Composite emulsified asphalt and preparation technology thereof

A technology of composite emulsification and preparation technology, which is applied in the field of composite emulsified asphalt and its preparation technology, can solve problems such as poor high temperature resistance, high temperature deformation of asphalt roads, and insufficient interlayer cohesion, so as to meet application requirements and high temperature resistance Good performance and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

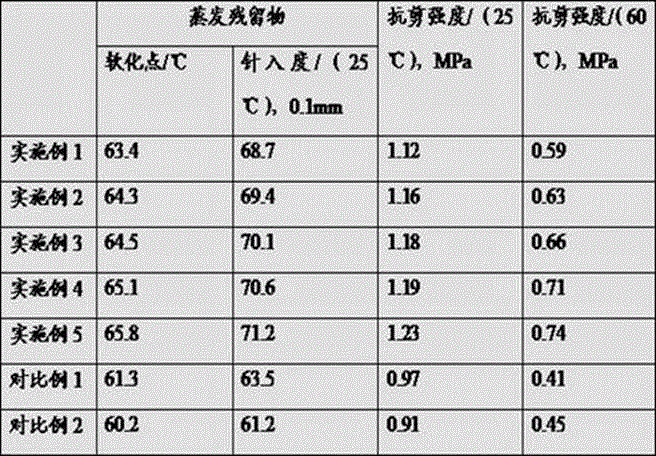

Examples

Embodiment 1

[0022] A kind of composite emulsified asphalt, by weight, is made up of following components: 45 parts of base pitch, 10 parts of petroleum coke, 2 parts of polybutene, 3 parts of EVA, 2 parts of pentaerythritol, 4 parts of 8-hydroxyquinoline 3 parts of monolauryl phosphate, 1 part of vinyl tertiary carbonate, 3 parts of propylene glycol block polyether, 6 parts of Swire oil, 2 parts of oleamide, 0.8 part of ethylene oxide diamine, 0.5 part of aminated lignin , 1 part of bentonite, 0.6 parts of phosphate betaine, 14 parts of water, 3 parts of sodium dodecylbenzenesulfonate, 2 parts of ammonium humate, 1.6 parts of hydrochloric acid, 2.2 parts of ammonium chloride, 1.5 parts of β-butyrolactone , 1.8 parts of vinyl bis stearamide.

[0023] The base asphalt is petroleum asphalt, and its penetration is 50-80 1 / 10mm.

[0024] The preparation technology of above-mentioned composite emulsified asphalt comprises the steps:

[0025] 1) Weigh according to the above parts by weight;

...

Embodiment 2

[0032] A composite emulsified asphalt, by weight, is composed of the following components: 58 parts of base asphalt, 18 parts of petroleum coke, 9 parts of polybutene, 7 parts of EVA, 6 parts of pentaerythritol, 4 parts of 8-hydroxyquinoline -8 parts, 9 parts of monolauryl phosphate, 5 parts of vinyl tertiary carbonate, 8 parts of propylene glycol block polyether, 10 parts of Swire oil, 9 parts of oleamide, 1.5 parts of ethylene oxide diamine, aminated lignin 2.4 parts, 3 parts of bentonite, 1.8 parts of phospholipid betaine, 20 parts of water, 6 parts of sodium dodecylbenzenesulfonate, 8 parts of ammonium humate, 3 parts of hydrochloric acid, 5 parts of ammonium chloride, β-butyrolactone 4 parts, 3 parts of vinyl bis stearamide.

[0033] The base asphalt is oxidized asphalt, and its penetration is 50-80 1 / 10mm.

[0034] The preparation technology of above-mentioned composite emulsified asphalt comprises the steps:

[0035] 1) Weigh according to the above parts by weight;

...

Embodiment 3

[0042]A kind of composite emulsified asphalt, by weight, is made up of following components: 48 parts of base pitch, 12 parts of petroleum coke, 2.5 parts of polybutene, 3.5 parts of EVA, 2.7 parts of pentaerythritol, 8-hydroxyquinone 4.6 parts of morphine, 3.5 parts of monolauryl phosphate, 1.2 parts of vinyl tertiary carbonate, 3.3 parts of propylene glycol block polyether, 6.4 parts of Swire oil, 2.6 parts of oleamide, 0.9 parts of ethylene oxide diamine, aminated lignin 0.7 parts, 1.6 parts of bentonite, 0.8 parts of phospholipid betaine, 16 parts of water, 3.5 parts of sodium dodecylbenzenesulfonate, 2.6 parts of ammonium humate, 1.8 parts of hydrochloric acid, 2.6 parts of ammonium chloride, β-butyrolactone 1.6 parts, 2 parts of vinyl bis stearamide.

[0043] The base asphalt is petroleum asphalt and deoiled asphalt with a weight ratio of 4:1, and its penetration is 50-80 1 / 10mm.

[0044] The preparation technology of above-mentioned composite emulsified asphalt compris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com