Frying process for lowering acid value of oil in red camphor oil hotpot soup base

A hot pot base and frying technology, which is applied in food preparation, application, food science and other directions, can solve the problems of unfavorable red oil hot pot base oil acid value, long stirring time, etc., and achieves low yield and lower acid value. , the effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

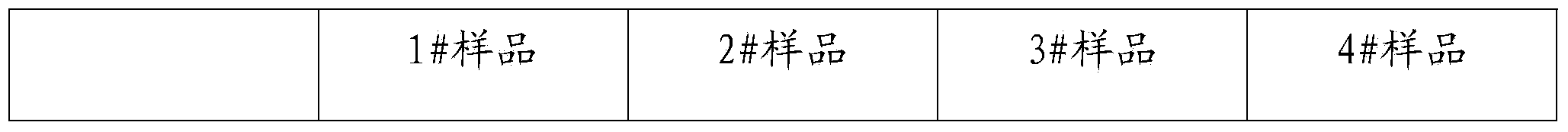

experiment example 1

[0035] Raw material ratio: 30 parts of rapeseed oil, 70 parts of butter, 24 parts of the first auxiliary material and 80 parts of the second auxiliary material.

[0036] Wherein, the first auxiliary material is composed of the following components: 4 parts of grass fruit, 2 parts of bean paste, 2 parts of ginger, 2 parts of clove, 6 parts of cinnamon, 5 parts of star anise, 0.5 part of salt, 0.5 part of pepper, 1 part of cardamom, 1 serving of cooking wine. The second auxiliary material is composed of the following components: 60 parts of pepper, 5 parts of Zanthoxylum bungeanum, 10 parts of chicken essence, and 5 parts of rock sugar.

[0037] Stir-frying process: a. Material preparation: configure rapeseed oil, butter, first auxiliary material and second auxiliary material in proportion;

[0038] b Frying: add the first auxiliary material to the rapeseed oil, fry at 80°C and 0.1MPa for 3 minutes, and then fry at 120°C and 0.5MPa for 3 minutes;

[0039] c Continue frying: he...

experiment example 2

[0043] Raw material ratio: 30 parts of rapeseed oil, 70 parts of butter, 24 parts of the first auxiliary material and 80 parts of the second auxiliary material.

[0044] Wherein, the first auxiliary material is composed of the following components: 4 parts of grass fruit, 2 parts of bean paste, 2 parts of ginger, 2 parts of clove, 6 parts of cinnamon, 5 parts of star anise, 0.5 part of salt, 0.5 part of pepper, 1 part of cardamom, 1 serving of cooking wine. The second auxiliary material is composed of the following components: 60 parts of pepper, 5 parts of Zanthoxylum bungeanum, 10 parts of chicken essence, and 5 parts of rock sugar.

[0045] Stir-frying process: a. Material preparation: configure vegetable oil, animal oil, first auxiliary material and second auxiliary material in proportion;

[0046] b Frying: add the first auxiliary material to the rapeseed oil, fry at 70°C and 0.1MPa for 5 minutes, and then fry at 110°C and 0.5MPa for 2 minutes;

[0047] c Continue fryin...

experiment example 3

[0051]Raw material ratio: 30 parts of rapeseed oil, 70 parts of butter, 24 parts of the first auxiliary material and 80 parts of the second auxiliary material.

[0052] Wherein, the first auxiliary material is composed of the following components: 4 parts of grass fruit, 2 parts of bean paste, 2 parts of ginger, 2 parts of clove, 6 parts of cinnamon, 5 parts of star anise, 0.5 part of salt, 0.5 part of pepper, 1 part of cardamom, 1 serving of cooking wine. The second auxiliary material is composed of the following components: 60 parts of pepper, 5 parts of Zanthoxylum bungeanum, 10 parts of chicken essence, and 5 parts of rock sugar.

[0053] Stir-frying process: a. Material preparation: configure rapeseed oil, butter, first auxiliary material and second auxiliary material in proportion;

[0054] b Frying: add the first auxiliary material to the rapeseed oil, fry at 90°C and 0.1MPa for 5 minutes, and then fry at 110°C and 0.5MPa for 2 minutes;

[0055] c Continue frying: hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com