTT fibers are blended to form the novel antibacterialthermal home textile yarns. The method for processing the novel antibacterial thermal home textile yarns includes working procedures of blowing, cotton carding, drawing, roving, spinning and the like. The method has the advantages that the method includes simple processes, and the novel antibacterial thermal home textile yarns can be automatically produced by the aid of the method on a large scale; the novel antibacterial thermal home textile yarns are skin-friendly, comfortable, antibacterial and thermal, and are high in yarn strength, low in hairiness and excellent in moisture absorption and breathability, pilling can be prevented, requirements of consumers in family, hotels and the like can be met, home textile fabrics woven by the aid of the method are fluffy and thermal, and accordingly the method has an excellent application prospect.

Owner:IANGSU COLLEGE OF ENG & TECH

Wear-resisting easy-to-dye cashmere composite fiber containing Bamdal fibers and preparation method thereof

InactiveCN105040145AWaterproofAntibacterial and moth-proofConjugated cellulose/protein artificial filamentsArtifical filament manufactureCarbon fibersSODIUM NAPHTHALENESULFONATE

The invention discloses a wear-resisting easy-to-dye cashmere composite fiber containing Bamdal fibers, which is prepared from following raw materials, by weight, 21-24 parts of Angora wool fibers, 15-19 parts of coconut charcoal fibers, 16-20 parts of the Bamdal fibers, 20-23 parts of long stapled cotton fiber, 14-17 parts of viscose fibers, 2.1-3.2 parts of tea saponin, 10-12 parts of ethylene glycol, 6-8 parts of polyoxyethylene oleate, 4-7 parts of 1-methoxyl-2-propanol, 2-4 parts of nano diatomite, 0.3-0.6 parts of sodium citrate, 3-5 parts of bee wax, 0.4-0.7 parts of [beta]-sodium naphthalenesulfonate, 2-3 parts of agastache rugosus, 1-4 parts of chrysanthemum, 100-110 parts of 1-ethyl-3-methylimidazole acetate, 105-110 parts of 1-allyl-3-methylimidazole chloride, 23-26 parts of additives and a proper amount of water. The cashmere composite fiber has the special functions of being wear-resisting and easy-to-dyeing, being waterproofing, being antibacterial and moth-resistant and being not liable to pill.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

Lightweight antibacterial sportswear fabric

InactiveCN102926096AGood hygroscopicityImprove smoothnessWoven fabricsYarnYarnAntibacterial property

The invention discloses a lightweight antibacterial sportswear fabric. The lightweight antibacterial sportswear fabric is weaved by warps and wefts. The warps are 40-60% of the fabric in weight; the wefts are 40-60% of the fabric in weight; the warps and the wefts are blended yarns of tencel fibers and linen fibers, wherein the tencel fibers are 40-50% of the blended yarns in weight, and the linen fibers are 50-60% of the blended yarns in weight. Therefore, the fabric has the advantages of excellent hygroscopicity, flexicity and elegant property, light weight, comfort, good toughness, antibacterial property and environmental protection and cannot pill easily.

Owner:WUJIANG HONGKAI TEXTILE

Anti-pilling finishing agent for polyester cotton garment fabric and preparing method thereof

InactiveCN105506996AImproved anti-pilling propertiesInhibit migrationAbrasion resistant fibresVegetal fibresPolyesterTherapeutic effect

The invention discloses an anti-pilling finishing agent for polyester cotton garment fabric and a preparing method thereof. The anti-pilling finishing agent is prepared from, by weight, 30-35 parts of polyester polyhydric alcohol, 20-25 parts of isophorone diisocyanate, 10-15 parts of organic tin, 16-19 parts of dihydroxy methyl propionate, 5-8 parts of N-methyl pyrrolidone, 12-15 parts of sodium hydrogen sulfite, 11-14 parts of carboxylic acid, 13-17 parts of triethylamine and 30-35 parts of deionized water. The preparing method includes the steps that polyester polyhydric alcohol is heated, dehydrated in vacuum and naturally cooled to 20 DEG C-25 DEG C, isophorone diisocyanate and organic tin are added and react with the polyester polyhydric alcohol for 1.5-2.5 h at the temperature of 60 DEG C-70 DEG C, then a solution prepared by mixing dihydroxy methyl propionate and N-methyl pyrrolidone for 5-10 min is added, and a polyurethane prepolymer containing carboxyl hydrophilic groups are prepared after reaction is conducted for 20-40 min. The anti-pilling finishing agent has an excellent anti-pilling function, the preparing process is simple, easy to operate and low in cost, a chemical method is used in the finishing process, the garment fabric is stable in performance after being treated, the treatment effect is good, the operation of finishing the garment fabric is simple, and finishing time is short.

Owner:福建省品诚环保科技有限公司

Production technology of novel antibacterial home textile fabric

The invention discloses a production technology of a novel antibacterial home textile fabric. The novel antibacterial home textile fabric is produced through interweaving of warp and weft; the patternis one of taffeta, satin and jacquard, the warp is blended yarn of graphene chinlon / viscose, and the weft is blended yarn of coconut carbon / combed cotton and wrap yarn of sliver fiber / honeycomb dacron; graphene in the graphene chinlon is added before spinning, and the adding proportion is 1-2%; the blended yarn of coconut carbon / combed cotton and the wrap yarn of sliver fiber / honeycomb dacron aresubjected to wefting insertion by the specified picking proportion of 3:1 or 4:1 to complete weaving; 2-4% of silane coupling agent is used for preprocessing the sliver fiber, obtained sliver layersare good in homogeneity and high in binding force, the coating crystal structure is complete, and the depth is 1-2 micrometers. The technology is simple, the novel home textile fabric is smooth, soft,skin-friendly, comfortable, antibacterial and warm, is not likely to pill, has good hygroscopicity and air permeability, and meets the needs of families, hotels and other consumers.

Owner:IANGSU COLLEGE OF ENG & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com