Silicon-carbon negative electrode material and preparation method thereof

A negative electrode material, silicon-carbon technology, applied in the field of silicon-carbon negative electrode materials and their preparation, can solve the problems of uneven dispersion of finished composite materials, complicated preparation methods, and high production costs, and achieve short preparation process time, simple preparation methods, and reduced The effect of preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

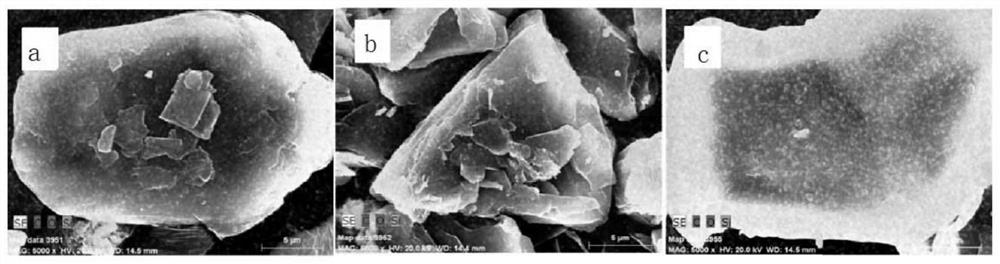

[0037] The existing preparation methods mainly include thermal decomposition method, gas phase precipitation method, ball milling method, sol-gel method, etc. Taking the ball milling method as an example, it is necessary to carry out blending ball milling of nano-scale silicon element or silicon oxide and graphite, and high-speed ball milling for 12 hours As above, carbon coating is carried out on the silicon-carbon composite material after ball milling by means of a spray drying method or the like. However, the existing preparation methods all have problems such as complex preparation methods, long preparation time, and high preparation costs, making it difficult to realize industrial production.

[0038] Moreover, in the finished product prepared by the existing preparation method, due to the uneven dispersion of the graphite negative electrode and the silicon-containing oxide in the mixture, the material consistency is poor, resulting in a large volume expansion of the silic...

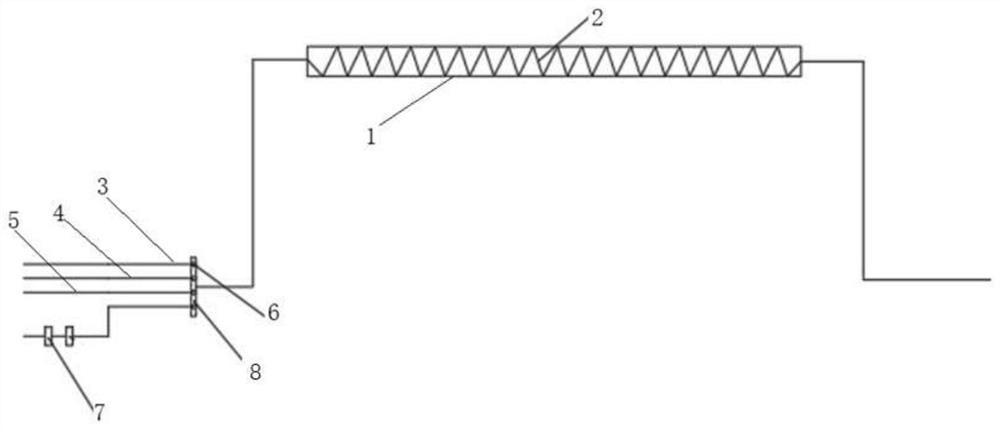

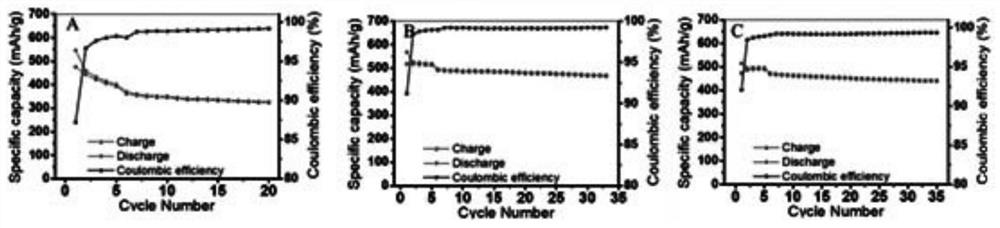

Embodiment 1

[0068] Select a graphite negative electrode material with a particle size of about 100nm, evenly attach it to the carrier, and send it into the reaction chamber of the tube furnace. Intake line 1, feed nitrogen gas for 3 minutes, remove the air in the chamber, and set the temperature to 120 degrees Celsius. Keep warm for 1 hour, set the temperature to 1200 degrees Celsius, when the temperature rises to 1000 degrees, open the air inlet line 2, close the gas line 1, and feed argon, when the temperature rises to 1200 degrees, open the gas line 4, and let the argon flow in The silicon source (silicon tetrachloride) carried by the hydrogen gas, the gas flow meter sets the flow rate to 20ul / min, close the gas circuit 2, and keep the reaction at 1200 degrees for 300 minutes. After the reaction, open the gas circuit 2, pass in argon, and close Gas path four, feed silicon source inert gas and hydrogen gas, use pure water as the exhaust gas collection device, wait for the temperature to ...

Embodiment 2

[0074] Other experimental steps are the same as in Example 1, and the reaction temperature is set at 1220 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com