Energy saving type primary crushing apparatus

A crushing device and energy-saving technology, which is applied in the field of energy-saving primary crushing devices, can solve the problems of affecting the cooking effect, poor cooking effect, and temperature not meeting the requirements, so as to save energy consumption, improve stirring quality and cooking efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing:

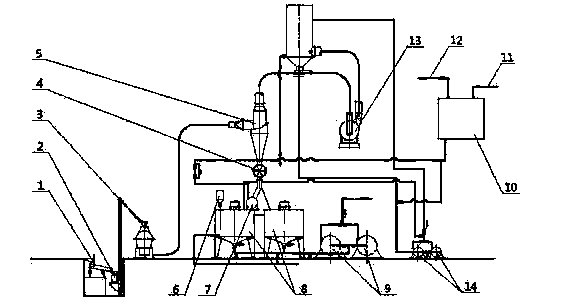

[0009] Such as figure 1 As shown, the present invention relates to an energy-saving primary crushing device, which is provided with a vibrating screen 1, a permanent magnet cylinder 2, a pulverizer 3, a cyclone separator 5, an air locker 4, a powder enzyme cylinder 6, a Jiaolong conveyor 7, Stirring tank 8, powder slurry pump 9, evaporator 14, hot water tank 10, fan 13, characterized in that: the lower end of the vibrating screen 1 leads to the upper port of the permanent magnet cylinder 2, and the lower end of the permanent magnet cylinder 2 passes through the pipeline and the pulverizer 3 are connected, the lower end of the pulverizer 3 is connected with the cyclone separator 5 through a pipeline, and the cyclone separator 5 is connected to the air closing device 4, and the air closing device 4 leads downward to one end of the Jiaolong conveyor 7, and the other end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com