Patents

Literature

149 results about "Red oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Red oil is defined as a substance of varying composition formed when an organic solution, typically tri-n-butyl phosphate (TBP, an agent used for extracting heavy metals in nuclear reprocessing plants) and its diluent, comes in contact with concentrated nitric acid at a temperature above 120 °C.

Stainless steel wire drawing liquid composition

The invention relates to stainless steel wire drawing liquid, the formula thereof comprises the following components: 10 to 30 percent of base oil, 10 to 30 percent of petroleum sodium sulfonate, 5 to 20 percent of mixed alcohol amine, 15 to 30 percent of turkey red oil and turkey red oil ammonium salt, 1 to 3 percent of bactericide, 0.1 to 1 percent of copper corrosion inhibitor, 10 to 20 percent of ester oil and the balance of water. The stainless steel wire drawing liquid is characterized by having excellent lubricating performance and stainless steel rust-preventing performance. In addition, the stainless steel wire drawing liquid related by the invention has an excellent defoaming function and can greatly improve the environmental hygiene of wire drawing processing enterprises.

Owner:河北九熙新材料科技有限公司

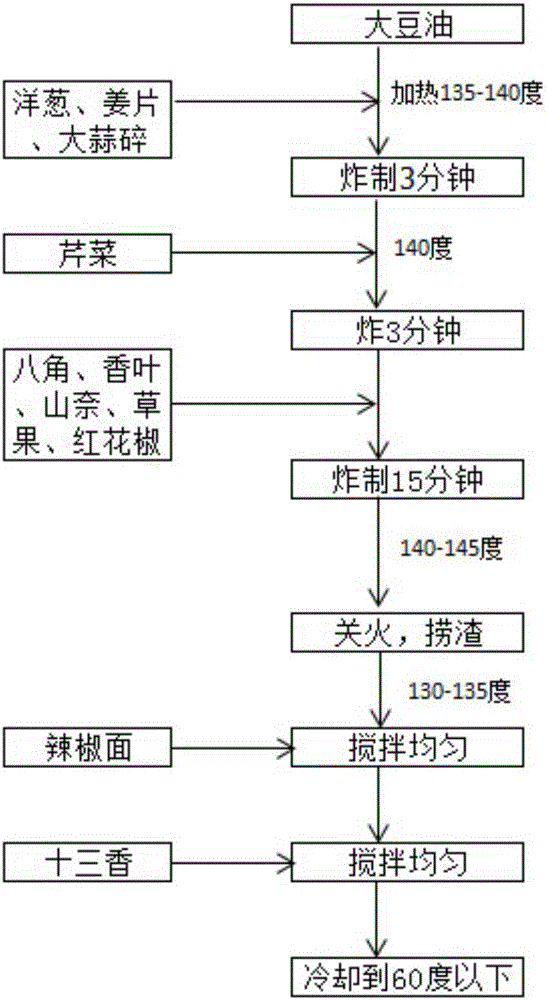

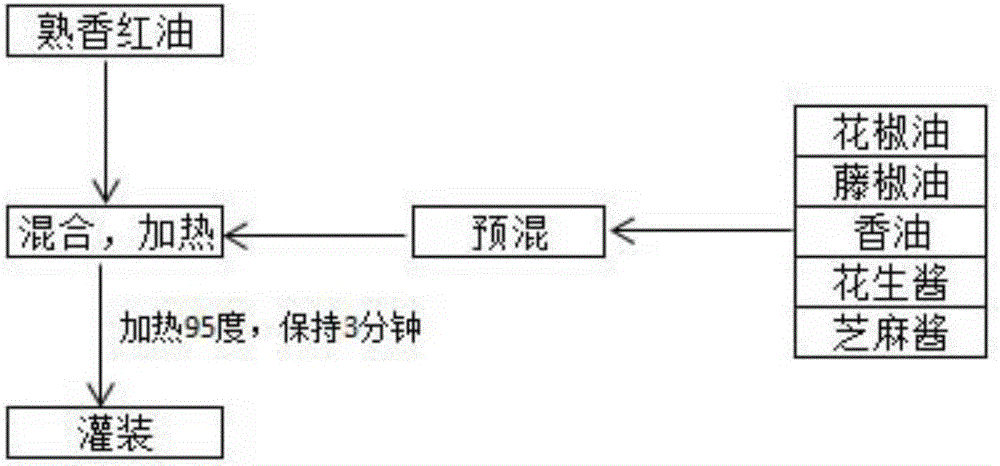

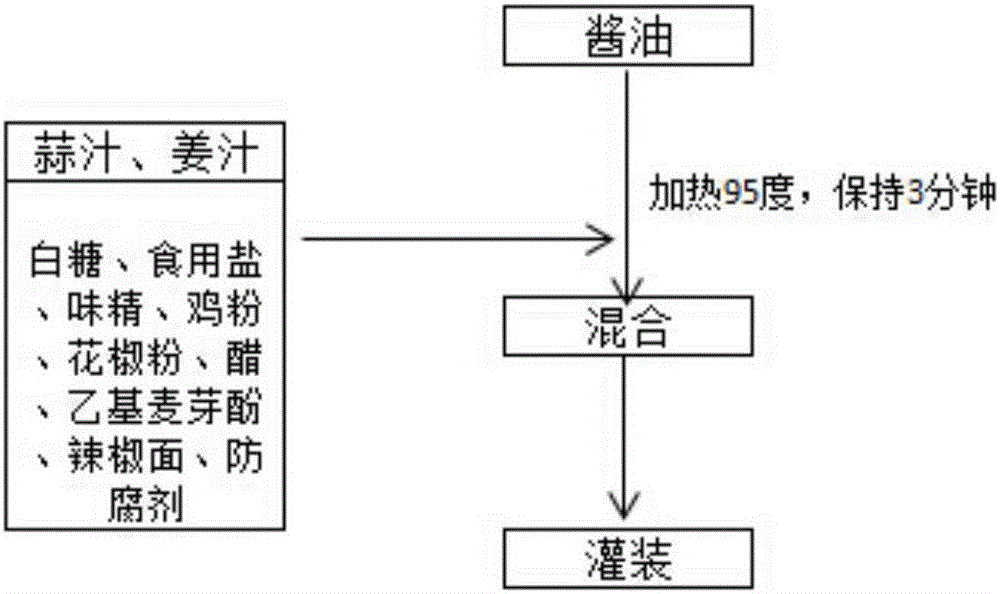

Seasoning for spicy mix and preparation method of seasoning

The invention relates to a seasoning for a spicy mix and a preparation method of the seasoning. The seasoning for the spicy mix is divided into forms of seasoning red oil packs and seasoning packs, wherein the seasoning red oil packs contain cooked fragrant red oil. The seasoning for the spicy mix disclosed by the invention is prepared through the following steps of separately filling the seasoning red oil packs and the seasoning packs, and performing combined packaging. According to the seasoning and the preparation method thereof disclosed by the invention, raw materials, components and the proportion thereof of the seasoning red packs are adjusted, and the refining technology of the cooked fragrant red oil is improved, so that the taste of products is guaranteed to the maximum extent, the quality guarantee period is prolonged, and the seasoning has the advantages of being convenient to eat and store, good in mouth feel, low in salt and the like.

Owner:YIHAI CHINA FOOD CO LTD

Environment-friendly type PVC (polyvinyl chloride) synthetic leather and production method thereof

InactiveCN104278539AImprove breathabilityReduce potential threatsSynthetic resin layered productsTextiles and paperPolyamidePolyvinyl chloride

The invention discloses environment-friendly type PVC (polyvinyl chloride) synthetic leather. The environment-friendly type PVC synthetic leather is prepared from the following raw materials in parts by weight: 30-60 parts of polyvinyl chloride resin SG-5 (PVCSG-5), 15-30 parts of polyvinyl chloride resin SG-8 (PVCSG-8), 10-15 parts of egg shell powder, 3-6 parts of rice bran, 2-5 parts of rice husk, 2-4 parts of wollastonite powder, 0.2-0.5 part of aluminum oxide, 40-70 parts of trioctyl citrate, 15-30 parts of trimethyl citrate, 1-2 parts of isopropanolamine, 0.5-1 parts of lactose, 0.2-0.5 part of calcium chloride, 0.5-1.5 parts of dioctyl sodium sulfosuccinate, 1-2 parts of turkey red oil, 0.5-1 part of polyamide epichlorohydrin, 5-10 parts of pigment and 5-10 parts of modifying additives. The PVC synthetic leather uses agricultural wastes as filling materials, is environmentally-friendly, can improve the air permeability and toughness and is suitable for practical production use, and energy can be saved.

Owner:ANHUI HUIAN ARTIFICAL LEATHER

Grinding fluid in use for superhard abrasive grinding wheel of metal binding agent electrolyzable online, and preparation method

InactiveCN1563244AStrong enoughSolve the lack of hardnessOther chemical processesLubricant compositionHydrogen phosphateAlcohol

The primary liquid of grinding liquid is prepared from sodium molyb date, sodium hydrogen phosphate, glycerin, triethanolamine, sodium sulfite, borax and red oil and grinding liquid is prepared by mixing primary liquid with water in mass ratio of 1:5-1:20. The preparing process includes heating water to ttemperature of 60-80 deg.c, placing abovementioned chemicals and materials in the water for mixing and dissolving to obtain solution, cooling solution to room temp for obtaining primary liquid and mixing the primary liquid with water for final product.

Owner:BEIJING UNIV OF TECH

Environment-friendly emulsified oil for hydraulic support and preparation method of environment-friendly emulsified oil

ActiveCN105462673ASolve the short service lifeReduce wearLubricant compositionOrganosolvSodium nitrite

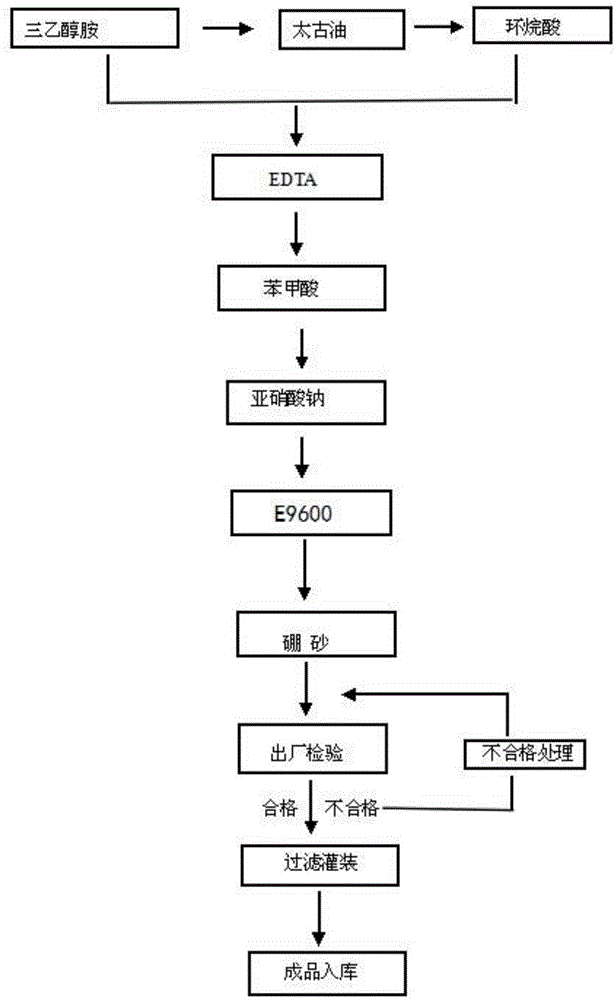

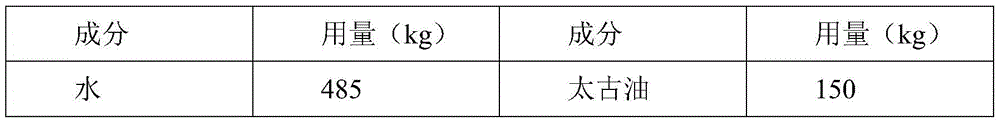

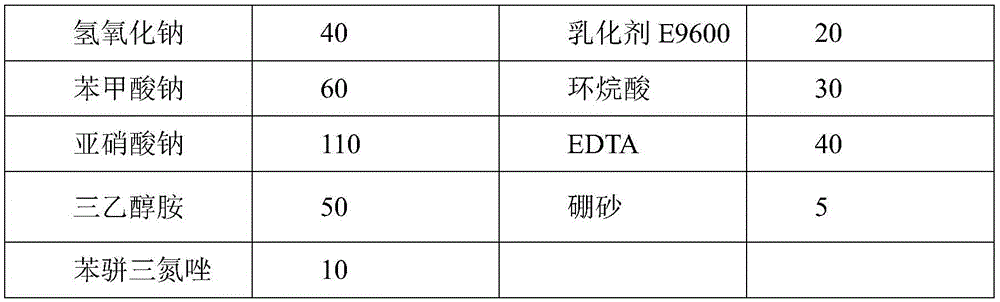

The invention discloses environment-friendly emulsified oil for a hydraulic support and a preparation method of the environment-friendly emulsified oil. The emulsified oil is prepared from the following raw materials in percentage by mass: 15.0 to 25.0 percent of Turkey red oil, 2 to 4 percent of sodium hydroxide, 2 to 5 percent of emulsifier E9600, 3 to 6 percent of sodium benzoate, 3 to 6 percent of naphthenic acid, 9 to 11 percent of sodium nitrite, 4 to 6 percent of EDTA, 5 to 7 percent of triethanolamine, 0.5 to 2.0 percent of borax, 0.1 to 1 percent of benzotriazole and the balance of water. According to the emulsified oil and the preparation method thereof, provided by the invention, the defects that the production technology process is complex, the materials are various and the odor is great in the prior art can be overcome, and the production cost is reduced; in the formula of the emulsified oil, the plant Turkey red oil is adopted, the quality of the emulsified oil is improved due to the selection of the raw materials, the using amount of organic solvents in the whole formula is reduced and the demand of environment protection is met.

Owner:ZIZHOU XINRUN BIOTECH CO LTD

Porous antibiotic air filter paper and making method thereof

InactiveCN104005278AHas antibacterial propertiesImprove adsorption capacityNon-fibrous pulp additionPaper/cardboardAir filterOxygen

The invention discloses a porous antibiotic air filter paper. The porous antibiotic air filter paper is made by using the following raw materials, by weight, 53-56 parts of a flax pulp, 43-45 parts of a softwood pulp, 0.2-0.3 parts of benzalkonium bromide, 0.3-0.5 parts of petroleum ether, 2-3 parts of soybean powder, 3-4 parts of nanometer porcelain clay, 1-2 parts of crushed horseradish, 2-3 parts of zircon, 1-2 parts of macro-porous silicon powder, 0.6-0.8 parts of calcium peroxide, 4-7 parts of chlorinated paraffin, 0.6-0.8 parts of turkey red oil, 0.3-0.4 parts of xanthan gum, 7-9 parts of a polyacrylate emulsion, 1-2 parts of an assistant and a proper amount of water. Horseradish in the above raw materials has a certain antibiosis effect; the addition of calcium peroxide realizes slow oxygen release after meeting water, and forms minimal holes on the filter paper layer, so the adsorption effect is increased; and the addition of the assistant is safe and environmentally friendly, and forms minimal holes on the surface of filter paper, so the adsorptivity is increased.

Owner:BENGBU DEMO FILTRATION TECH

Pigment release agent for cold transfer printing paper

ActiveCN1844573AGood printing adaptabilityGood transferabilityNon-fibrous pulp additionTransfer printing processPotassium peroxodisulfateSilicon dioxide

The invention relates to a pigment separator of cold-transfer print paper, whose formula in mass percentage comprises: the copolymer of crylic acid and styrene in 35-80%; silicon dioxide in 0.05-0.5%; Turkey chilli oil in 0.2-1.8%; three-butonate in 0.1-0.8%; starch in 5-30% whose etherified degree is 0.7-1.2; and water. The producing method comprises: in the emulsion of initiator, mixing and adding sodium bisulfite and potassium peroxodisulfate, and heating it to 50Deg. C; adding the butyl acrylate, the mixture of crylic acid and styrene monomer into said emulsion, to initiate aggregation, and heating it to 70-80Deg. C; at said temperature, reacting for 1-2h, to attain the copolymer; adding turkey chilli, silicon dioxide, three-butonate, and starch whose etherified degrees is 0.7-1.2 and adding water; attaining the cold transfer print paper. The inventive transfer print paper coated with separator has the function for shielding carrier, with better print transfer property, anti-penetrate property, and anti-compress property, etc, to support the coil paper production.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

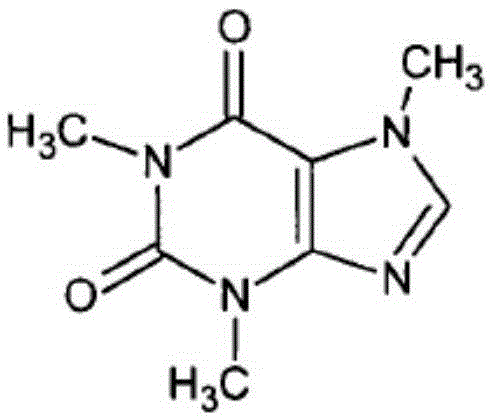

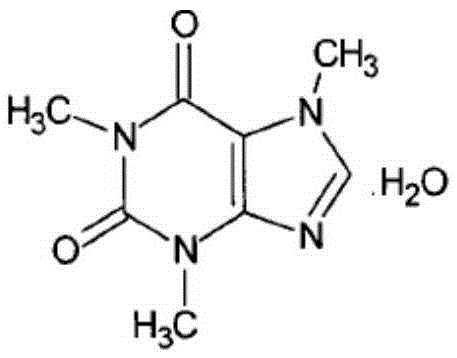

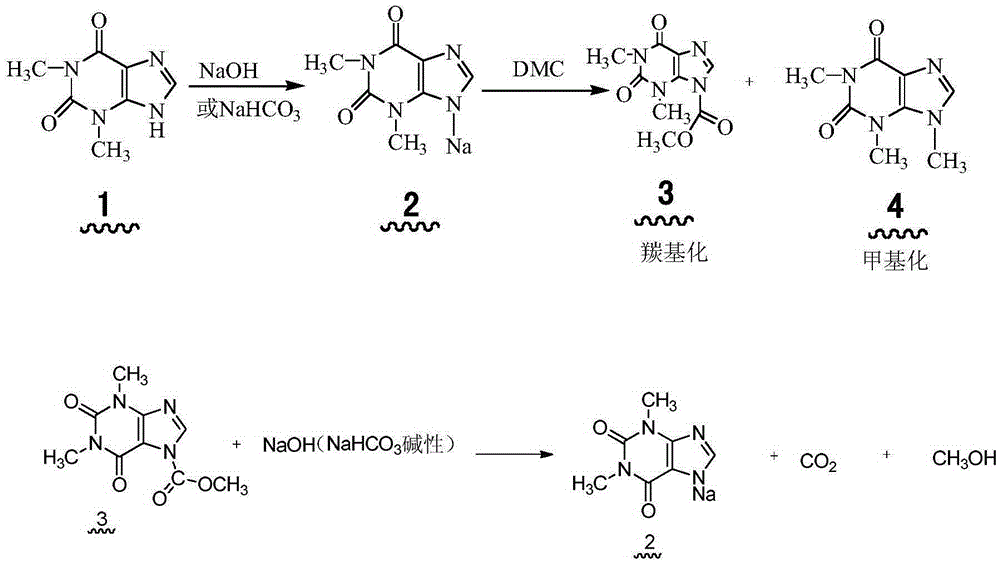

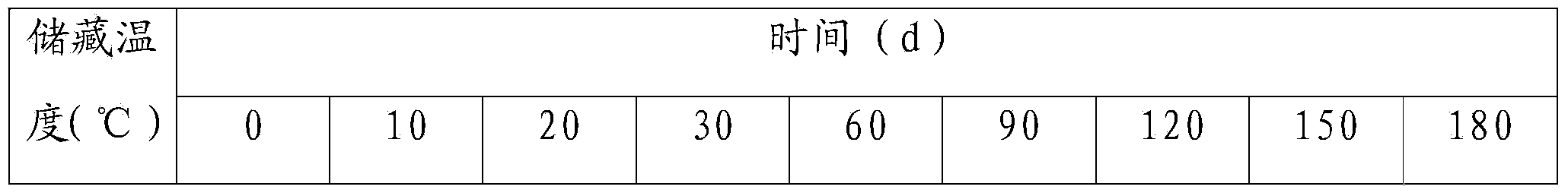

Preparation process for environment-friendly semisynthetic caffeine

ActiveCN105294691AIncrease the reaction interfaceImprove responseOrganic chemistryCaffeine productsSulphate Ion

The invention relates to a preparation process for environment-friendly semisynthetic caffeine. According to the preparation process, preparation is carried out under the specific conditions like a temperature range of 90 to 160 DEG C, usage of an alkaline substance Y type zeolite as a catalyst, addition of a proper amount of surfactant substance Turkey red oil as an emulsifier and the like, and dimethyl carbonate (DMC) is used to replace limited toxic dimethyl sulphate (DMS); reaction yield is as high as 97.8%; and the quality of a caffeine product meets requirements.

Owner:CHENGWU CHENHUI ENVIRONMENTAL PROTECTION TECH CO LTD +1

Red oil radish with mulberry flavor and preparation method of red oil radish

The invention discloses a red oil radish with a mulberry flavor and a preparation method of the red oil radish. The red oil radish is prepared from the following raw materials in parts by weight: 2-3 parts of dried kelp powder, 2-3 parts of chinensis tea powder, 5-6 parts of mulberry pulp, 20-25 parts of camellia oil, 1-2 parts of schisandra chinensis, 1-2 parts of semen cassia, 15-17 parts of pod pepper, 1-2 parts of seed powder of Chinese prickly ash, 1-2 parts of chopped green onions, 1-2 parts of chicken powder, 2-3 parts of white sugar, 110-120 parts of fresh radish and a proper amount of edible salt, calcium chloride, vitamin C liquid, tea water, sodium diacetate, nipagin complex esters, pectin methylesterase and water. The preparation method comprises the following steps: mixing and rubbing the dried kelp powder and the mulberry pulp; adding the chinensis tea powder and drying to obtain powder; and mutually mixing the dried kelp powder, the mulberry pulp and the chinensis tea powder. The red oil radish is abundant in taste and diverse in nutrient; a yellow pigment is reduced by blanching, and the quality of the radish is well kept; and the edible salt, the calcium chloride, the tea water and the vitamin C liquid are added, so that the brittleness is improved, and the content of nitrite can be well reduced.

Owner:曹红云

Carbon sol modified fountain solution compounded by kappa-carrageenan-konjac glucomannan and preparation method thereof

InactiveCN106183522AImprove durabilityPromote wettingPrinting pre-treatmentKappa-CarrageenanMicrosphere

The invention discloses carbon sol modified fountain solution compounded by kappa-carrageenan-konjac glucomannan. The carbon sol modified fountain solution comprises the following raw materials in parts by weight: 70-85 parts of de-ionized water, 10-15 parts of kappa-carrageenan, 6-10 parts of konjac glucomannan, 3-6 parts of tea polyphenol, 2-5 parts of Turkey red oil, 1-3 parts of sorbitol, 3-6 parts of pH modifier, 1-3 parts of non-ionic fluorocarbon surface active agent, 1-3 parts of nanocarbon sol, and 0.5-1 part of sorbitol fatty acid ester. The fountain solution serves as a hydrophilic film forming agent through compounding of kappa-carrageenan and konjac glucomannan, so that the durability of a water film is improved, and the fountain solution is excellent in wettability and permeability during using; and kappa-carrageenan-konjac glucomannan-tea polyphenol microballs have the characteristics of fine average particle sizes and slow tea polyphenol release, and the release of tea polyphenol is slowed in use of the fountain solution, so that the oxidation resistance of tea polyphenol is greatly improved, and the use stability of the fountain solution is guaranteed.

Owner:HEFEI DINGLIANG OPTICAL TECH

Preparation method of modified casein for leather finishing

The invention discloses a preparation method of modified casein for leather finishing. The preparation method comprises the following steps: adding part of boiled water into a reaction kettle, and adding ammonia water, casein, TX-10 and Turkey red oil; adding part of caprolactam assistant 1 into part of boiled water; adding the rest caprolactam assistant 2 into part of boiled water; adding ammonium persulfate assistant 3 into part of boiled water; adding a formula amount of sodium benzoate assistant 4 into part of boiled water; adding phenol assistant 5 into part of boiled water; adding the assistant 1, the assistant 3 and glycol into the reaction kettle; dripping the assistant 2 into the reaction kettle, and slowly heating; adding the assistant 4, the assistant 5 and glycerol into the reaction kettle; and stirring, and then, discharging. The modified casein prepared by the invention has the advantages of bright coating, high-temperature ironing resistance and the like, is suitable for polishing, and is used for surface finishing of light leather to enable the light leather to have the characteristics of full and soft hand feeling, good elasticity, cold resistance, strong bonding force, good water resistance and the like.

Owner:刘连生

High-moisture-retention fountain solution compounded by k-carrageenan and konjac glucomannan and preparation method thereof

The invention discloses high-moisture-retention fountain solution compounded by k-carrageenan and konjac glucomannan. The fountain solution consists of the following raw materials in parts by weight: 70-85 parts of deionized water, 10-15 parts of k-carrageenan, 6-10 parts of konjac glucomannan, 3-6 parts of tea polyphenol, 2-5 parts of Turkey red oil, 1-3 parts of sorbitol, 3-6 parts of pH modifier, 1-3 parts of coconut oil fatty acid diethanolamide, and 1-3 parts of wetting agent. The fountain solution serves as a hydrophilic film-forming agent through compounding k-carrageenan with konjac glucomannan, improves durability of a water film, and is excellent in wettability and permeability in use.

Owner:HEFEI ALL ROUND POLYMER MATERIAL FACTORY

High-performance fountain solution containing k-carrageenan-konjac gum compound and preparation method of fountain solution

PendingCN105966102AImprove durabilityPromote wettingPrinting pre-treatmentFilm-forming agentPolyphenol

The invention discloses a high-performance fountain solution containing a k-carrageenan-konjac gum compound. The fountain solution comprises the following raw materials in parts by weight: 70-85 parts of deionized water, 10-15 parts of k-carrageenan, 6-10 parts of konjac gum, 3-6 parts of tea polyphenol, 2-5 parts of Turkey red oil, 1-3 parts of sorbitol, 3-6 parts of pH conditioning agent, 1-2 parts of allyl alcohol polyoxy alkyl ether, 3-5 parts of water film regulator, and 1-3 parts of fatty alcohol polyoxy alkyl ether. According to the fountain solution, through the k-carrageenan-konjac gum compound acting as a hydrophilic film-forming agent, the durability of a water film is improved, and the fountain solution has good wettability and permeability when in use.

Owner:HEFEI ALL ROUND POLYMER MATERIAL FACTORY

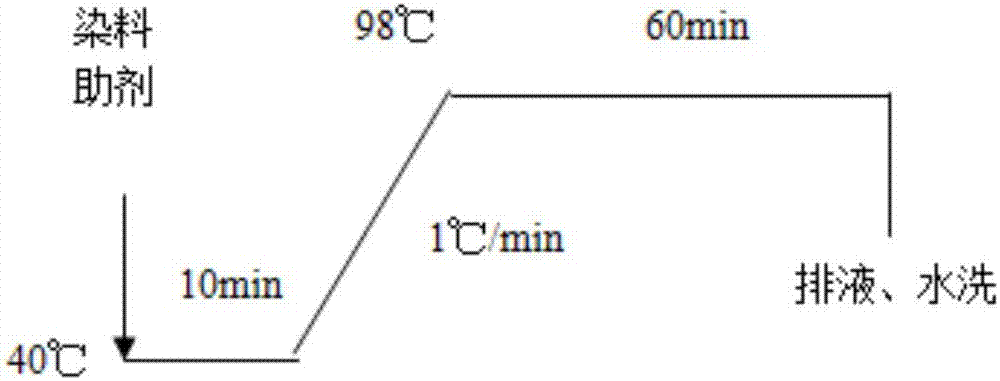

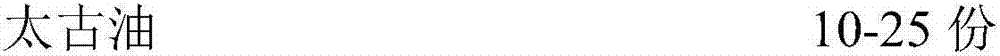

Wool-chinlon leveling agent and preparation method thereof

ActiveCN107268302ALower dyeing temperatureNo stain blocking effectDyeing processDispersityEthylene oxide

The invention discloses a wool-chinlon leveling agent. The wool-chinlon leveling agent is prepared from the following raw materials in parts by weight: 10-25 parts of Turker red oil, 1-3 parts of diglycol, 5-10 parts of disodium methylene dinaphthalenesulfonate, 4-8 parts of alkanolamide sulfosuccinate monoester salt, 5-15 parts of stearyl amine 30, 3-10 parts of fatty alcohol and ethylene oxide condensation compound, 0.6-2 parts of chitosan and 35-75 parts of deionized water. The wool-chinlon leveling agent does not contain substances of alkylphenol polyoxyethylene, organic halides and the like, is easily dissolved into water, can resist acid, alkali and hard water, is low-foam and convenient to use; and meanwhile, the wool-chinlon leveling agent has excellent dispersity, dye retarding property, leveling property and stability, the dye fastness can be increased, and dyed wool or chinlon has bright and uniform colors and is flexible and comfortable.

Owner:JIANGSU NEW REBA TECH CO LTD

Alcohol-free fountain solution containing k-carrageenan-konjac gum compound and preparation method of alcohol-free fountain solution

The invention discloses an alcohol-free fountain solution containing a k-carrageenan-konjac gum compound. The alcohol-free fountain solution comprises the following raw materials in parts by weight: 70-85 parts of deionized water, 10-15 parts of k-carrageenan, 6-10 parts of konjac gum, 3-6 parts of tea polyphenol, 2-5 parts of Turkey red oil, 1-3 parts of sorbitol, 3-6 parts of pH conditioning agent and 1-3 parts of polysorbate-80. According to the alcohol-free fountain solution, through the k-carrageenan-konjac gum compound acting as a hydrophilic film-forming agent, the durability of a water film is improved, so that the alcohol-free fountain solution has good wettability and permeability when in use. When k-carrageenan-konjac gum-tea polyphenol microspheres which have the characteristics of low mean particle size and tea polyphenol slow release are used in the alcohol-free fountain solution, the release of tea polyphenol is retarded, the oxidation resistance of tea polyphenol is improved greatly, and the use stability of the alcohol-free fountain solution is ensured.

Owner:HEFEI ALL ROUND POLYMER MATERIAL FACTORY

UV quick adhesive fountain solution containing kappa-carrageenan-konjac gum compound and preparation method thereof

InactiveCN106113968AImprove durabilityPromote wettingPrinting pre-treatmentMicrosphereKappa-Carrageenan

The invention discloses a UV quick adhesive fountain solution containing a kappa-carrageenan-konjac gum compound. The UV quick adhesive fountain solution containing the kappa-carrageenan-konjac gum compound is composed of the following raw materials in parts by weight: 70 to 85 parts of deionized water, 10 to 15 parts of kappa-carrageenan, 6 to 10 parts of konjac gum, 3 to 6 parts of tea polyphenol, 2 to 5 parts of turkey red oil, 1 to 3 parts of sorbitol, 3 to 6 parts of pH regulator, 1 to 3 parts of iso-tridecanol polyoxyethylene ether, 1 to 2 parts of polyether defoamer, and 0.5 to 1 part of aluminum-zirconium coupling agent. According to the fountain solution, the kappa-carrageenan and the konjac gum are compounded to be used as a hydrophilic film-forming agent through which the durability of a water film can be improved, and as a result, the fountain solution is high in wettability and permeability during use; kappa-carrageenan-konjac gum-tea polyphenol microspheres have the characteristics of being small in average particle size and slow to release tea polyphenol, so that the tea polyphenol can be slowly released during the use of the fountain solution, and as a result, the oxidation resistance of the tea polyphenol can be greatly improved, and the use stability of the fountain solution can be ensured.

Owner:HEFEI DINGLIANG OPTICAL TECH

Viscose oil agent

InactiveCN101725041AReasonable formulaImprove work performanceVegetal fibresSpindle oilViscose fiber

The invention discloses a viscose oil agent, which is formed by mixing spindle oil, turkey red oil, an emulsifier OP-10, triethanolamine, a softening agent DC and water. The invention is reasonable in formula, good in service performance, convenient in production and use and low in production cost.

Owner:何培祥

Improved mechanical processing lubricating oil

InactiveCN104830463ALubricates and coolsImprove high temperature resistanceLubricant compositionTetramethylammonium hydroxidePolyester

Improved mechanical processing lubricating oil comprises the following raw materials by weight: 6-9 parts of sodium sulfite, 4-7 parts of ricinoleic acid polyester, 3-5 parts of hydroxyl sodium sulfonate, 4-8 parts of polyethylene glycol monomethyl ether, 2-4 parts of ethanolamine, 7-9 parts of nitromethane, 3-6 parts of triethanolamine, 4-9 parts of Turkey red oil, 6-8 parts of low molecular polyethylene wax, 2-6 parts of benzene methanol, 3-8 parts of paraffin, 4-10 parts of tetramethylammonium hydroxide, 2-5 parts of methyl polytetrafluoroethylene, 1-4 parts of sodium hydroxide, 2-6 parts of epoxy ethane and 15-24 parts of base oil. The beneficial effects are that the mechanical processing lubricating oil can be used to well play the lubricating and cooling effect, reduces the friction, and has good high temperature tolerance.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

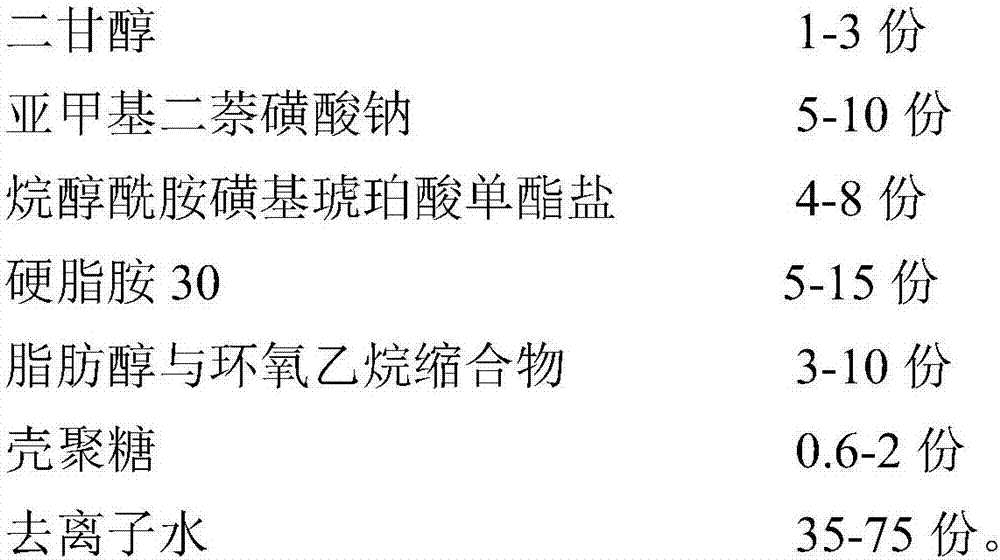

Composite emulsified asphalt and preparation technology thereof

InactiveCN106675050AHigh bonding strengthImprove high temperature resistanceBuilding insulationsBetainePolybutylene

The invention provides composite emulsified asphalt and a preparation technology thereof. The composite emulsified asphalt is prepared from the following components: matrix asphalt, petroleum tar, polybutylene, EVA (ethylene-vinyl acetate), pentaerythritol, 8-hydroxyquinoline, lauryl alcohol phosphate acid ester, vinyl versatate, propylene glycol block polyether, Turkey red oil, oleamide, epoxy ethanediamine ethylene diamine, aminated lignin, bentonite, phosphonolipid betaine, water, sodium dodecyl benzene sulfonate, ammonuim humate, hydrochloric acid, ammonium chloride, beta-butyrolactone and ethylene bis stearamide. The prepared composite emulsified asphalt has the advantages that the shear strength is 1.12 to 1.23MPa at the temperature of 25 DEG C, and is 0.59 to 0.74MPa at the temperature of 60 DEG C, the adhering strength is good, and the high temperature-resistant property is better; the softening point is higher than 63 DEG C, the needle penetration is 68 / 0.1mm at the temperature of 25 DEG C, the comprehensive property is excellent, and the application requirement of road construction projects can be met.

Owner:SUZHOU AIBOMAIER NEW MATERIAL CO LTD

Frying process for lowering acid value of oil in red camphor oil hotpot soup base

ActiveCN103931964ADoes not affect flavorExtended shelf lifeFood preparationOil and greaseEngineering

The invention mainly relates to a frying process for lowering the acid value of oil in red camphor oil hotpot soup base. The frying process comprises the following steps: a, preparing materials; b, frying; c, continually frying; d, decocting; e, bagging. In the step b, frying is performed at the temperature of 70-130 DEG C and under the pressure of 0.1-0.5MPa; in the step c, continual frying is performed at the temperature of 70-130 DEG C and under the pressure of 0.1-0.5MPa. According to the frying process for lowering the acid value of oil in red camphor oil hotpot soup base, oil oxidation and the extraction effects of seasonings are controlled accurately by means of synergistic research of temperature, pressure and the like, so that the maximum yield and a low acid value are achieved.

Owner:CHONGQING UNIV OF EDUCATION

High-viscosity low-surface-tension fountain solution containing k-carrageenan and preparation method of high-viscosity low-surface-tension fountain solution

The invention discloses a high-viscosity low-surface-tension fountain solution containing k-carrageenan. The high-viscosity low-surface-tension fountain solution containing k-carrageenan consists of the following raw materials in parts by weight: 70-85 parts of deionized water, 10-15 parts of k-carrageenan, 6-10 parts of konjac gum, 3-6 parts of tea polyphenol, 2-5 parts of Turkey red oil, 1-3 parts of sorbitol, 3-6 parts of a pH regulator, 1-3 parts of cocoanut fatty acid diethanolamide, 1-3 parts of fatty alcohol-polyoxyethylene ether and 3-8 parts of glycerin. According to the fountain solution, k-carrageenan and konjac gum are compounded to serve as a hydrophilic film-forming agent to improve the durability of a water film, so that the fountain solution has favorable wettability and permeability.

Owner:HEFEI ALL ROUND POLYMER MATERIAL FACTORY

Synthesis method of environment-friendly p-methyl anisole

ActiveCN106916055AAchieving Green Synthesis GoalsThe synthetic method is green and environmentally friendlyEther preparation by ester reactionsMethyl carbonateSynthesis methods

The invention relates to a synthesis method of environment-friendly p-methyl anisole. The method includes: taking p-cresol as the raw material, using a polar solvent like water as the solvent, adopting an alkaline substance Y type zeolite as the catalyst, and adding a proper surfactant Turkey red oil as the emulsifier, and under a 130-180DEG C temperature range and other specific conditions, using environment-friendly dimethyl carbonate (DMC) as the methylation raw material to prepare p-methyl anisole. The yield is up to 96% or above, and the final product purity is up to 99% or more.

Owner:山东达冠科技有限责任公司

Abrasion-resistant and scraping-resistant aluminum alloy chromium-free passivating agent and preparation method thereof

InactiveCN105316665AReduce wearLess scratchesMetallic material coating processesChromium freeSodium gluconate

The invention discloses an abrasion-resistant and scraping-resistant aluminum alloy chromium-free passivating agent and a preparation method thereof. The passivating agent is prepared from, by weight, 5-10 parts of 30-40% hexafluorotitanic acid, 5-10 parts of 40-45% hexafluorozirconic acid, 1-2 parts of polyepoxysuccinic acid, 4-6 parts of sodium gluconate, 1-2 parts of sodium fluoride, 1-2 parts of 65-70% nitric acid, 1-2 parts of Turkey red oil, 1-2 parts of simethicone, 50-100 parts of 40-50% polyethylene wax emulsion, 50-100 parts of coalescing agents and 800-1000 parts of water. According to the aluminum alloy passivating agent, a compact film of a net structure can be formed on the surface of aluminum alloy, excellent strength, tenacity and adhesive capacity are achieved, and the corrosion resistance is good; meanwhile, good abrasion resistance is achieved, abrasion and scraping on the surface of the aluminum alloy can be reduced, environment pollution can be reduced, and good economic benefits and social benefits are achieved.

Owner:HEFEI HAIYUAN MACHINERY

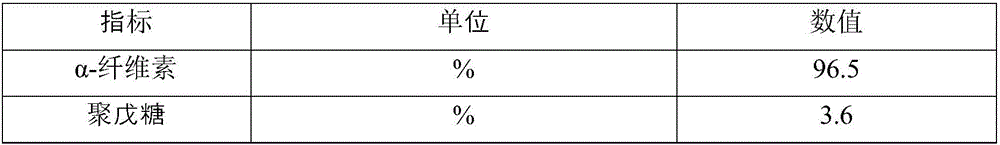

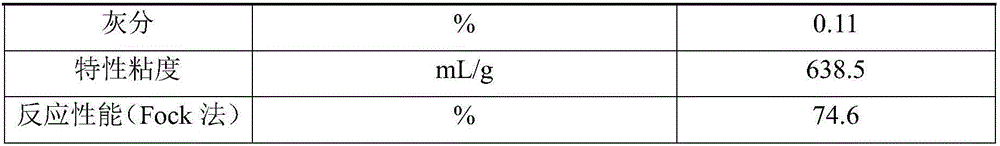

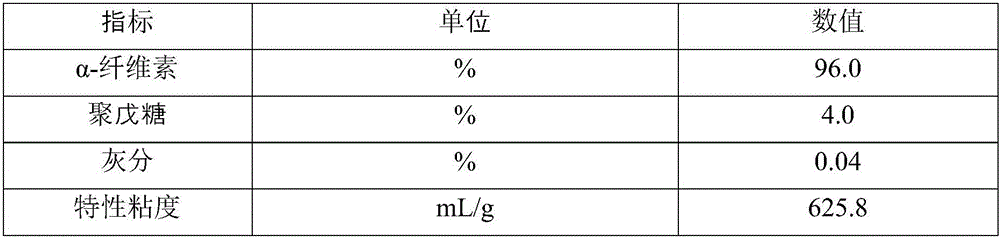

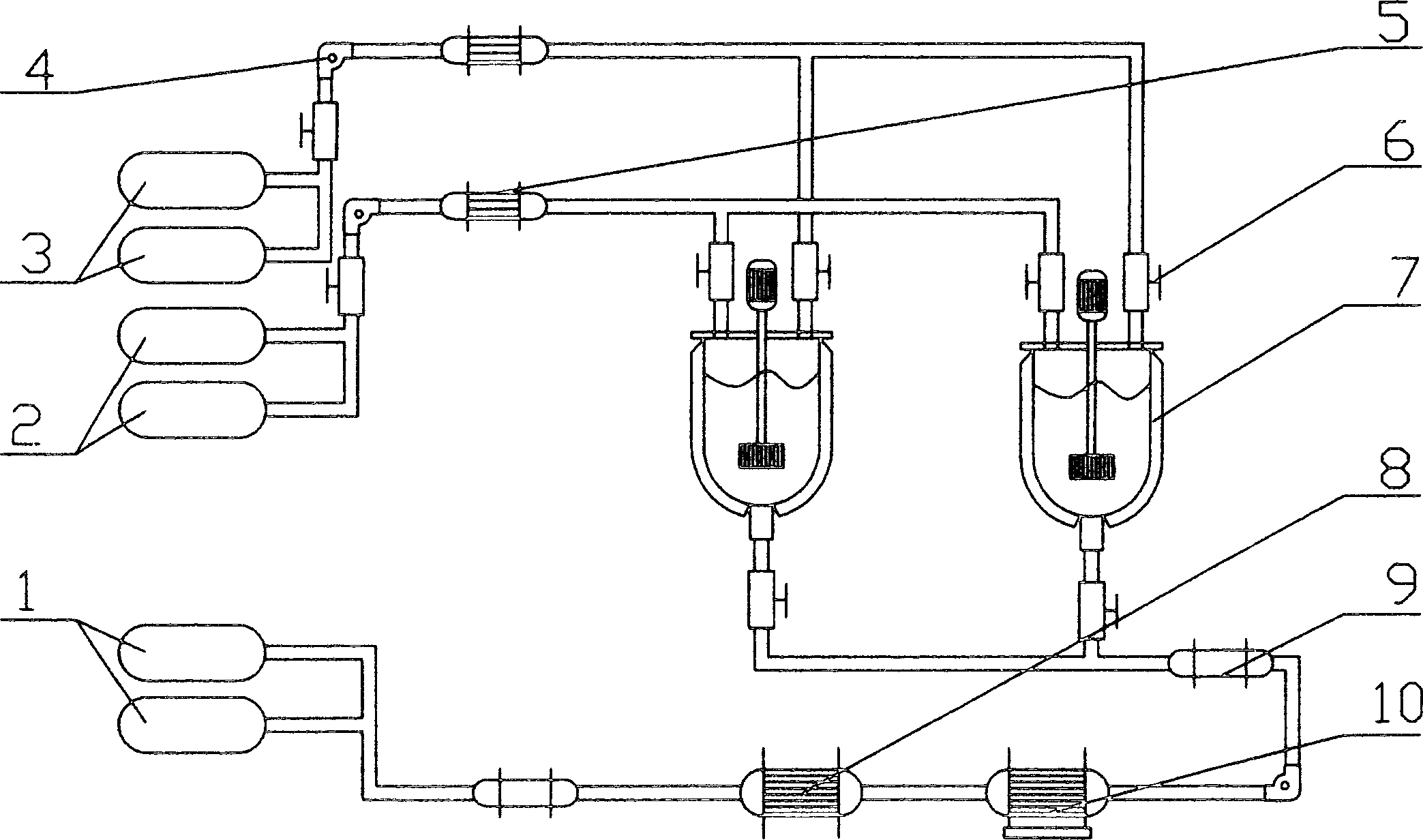

Method for improving viscose bamboo pulp reaction performance

InactiveCN105803841AAvoid degradationAvoid React Performance Negative ImpactPulp beating methodsCellulosePolyethylene glycol

The invention relates to a method for improving a bamboo pulp reaction performance. The method comprises the following steps of (1) pre-processing a pulp board; (2) pre-processing before processing an accessory ingredient; (3) processing the accessory ingredient, wherein the accessory ingredient is one or a mixture of polyglycol ether, polyoxyethylated castor oil, Turkey red oil, polyethylene glycol diamine, polyoxyethylene and sodium tripolyphosphate. The accessory ingredient processing provided by the invention has the advantages that the reaction performance adverse impact brought by cornification effect caused by further removing hemicellulose drying at the same time is avoided, the selectivity is good, and the degradation of cellulose is avoided; under the condition of keeping the pulp viscosity, the reaction performance can be improved by 5 to 20 percent.

Owner:FUJIAN AGRI & FORESTRY UNIV

Purified diesel and its preparation process

InactiveCN1632065AWith cleanEnergy savingRefining by water treatmentLiquid carbonaceous fuelsDemulsifierHigh pressure

The invention relates to a diesel oil purified by water and its preparing technique, belonging to the fuel field. The purified diesel oil is comprised of diesel oil, water, compound additive, and the compound additive is comprised of amyl nitrate, alkene, demulsifier, tetraethyllead, saponifiable oil, Italian red oil, auxiliary diesel oil, cyclanes, methylnaphthalene and aromatic hydrocarbon ect, through the techniques of synthesis, atomization, and mixing, make water disperse averagely and stably in nm to form oil-covering water. It has remarkable characteristics that its transparent as the general diesel oil, can be mixed with the general diesel oil willingly with good stability, and saving-oil rate is 18-30%, it has simple productive technique which does not relate to high temperature and high pressure, without 'three waste' is clean, energy-saving, economic and safe.

Owner:高扬飞

Method for electrodeposition of solid lubricating film by molybdenum disulfide liquid lubricant

ActiveCN102965707AImprove uniformityImprove bindingElectrolytic inorganic material coatingBase-materialsElectricityBinding force

The invention discloses a method for electrodeposition of a solid lubricating film by a molybdenum disulfide liquid lubricant. The method consists of: first cleaning a part, putting the part in a molybdenum disulfide liquid lubricant, conducting electrodeposition for 1-5min under a voltage of 50-90V and a temperature of 26-30DEG C, then taking the part out, cleaning and draining it, and curing the part for 20-40min at 170-180DEG C, thus obtaining a molybdenum disulfide solid lubricating film formed on the part. Compared with current methods that always rely on the traditional mode of spraying a solid lubricating film to satisfy lubrication performance need, the method provided in the invention makes the lubricating film with good uniformity and binding force. The film can be assembled and disassembled repeatedly without being damaged, can work under high and low temperature environments, has the property of special medium (red oil) resistance, and guarantees the lubrication property, resistance to corrosion, seizure and the like of the lubricating part, thus being able to be applied to lubrication of various high precision bearings in the fields of aviation, aerospace, and ships etc., and also being applicable to solid lubrication of parts in other fields.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

Quick glass detergent

InactiveCN104342303AFast dissolutionEasy to cleanAnionic-cationic-non-ionic surface-active compoundsDetergent compounding agentsHydration reactionO-Phosphoric Acid

The invention relates to a quick glass detergent which is prepared from the following raw materials in parts by weight: 6-8 parts of isooctanol polyethenoxy ether, 5-9 parts of sodium dodecyl benzene sulfonate, 5-7 parts of 65 wt% phosphoric acid, 7-10 parts of sodium hypochlorite, 3-9 parts of ethylene glycol monoethyl ether, 4-6 parts of sodium silicate, 3-8 parts of ethanol, 5-10 parts of magnesium sulfate heptahydrate, 2-6 parts of Turkey red oil, 5-9 parts of methyl chlorofluoride and 5-10 parts of isopropanol. The quick glass detergent has the advantages of high dissolution rate and high cleaning power, can form a protective film, and is widely used.

Owner:QINGDAO ZHIGU INNOVATION TECH

Improved high-permeability wood preservative

InactiveCN104802259AImprove permeabilityWood treatment detailsWood impregnation detailsBENZYL ALCOHOL/WATERMaterials science

An improved high-permeability wood preservative is prepared from the following raw materials in parts by weight: 3-9 parts of zinc oxide, 4-8 parts of titanium dioxide, 1-4 parts of anthraquinone, 6-10 parts of sodium dodecyl benzene sulfonate, 3-8 parts of sodium silicate, 7-9 parts of calcium hydroxide, 6-11 parts of propylene glycol, 5-10 parts of acrylic acid methyl ester, 4-9 parts of dimethylacetamide, 5-11 parts of triethanolamine, 4-7 parts of Turkey red oil, 4-10 parts of benzyl alcohol, 6-10 parts of castor oil polyoxyethylene ether, 7-11 parts of succinic acid alkyl ester disulphonic acid sodium salt and 6-8 parts of an organic solvent. The improved high-permeability wood preservative provided by the invention has the benefits that good permeability is achieved, wood can be deeply protected, and nontoxicity and harmlessness are achieved.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

Novel gear extreme pressure grease

The invention discloses a novel gear extreme pressure grease, which is prepared from the following raw materials by weight: 1.5-4.1 parts of dimethyl-dithio-dipropyl amide, 2.3-4.4 parts of hydrogenated dimeric acid, 25-33 parts of industrial red oil, 2.5-7.1 parts of 2-amino-2-methyl-1-propyl alcohol, 2.5-4.5 parts of sorbitan monooleate, 10-17 parts of glycerol and 3.5-4.7 parts of boric acid. The invention can greatly improve bearing capacity of the gear grease but also eliminate the influences of a traditional lead formula on the health of workers and can effectively prevent wearing on the surfaces of steel and copper parts; proper adhesion and extremely low coefficient of friction can effectively reduce the noise produced during gear running and machine temperature and reduce energy consumption; and in the premise of excellent performance and ensuring normal operation of a steam turbine, the novel gear extreme pressure grease greatly prolongs the service life of oil, reduces the oil change frequency and saves cost for enterprises.

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

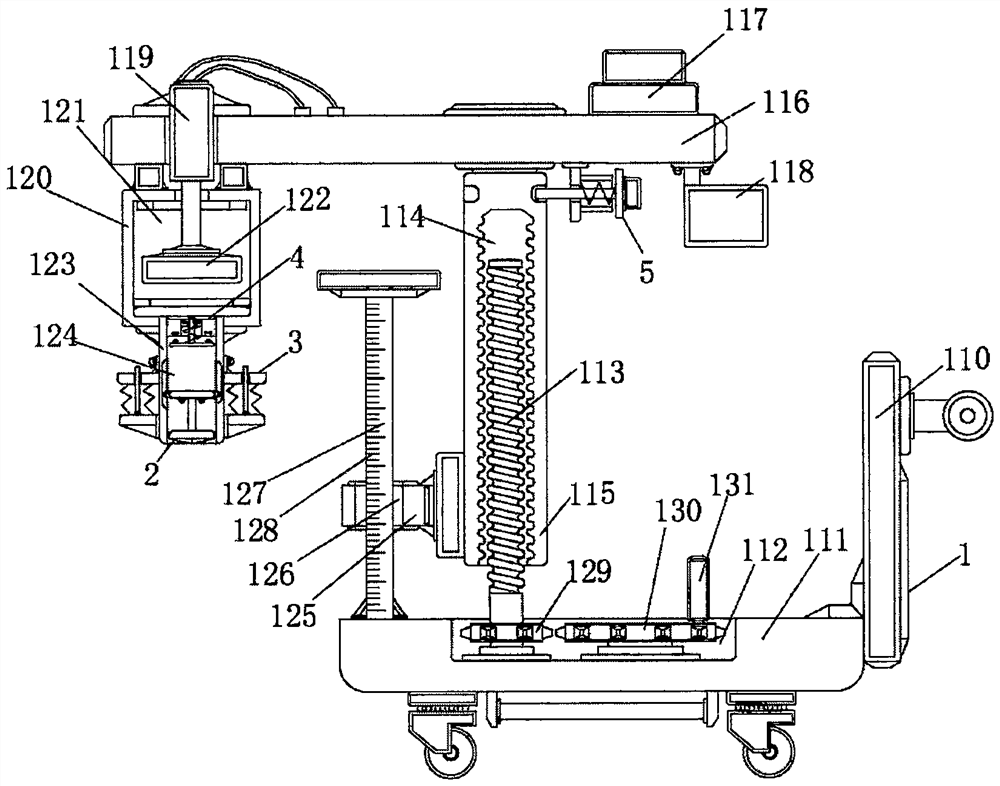

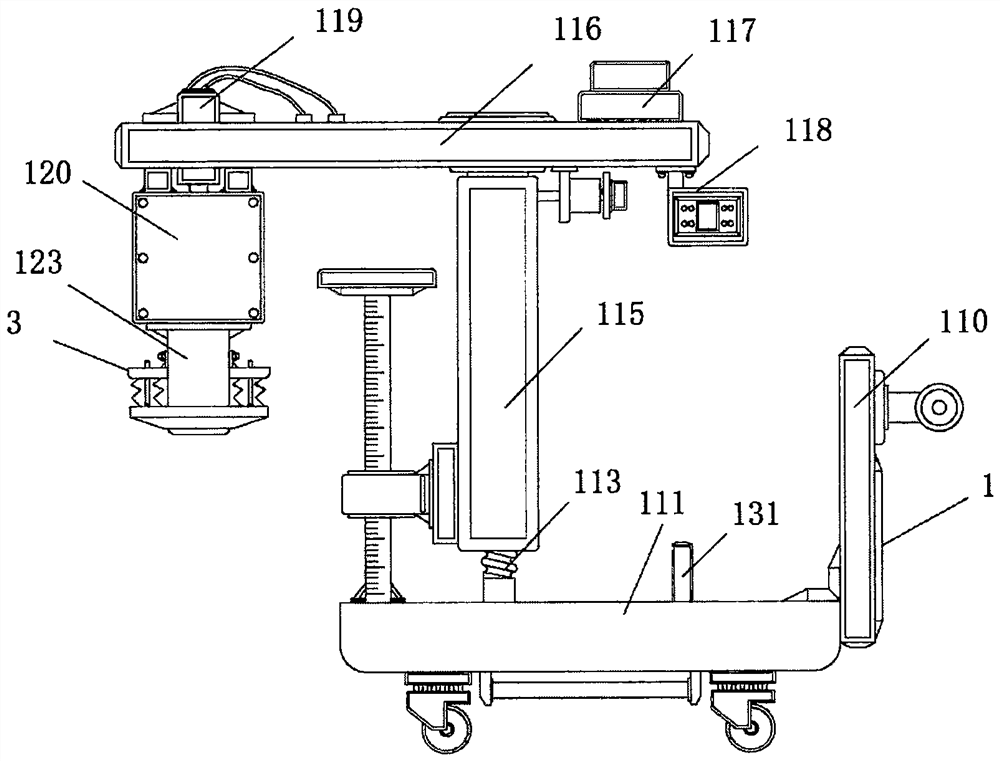

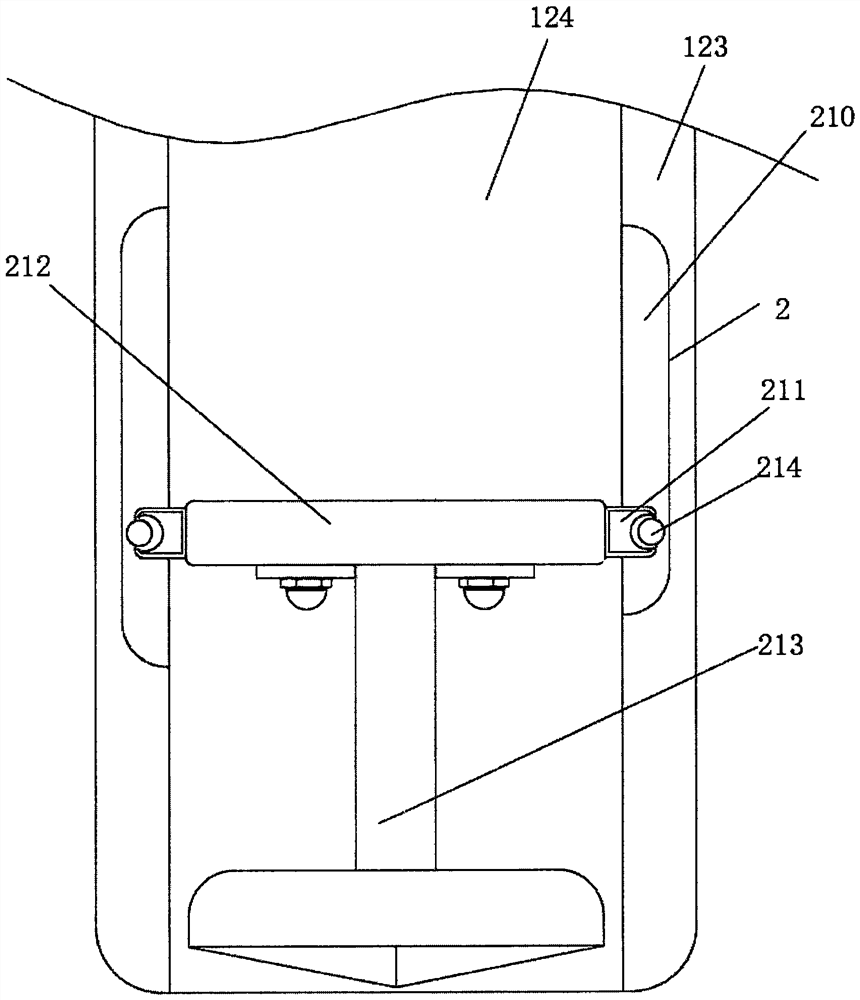

Food nutrition safety detection sampling device based on negative pressure suction technology

ActiveCN112326359AReduce adhesionAvoid dry cloggingClimate change adaptationWithdrawing sample devicesAnimal scienceMedicine

The invention relates to the technical field of food detection and sampling, in particular to a food nutrition safety detection and sampling device based on a negative pressure suction technology, thedevice comprises a device body, the device body comprises a moving base, a pushing handle is fixedly installed on one side of one end of the moving base, and an adjusting groove is formed in one endof the moving base; and an inner screw rod is arranged at one end of the movable base, and a threaded bin is formed in one end of the inner screw rod. By arranging the sliding groove, the sliding block, the inner scraping block, the compression spring, the outer scraping sleeve and the mounting strip, after sampling is completed, the outer surface of the material taking pipe body and the inner wall of the material taking bin can be cleaned through the outer scraping sleeve with one conical end and the inner scraping block; therefore, after the device completes sampling, less hot pot red oil adhered to the device is less, so that the device is more convenient for workers to carry out subsequent maintenance work, and the condition of drying blockage caused by the hot pot red oil can be further avoided.

Owner:ZIBO VOCATIONAL INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com