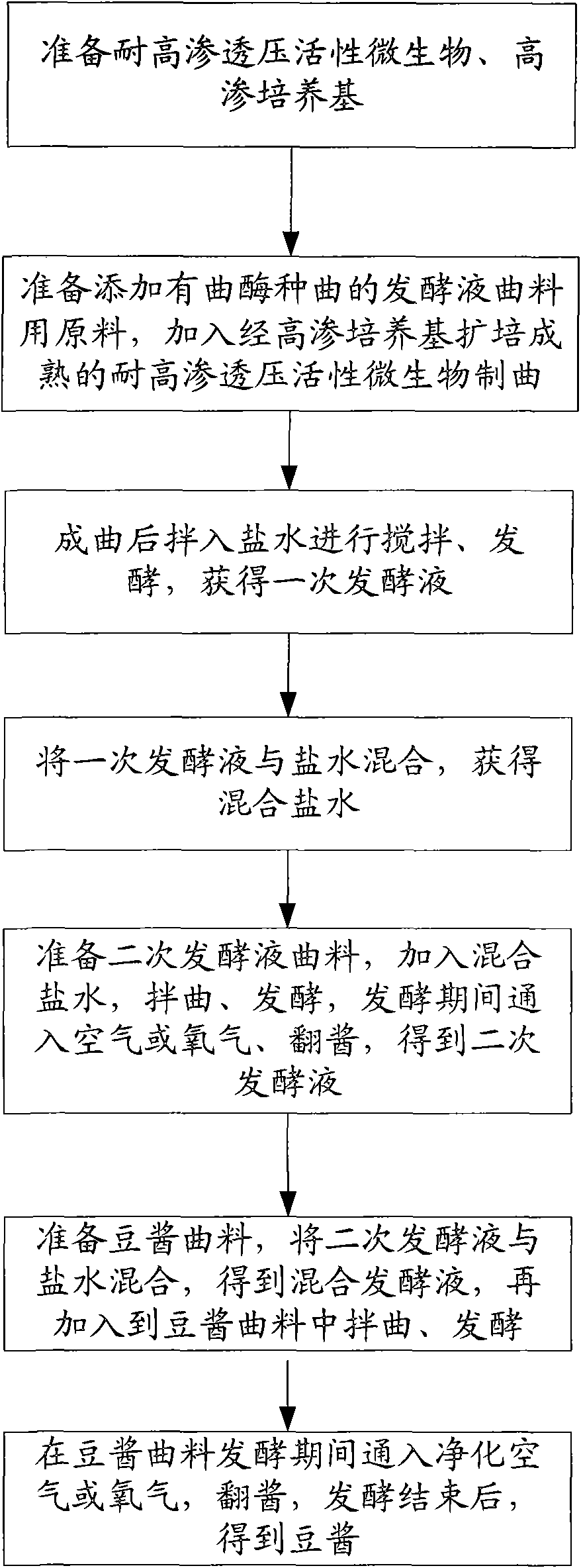

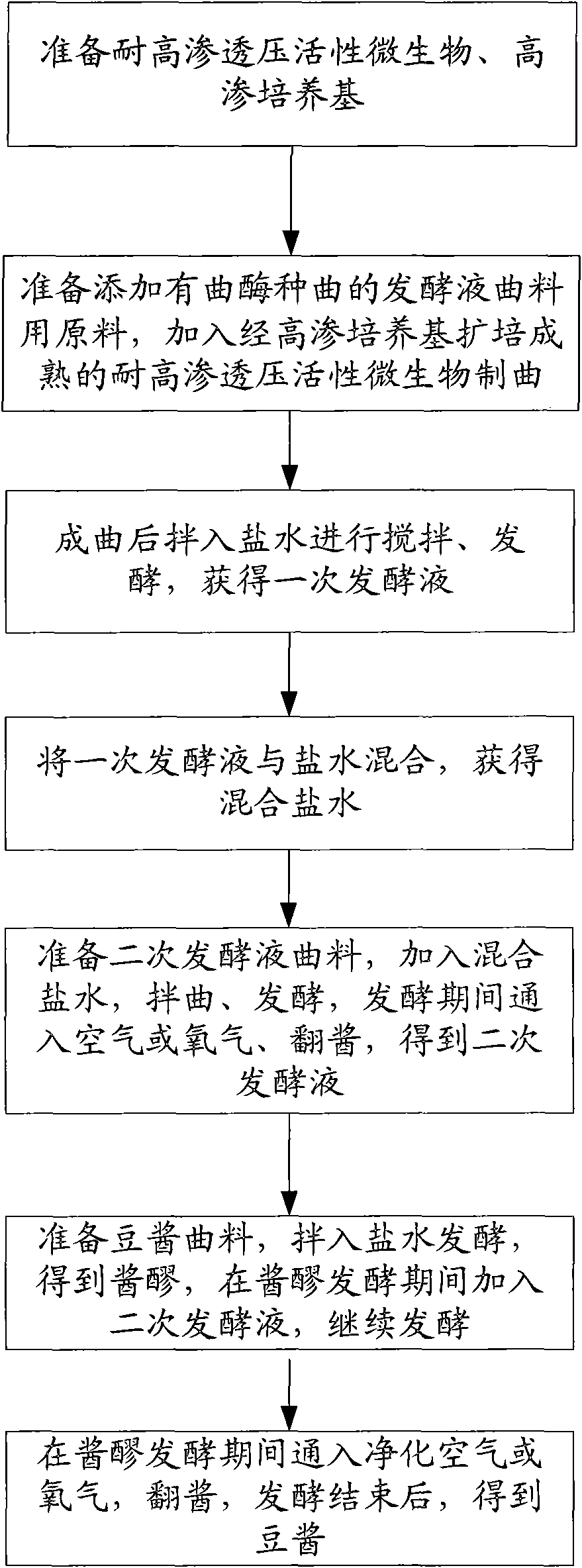

Fermentation method of soybean paste

A fermentation method and soybean paste technology, which are applied in the field of fermentation engineering, can solve the problems of large influence on the flavor of soybean paste, reduced tyrosine concentration, limited effect, etc., and can prevent the precipitation of tyrosine white matter, and the operation is simple and convenient. mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) Prepare hyperosmotic pressure-resistant ruckeri yeast, hyperosmotic medium with 10% by weight of NaCl, and soybean paste koji;

[0047] 2) Prepare raw materials for primary fermentation liquid koji with Aspergillus seed koji, add mature hyperosmotic pressure-resistant Luxie yeast that has been expanded and cultivated in hyperosmotic medium to make koji, mix it with salt water after making koji, stir and ferment, and obtain bacteria Concentration is 10 2 cfu / mL of the primary fermentation broth; wherein, the addition ratio of the hyperosmotic pressure-resistant Ruby yeast was 10 2 cfu / g primary fermentation broth koji, the added weight of brine is 1.5 times of the total weight of fermentation broth koji;

[0048] 3) mixing the primary fermentation broth and brine in a weight ratio of 1:2 to obtain mixed brine;

[0049] 4) Prepare the secondary fermentation liquid koji, add mixed salt water, the weight ratio of the mixed salt water to the secondary fermentation liqui...

Embodiment 2

[0054] 1) Prepare hyperosmotic pressure-resistant Pediococcus halophilus, hyperosmotic medium with a NaCl content of 1%, and soybean paste koji;

[0055] 2) Prepare raw materials for primary fermentation liquid koji with Aspergillus seed koji, add mature hyperosmotic pressure-resistant Pediococcus halophilus through hyperosmotic medium to make koji, mix it with salt water after making koji, stir and ferment, and obtain bacteria body concentration of 10 6 The primary fermentation broth of cfu / mL; among them, the addition ratio of Pediococcus halophilus resistant to high osmotic pressure is 10 7 cfu / g primary fermentation liquid koji, the added weight of salt water is 1.5 times of the total weight of primary fermentation liquid koji;

[0056] 3) mixing the primary fermentation broth and brine at a weight ratio of 1:10 to obtain mixed brine;

[0057] 4) Prepare the koji material of the secondary fermentation liquid, add mixed salt water, the weight ratio of the mixed salt water...

Embodiment 3

[0062] 1) Prepare Candida tropicalis, hyperosmotic medium with a NaCl content of 10%, and soybean paste koji;

[0063] 2) Prepare koji raw materials for the primary fermentation broth with the addition of Aspergillus species koji, add mature Candida tropicalis koji made by hyperosmotic medium expansion, and mix it with salt water for stirring and fermentation after the koji is formed to obtain a bacterial cell concentration of 10 6 cfu / mL primary fermentation broth; wherein, the addition ratio of Candida tropicalis is 10 6 cfu / g primary fermentation liquid koji, the added weight of salt water is 2.5 times of the total weight of primary fermentation liquid koji;

[0064] 3) mixing the primary fermentation broth and brine in a weight ratio of 1:2 to obtain mixed brine;

[0065] 4) Prepare the koji material of the secondary fermentation liquid, add mixed salt water, the weight ratio of the mixed salt water to the koji material of the secondary fermentation liquid is 5:2, then mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com