Subgrade filling method for physical improvement of fine silt

A technology of fine silt and roadbed, applied in roads, buildings, tracks, etc., can solve the problems that cannot meet the basic requirements of roadbed construction, low cohesiveness and plasticity, and difficult to form boards, etc., and achieve good economic and social effects , good water stability, uniform settlement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the drawings.

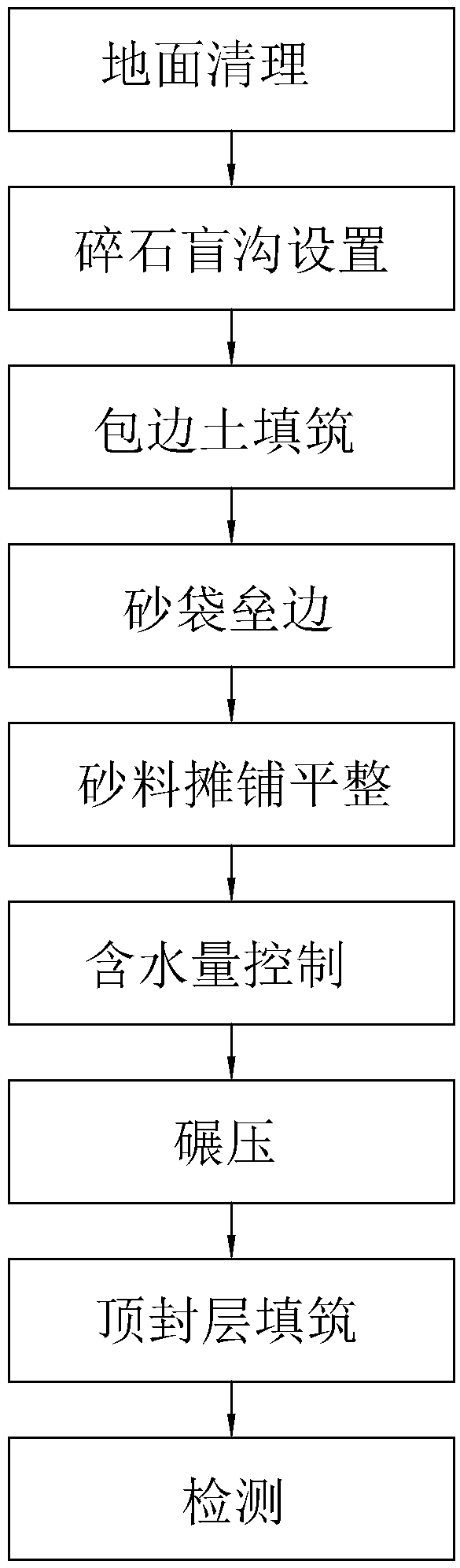

[0034] A roadbed filling method with physical improvement of fine silt sand, such as figure 1 As shown, including the following steps:

[0035] S1: Ground cleaning, manual construction with bulldozers, weeds and corrosive soil on the original ground are removed from the roadbed, and tree roots are excavated by excavators;

[0036] S2: Blind gravel ditch is set, and gravel drainage blind ditch is set every 20 meters along the slope toe on both sides of the roadbed.

[0037] S3: Filling with edging soil. Set edging soil along both sides of the roadbed. The width of edging soil should meet the requirements of compaction machinery walking and effective compaction width. During construction, the width should be appropriately increased to ensure edge compaction quality. The edging soil and sand core shall be filled and rolled simultaneously;

[0038] S4: Sand bag edge, after layered fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com