Anti-pilling finishing agent for polyester cotton garment fabric and preparing method thereof

An anti-pilling and finishing agent technology, applied in the direction of wear-resistant fibers, plant fibers, etc., can solve the problems of easy pilling on the surface of the fabric, affecting the color and light strength of the hand, affecting the appearance and comfort, and avoiding fiber migration , not easy to pilling, improve the effect of anti-pilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

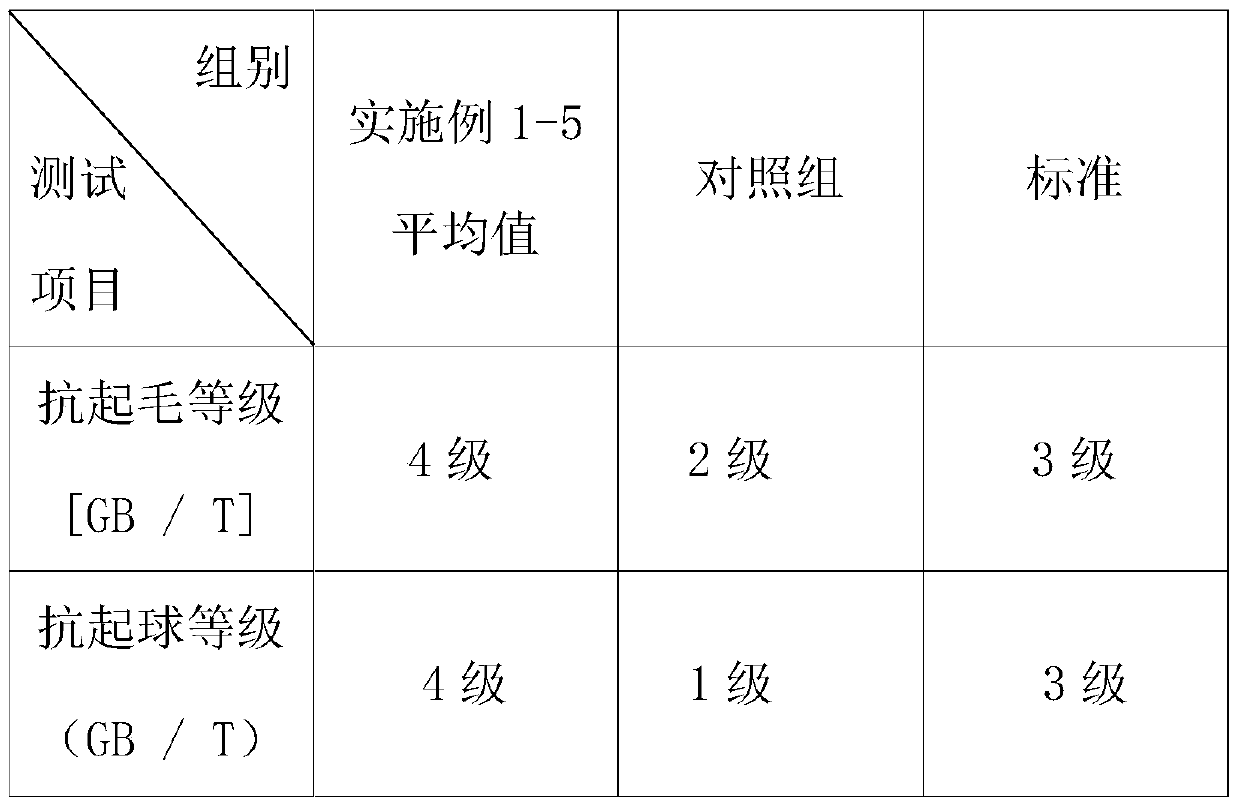

Examples

Embodiment 1

[0017] A kind of anti-pilling finishing agent for polyester-cotton clothing fabric proposed by the present invention, its raw material comprises by weight: 30 parts of polypolyol, 20 parts of isophorone diisocyanate, 10 parts of organotin, dihydroxyformaldehyde 16 parts of propionic acid, 5 parts of N-methylpyrrolidone, 12 parts of sodium bisulfite, 11 parts of carboxylic acid, 13 parts of triethylamine, and 30 parts of deionized water.

[0018] The present invention also proposes a kind of anti-pilling preparation method for polyester-cotton garment fabric, and its preparation method is as follows:

[0019] S1: Heat the polypolyol to vacuum dehydrate and cool it naturally to 20°C, then add isophorone diisocyanate and organotin to react at 60°C for 1.5 hours, then add dimethylolpropionic acid and N-methylpyrrolidone to mix The solution prepared after 5 minutes, reacted after 20 minutes, made the polyurethane prepolymer containing carboxyl hydrophilic group;

[0020] S2: Mix s...

Embodiment 2

[0023] A kind of anti-pilling finishing agent for polyester-cotton garment fabric proposed by the present invention, its raw material comprises by weight: polypolyol 31 parts, isophorone diisocyanate 21 parts, organotin 11 parts, dihydroxyformaldehyde 17 parts of propionic acid, 6 parts of N-methylpyrrolidone, 13 parts of sodium bisulfite, 12 parts of carboxylic acid, 14 parts of triethylamine, and 31 parts of deionized water.

[0024] The present invention also proposes a kind of anti-pilling preparation method for polyester-cotton garment fabric, and its preparation method is as follows:

[0025] S1: Heat the polypolyol to vacuum dehydrate and cool it naturally to 21°C, then add isophorone diisocyanate and organotin to react at 62°C for 1.7 hours, then add dimethylolpropionic acid and N-methylpyrrolidone to mix The solution prepared after 6 minutes, reacted after 22 minutes, made the polyurethane prepolymer containing carboxyl hydrophilic group;

[0026] S2: Mix sodium bisu...

Embodiment 3

[0029] A kind of anti-pilling finishing agent for polyester-cotton garment fabric proposed by the present invention, its raw material comprises by weight: polypolyol 32 parts, isophorone diisocyanate 22 parts, organotin 12 parts, dihydroxyformaldehyde 18 parts of propionic acid, 7 parts of N-methylpyrrolidone, 14 parts of sodium bisulfite, 13 parts of carboxylic acid, 15 parts of triethylamine, and 32 parts of deionized water.

[0030] The present invention also proposes a kind of anti-pilling preparation method for polyester-cotton garment fabric, and its preparation method is as follows:

[0031] S1: Heat the polypolyol and vacuum dehydrate it, cool it naturally to 22°C, then add isophorone diisocyanate and organotin to react at 64°C for 1.9 hours, then add dimethylolpropionic acid and N-methylpyrrolidone to mix The solution obtained after 7 minutes reacted after 24 minutes to obtain a polyurethane prepolymer containing carboxyl hydrophilic groups;

[0032] S2: Mix sodium b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com