Wool-chinlon leveling agent and preparation method thereof

A leveling agent and nylon technology, which is applied in the field of textile printing and dyeing, can solve the problems of leveling performance failing to meet the use requirements and uneven quality, and achieve excellent dispersibility and leveling properties, reduce energy consumption, and bright color effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

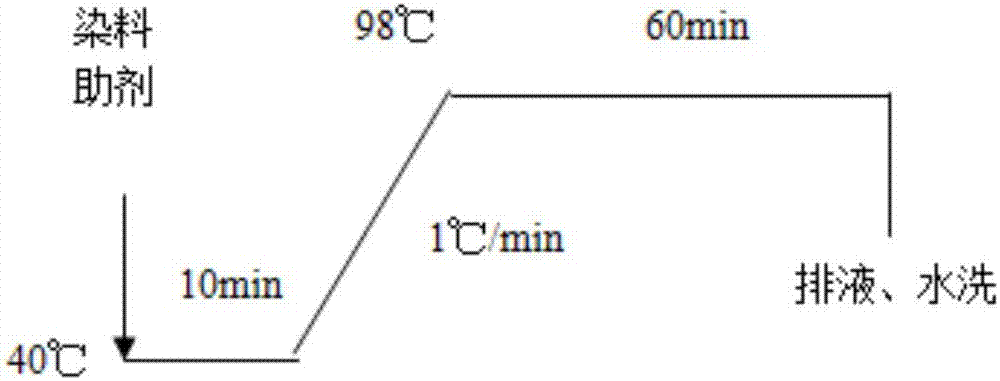

Method used

Image

Examples

Embodiment 1

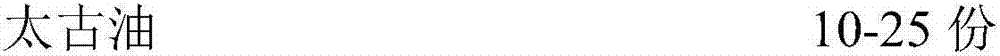

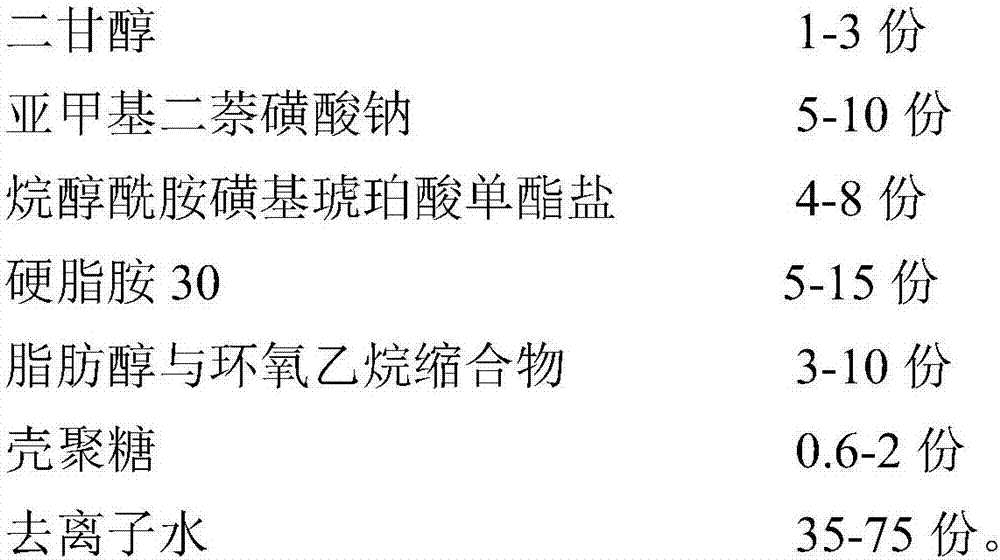

[0033] A wool nylon leveling agent, the preparation method of the wool nylon leveling agent is:

[0034] (1) Add 75 parts of deionized water into a clean reactor, heat up to 90°C, add 10 parts of fatty alcohol and ethylene oxide condensate (Pingping plus O-25, HLB value is 13.5, pH value is 6, The cloud point is greater than 100°C), 10 parts of methylene dinaphthalene sulfonic acid (the active substance content is 60%, the moisture content is 7%, the pH value is 8.3), at the speed of 800 rpm, stir for 30 minutes until completely uniform ;

[0035] (2) Add 25 parts of Swire oil (active matter content greater than 10%, pH value 7.8, flash point: 109°C), and stir for 10 minutes at a speed of 1000 rpm until completely uniform;

[0036] (3) Add 15 parts of stearylamine 30, at a speed of 800 rpm, stir for 20 minutes until completely dissolved;

[0037] (4) Add 4 parts of alkanolamide sulfosuccinic acid monoester salt (solid content is 40%, HLB value is 13.1, pH value is 6), at 800...

Embodiment 2

[0043] A wool nylon leveling agent, the preparation method of the wool nylon leveling agent is:

[0044] (1) Add 35 parts of deionized water into a clean reactor, heat up to 80°C, add 3 parts of fatty alcohol and ethylene oxide condensate (Pingping plus O-25, HLB value is 13.5, pH value is 6, cloud point greater than 100 ° C), 5 parts of sodium methylene dinaphthalene sulfonate (active matter content is 60%, moisture content is 7%, pH value is 8.3), under the rotating speed of 200 rpm, stir for 15 minutes until complete Uniform;

[0045] (2) Add 10 parts of swire oil (active substance content greater than 10%, pH value 7.8, flash point: 109°C), and stir for 5 minutes at a speed of 500 rpm until completely uniform;

[0046] (3) Add 5 parts of stearylamine 30, and stir for 10 minutes at a speed of 200 rpm until completely dissolved;

[0047] (4) Add 8 parts of alkanolamide sulfosuccinic acid monoester salt (solid content is 40%, HLB value is 13.1, pH value is 6), at 200 rpm, s...

Embodiment 3

[0053] A wool nylon leveling agent, the preparation method of the wool nylon leveling agent is:

[0054] (1) Add 55 parts of deionized water into a clean reactor, heat up to 85°C, add 6.5 parts of fatty alcohol and ethylene oxide condensate (Pingping plus O-25, HLB value is 13.5, pH value is 6, The cloud point is greater than 100°C), 7.5 parts of sodium methylene dinaphthalene sulfonate (active matter content is 60%, moisture content is 7%, pH value is 8.3), under the rotating speed of 500 rpm, stir for 22.5 minutes until complete Uniform;

[0055] (2) Add 17.5 parts of Swire oil (active matter content greater than 10%, pH value 7.8, flash point: 109°C), and stir for 7.5 minutes at a speed of 750 rpm until completely uniform;

[0056] (3) Add 10 parts of stearylamine 30, at a speed of 500 rpm, stir for 15 minutes until completely dissolved;

[0057] (4) Add 6 parts of alkanolamide sulfosuccinic acid monoester salt (solid content is 40%, HLB value is 13.1, pH value is 6), at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com