Method and device for continuously neutralizing beta-naphthalene sulfonic acid and comprehensively recycling waste gas

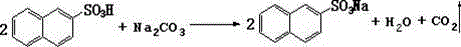

A technology of waste gas recovery and naphthalene sulfonic acid, applied in the field of β-naphthalene sulfonic acid neutralization method, can solve the problems of difficult treatment, difficult to achieve energy saving and emission reduction, clean production, incomplete neutralization reaction, etc., and achieve good economic benefits and environmental benefits, green production requirements, and the effect of reducing enterprise cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

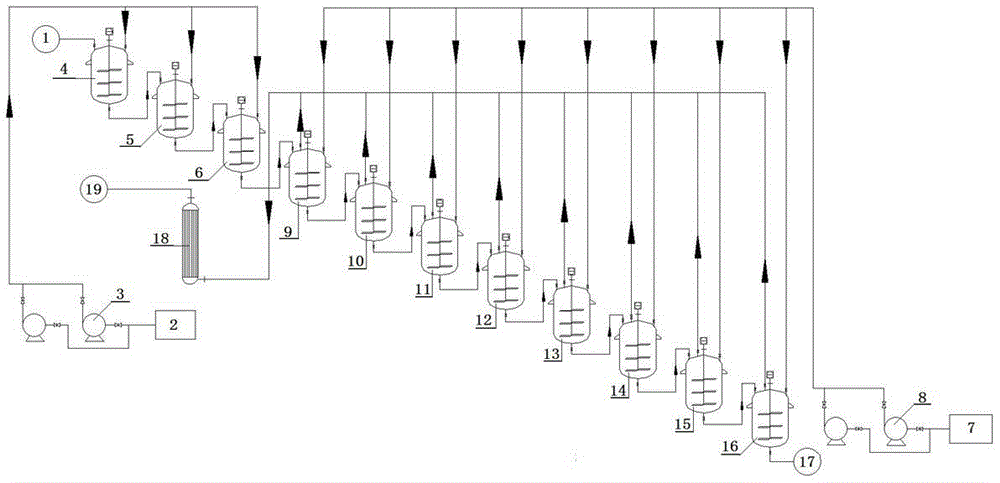

[0049] One-level neutralization: the temperature of reaction in No. 1 neutralization reactor 4 is 90 ° C, the sodium hydroxide solution sent in is 20% of the total amount of sodium hydroxide solution required for the first-level neutralization, and the reaction time is 25min, No. 2 In the neutralization reactor 5, the temperature of reaction is 90 ℃, and the sodium hydroxide solution that sends is 50% of the total amount of sodium hydroxide solution required for one-level neutralization, and the reaction times is 25min, and the No. 3 neutralization reactor 6 reacts The temperature is 90 ℃, the sodium hydroxide solution sent is 30% of the total amount of sodium hydroxide solution required for the first-level neutralization, and the reaction time is 25min;

[0050] Secondary neutralization: the saturated sodium carbonate solution sent into No. 4 neutralization reactor 9 is 5% of the total amount of saturated sodium carbonate solution required for secondary neutralization, and the...

Embodiment 2

[0052] One-level neutralization: the temperature of reaction in No. 1 neutralization reactor 4 is 95 ° C, the sodium hydroxide solution that is sent in is 20% of the total amount of sodium hydroxide solution required for the first-level neutralization, and the reaction time is 20min, and No. 2 In the neutralization reactor 5, the temperature of reaction is 95 ℃, and the sodium hydroxide solution that sends is 50% of the total amount of sodium hydroxide solution required for one-level neutralization, and the reaction times is 20min, and the No. 3 neutralization reactor 6 reacts The temperature is 95 ℃, the sodium hydroxide solution sent is 30% of the total amount of sodium hydroxide solution required for the first-level neutralization, and the reaction time is 20min;

[0053] Secondary neutralization: the saturated sodium carbonate solution sent into No. 4 neutralization reactor 9 is 5% of the total amount of saturated sodium carbonate solution required for secondary neutralizat...

Embodiment 3

[0055] One-level neutralization: the temperature of reaction in No. 1 neutralization reactor 4 is 90 ° C, and the sodium hydroxide solution sent in is 20% of the total amount of sodium hydroxide solution required for the first-level neutralization, and the reaction time is 20min, and No. 2 In the neutralization reactor 5, the temperature of reaction is 90 ℃, and the sodium hydroxide solution that sends is 50% of the total amount of sodium hydroxide solution required for one-level neutralization, and the reaction times is 20min, and the reaction in No. 3 neutralization reactors 6 The temperature is 90 ℃, the sodium hydroxide solution sent is 30% of the total amount of sodium hydroxide solution required for the first-level neutralization, and the reaction time is 20min;

[0056]Secondary neutralization: the saturated sodium carbonate solution sent into No. 4 neutralization reactor 9 is 5% of the total amount of saturated sodium carbonate solution required for secondary neutraliza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com