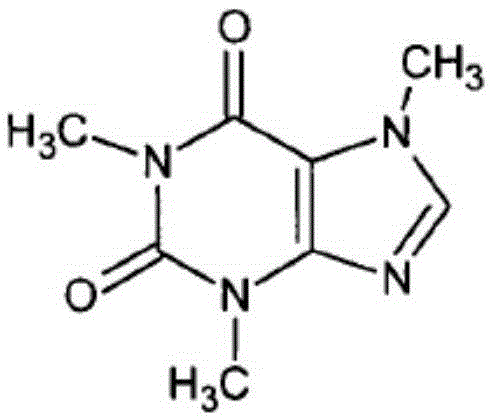

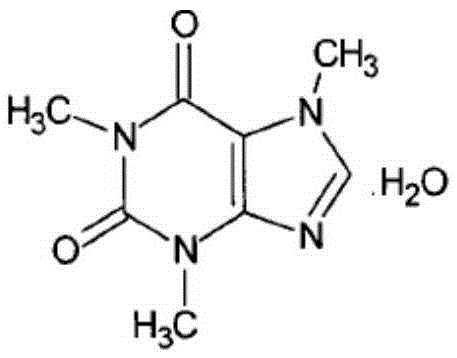

Preparation process for environment-friendly semisynthetic caffeine

A technology of caffeine and synthesis method, applied in the direction of organic chemistry and the like, can solve the problems of low reaction efficiency and low reaction efficiency, and achieve the effects of improving utilization rate, low cost and obvious reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

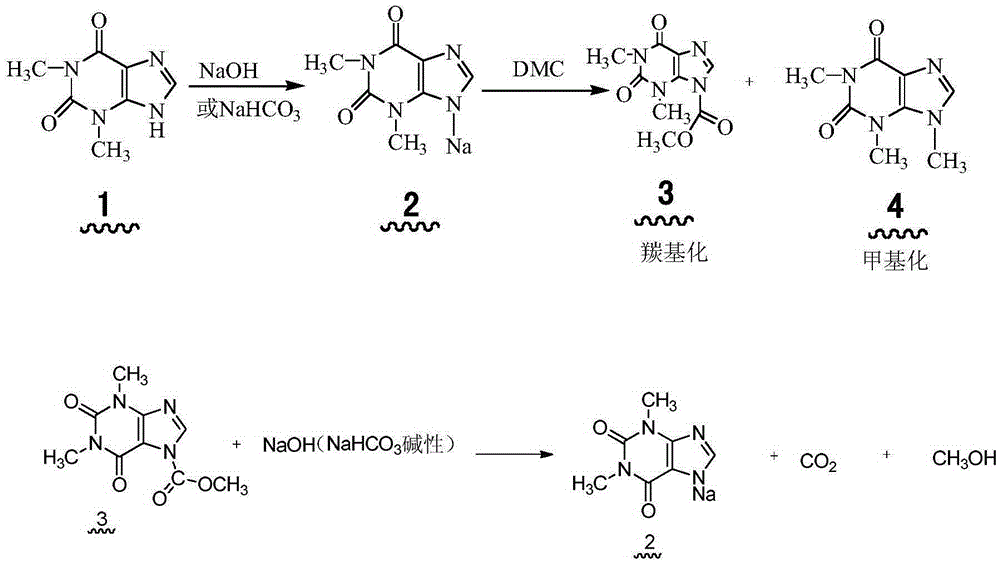

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: Add 1 mole of sodium theophylline, 2 moles of DMC, 800 grams of water, 10 grams of NaY and 10 grams of Turkish red oil in a 2-liter three-neck flask with a mechanical stirrer, a reflux condenser and a thermometer device. The reaction was heated to reflux under stirring conditions. After 5 hours of reaction, carry out TLC detection (petroleum ether: ethyl acetate 5:1). When the transformation of theophylline sodium is complete, stop the reaction, and naturally cool down. When the room temperature is reached, the solid in the reaction is separated by suction filtration. The crude product can be obtained by organic solvent acetic acid Extract the product with ethyl ester or methanol to separate the catalyst NaY. After distilling off the solvent, 161 grams of earthy red caffeine crude product is obtained, with a yield of 83%. The product is dried and has a melting point of 233-238°C. The crude product is oxidized and decolorized by potassium permanganate to ob...

Embodiment 2

[0050] Embodiment 2: In 2 liters of there-necked flasks with mechanical stirrer, reflux condenser and thermometer device, add respectively 1 mole of theophylline sodium, 2 moles of DMC, the mother liquor in Example 1, 10 grams of NaY. The reaction was heated to reflux under stirring conditions. After 5 hours of reaction, carry out TLC detection (petroleum ether: ethyl acetate 5:1). When the transformation of theophylline sodium is complete, stop the reaction, and naturally cool down. When the room temperature is reached, the solid in the reaction is separated by suction filtration. The crude product can be obtained by organic solvent acetic acid Extract the product with ethyl ester or methanol to separate the catalyst NaY. After distilling off the solvent, 180 grams of earthy red caffeine crude product is obtained, with a yield of 92.7%. The melting point of the product is 230-240° C. after drying.

Embodiment 3

[0051] Embodiment 3: Add 1 mole of theophylline, 2 moles of DMC, 800 milliliters of water, 10 grams of DABCO-10 grams of NaY respectively in a 2-liter three-necked flask with a mechanical stirrer, a reflux condenser and a thermometer device (i.e. 1:1 compound) complex and 10 grams of Turkish red oil. Heating to reflux reaction was carried out under the condition of continuing stirring. After 5 hours of reaction, carry out TLC detection (petroleum ether: ethyl acetate 5:1). When the transformation of theophylline sodium is complete, stop the reaction, and naturally cool down. When the room temperature is reached, the solid in the reaction is separated by suction filtration. The crude product can be obtained by organic solvent acetic acid Extract the product with ethyl ester or methanol to separate the catalyst NaY. After distilling off the solvent, 186 grams of earthy red caffeine crude product is obtained, with a yield of 95.8%. The melting point of the product is 233-239° C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com