Patents

Literature

251 results about "SODIUM NAPHTHALENESULFONATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medicament for treating composite water in hot water boiler as well as preparation method and use method thereof

ActiveCN103183417ADoes not reduce corrosion inhibitionWill not reduce the effect of anti-scalingScale removal and water softeningInorganic phosphatePhosphoric acid

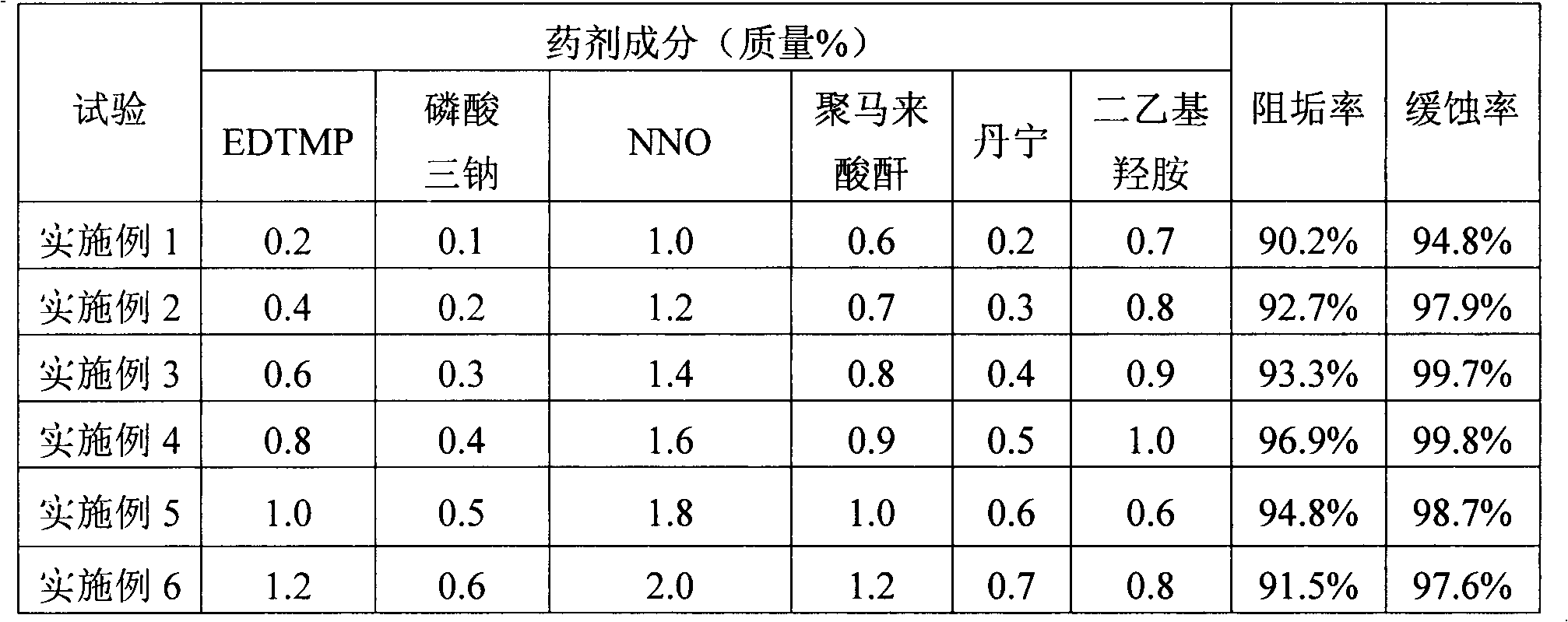

The invention discloses a medicament for treating composite water in a hot water boiler. The medicament comprises the following components by mass percent: 0.1-3% of inorganic phosphate, 0.1-2% of organic phosphoric acid and / or organic phosphate, 0.1-4% of component A, 0.1-3% of component B, 0.6-1.0% of organic amine deoxidizer, 0.1-2% of tannin and / or chitosan and the balance of water, wherein the mass percent of the components is 100%, the component A is one or more of an organic antisludging agent, an organic dispersant and an organic dispersible antisludging agent, and the component B is one or more of an organic carboxylic acid corrosion inhibitor, an organic carboxylate corrosion inhibitor and sodium methylene dinaphthalenesulfonate. The invention further discloses a preparation method and a use method of the medicament, the preparation process is clean, and the medicament is low in toxicity for body health and environment in the using process. The medicament is excellent in corrosion resistance and scale inhibition effects and simple and convenient to store and transport, and the corrosion and scale inhibition effects cannot be reduced after the medicament is stored and transported for a long term.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

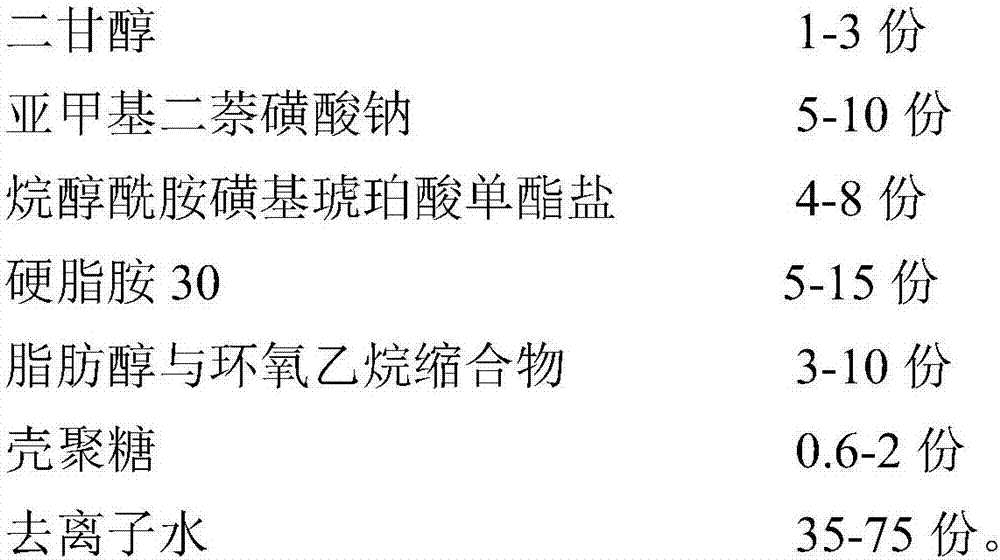

Method for producing nano-cement, and nano-cement

ActiveUS9505659B2Improve construction and technical propertyLow costMaterial nanotechnologyCement grindingPolymer modifiedCALCIUM CATION

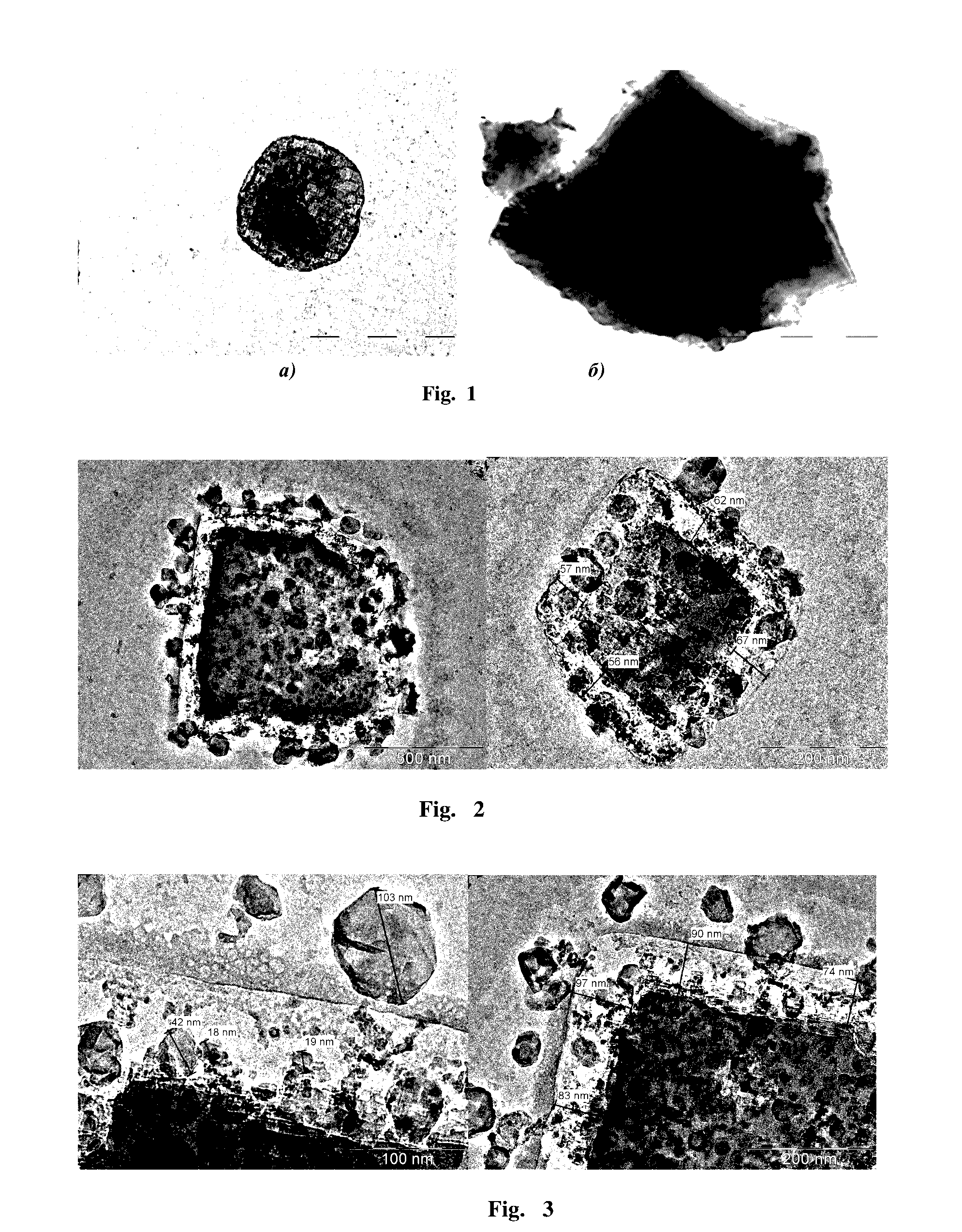

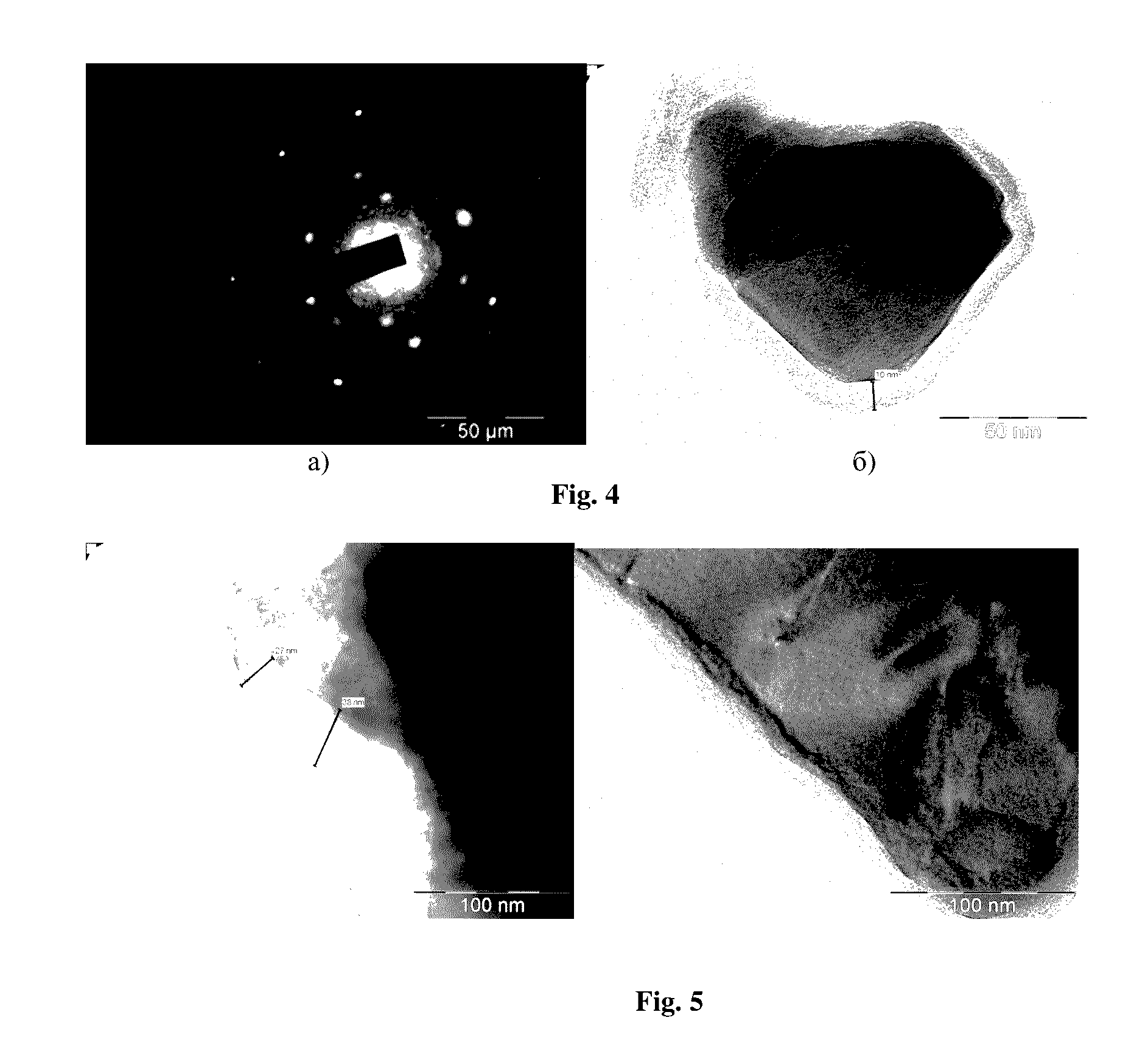

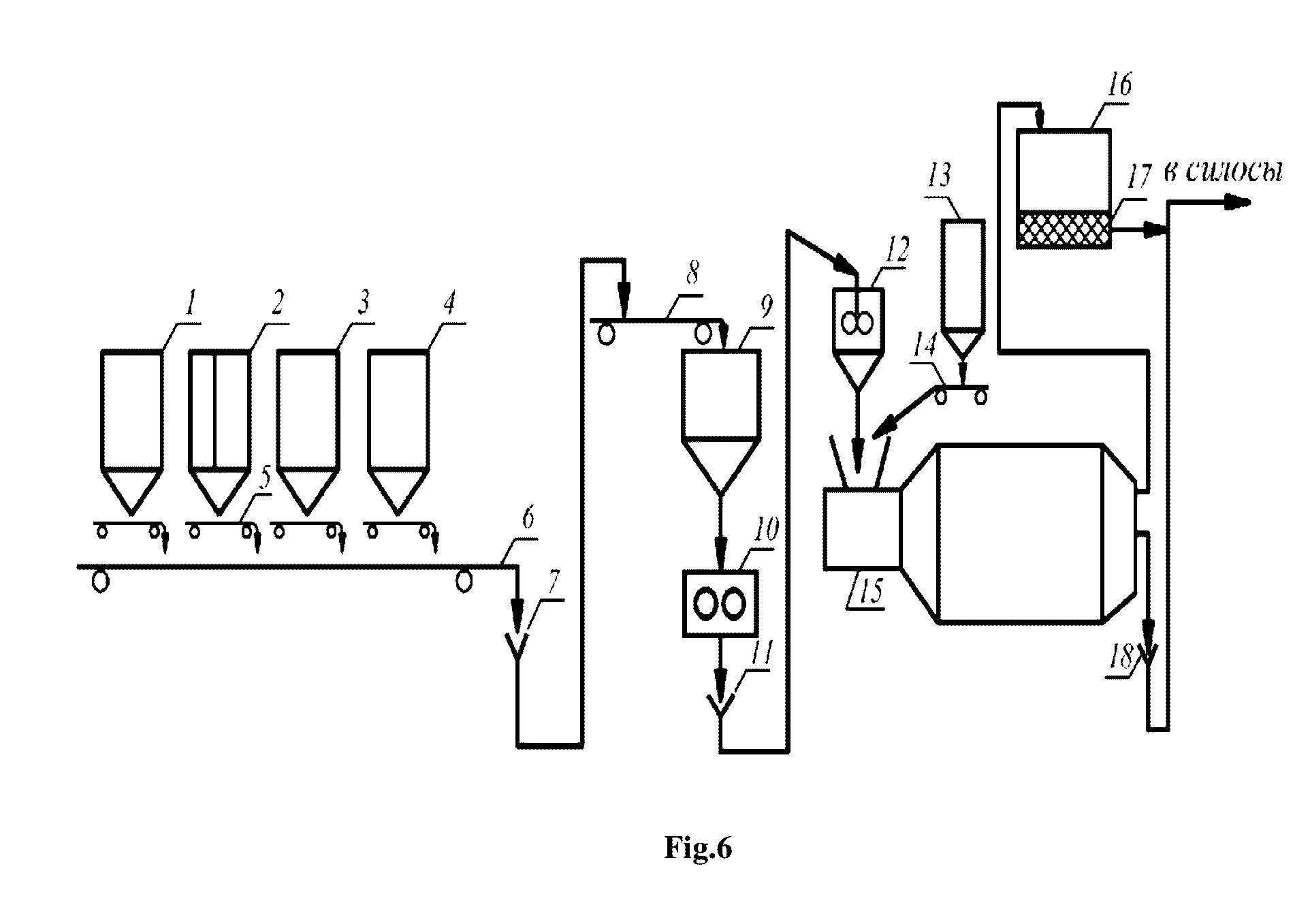

The invention is related to nanocement production methods by modifying Portland cement, as well as to nanocement compositions. The nanocement production method involves a mechanochemical activation of dispersed grains of Portland cement in the presence of polymeric modifier, with the sodium naphthalenesulfonate content of at least 60 wt %, mineral siliceous additive containing at least 30 wt % SiO2 and gypsum, to form continuous nanoshells—capsules of 20-100 nm in thickness on Portland cement grains made of sodium naphthalenesulfonate structured by calcium cations.

Owner:BICKBAU MARSEL YANOVICH

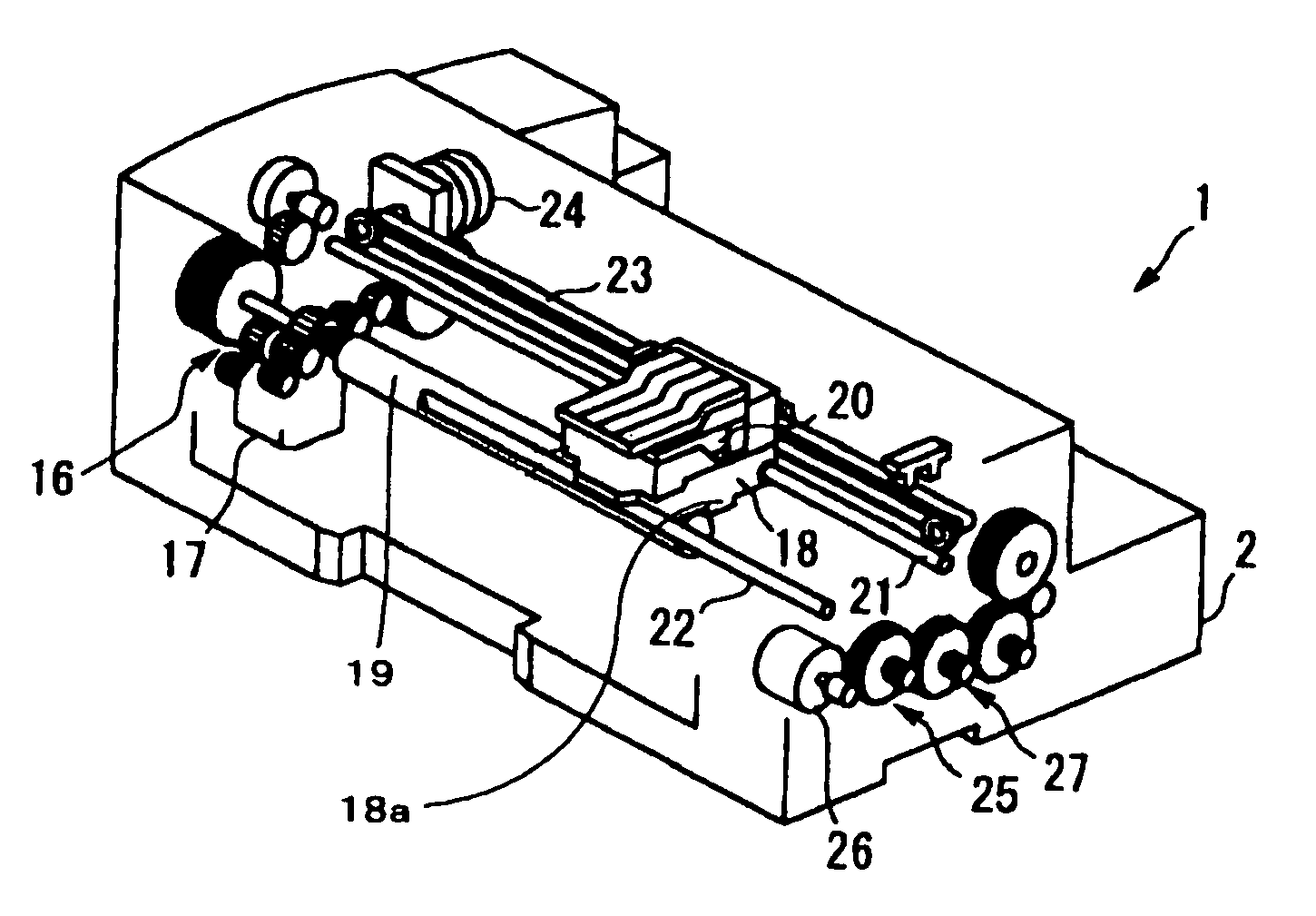

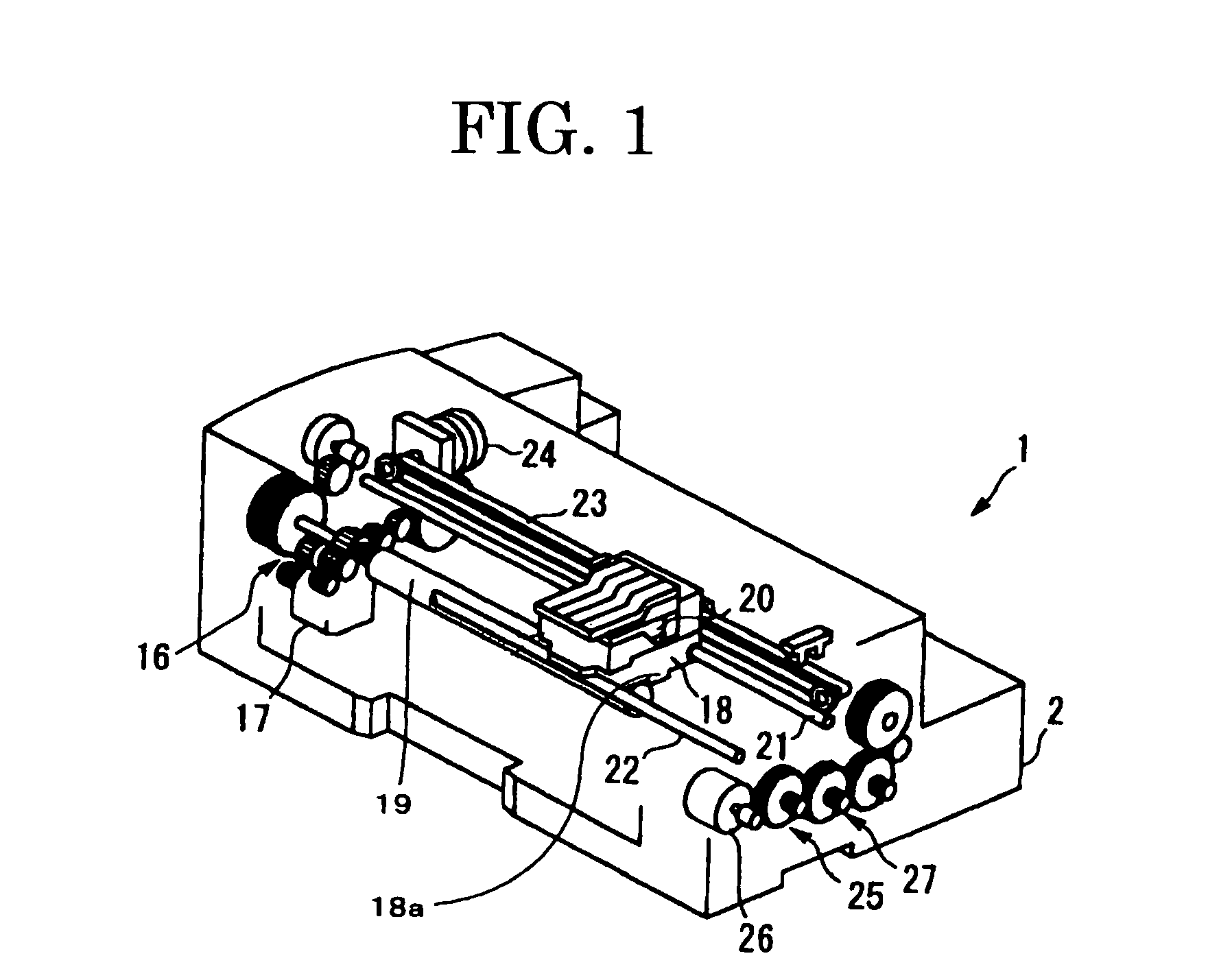

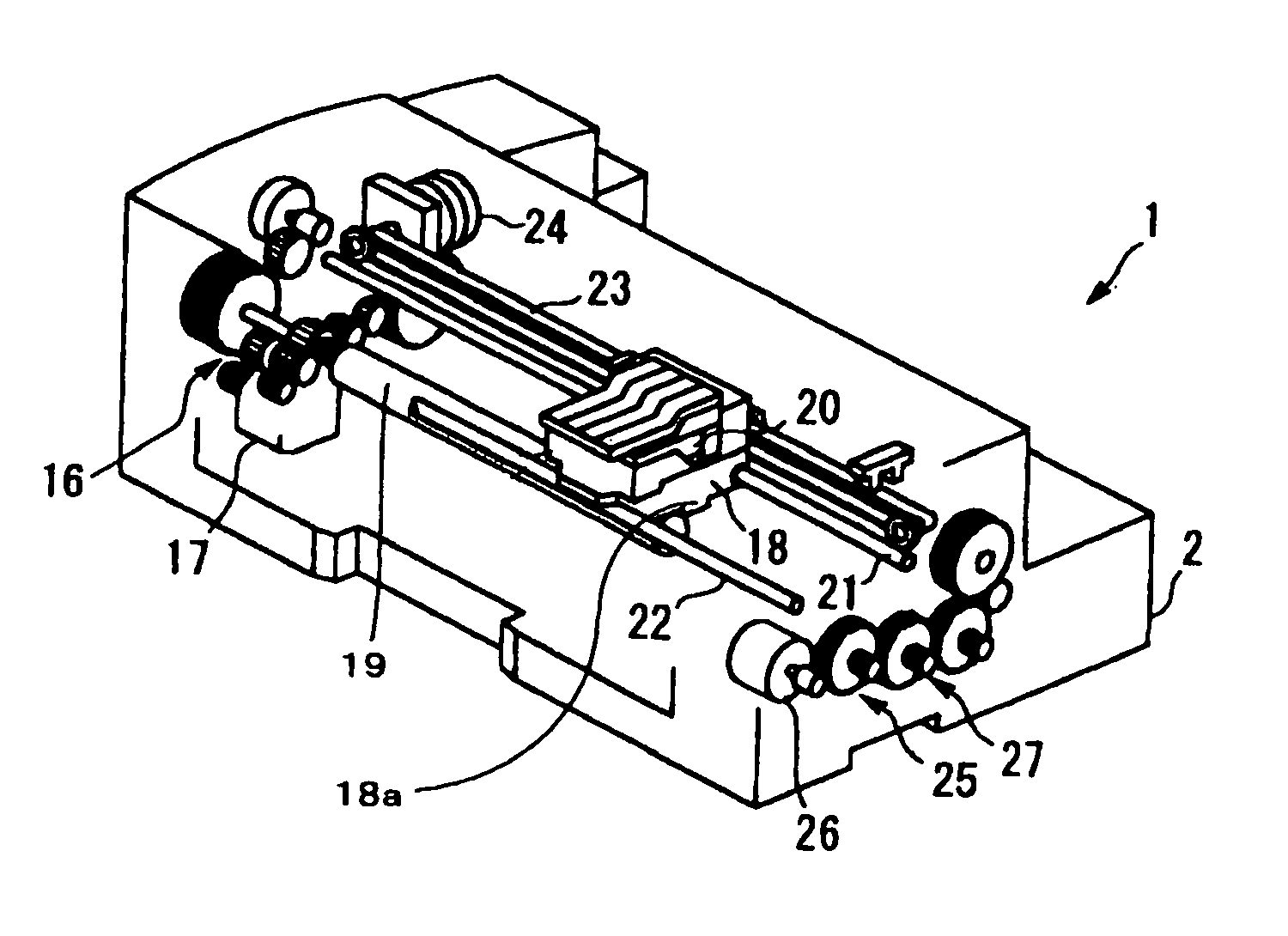

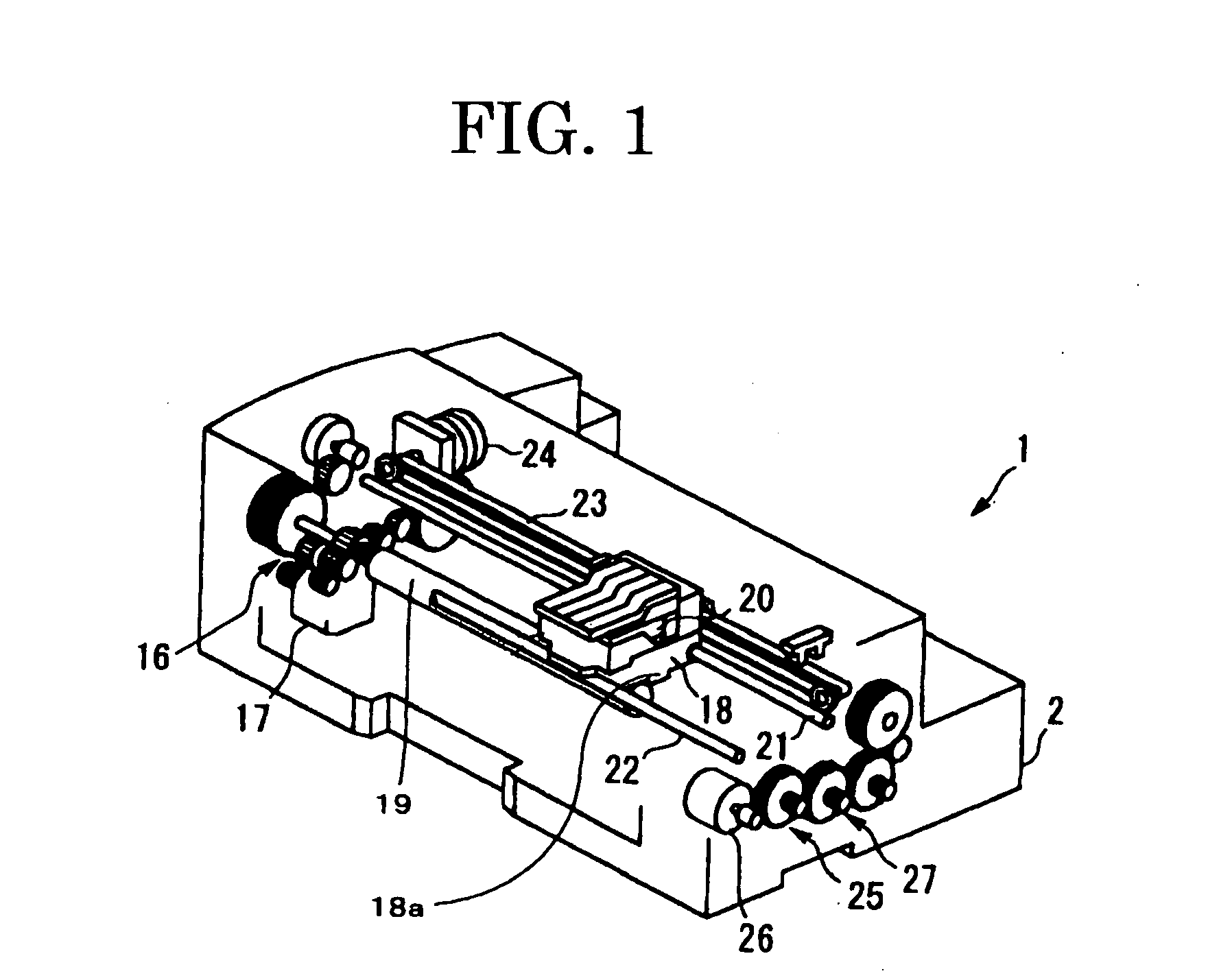

Inkjet recording ink and image forming method

ActiveUS8474963B2Realizes both shelf-stability and image qualityInhibition of attachmentMeasurement apparatus componentsDuplicating/marking methodsEmulsionSODIUM NAPHTHALENESULFONATE

An inkjet recording ink which includes: a carbon black; a dispersant, wherein the dispersant is a sodium naphthalenesulfonate-formalin condensate; resin emulsion; and water, in which the resin emulsion contains a resin which is at least one of a urethane resin and a styrene-acryl resin, and the ink satisfies the following relationship: 20≦B−A≦50, where A(nm) represents a particle diameter D90 of particles contained in dispersion containing the carbon black, the dispersant, and water, which is before added with the resin emulsion, and B(nm) represents a particle diameter D90 of particles contained in the ink.

Owner:RICOH KK

Urea-formaldehyde foam plant cultivation substrate and method for preparing the same

ActiveCN101134803ANo residueReasonable content of ingredientsAgriculture gas emission reductionCultivating equipmentsPhosphoric acidUrea formaldehyde foam

The present invention discloses one kind of urea-formaldehyde foam as plant cultivating matrix and its preparation process. The urea-formaldehyde foam as plant cultivating matrix is prepared through the following steps: 1. mixing formaldehyde and urea to produce polycondensation reaction to obtain urea-formaldehyde resin solution; 2. mixing sodium butyl naphthalenesulfonate to obtain foaming liquid; 3. foaming the urea-formaldehyde resin solution with the foaming liquid in a foaming machine to obtain liquid foam; 4. solidifying the liquid foam and drying to operate foamed matrix; and 5. eliminating aldehyde group from the matrix to obtain urea-formaldehyde foam as plant cultivating matrix. The preparation process is simple and low in cost, and the prepared urea-formaldehyde foam as plant cultivating matrix has penetrating porous structure, high hydroscopicity and high soil-less culturing character.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Pigment dispersion, inkjet-ink using the pigment dispersion, image forming process, and image forming apparatus

ActiveUS7798629B2High densityGood storage stabilityPigmenting treatmentMeasurement apparatus componentsPigment dispersionSODIUM NAPHTHALENESULFONATE

Owner:RICOH KK

Manufacture method for autoclaved fly-ash aerated concrete block

ActiveCN105130324AReduce manufacturing costImprove adhesionSolid waste managementCeramicwarePolyvinyl alcoholAluminium hydroxide

The invention relates to a manufacture method for an autoclaved fly-ash aerated concrete block, and belongs to the field of building materials. The method comprises performing granulation and sintering on a waste fly-ash aerated block, fly ash, quicklime, desulfurized gypsum, waste concrete, crushed waste glass and water glass, so as to obtain an aggregate C; and then preparing a mixed slurry from a non ferrous metal slag powder, cement, quicklime, the aggregate C, desulfurized gypsum, an efficient foaming agent, an efficient mortar thickening powder, sodium poly[(naphthaleneformaldehyde)sulfonate], polyvinyl alcohol, aluminium hydroxide and water, pouring into a die for molding, and performing autoclave curing, so as to obtain the target product. The method consumes a large amount of solid wastes, and the building block firm in bonding, good in impermeability and low in shrinkage value, and quality disadvantages such as peeling, cracking and the like of a built wall are overcome. By adding the aggregate C with high strength and light weight, the autoclaved fly-ash aerated concrete block is improved in structure, improved in limit load and compressive strength, and high in thermal-insulation performance. The efficient foaming agent is capable of forming stable foams, and is large in foaming amount and high in foaming multiple.

Owner:铜陵铜冠建安新型环保建材科技有限公司

Bacillus subtilis PTS-394 for preventing and controlling soil-borne diseases of solanaceous fruit vegetables and application thereof

ActiveCN102550607AReduce dosageResidue reductionBiocideFungicidesBiotechnologyEcological environment

The invention relates to a biocontrol bacterial agent. An effective active constituent consists of bacillus subtilis PTS-394. The biocontrol bacterial agent is characterized in that: the biocontrol bacterial agent is aqueous solution or wettable powder. The aqueous solution comprises the following components in percentage by weight: bacillus subtilis PTS-394 with 2 *1,010 cfu / mL of content of bacteria, 0.5 percent of NNO (sodium methylene naphthalene sulfonate), 6 percent of SDBS (sodium dodecyl benzene sulfonate) and 0.1 percent of sodium benzoate. The wettable powder comprises the following components in percentage by weight: 40 percent of bacillus subtilis PTS-394 viable bacterium raw powder with 5 *1,010 cfu / g of content of bacteria, 7 percent of NNO (sodium methylene naphthalene sulfonate), 3 percent of polyethylene glycol, 5 percent of SDBS (sodium dodecyl benzene sulfonate) and 45 percent of light calcium carbonate. The biocontrol bacterial agent is poured into vegetable roots when applied and is used for preventing and controlling vegetable soil-borne diseases such as solanaceous fruit vegetable blight and bacterial wilt mainly; and the content of effective agent components is between 104 and 108 cfu / mL or between 104 and 108 cfu / g after finished product agents are diluted. The biocontrol bacterial agent has the advantages that: the aims of preventing and controlling two kinds of soil-borne diseases by means of one kind of biocontrol bacterial agent are fulfilled by introducing the bacillus subtilis PTS-394 which is safe to people and livestock and has better inhibition effect on the solanaceous fruit vegetable blight and the bacterial wilt; the using amount of chemical agents is reduced, and the agent cost is reduced; and the ecological environment is improved, and the residues of the chemical agents in the vegetables are reduced and the same time.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

4-hydroxy-4'isopropoxydiphenyl sulfone temperature-sensitive developer dispersion liquid and transparent temperature-sensitive record material

ActiveCN103072396AFine particleImprove heat sensitivityDuplicating/marking methodsImaging qualitySODIUM NAPHTHALENESULFONATE

The invention relates to a 4-hydroxy-4'isopropoxydiphenyl sulfone temperature-sensitive developer dispersion liquid and a transparent temperature-sensitive record material, the dispersion liquid can be obtained by performing wet type crushing on 4-hydroxy-4'isopropoxydiphenyl sulfone temperature-sensitive developer through existence of a dispersion protective agent, the dispersion protective agent selects from sodium naphthalenesulfonate, relative to 100 mass fraction of temperature-sensitive developer, the dispersion protective agent is 0.05-2 mass parts; the average particle size of the temperature-sensitive developer after dispersing is 0.2-0.8 micrometers, and the particle size distribution is less than 15%. The dispersion liquid has good stability, and can effectively solves the problem that the temperature-sensitive developer enables easy hydration effect generation to generate crystallization in the processes of grinding and storing, and the industrialization period production requirement can be satisfied; the temperature-sensitive record material has fine particles, high temperature-sensitive degree, low haze and good transparency, and the image quality can satisfy the medical diagnosis requirement.

Owner:BAODING LUCKY FILM

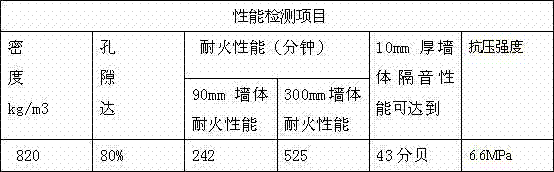

Oil shale residue aerated brick and preparation method thereof

ActiveCN102875184AGood heat insulationImprove sound insulationSolid waste managementCeramicwareCelluloseCalcium bicarbonate

The invention provides an oil shale residue aerated brick. The oil shale residue aerated brick is prepared from the following raw materials: 20 to 30 weight parts of oil shale residue, 25 to 30 weight parts of coal ash, 5 to 10 weight parts of cement, 4 to 6 weight parts of modified attapulgite, 5 to 10 weight parts of mica powder, 5 to 10 weight parts of ceramics factory waste, 5 to 10 weight parts of calcium carbonate powder, 10 to 15 weight parts of lime, 0.1 to 0.3 weight percent of triethanolamine lime, 4 to 5 weight parts of gypsum, 0.02 to 0.08 weight part of aluminum powder, nekal which is 3 to 5 percent based on weight of aluminum powder, 0.01 to 0.02 weight part of calcium bicarbonate, 2 to 3 weight parts of volcanic rock, 1 to 2 weight parts of lignocellulose, 0.3 to 0.5 weight part of soda ash, 0.03 to 0.05 weight part of borax, 1 to 2 weight parts of sodium diacetate, 1 to 2 weight parts of hydroxypropyl methyl cellulose sodium, and 1 to 2 weight parts of superfine polyvinyl alcohol. The oil shale residues are added into the raw materials of the aerated brick, other conventional aids and modified nano aids are added, and the aerated brick which is processed by an appropriate process is low in cost and high in performance, achieves the cyclic economy effect of changing waste into wealth, and reduces pollution; and the processed aerated brick has the characteristics of light volume weight, high thermal insulation property, good sound absorption effect, and high intensity and can be used for a non-load bearing wall body or a load-bearing wall body.

Owner:深圳市嘉能新型环保建材有限公司

Pigment dispersion, inkjet-ink using the pigment dispersion, image forming process, and image forming apparatus

ActiveUS20080036840A1High density imageGood storage stabilityPigmenting treatmentMeasurement apparatus componentsPigment dispersionSODIUM NAPHTHALENESULFONATE

The present invention provides a pigment dispersion that contains a carbon black, a dispersing agent and water, wherein the carbon black is any one of a channel black and a gas black, the dispersing agent is a sodium naphthalenesulfonate formalin condensate, and the total content of a dimer, a trimer and a tetramer of naphthalenesulfonate in the sodium naphthalenesulfonate formalin condensate is 20% by weight to 80% by weight. The present invention also provides an inkjet ink using the pigment dispersion.

Owner:RICOH KK

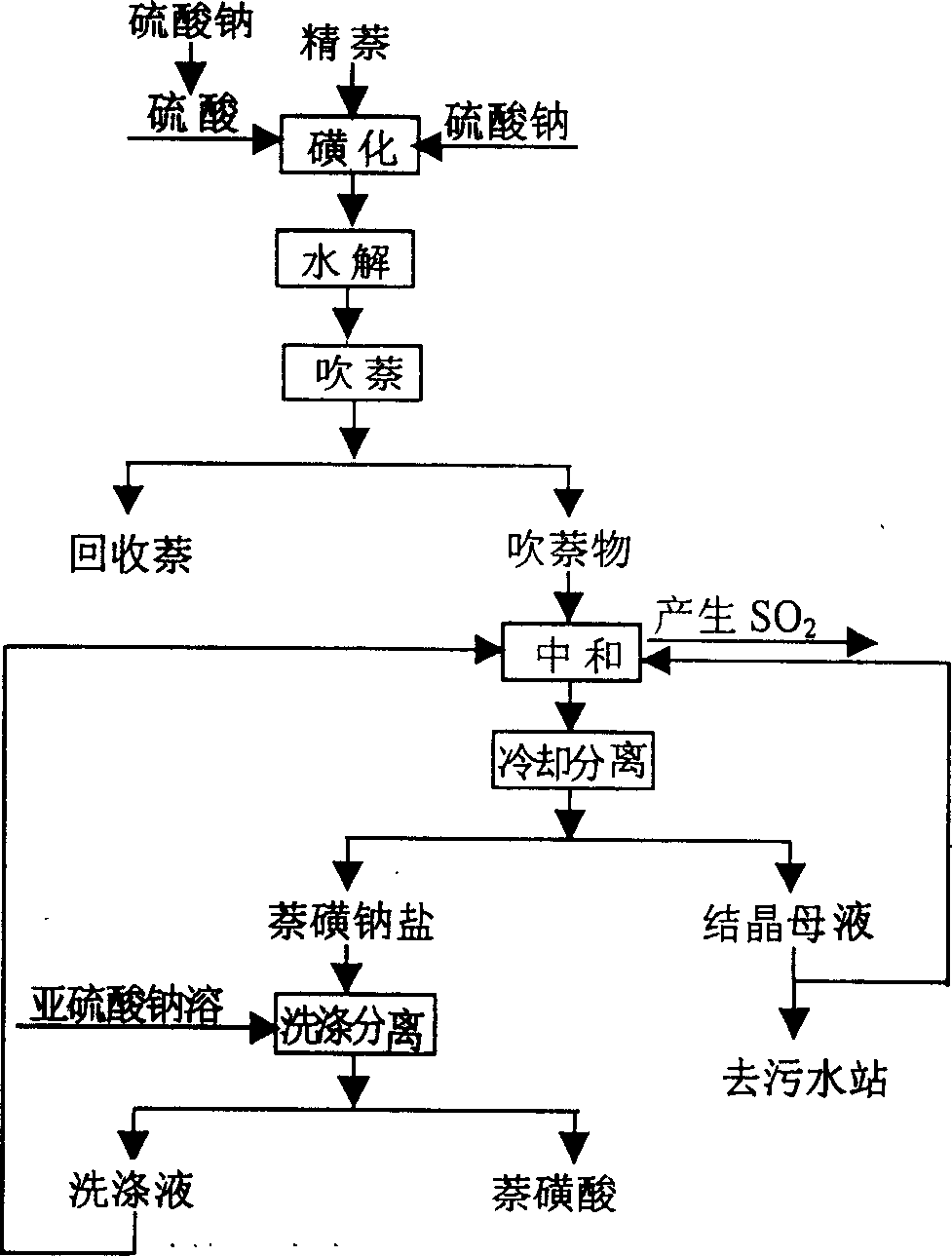

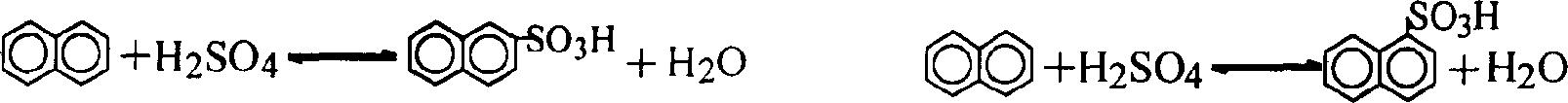

Method for preparing mononaphthalenesulfonic acid and sodium salt of mononaphthalenesulfonic acid

InactiveCN1958567APromote absorptionHigh selectivitySulfonic acids salts preparationSulfonic acid preparationChlorosulfuric acidSODIUM NAPHTHALENESULFONATE

This invention discloses a method for synthesizing 1-naphthalene sulfonic acid and / or sodium 1-naphthalene sulfonate. The method comprises: (1) dissolving naphthalene in solvent, adding appropriate 1-naphthalene sulfonic acid seed crystals, cooling to 0 minus or plus 5 deg.C, stirring, dropping chlorosulfonic acid within 1-2 h, and keeping at -2-8 deg.C for 1.5-3 h; (2) cooling to 0 minus or plus 2 deg.C, and filtering to obtain the filter cake of 1-naphthalene sulfonic acid; (3) washing the filtrate with water, phase-separating to obtain the solvent and water scrubbing acid (for producing high-performance naphthalene water reducer); (4) neutralizing 1-naphthalene sulfonic acid and the solvent with 5-15% NaOH, keeping at 90 minus or plus 5 deg.C for 10-30 min, phase-separating the neutralization solution to obtain sodium 1-naphthalene sulfonate aqueous solution, cooling to lower than 35 deg.C, crystallizing, filtering to obtain the filter cake of sodium 1-naphthalene sulfonate, and utilizing the filtrate to prepare NaOH solution. The method has such advantages as high sulfonation selectivity, low product isomer content, easy operation and no wastewater.

Owner:江苏华达化工集团有限公司

Multifunctional environment protection metal degreasing derusting rust-proofing liquid

InactiveCN101082128ANo pollutionCause flammabilityMetallic material coating processesSodium bicarbonateThiourea

The functional environment friendly metal deoiling, derusting and antirusting fluid is prepared with polyoxyethylene alkyl ether, sodium dodecyl sulfate, 1.3-dibutyl thiourea, hexamethylidyene tetraamine, zinc dihydrogene phosphate, phosphoric acid, sodium butylnaphthalene sulfonate, sodium sulfosuccinate, triethanolamine, sodium bicarbonate, tartaric acid and 1.3-diethyl sulfourea in certain weight proportion, and through dissolving, diluting with water, mixing to react, and filtering. It has the synergistic effect of the components to deoil, derust, phosphorize, deactivate and antirust metal surface, no harm to human body and no environmental pollution.

Owner:彭文表

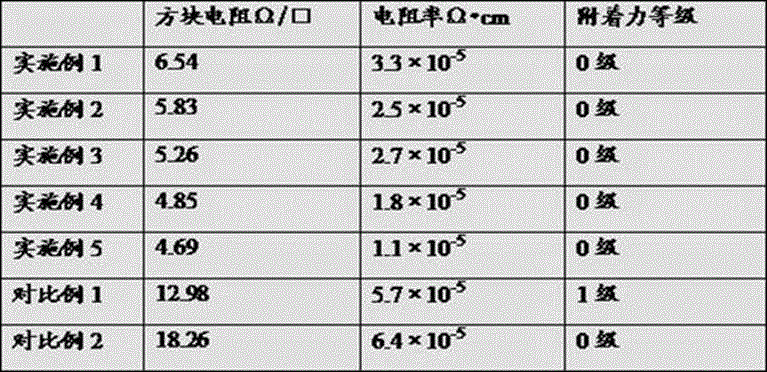

Low-silver copper-base conductive ink and preparation method thereof

The invention discloses a low-silver copper-base conductive ink and a preparation method thereof. The conductive ink is prepared from the following components in parts by weight: nano copper wires, silver nitrate, indium powder, titanium dioxide powder, bismuth tungstate powder, 500-mesh tourmaline powder acidified carbon fibers, an epoxy resin, sodium hypophosphite, trimethylamine borane, polyoxypropylene glycerol ether, diphenyl phosphite, ethylene bis stearamide, sodium methylene bis-naphthalene sulfonate, polydimethylsiloxane, dipropylene glycol, isopropanol and acetone. The conductive ink has low silver content, thereby greatly lowering the manufacturing and use cost; the conductive ink has the advantages of favorable conductivity and favorable adhesive force, and thus, can be widely used in solar electromagnetic devices, thin film switches, flexible printed circuits and other electronic devices; and therefore, the conductive ink has huge use and application values.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

Urea formaldehyde foam matrix for cultivating cold-season turfgrass and preparation method thereof

InactiveCN101798437AThe method of establishment is simple and convenientImprove water absorption and retention capacityAgriculture gas emission reductionCultivating equipmentsCold seasonPhosphate

The invention discloses a urea formaldehyde foam matrix for cultivating cold-season turfgrass and a preparation method thereof. The method comprises the following steps that: (1) formaldehyde and urea are mixed to carry out polycondensation reaction, and urea-formaldehyde resin solution is prepared; (2) butyl naphthalene sulfonate, phosphate and water are mixed, and blister fluid is prepared; (3) the blister fluid and the urea-formaldehyde resin solution are foamed in a foaming machine, and liquid foam is prepared; (4) the liquid foam is cured and dried, and a foam matrix is prepared; and (5) aldehyde removal agent, hydrophilizing agent and potassium are dissolved into the water to prepare a mixture, the mixture is sprayed on the surface of the foam matrix and dried, and the urea formaldehyde foam matrix for cultivating cold-season turfgrass is prepared. The matrix is characterized in that water absorption and preservation properties are good, and releasing nitrogen nutrient and nutrition elements required by the growth of other turf are contained. When being used to turf establishment, the matrix not only can be used for turf production on a cultivated land and then paved on other lands, but also can be directly used for turf establishment, and has significant economic, social and ecological benefits.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Building internal wall coating and preparation method thereof

InactiveCN106995628AImprove adsorption capacityEfficient removalAntifouling/underwater paintsPaints with biocidesCellulosePolyvinyl alcohol

The invention discloses building internal wall coating and a preparation method thereof. The building internal wall coating is prepared from the following raw material components in parts by mass: 3 percent to 5 percent of an active component of the building internal wall coating, 1 percent to 2 percent of an adsorbent diatomite, 1 percent to 2 percent of an adhesive polyvinyl alcohol, 0.5 percent to 1 percent of a dispersant cellulose, 0.5 percent to 1 percent of a stabilizer, 70 percent to 80 percent of film-forming emulsion and 9 percent to 24 percent of water; the preparation method of the building internal wall coating comprises the following steps: putting all the components into a reaction kettle according to a ratio; grinding and stirring to obtain the uniformly mixed building internal wall coating. The active component of the building internal wall coating is a composite material prepared from titanium dioxide, hafnium oxide, zinc oxide, graphene oxide, sodium naphthalenesulfonate and glucose and is synthesized through a chemical method. The building internal wall coating disclosed by the invention has functions of removing formaldehyde, sterilizing and removing odor, resisting radiation and resisting ageing and an indoor air pollution and management problem is solved.

Owner:南京市雨花台区绿宝工业设计服务中心

Lubricant for cold forging and cold extruding and preparation method and using method thereof

InactiveCN107523386AStrong environmental protectionEasy to useLubricant compositionPolyethylene glycolTalc

The invention discloses a lubricant for cold forging and cold extruding and a preparation method and a using method thereof. The lubricant comprises distilled water, sodium carboxymethylcellulose, sodium polyacrylate, polymethacrylate, mica powder, talc powder, boron nitride, zinc stearate, sodium stearate, alkyl sodium sulfonate, diglycol, triethanolamine, polyvinylpyrrolidone, vinyl triethoxy silane, polyisobutene, polyethylene glycol, nonyl phenol polyoxyethylene ether, an ethylene-vinyl acetate copolymer, an alkaline silica sol, sodium silicate, a styrene-acrylic emulsion, oxalate, vulcanized fat, alkylated aromatic amine and sodium methylenedinaphthalene. The lubricant disclosed by the invention can adsorb a uniform plastic film formed on the surface of a workpiece, so that the workpiece and a mold are isolated by the lubricating film all the way, and the lubricant is good in environmental friendliness and convenient to use, can replace a phosphorizing-saponifying treatment process, and is a non-graphite high molecular lubricant suitable for cold forging and cold extruding forming of metals or nonferrous metals.

Owner:QINGDAO YUANDA GRAPHITE

Coal burning catalyst as well as preparation and use method thereof

InactiveCN103103006ASave raw materialsReduce manufacturing costOrganic-compounds/hydrides/coordination-complexes catalystsSolid fuelsPtru catalystHexamethylenetetramine

The invention discloses a coal burning catalyst as well as a preparation and a use method thereof, which belong to the energy conservation and emission reduction field of catalytic combustion of the coal. The catalyst comprises the following raw materials in parts by weight: 326-472 parts of water, 202-292 parts of ferrous chloride, 125-181 parts of potassium chloride, 77-111 parts of calcium chloride, 48-69 parts of urotropin, 19-27 parts of tourmaline powder, 18-26 parts of fumed silica, 15-21 parts of octaphenyl polyoxyethyiene, 15-21 parts of sodium dodecyl benzene sulfonate, and 11-16 parts of methylene-naphthalene sulfonate. When the coal burning catalyst is used, the catalyst is diluted with water actively processed via the tourmaline powder, and then uniformly sprayed on the coal. The catalyst disclosed by the invention has the beneficial effects of low material price, no any safety hidden trouble, good stability and convenience for use. After the activating treatment carried out via the tourmaline powder, the effect of the catalyst is further improved, and the coal-saving effect and the sulfur fixation effect are obvious; and at the same time, the coking accidents of boilers can be prevented.

Owner:URUMQI SAIMENGDE ENVIRONMENTAL PROTECTION TECH

Raw material dry state proportion for rubber latex for producing ultrathin condom and formulating vulcanization process thereof

The invention relates to a dried material ratio of rubber latex for producing ultra-thin condoms and a sulfuration technology for preparing the rubber latex. The dried weight ratios are respectively as follows: 1.20 portions of sulfur, 0.70 portion of ZnO, 0.40 portion of zinc diethyl dithiocarbamate, 1.00 portion of 2, 6-bis-tert buty-4-methyl phenol, 0.08 portion of KOH, 0.25 portion of fatty alcohol polyoxyethylene (20) ether, 0.05 portion of sodium hexametaphosphate, 0.10 portion of sodium methylene dinaphthyl sulphonate, 100.00 portions of natural rubber and 3.00 portions to 5.00 portions of modified rubber latex. The sulfuration technology comprises 10 steps and can be used for the preparation of the rubber latex for producing the ultra-thin condoms. The rubber latex can be used for the production of ultra-thin and ultra ultra-thin condom products with the thickness of about 0.050mm. Under the premise of guaranteeing the strength quality and meeting the national and international standards, the products have excellent comfortableness when in use, can realize effective contraception and also more effectively prevent the spread of diseases, such as AIDS, gonorrhea and chancroid and the like.

Owner:QINGDAO DOUBLE BUTTERFLY GROUP

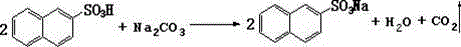

2-naphthalenesulfonic acid, sodium naphthalene sulfonate and preparation thereof

InactiveCN101372466AImprove conversion rateReduce salt contentSulfonic acid preparationSulfonateSulfite salt

The invention relates to 2-naphthalene sulfonic acid, 2-sodium naphthalene sulfonate and a preparation technology thereof. The technical proposal is as follows: naphthalene and a little amount of anhydrous sodium sulfate are added to a reactor containing sulfuric acid with the concentration of 98% according to the mol ratio of the naphthalene to sulfuric acid being 1:0.1-0.5, and heated while stirring until the naphthalene and the anhydrous sodium sulfate are completely dissolved; SO3 gas is fed into the reactor within 1-3h for sulfonation reaction at the temperature of 120-180 DEG C; and then at the temperature of 150-180 DEG C, the naphthalene and the SO3 in the mixture obtained from the sulfonation reaction are blown away by compressed nitrogen gas when the mixture is stirred, so as to prepare the 2-naphthalene sulfonic acid. In addition, the prepared 2-naphthalene sulfonic acid can be added to a neutralization pot, and sodium sulfite solution with the concentration of 5%-15% which is preheated to 80-90 DEG C is added to the neutralization pot by a measuring tank, so the 2-naphthalene sulfonic acid and sodium sulfite solution can have neutralization reaction; crystallization and separation are carried out to obtain the 2-sodium naphthalene sulfonate. The preparation technology has the advantages of full utilization of the existing resources, high naphthalene conversion rate, good product quality, little environmental pollution, low cost and high economic benefits.

Owner:WUHAN UNIV OF SCI & TECH

High-effective concrete compound additive and its production method

InactiveCN1394824ASolve the difficulty of productionAdjustment (shorten or delay the initial and final setting timeSulfonateMaterials science

The composition of high-efficiency composite additive for concrete is formed from (wt%) triethanolamine 10-50, sodium metnylene bis-naphthalene sulfonate 20-50, bone glue 4-8, tartaric acid 10-20, rosin 3-6, stearic and 8-10 and water 105-210. Said invention is low in cost, small in addition quantity, easy to transport and store and convenient for operation and construction, and said additive can resist the corrosion action of preembedded metal, can improve plasticity and workability of concrete, can greatly reduce water gain and segregation and can make poured concrete more homogeneous and compact, etc.

Owner:左正才

Foaming insulation board and manufacturing method thereof

InactiveCN104250090AImprove insulation effectHigh compressive strengthCeramicwareThermal insulationSODIUM NAPHTHALENESULFONATE

The invention belongs to a foaming insulation board used for building industry, and relates to a foaming insulation board made by industrial waste residue and a manufacturing method thereof. The foaming insulation board comprises the following raw materials by weight ratio: slag powder, desulfurized gypsum, fly ash, quicklime, cement, polypropylene fiber, hydrogen peroxide, water glass, disodium methylene dinaphthalenesulfonate, a water reducer, a waterproof agent and water. The method comprises the following steps: placing the raw materials according to ratio in a mixer for stirring and mixing, casting in a die, and solidifying and performing wet and heat maintenance to obtain the foaming insulation board. The foaming insulation board mainly employs industrial waste residue, and has the advantages of energy saving and environmental protection, good thermal insulation performance, high compressive strength, low production cost and simple process.

Owner:湖北中明乾汇新材料科技有限公司

Deep well resistance-reducing packing

InactiveCN102324260AReduce the amount of waterGood water workabilityNon-metal conductorsConductive materialMeth-Polyvinyl alcohol

The invention discloses a deep well resistance-reducing packing which mainly comprises the following components in parts by weight: 10-50 parts of conducting materials, 10-50 parts of curing agent, 0.5-25 parts of leavening agent and 0.1-10 parts of retarding agent, wherein the conducting material is selected from one or more of sodium salts, potassium chloride, calcium chloride and graphite; the curing agent is selected from one or more of polyvinyl alcohol, aluminosilicate (kaolin), sodium silicate, calcium sulfate and cement; the leavening agent is selected from one of polyacrylamide and bentonite; and the retarding agent is selected from one of sodium methylenebisnaphthalenesulfonate and peregal. The deep well resistance-reducing packing has the advantages of saving of 15-30 percent of water quantity, good peaceability with water, no demixing and convenience for site configuration and construction: in addition, no demixing is caused, the solidifying time is prolonged and the flowability and the permeability are enhanced, therefore, no bridging phenomenon is caused during pouring, resistance reduction efficiency is increased, the quantity of deep wells is reduced, and the construction cost is reduced.

Owner:SICHUAN SUNLIGHT INTELLIGENT ELECTRIC EQUIP CO LTD

Improved process for preparing 2-sodium naphthalenesulfonate in production of beta-naphthol

InactiveCN1557807AReduce processing costsHigh yieldSulfonic acids salts preparationSODIUM NAPHTHALENESULFONATEWastewater

The present invention is one improved sodium beta-naphthalenesulfonate in ethyl naphthol producing process. During refined naphthalene sulfonating process, one kind of assistant is added to raise the sulfuric acid utilization to 50-65 %, raise the naphthalene sulfonating rate, lower the total acidity of the sulfonated matter, reduce the amount of generated neutralizing mother liquid, reduce the loss of sodium naphthalenesulfonate, raise product quality and yield, raise ethyl naphthol yield, reduce effluent and lower production cost. The said technology of the present invention may be used in available ethyl naphthol producing apparatus without needing significant altering.

Owner:李阳

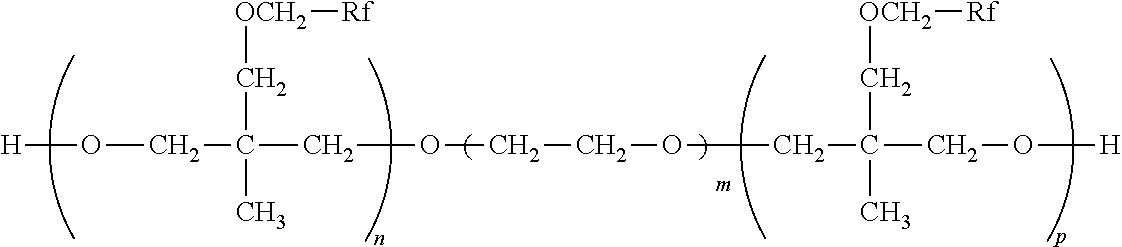

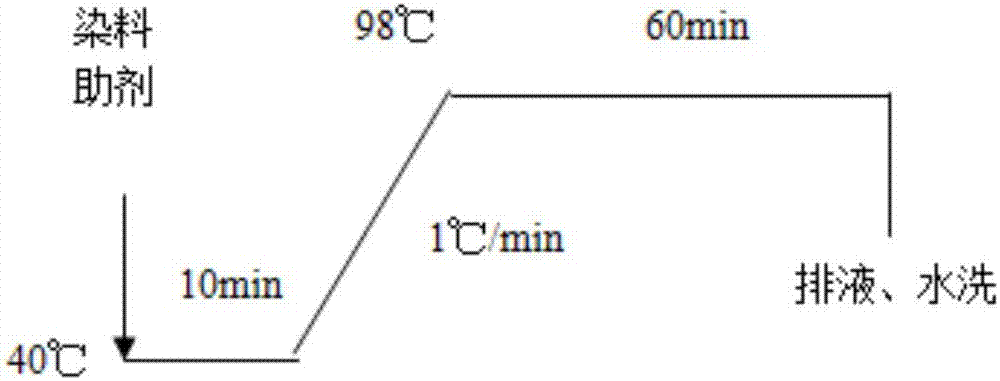

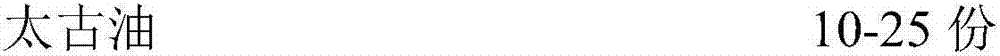

Wool-chinlon leveling agent and preparation method thereof

ActiveCN107268302ALower dyeing temperatureNo stain blocking effectDyeing processDispersityEthylene oxide

The invention discloses a wool-chinlon leveling agent. The wool-chinlon leveling agent is prepared from the following raw materials in parts by weight: 10-25 parts of Turker red oil, 1-3 parts of diglycol, 5-10 parts of disodium methylene dinaphthalenesulfonate, 4-8 parts of alkanolamide sulfosuccinate monoester salt, 5-15 parts of stearyl amine 30, 3-10 parts of fatty alcohol and ethylene oxide condensation compound, 0.6-2 parts of chitosan and 35-75 parts of deionized water. The wool-chinlon leveling agent does not contain substances of alkylphenol polyoxyethylene, organic halides and the like, is easily dissolved into water, can resist acid, alkali and hard water, is low-foam and convenient to use; and meanwhile, the wool-chinlon leveling agent has excellent dispersity, dye retarding property, leveling property and stability, the dye fastness can be increased, and dyed wool or chinlon has bright and uniform colors and is flexible and comfortable.

Owner:JIANGSU NEW REBA TECH CO LTD

Wear-resisting easy-to-dye cashmere composite fiber containing Bamdal fibers and preparation method thereof

InactiveCN105040145AWaterproofAntibacterial and moth-proofConjugated cellulose/protein artificial filamentsArtifical filament manufactureCarbon fibersSODIUM NAPHTHALENESULFONATE

The invention discloses a wear-resisting easy-to-dye cashmere composite fiber containing Bamdal fibers, which is prepared from following raw materials, by weight, 21-24 parts of Angora wool fibers, 15-19 parts of coconut charcoal fibers, 16-20 parts of the Bamdal fibers, 20-23 parts of long stapled cotton fiber, 14-17 parts of viscose fibers, 2.1-3.2 parts of tea saponin, 10-12 parts of ethylene glycol, 6-8 parts of polyoxyethylene oleate, 4-7 parts of 1-methoxyl-2-propanol, 2-4 parts of nano diatomite, 0.3-0.6 parts of sodium citrate, 3-5 parts of bee wax, 0.4-0.7 parts of [beta]-sodium naphthalenesulfonate, 2-3 parts of agastache rugosus, 1-4 parts of chrysanthemum, 100-110 parts of 1-ethyl-3-methylimidazole acetate, 105-110 parts of 1-allyl-3-methylimidazole chloride, 23-26 parts of additives and a proper amount of water. The cashmere composite fiber has the special functions of being wear-resisting and easy-to-dyeing, being waterproofing, being antibacterial and moth-resistant and being not liable to pill.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

C. medinalis granulovirus bacillus thuringiensis bio-pesticide and preparation method thereof

ActiveCN103355350AImprove the effect of prevention and controlShorten the time to deathBiocideAnimal repellantsBacillus thuringiensisSODIUM NAPHTHALENESULFONATE

The invention discloses a C. medinalis granulovirus bacillus thuringiensis bio-pesticide and a preparation method thereof. Main components of the bio-pesticide are C. medinalis granulovirus and bacillus thuringiensis, wherein the content of the C. medinalis granulovirus is 1.0*10<4>-1.0*10<8>OB / mg, and the titer of bacillus thuringiensis is 16000IU / mg. The bio-pesticide is prepared by using bio-pesticide, bacillus thuringiensis, lignin sodium sulfonate, methylene naphthalene sulfonate, and kaolin according to a certain ratio. The bio-pesticide provided by the invention has the advantages of wide insecticidal spectrum, fast effect, good product stability, safety to environment, human and livestock, and no residue. The method has the advantages of simple process and convenient operation. With the bio-pesticide, occurrence and harm of C. medinalis can be effectively controlled. The bio-pesticide can be applied with large amount on paddy rice, especially on pollution-free rice and organic rice.

Owner:扬州绿源生物化工有限公司

Alkali slag concrete water reducing agent

The invention discloses an alkali slag concrete water reducing agent which comprises following components, by mass: 11-23 parts of nitrates, 15-25 parts of a [beta]-naphthalenesulfonate-formaldehyde condensate, 3-5 parts of a lignosulfonate and 1-2 parts of a dodecyl benzene sulfonate. An alkali slag concrete is a WG-slag concrete and herein the WG represents for water glass; the [beta]-naphthalenesulfonate-formaldehyde condensate is [beta]-sodium naphthalenesulfonate-formaldehyde condensate; the lignosulfonate is calcium lignosulfonate; the dodecyl benzene sulfonate is sodium dodecyl benzene sulfonate; and the nitrates is a mixture composed of 1-3 parts of barium nitrate and 10-20 parts of lead nitrate. The water reducing agent can account for more than 20% of the WG-slag concrete, is good in adaptation with the WG-slag concrete, can effectively reduce an initial viscosity of newly-mixed WG-slag concrete, can improve a flowability and a workability of the concrete, can reduce a usage amount of the WG-slag concrete and can enhance the strength of the concrete.

Owner:重庆富普新材料有限公司

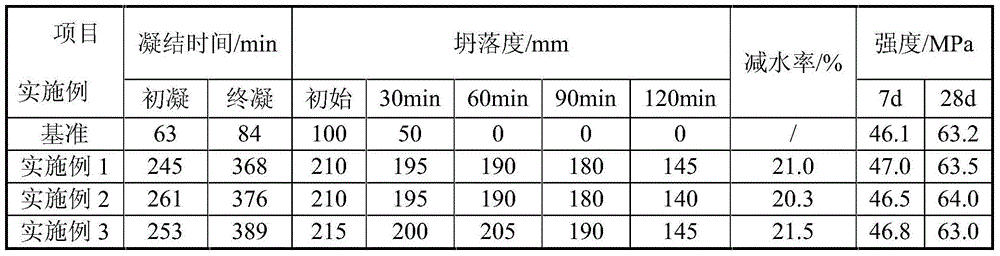

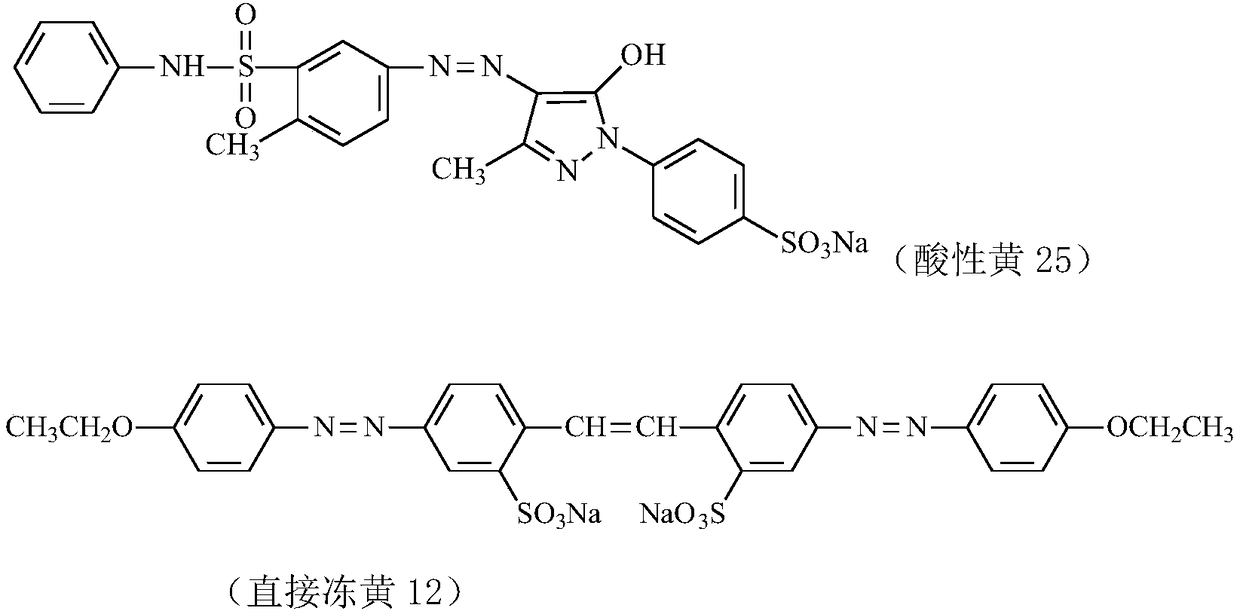

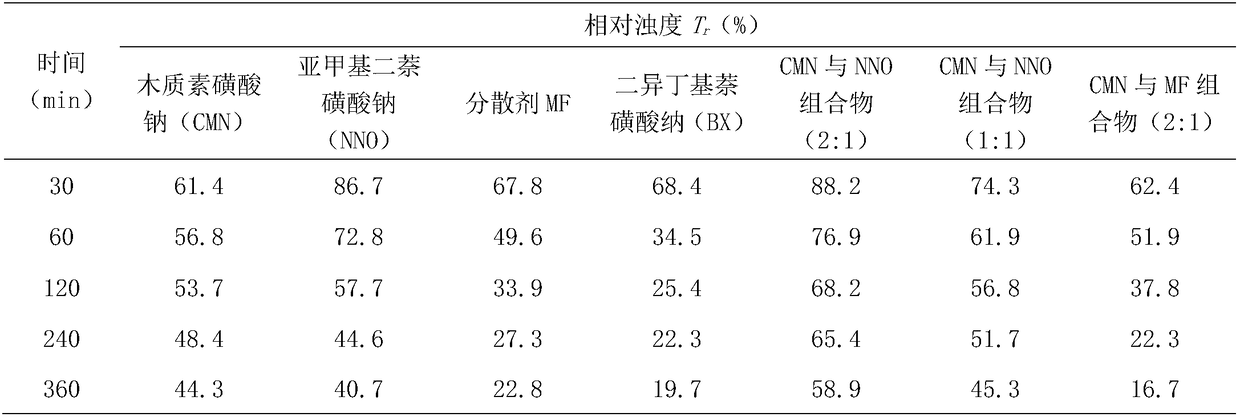

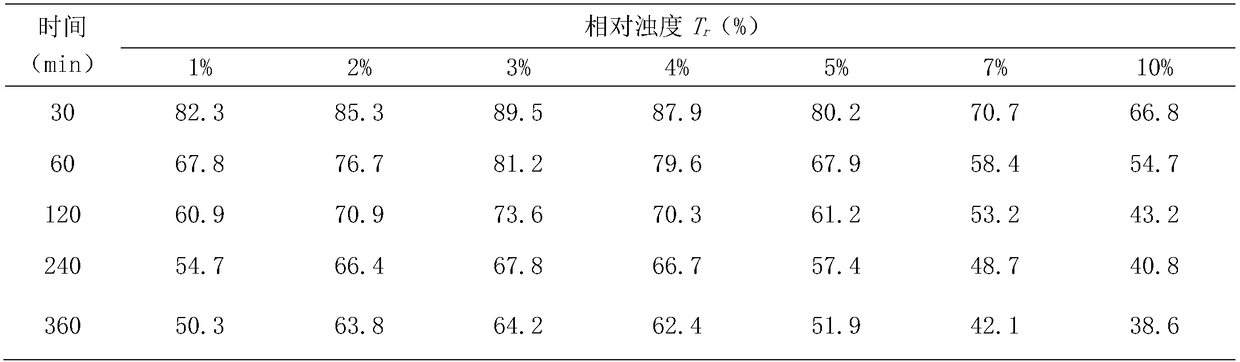

Isaria fumosorosea water dispersible granule and preparation method thereof

ActiveCN108770870AExcellent formulation performanceImprove germination abilityBiocideAnimal repellantsWater dispersibleBiocompatibility Testing

The invention discloses an Isaria fumosorosea water dispersible granule. The water dispersible granule is prepared from Isaria fumosorosea spore powder, sodium lignosulfonate (CMN), sodium dinaphthylmethanedisulfonate (NNO), isooctyl alcohol polyoxyethylene ether polyoxypropylene ether (CA-60), sodium alpha-olefin sulfonate, corn starch, fumed silica, ammonium sulfate, polyvinylpyrrolidone K30, pre-gelatinized starch, a combination of fumed silica and acid yellow 25 or chrysophenine 12, skim milk powder or chitosan oligosaccharide, water-absorbent resin SAP and diatomaceous earth. Low-cost andhigh-stress resistance fermentation, drying and coarse spore powder preparation processes are adopted; a surfactant with best biocompatibility, wettability, dispersibility, disintegration property and adhesion property is screened; and the invasion and germination ability of the above preparation in low-humidity fields is improved. The production cost is reduced, the performances of the preparation are effectively improved, the shelf life is especially prolonged, and the field drug effect is especially improved.

Owner:SHANXI AGRI UNIV

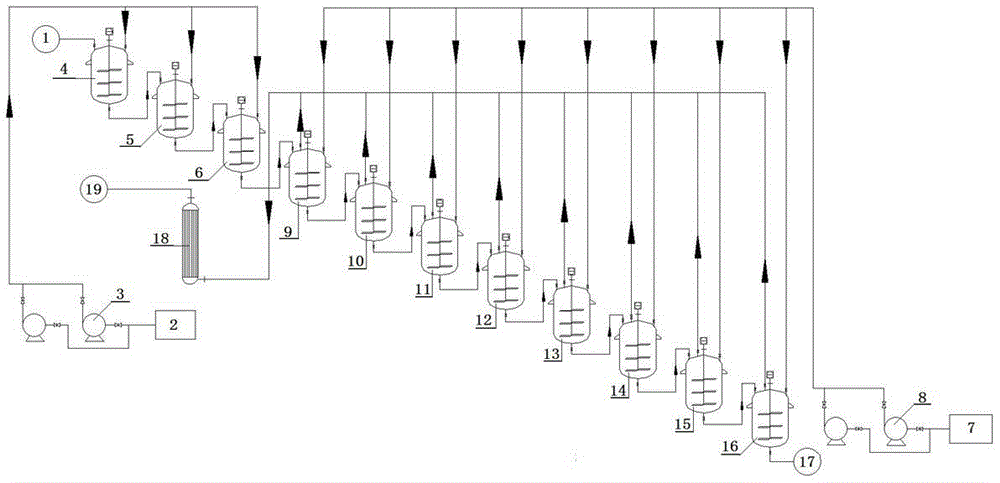

Method and device for continuously neutralizing beta-naphthalene sulfonic acid and comprehensively recycling waste gas

ActiveCN104592062AReduce manufacturing costLess corrosiveSulfonic acids salts preparationSODIUM NAPHTHALENESULFONATESodium acid carbonate

The invention discloses a method and a device for continuously neutralizing beta-naphthalene sulfonic acid and comprehensively recycling a waste gas. According to the method and the device, sodium hydroxide and sodium carbonate are adopted for two-stage continuous neutralization on a sulfonation material, sodium hydroxide is used for continuously neutralizing free acid in the sulfonation material in first-stage neutralization reaction, sodium carbonate is used for continuously neutralizing beta-naphthalene sulfonic acid in second-stage neutralization reaction, the neutralization reaction is thorough, the beta-naphthalene sulfonic acid obtained from the reaction is relatively high in purity, low in impurity content and relatively good in neutralization effect, and carbon dioxide generated from the second-stage neutralization reaction can be recycled, treated and used as a raw material for later carboxylation reaction, so that comprehensive utilization of resources is achieved; no sulfur dioxide which is hard to treat is generated in the neutralization process, the environment is slightly polluted, the corrosion to equipment pipelines is alleviated under same capacity, the construction investment is small, good economic and environment benefits are made, the cost of companies is lowered, and the production requirements of energy conservation, emission reduction and environment-friendliness are met.

Owner:QUJING ZHONGYI SYNTHETIC CHEMICAL CO LTD

Environment-friendly waterproof coating

InactiveCN105968965ANo pollution in the processImprove corrosion resistanceAnti-corrosive paintsCellulosePolyethylene glycol

The invention discloses environment-friendly waterproof coating. The environment-friendly waterproof coating comprises, by weight, 6-9 parts of sodium carboxymethylcellulose, 3-5 parts of fullerene, 1-3 parts of anti-freezing agents, 2-5 parts of methyl isobutyl ketone, 3.5-7 parts of benzyl naphthalene sulfonic acid formaldehyde condensation compound dispersing agents, 6-9 parts of nekal, 4-6 parts of boride oleamide, 3-10 parts of carboxymethylcellulose, 3-6 parts of defoaming agents, 1-3 parts of polyethylene glycol, 5-9 parts of vinyltriethoxysilane, 2-4 parts of titanium dioxide powder, 10-13 parts of talc powder and 2-5 parts of conductive carbon black. The environment-friendly waterproof coating has the advantages that the environment-friendly waterproof coating is free of environmental pollution, good in corrosion resistance, high in adhesion and applicable to diversified environments.

Owner:青岛千帆高新技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com