Prograding mudflat foundation reinforcing device and construction method thereof

A technology for foundation reinforcement and tidal flats, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of inconsistent soil solidification at different depths, difficulty in controlling the uniformity, and unsatisfactory reinforcement effects, etc., to improve consolidation efficiency , less noise pollution and shorter construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The directions shown in the accompanying drawings are up, down, left, and right.

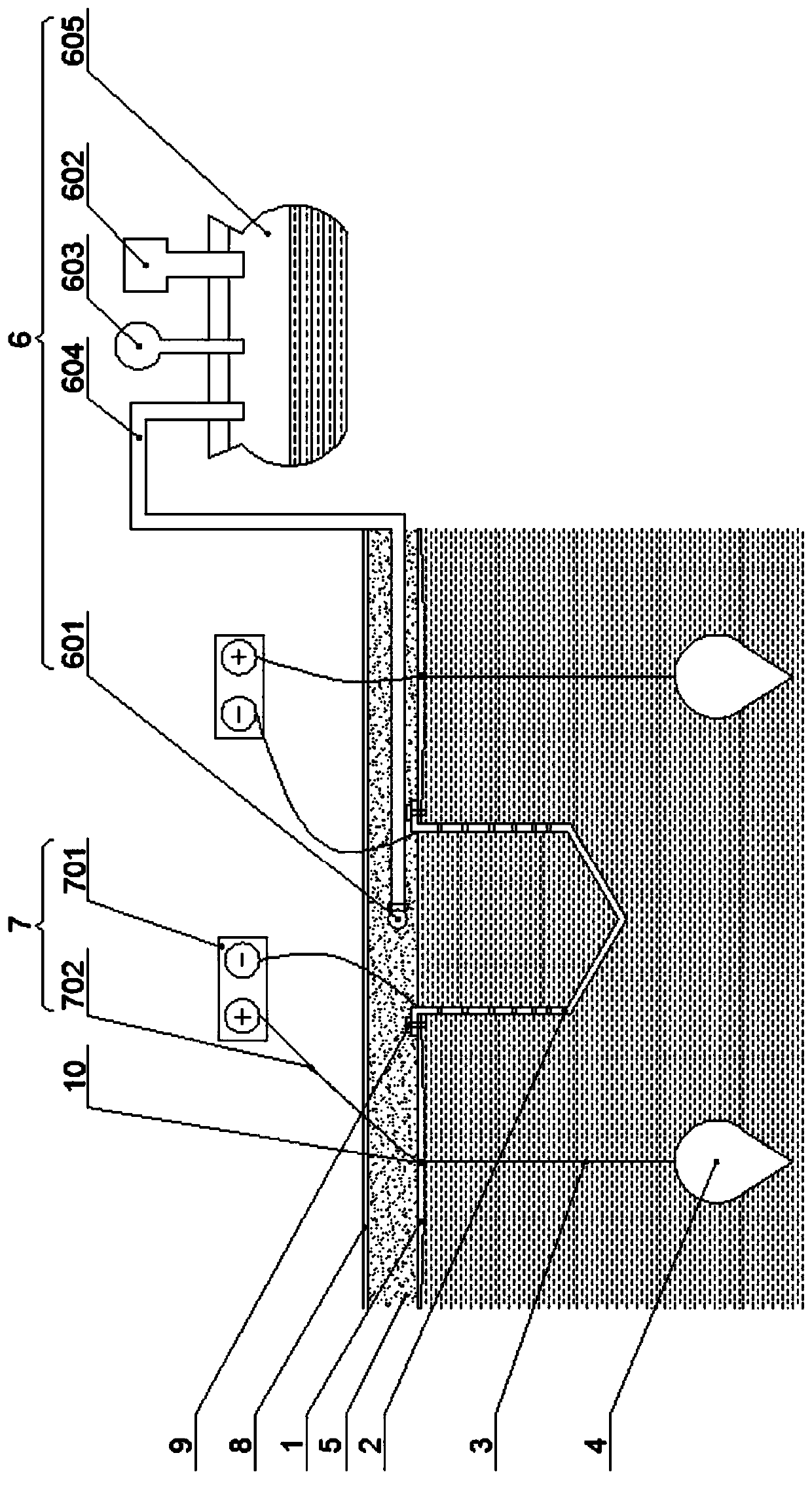

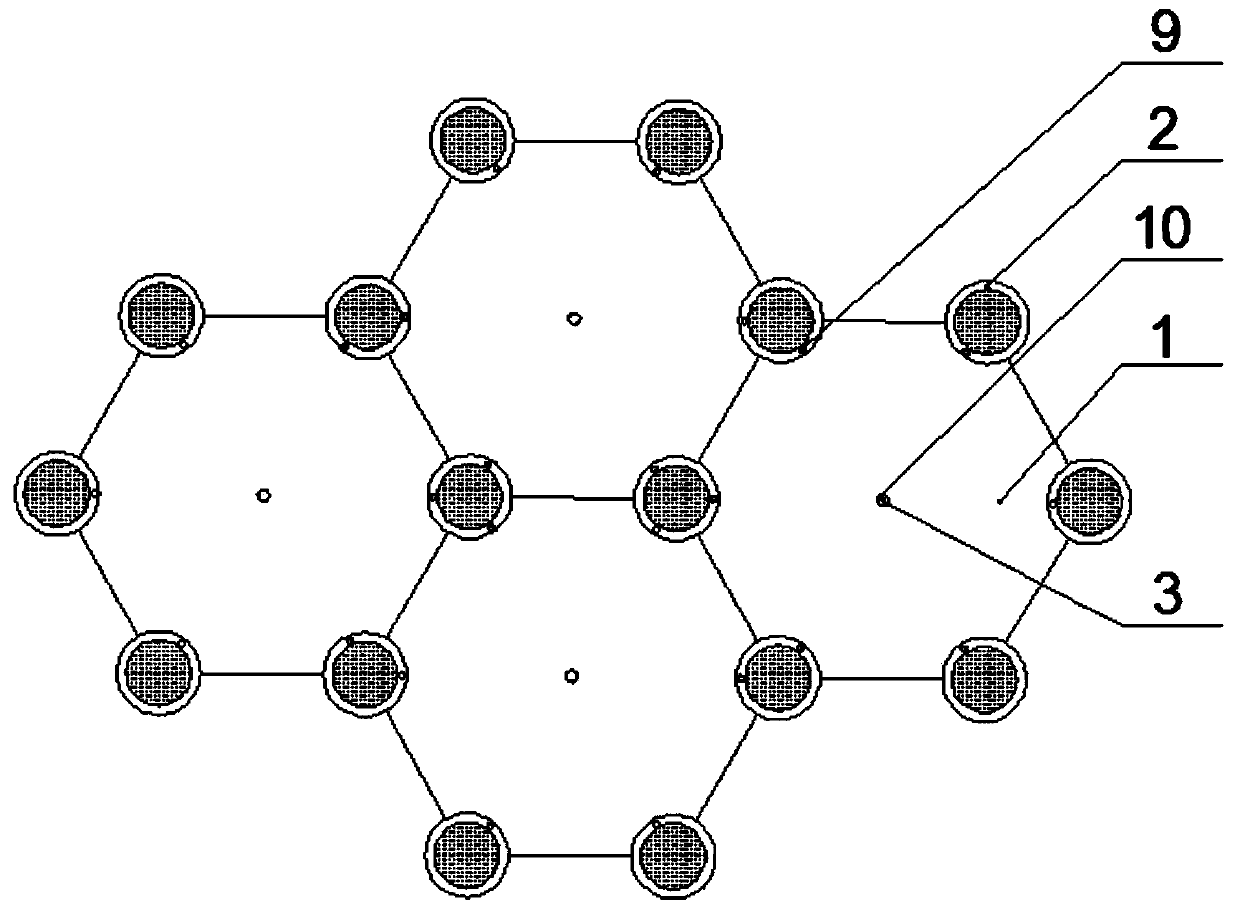

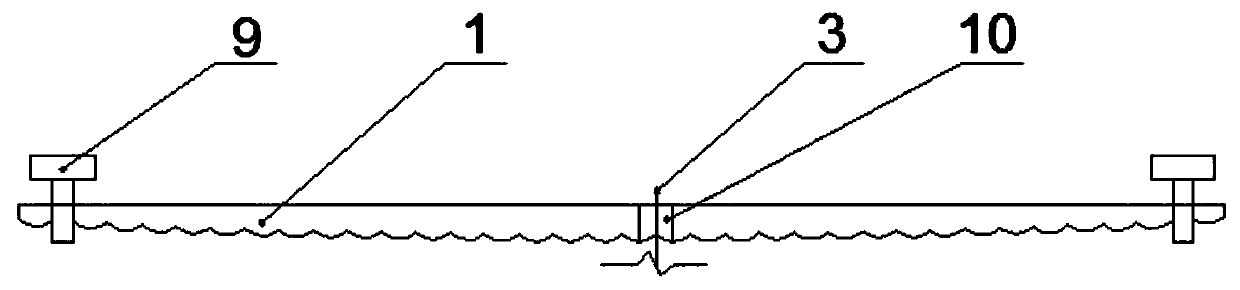

[0035] Such as figure 1 The hollow steel plate 1, the hollow steel cylinder 2, and the solid steel ball 4 are positioned and installed on the muddy soft soil foundation of the tidal flat, and the hollow steel plate 1 and the hollow steel cylinder 2 are connected by bolts 9 to form a whole. After the vacuum device 6 and the electroosmosis device 7 are installed on the upper part of the hollow steel plate 1, the sand cushion layer 5 is laid, and the vacuum sealing film 8 is laid on the upper part of the sand cushion layer 5. The vacuum device 6 comprises a vacuum probe 601, a vacuum pump 602, a vacuum gauge 603, a drainage pipe 604 and a water collection tank 605. One end of the drainage pipe 604 is connected with the vacuum probe 601 and buried in the sand cushion 5, and the other end is connected to the water collection tank. 605 is connected, and a vacuum gauge 603 is installed on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com