Low-silver copper-base conductive ink and preparation method thereof

A conductive ink, copper-based technology, used in inks, household appliances, applications, etc., can solve the problems of restricting the application of silver conductive ink, increasing the manufacturing cost of silver conductive ink, and non-conductive ink, achieving great application value and good conductivity. good performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

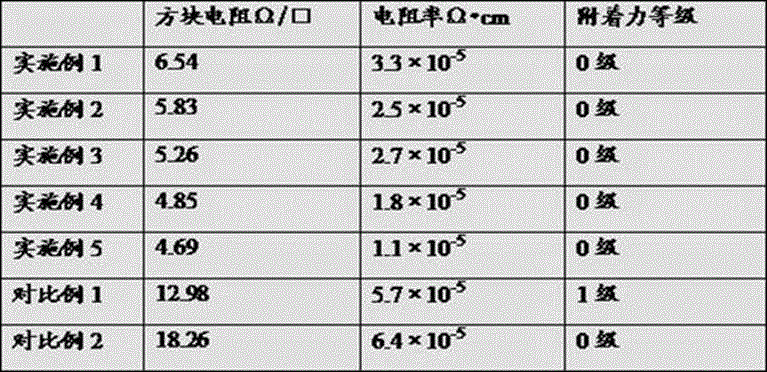

Examples

Embodiment 1

[0023] A preparation method of the above-mentioned low-silver copper-based conductive ink, comprising the following steps:

[0024] (1) Weigh each component according to the proportion by weight: 7 parts of nano copper wire, 0.1 part of silver nitrate, 2 parts of indium powder, 3 parts of titanium dioxide powder, 2 parts of bismuth tungstate powder, 2 parts of 500 mesh tourmaline powder, acidification 1 part of carbon fiber, 10 parts of epoxy resin, 2 parts of sodium hypophosphite, 1 part of trimethylamine borane, 1.2 parts of polyoxypropylene glyceryl ether, 4 parts of diphenyl phosphite, 3.5 parts of ethylene bis stearamide, 2 parts of sodium methylene dinaphthalene sulfonate, 0.5 parts of polydimethylsiloxane, 40 parts of dipropylene glycol, 6-18 parts of isopropanol, and 32 parts of acetone; wherein, the diameter of the nano copper wire is 50-100nm, length 10-40um;

[0025] (2) Add sodium hypophosphite and trimethylamine borane into acetone and mix evenly, then add nano-c...

Embodiment 2

[0030] A preparation method of the above-mentioned low-silver copper-based conductive ink, comprising the following steps:

[0031] (1) Weigh each component according to the proportion by weight: 16 parts of nano copper wire, 0.9 part of silver nitrate, 10 parts of indium powder, 8 parts of titanium dioxide powder, 7 parts of bismuth tungstate powder, 6 parts of 500 mesh tourmaline powder, acidification 5 parts of carbon fiber, 22 parts of epoxy resin, 11 parts of sodium hypophosphite, 6 parts of trimethylamine borane, 5 parts of polyoxypropylene glyceryl ether, 10 parts of diphenyl phosphite, 9 parts of ethylene bis stearamide, 4 parts of sodium methylene dinaphthalene sulfonate, 3 parts of polydimethylsiloxane, 55 parts of dipropylene glycol, 6-18 parts of isopropanol, and 48 parts of acetone; wherein, the diameter of the nano copper wire is 50-100nm, length 10-40um;

[0032] (2) Add sodium hypophosphite and trimethylamine borane to acetone and mix evenly, then add nano-cop...

Embodiment 3

[0037] A preparation method of the above-mentioned low-silver copper-based conductive ink, comprising the following steps:

[0038] (1) Weigh each component according to the proportion by weight: 12 parts of nano copper wire, 0.5 parts of silver nitrate, 6 parts of indium powder, 5 parts of titanium dioxide powder, 4.5 parts of bismuth tungstate powder, 4 parts of 500 mesh tourmaline powder, acidification 3 parts of carbon fiber, 16 parts of epoxy resin, 6.5 parts of sodium hypophosphite, 3.5 parts of trimethylamine borane, 3.1 parts of polyoxypropylene glyceryl ether, 7 parts of diphenyl phosphite, 6.2 parts of ethylene bis stearamide, 3 parts of sodium methylene dinaphthalene sulfonate, 1.7 parts of polydimethylsiloxane, 47 parts of dipropylene glycol, 12 parts of isopropanol, and 40 parts of acetone; wherein, the diameter of the nano copper wire is 50- 100nm, length 10-40um;

[0039] (2) Add sodium hypophosphite and trimethylamine borane into acetone and mix evenly, then a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com