Method for improving yarn evenness of spun yarns based on circular yarn path

A yarn path and spun yarn technology, applied in spinning machines, textiles, papermaking, drafting equipment, etc., can solve problems such as high fixed costs and start-up costs, high processing precision requirements, and difficult industrialization promotion, etc. Improved drying unevenness, improved anti-pilling performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

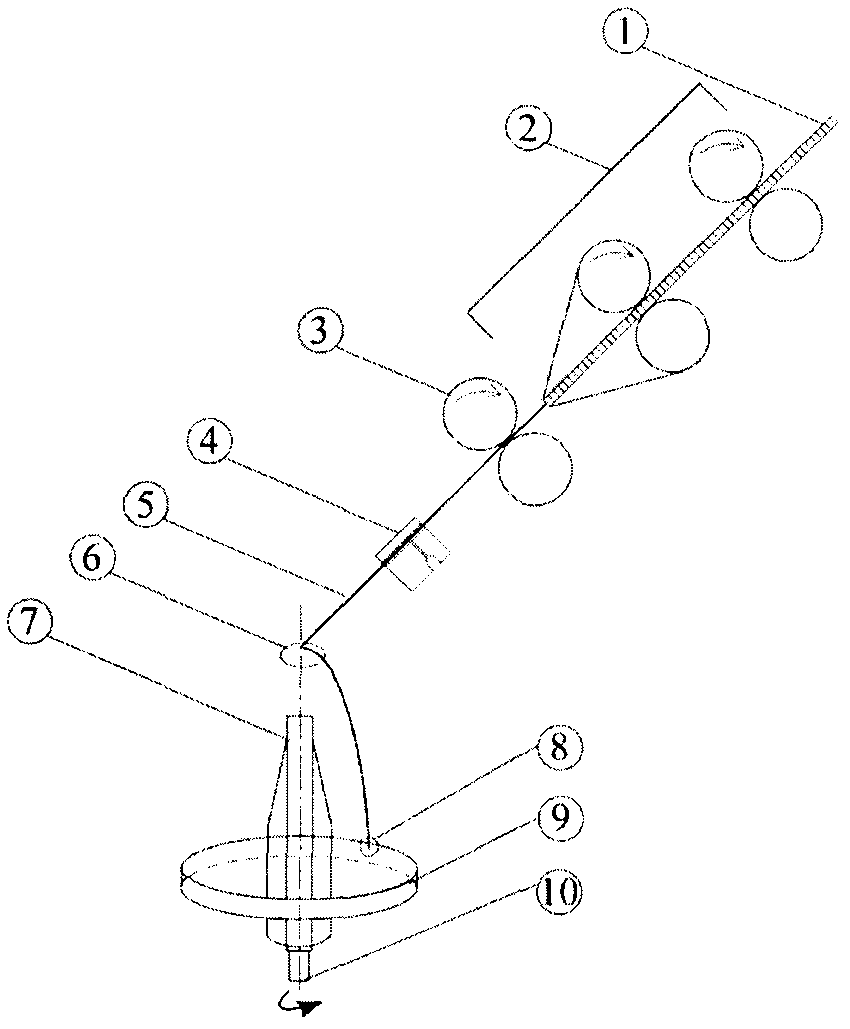

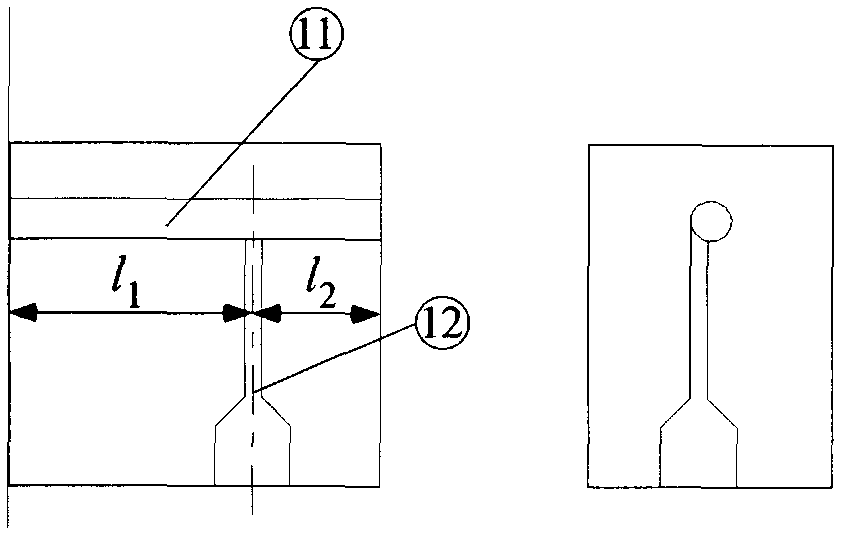

[0011] Raw material: pure cotton yarn with a basis weight of 4.495g / 10m. The spinning process conditions are: the pressure (gauge pressure) at the inlet of the vortex nozzle air passage is 0.15MPa, the distance from the axis of the vortex nozzle air passage to the output roller is 8.5cm; the spindle speed is 10000rpm. The diameter of the nozzle air passage d 1 is 1.0mm; the cross-sectional diameter of the yarn path is 2.4mm, and the length of the yarn path is 16mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com