Patents

Literature

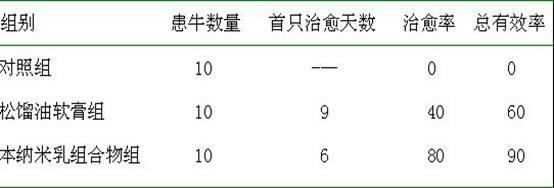

233 results about "CAMPHOR OIL" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano-emulsion medicine for treating foot rot and preparation method thereof

InactiveCN102552339AHigh thermodynamic stabilityEasy to operateAntibacterial agentsHydroxy compound active ingredientsPropanoic acidCutin

The invention discloses a nano-emulsion medicine for treating foot rot. The grain diameter of the nano-emulsion is in a range of 1-100 nanometers and the nano-emulsion is composed of the following raw materials: 0.1-10.0% of pine tar, 0.1-6.0% of cinnamyl aldehyde, 0.1-6.0% of carvacrol, 0.1-5.0% of camphor oil, 0.01-0.1% of clobetasol propionate, 18.0-35.0% of surfactant, 0-7.0% of co-surfactant and residual amount of distilled water; and the sum of the mass percentages of the components is 100%. The nano-emulsion disclosed by the invention has the functions of dissolving cutin, relieving itching, diminishing inflammation, restraining, partially disinfecting and resisting corrosion, accelerating absorption and the like, and is mainly used for treating animal foot rot. According to the nano-emulsion medicine for treating the foot rot, the solubility of the medicine is increased, the medicinal stability and the biological utilization rate are improved, the dosage of the medicine is reduced, the skin transmission rate is higher than that of common preparations including a medicinal extract and the like, and the cost is low, so that the nano-emulsion medicine has a wide market prospect in a veterinary medicine field.

Owner:NORTHWEST A & F UNIV

Method for production of preserved flower, and processing solution for use in the method

InactiveCN101861092AKeep natural colorReduce processDead plant preservationNatural resinVegetable oil

Disclosed is a method for producing a preserved flower, which enables to keep the original color of a real flower, particularly the subtle gradation in color of the real flower. Also disclosed is a processing solution for use in the method. Specifically disclosed is a method for producing a preserved flower, which comprises immersing a real flower in a processing solution and drying the flower, wherein the processing solution comprises a solution or dispersion containing at least one component selected from a natural oil material oil, a natural resin material, a siloxane, a synthetic resin, a water-addition-reaction-type urethane, a fatty acid ester and a surfactant, wherein the natural oil material is terpin oil, stand oil, whale oil, boiled oil, linseed oil, camellia oil, olive oil, rapeseed oil, a salad oil (a purified plant oil), sesame oil, camphor oil or the like, wherein the natural resin material is rosin, glue, wax, bees wax, rubber, rhus lacquer or the like, and wherein the fatty acid ester is an ester of a saturated or unsaturated fatty acid such as lauric acid, palmitic acid, stearic acid and myristic acid and a lower or polyhydric alcohol.

Owner:坂本好央

External preparation capable of relieving swelling and pain and preparation method thereof

ActiveCN104784270AShort onset timeImprove TCM syndromeAntipyreticAnalgesicsLycopodium clavatumOil phase

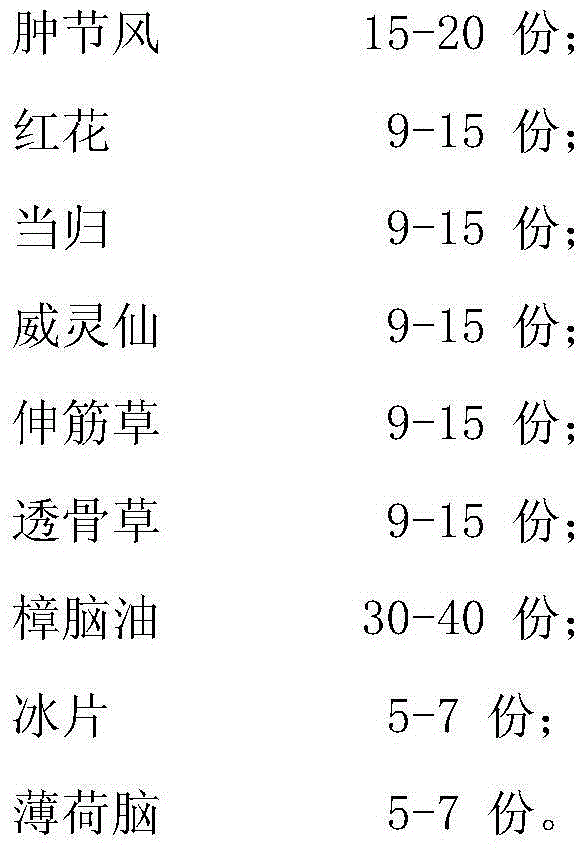

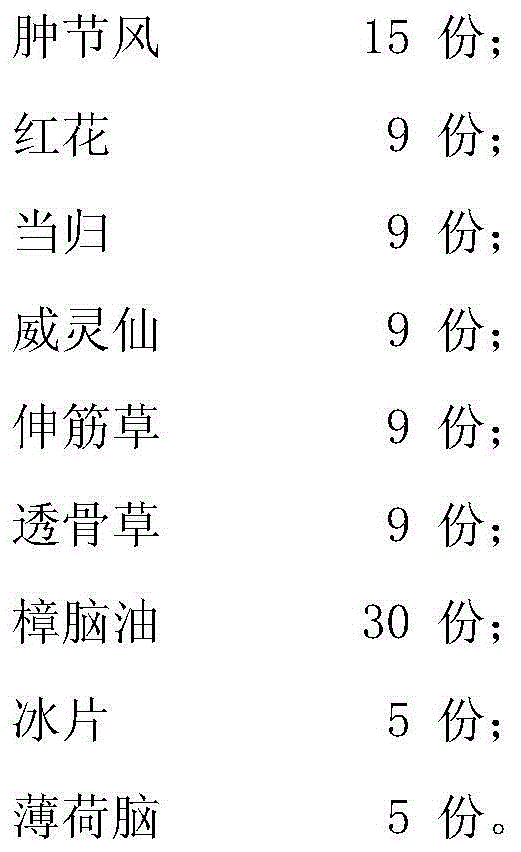

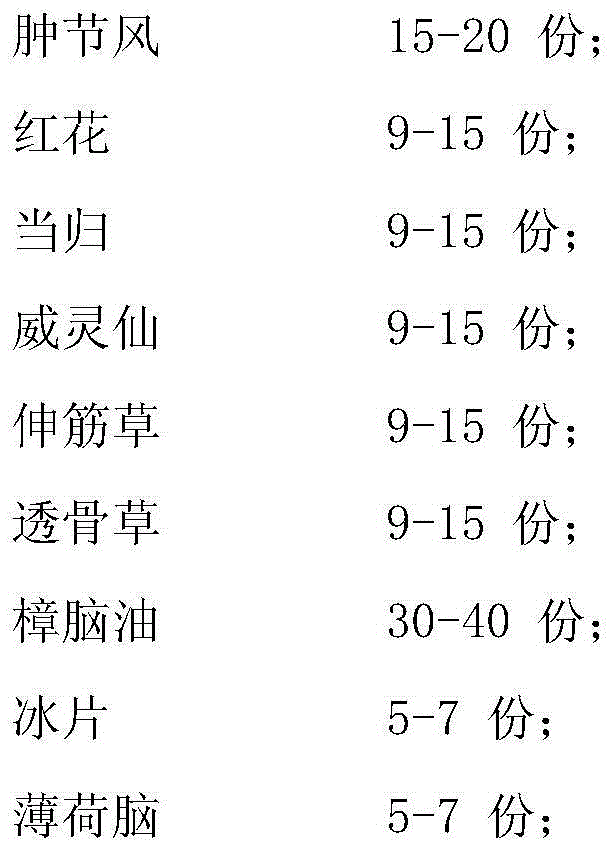

The invention discloses an external preparation capable of relieving swelling and pain and a preparation method thereof. The external preparation is prepared from the following raw materials in parts by weight: 15-20 parts of herba sarcandrae, 9-15 parts of safflower carthamus, 9-15 parts of angelica sinensis, 9-15 parts of radix clematidis, 9-15 parts of lycopodium clavatum, 9-15 parts of speranskia tuberculata, 30-40 parts of camphor oil, 5-7 parts of borneol and 5-7 parts of menthol. The preparation method of the external preparation comprises the following steps: preparing an oil phase with the camphor oil, stearic acid and glyceride, preparing an aqueous phase with triethanolamine and a OP emulsifying agent, then adding the aqueous phase into the oil phase while stirring, adding an appropriate amount of essence as well as an extract prepared from herba sarcandrae and borneol-menthol ethanol liquid at the temperature of 40 DEG C, uniformly mixing by a melting method, and cooling, so as to obtain the product. The external preparation disclosed by the invention is quick in initial effect time, capable of effectively improving traditional Chinese medicinal syndromes, safe to use, free of toxic and side effects, safe and effective to treat knee osteoarthritis.

Owner:王和鸣

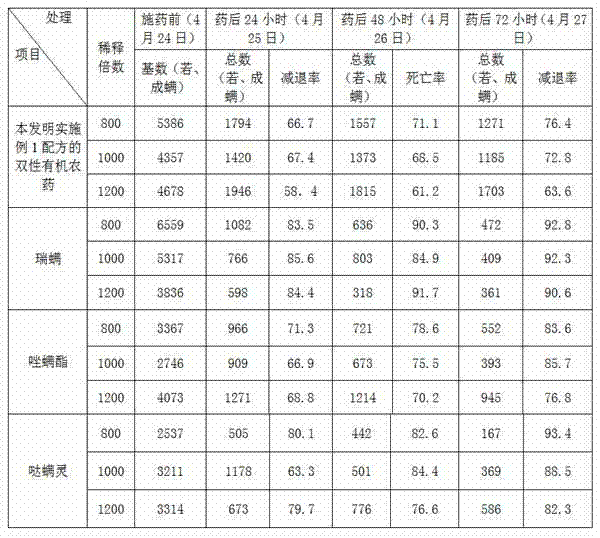

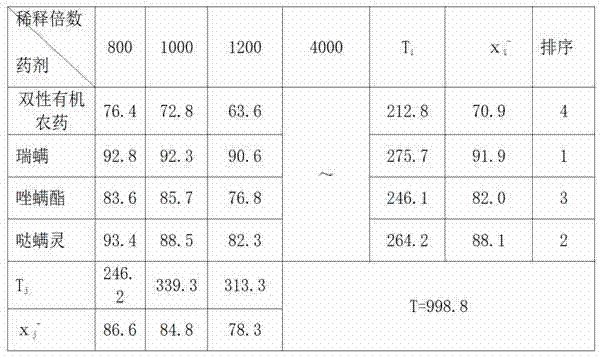

Ampholytic organic pesticide

The invention discloses an ampholytic organic pesticide. The ampholytic organic pesticide is prepared from the following components by weight percent: 35-45% of bamboo vinegar or wood vinegar, 15-25% of tobacco stem extract, 5-8% of allicin oil, 3-5% of camphor oil, 5-8% of rotenone, 8-16% of pesticide emulsifier, 5-8% of orange peel extract and 5-10% of alcohol. The preparation method of the tobacco stem extract comprises the following steps: soaking tobacco stems with bamboo vinegar in a volume ratio of 1:1, boiling, distilling to obtain distillate, cooling the distillate and filtering to obtain filtrate, namely the tobacco stem extract. The preparation method of the orange peel extract comprises the following steps: mixing fresh orange peels and bamboo vinegar in a ratio of 1:1, adopting the water distillation method to distill and obtain distillate, namely the orange peel extract. The tobacco stem waste is utilized, thus the method is economical and environmentally-friendly. The preparation method of the ampholytic organic pesticide is simple, the used raw materials are available; and the method uses pollution-free materials and is harmless for human body and crop.

Owner:唐恺

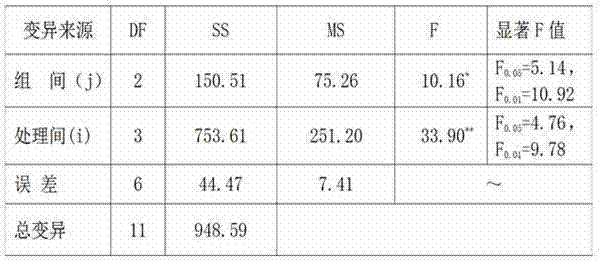

Kraft pulping process of camphorwood

ActiveCN110438834AQuality improvementMeet production needsPulping with inorganic basesChemical/chemomechanical pulpPaper productionSlurry

The invention discloses a kraft pulping process of camphorwood. The kraft pulping process comprises the following preparation steps that 100% camphorwood pieces are taken out for peeling, chipping andscreening operations, sent into a cooking pot for cooking operation, put into a scrubber for washing operation, sent into a pressure screen for screening operation, carried out bleaching operation byusing hydrogen peroxide, and sent into a slurry tower for storage operation. According to the kraft pulping process of the camphorwood, the purpose is that the camphorwood pieces after stewed camphorand camphor oil can be reused, process flow and process parameters can be made according to the material characteristics of camphorwood, the pulping cost is low, the pulp quality is good, and needs of high-grade paper production can be fully met.

Owner:YUEYANG FOREST & PAPER CO LTD

Frankincense protein peanut butter and preparation method thereof

InactiveCN103689695AFull of nutritionEnhance liver clearing and eyesightFood ingredient functionsFood preparationVegetable oilChilli con carne

The invention discloses frankincense protein peanut butter and a preparation method thereof. The frankincense protein peanut butter is prepared from the following raw materials: peanut kernel, peanut protein flour, whey protein powder, condensed milk, semen coicis powder, pine nut powder, coix seed oil, root of rehmannia, the root bark of the peony tree, folium isatidis, radix puerariae, hovenia dulcis thumb, artichoke, receptaculum nelumbinis, houttuynia cordata, fresh imperata cylindrical root, chilli sauce, red camphor oil, salt, rice vinegar, vegetable oil and a proper amount of water. According to the frankincense protein peanut butter, multiple high-protein components are added, the nutrition is rich, and the added artichoke has the effects of clearing liver and improving vision, treating dyspepsia and improving the intestines and stomach; the folium isatidis has the effects of inhibiting bacteria and detoxifying; the frankincense protein peanut butter is safe to eat, has the effects of increasing the appetite, appetizing and going with rice. As the chilli sauce is added into the frankincense protein peanut butter, the color is increased, so that the color, smell and taste are complete in all varieties, and the frankincense protein peanut butter is a green food which is rich in nutrition and convenient to eat.

Owner:田世伟

Wound disinfecting spraying film agent and preparation method thereof

ActiveCN106361816AEasy to useSimple preparation processAntibacterial agentsHydroxy compound active ingredientsPeppermintsGlycerol

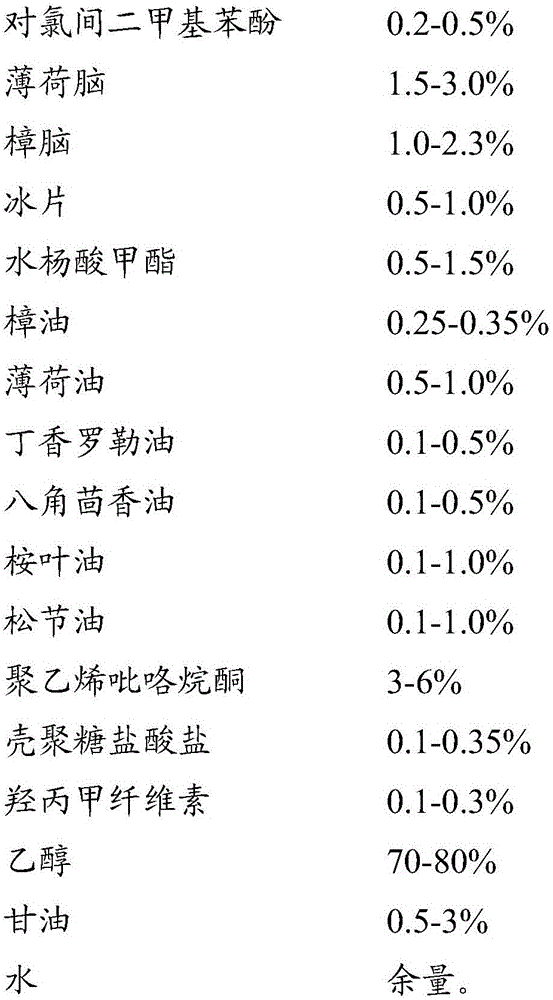

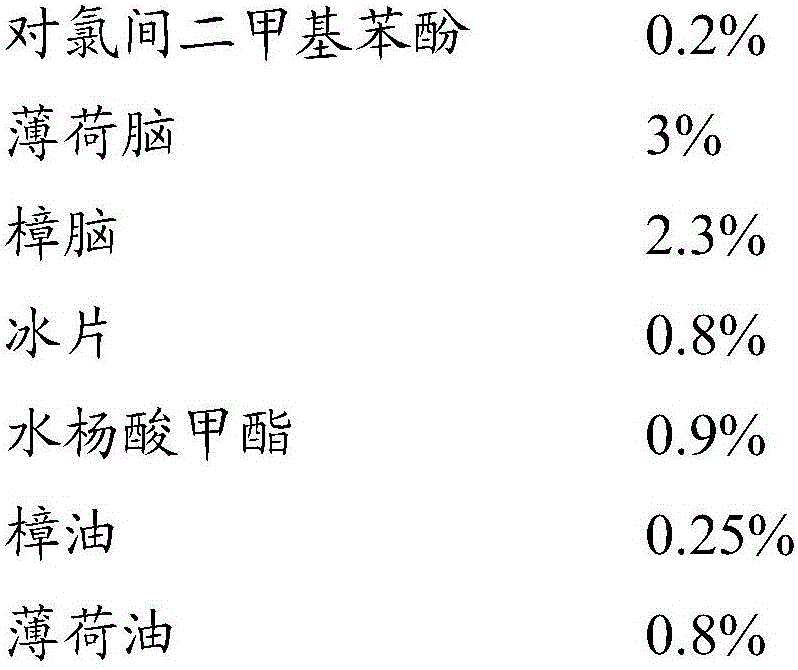

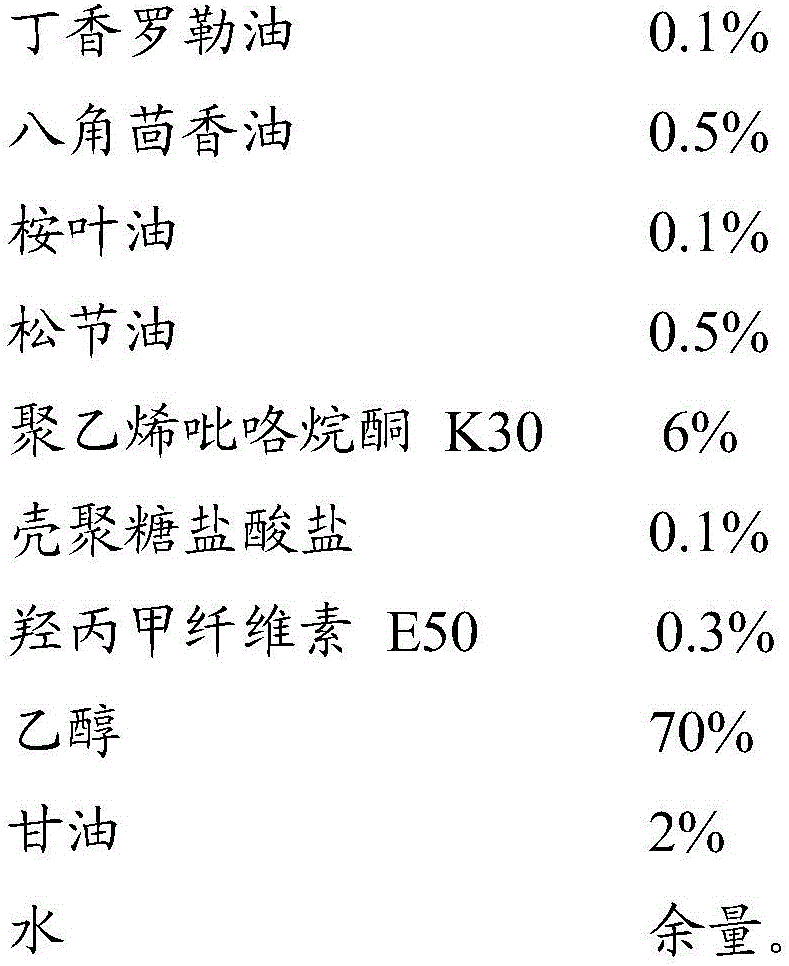

The invention discloses a wound disinfecting spraying film agent and a preparation method thereof. The wound disinfecting spraying film agent consists of the following components in percentage by mass: 0.2-0.5% of p-chloro-m-xylenol, 1.5-3.0% of menthol, 1.0-2.3% of camphor, 0.5-1.0% of borneol, 0.5-1.5% of methyl salicylate, 0.25-0.35% of camphor oil, 0.5-1.0% of peppermint oil, 0.1-0.5% of ocimi gratissimi oil, 0.1-0.5% of star anise oil, 0.1-1.0% of eucalyptus oil, 0.1-1.0% of turpentine oil, 3-6% of polyvinylpyrrolidone, 0.1-0.35% of chitosan hydrochloride, 0.1-0.3% of hydroxypropyl methylcellulose, 70-80% of ethanol, 0.5-3% of glycerol and the balance of water. The wound disinfecting spraying film agent provided by the invention has broad-spectrum bactericidal, rapid bactericidal and long-acting antibacterial functions and the like, and the wound disinfecting spraying film agent is rapid to stop bleeding and promote healing; a film can be formed on skin within several minutes so as to isolate bacteria and prevent re-infection of a wound; and in addition, the wound disinfecting spraying film agent is low in irritation of the human skin and is safe and convenient to use.

Owner:GUANGDONG LUOFUSHAN SINOPHARM

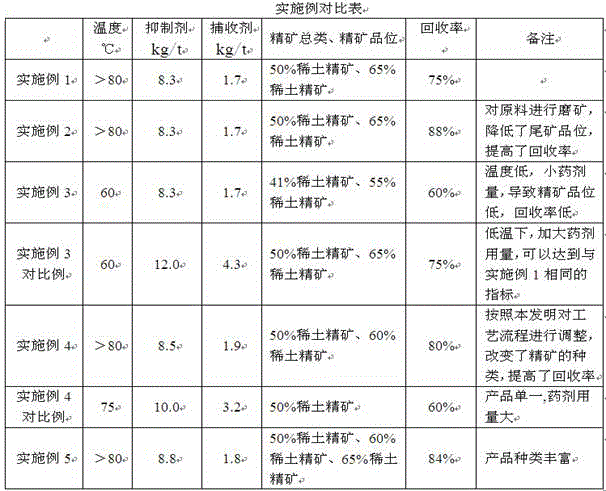

Method of improving rare earth grade of hybrid rare earth ores

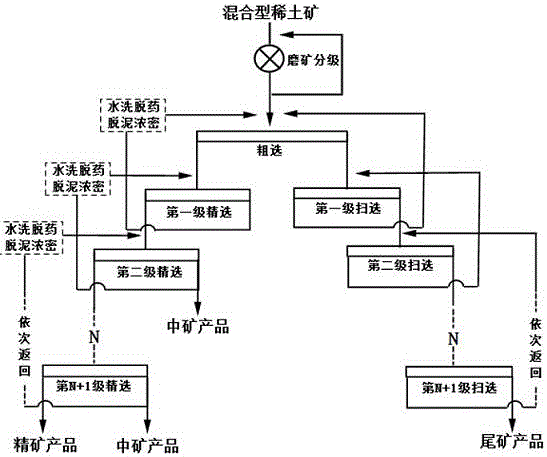

The invention relates to a method of improving the rare earth grade of hybrid rare earth ores. The method is characterized by comprising the following steps: grinding the hybrid rare earth ores firstly until granules with the granularity being 200 meshes account for 85 percent or more, and then carrying out size mixing and flotation separation, wherein flotation separation is composed of roughing, scavenging and concentrating, the flotation separation temperature is larger than 80 DEG C, the activity of a collector is strengthened by raising the flotation separation temperature, and thus the dosage of the collector is lowered, and the rare earth recovery rate is also ensured; with adoption of a flotation flow combined by closed cycle and opened flow, middlings produced during flotation separation returns last flotation separation after being thickened through washing, reagent removal and desliming or directly returns last flotation separation sequentially, and various products including rare earth ore concentrates with higher grade, one or more kinds of middle-grade rare earth ore concentrates and low-grade rare earth ore tailings can be simultaneously obtained, or two kinds of products including higher-grade rare earth ore concentrates and low-grade rare earth ore tailings are obtained only through flotation separation; and the adopted reagents are as follows: sodium silicate is taken as an inhibitor, the collector is a hydroxamic acid collector, and pine camphor oil is taken as a foaming agent. The method is wide in application range, multiple in product varieties, little in reagent dosage and high in rare earth recovery rate, can be directly applied to large rare earth concentration plants and realizes diversification of hybrid rare earth ore concentrate products.

Owner:李梅

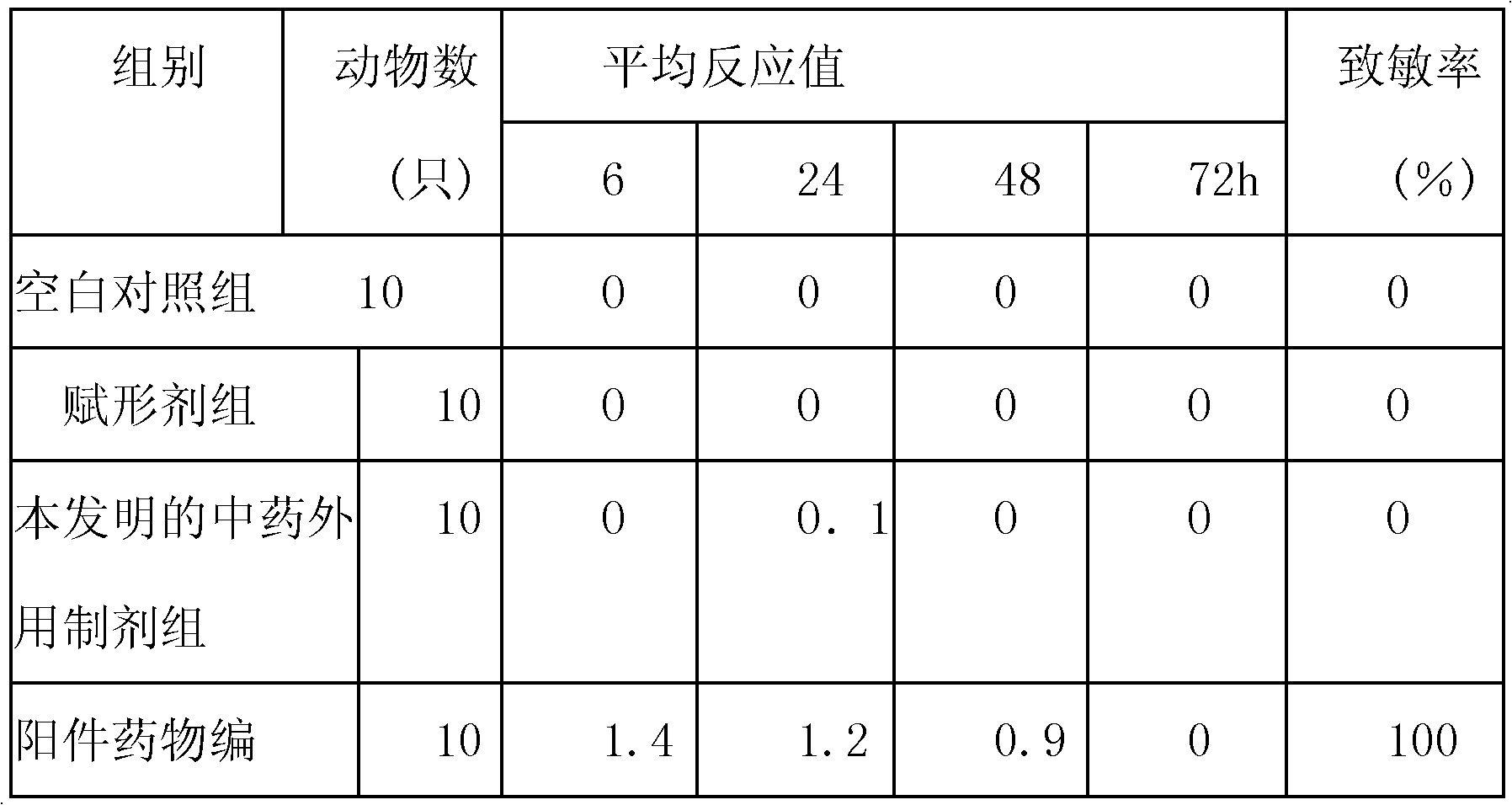

Externally-applied traditional Chinese medicinal preparation for treating skin allergy and pruritus, and preparation method thereof

InactiveCN103356890AHydroxy compound active ingredientsRespiratory disorderForsythiaCutaneous allergy

The invention provides an externally-applied traditional Chinese medicinal preparation for treating skin allergy and pruritus, and a preparation method thereof. The preparation method comprises the following steps: respectively cleaning Rhizoma Coptidis, Amur Corktree Bark, Sophora flavescens, Cortex Dictamni, Fructus Kochiae, Polygonatum sibiricum, camphor, borax, Natural Indigo, honeysuckle flower and Weeping Forsythia, airing, drying, disinfecting, grinding to form fine powder, sieving by a 120 mesh sieve, crushing menthol and borneol to 120 mesh powder, mixing the above powders, adding clove oil, camphor oil and Vaseline, blending for 30min, taking out, loading, and filing to a box. The externally-applied traditional Chinese medicinal preparation is developed through combining the modern medicinal research achievement with the traditional Chinese medicinal clinic experience according to the traditional Chinese medicinal theories. The medicines selected by the externally-applied traditional Chinese medicinal preparation are pure Chinese herbal medicines, and the externally-applied traditional Chinese medicinal preparation has the advantages of reasonable synergistic compatibility, rapid and direct action on the affected parts, avoiding of the stimulation of an oral preparation to the stomach, intestine, liver and kidney, reduction of the pains of a patient, short treatment course, low cost, use convenience, rapid disappearance of clinic symptoms, substantial curative effect, practicality, convenience, safety and no toxic side effects.

Owner:徐冰娜

Micro emulsion drinking water matrix for livestock

InactiveCN102318731AReduce manufacturing costImprove anti-corrosion performanceFood processingAnimal feeding stuffNepetaPeppermints

The invention discloses a micro emulsion drinking water matrix for livestock, which consists the following constituents in percentage weight: 1.5-11% of oil phase, 4-30% of surfactant, 0-10% of cosurfactant and 50-90% of aqueous phase; the oil phase is the mixture of one or a plurality of tangerine peel oil, blumea oil, rhizoma atractylodis macrocephalae oil, zedoary turmeric oil, peppermint oil, forsythia oil, sweet wormwood oil, clove oil, camphor oil, chili oil, nepeta oil, brucea javanica emulsion, patchouli oil, grape seed oil, evening primrose oil and eucalyptus oil; the surfactant is the mixture of one or a plurality of tween-80, tween-85, polyethyleneglycol hydrogenated castor oil and arlacel-80; the cosurfactant is the mixture of one or a plurality of propylene glycol, glycerol, alcohol, normal butanol and 1,3 butanediol; and the water phase is the distilled water. The invention has the advantages of simple technology, safety and good stability, is widely applied, and has wide prospect.

Owner:HEBEI AGRICULTURAL UNIV.

Seasoner containing edible mushrooms and preparation method thereof

The invention discloses a seasoner containing edible mushrooms. The seasoner is prepared from the following materials in parts by weight: 5 to 20 parts of agrocybe cylindracea, 1 to 10 parts of pleurotus eryngii, 1 to 10 parts of pholiota nameko, 1 to 10 parts of abalone mushrooms, 1 to 5 parts of bolete, 5 to 20 parts of lentinula edodes, 1 to 10 parts of wild portobello, 0.1 to 2 parts of cordyceps flowers, 1 to 10 parts of fresh ginger, 10 to 30 parts of scallion oil, 40 to 60 parts of vegetable oil, 5 to 20 parts of red camphor oil, 1 to 10 parts of aginomoto, 1 to 5 parts of white spirit and 0.1 to 1 part of a fungus flavoring agent. Meanwhile, the invention also discloses a preparation method of the seasoner. The seasoner provided by the invention comprises various edible mushrooms, is special in flavor, intense and rich in mouthfeel, long in aftertaste, thick in taste, delicious and mellow, natural in color, and suitable for all seasons and all groups of people.

Owner:SICHUAN WUDOUMI FOOD DEV

Preparation method of anti-cancer and anti-aging pickled cabbage

InactiveCN103082256ACompatibility is reasonableWon't spoilFood preparationMonosodium glutamateSide effect

The invention discloses a preparation method of anti-cancer and anti-aging pickled cabbage. The preparation method comprises the following steps of: uniformly mixing 250-260 parts by weight of pickled cabbage, 1-2 parts by weight of nutritional extracts, 2-4 parts by weight of monosodium glutamate, 7-9 parts by weight of red camphor oil, 0.3-0.5 part by weight of citric acid, 8-12 parts by weight of red chili paste and 15-18 parts by weight of capsicum frutescens, putting the mixture in a jar and sealing for 15-20 days to obtain the anti-cancer and anti-aging pickled cabbage. The anti-cancer and anti-aging pickled cabbage is crispy and delicious and has an anti-cancer and anti-aging dietary therapy effect; and raw materials of the nutritional extracts are reasonable in compatibility and are safe and free of side effects.

Owner:蚌埠市楠慧川味食品厂

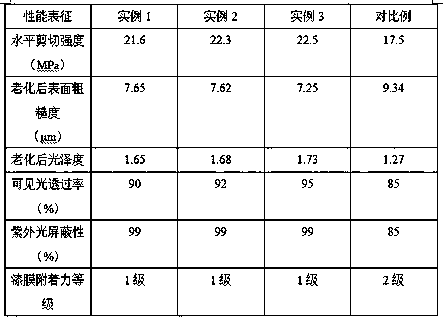

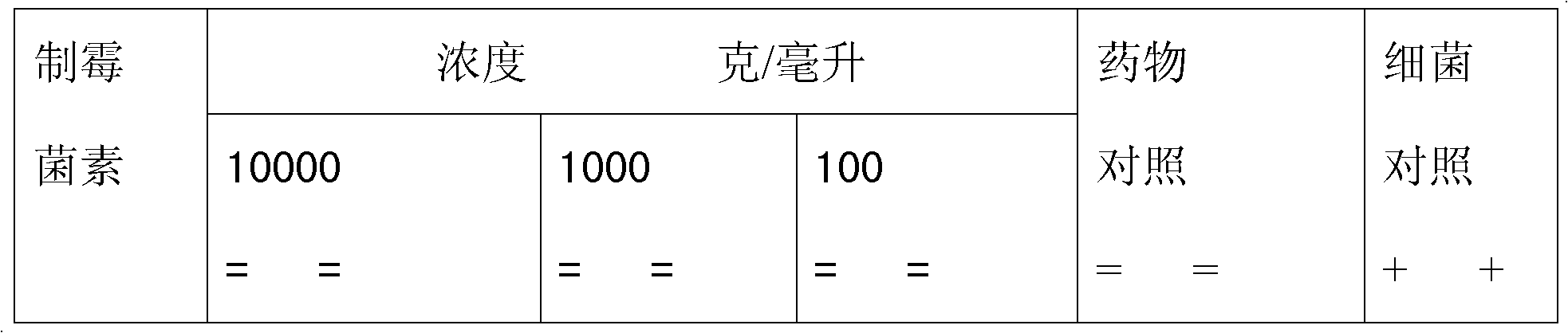

Preparation method of light aging-resistant outdoor recombinant bamboo wood board

InactiveCN108214751ALong-term bacteriostasisImprove water resistanceWood treatment detailsCane mechanical workingFiberAging resistance

The invention relates to a preparation method of a light aging-resistant outdoor recombinant bamboo wood board and belongs to the technical field of bamboo products. By fumigating bamboo bundles, lignin is cracked and crosslinked to form a more stable structure and generate many phenol components and antioxidant components, absorption of ultraviolet light is reduced obviously, and the light aging-resistance of the material is improved. Meanwhile, pores generated by cracking and crosslinking lignin cure and lock camphor oil in the bamboo bundles to achieve the purpose of continuously releasingthe camphor oil; the camphor oil and the generated many phenol components and antioxidant components form a barrier to coat the bamboo bundles to hinder permeation of water, so that the water resistance and the durability of the bamboo bundles are improved. By veneering the surfaces of the recombinant bamboos with fiber cloth layers, an ultraviolet shielding system suitable for the recombinant bamboos is constructed, and is high in ultraviolet shielding property and high in visible light transmittance. The light aging-resistant outdoor recombinant bamboo wood board also has a good protective effect to the shielding system while protecting a base material, and the color and luster of the recombinant bamboos can be protected effectively.

Owner:汪逸凡

Method for preparing preparation for treating gastroenteritis and its new use

ActiveCN101125160AConstipationHas the effect of treating constipationOrganic active ingredientsDigestive systemWater vaporAstrovirus gastroenteritis

The present invention discloses a preparation method and a new usage of a pharmaceutical preparation for treating enteritis. The preparation method is that: the Chinese mosla herb is distilled by using water vapor or is extracted the volatile oil by refluxing / supercritical extraction, the distilled liquid is preserved in another container for standby; the medicine residues, humifuse euphorbia herb, goldhair hedyotis herb, camphor root and maple leaves are treated by water extraction for 2 to 3 times, 1 to 4 hours for each time, the water extraction liquid is concentrated to the relative density of 1.04 to 1.35 at 80 DEG C, the excipients are added, then drying and smashing are carried out, the distilled liquid of Chinese mosla herb is used for granulation or the clear paste is dried at low temperature to prepare the dry extract, then the smashing is carried out, the excipients are added, the distilled liquid is used for granulation and drying, the volatile oil of the Chinese mosla herb and the camphor or camphor oil which is dissolved and diluted by ethanol are sprayed in, so as to prepare the granules by granulation or prepare the tablets by compression / prepare the capsules. The present invention also discloses the new usage of the preparation for treating enteritis prepared by the method in the treatment of constipation.

Owner:JIANGXI HERBI SKY CO LTD

Natural bird repellent composition and preparation method thereof

InactiveCN104855447ASense of smellTo achieve the purpose of avoiding birdsBiocidePest repellentsVegetable oilAlcohol ethyl

The invention relates to the field of agricultural bird repellent, particularly to a natural bird repellent composition and a preparation method thereof, and aims to provide the natural bird repellent composition to overcome the defects that the sound bird repellent and visual bird repellent are effective within short time but ineffective after long time when birds are adaptive, and physical bird repellent equipment is high in cost and large in maintenance workload. The natural bird repellent composition is prepared from the following components in parts by mass: 20-70 parts of vegetable oil, 1-50 parts of wintergreen oil, 10-60 parts of dimethyl phthalate, 10-30 parts of camphor oil, 10-30 parts of citionella oil, 10-50 parts of AEO, 5-30 parts of ethyl alcohol and 5-20 parts of water. The preparation method of the natural bird repellent composition comprises the following steps: adding the vegetable oil in a reaction tank, then adding the AEO under the normal temperature stirring condition, and after full dissolution, adding the dimethyl phthalate, wintergreen oil, other plant essential oil, water and ethyl alcohol. The natural bird repellent composition does not take toll on birds, does not pollute the environment, and is convenient to use, high in smell bird repellent content, and durable in effect.

Owner:郭广杰

Method for preparing solid fragrant mosquito repellent

InactiveCN101642137AAnti-inflammatoryAntipruriticBiocidePest repellentsSandalwood oilReverse osmosis

The invention belongs to the field of daily life articles, which in particular relates to a method for preparing a solid fragrant mosquito repellent. The solid fragrant mosquito repellent comprises the main components of peppermint oil, camphor oil, clove oil, sandalwood oil, benzoin, jasmine flower and seaweed gel. The method comprises the following steps: mixing, soaking, clarifying, filtering,concentrating by reverse osmosis, sterilizing and obtaining the solid fragrant mosquito repellent. Because the invention adopts the peppermint oil, the camphor oil, the clove oil, the sandalwood oil,the benzoin and the jasmine flower as main raw materials, the solid fragrant mosquito repellent can repel mosquitoes, also has the functions of diminishing inflammation, relieving itching, strengthening the stomach, calming emotion and the like, and can bring happy, auspicious and calm feelings to a user.

Owner:HANGZHOU LIUYI TECH

Frying process for lowering acid value of oil in red camphor oil hotpot soup base

ActiveCN103931964ADoes not affect flavorExtended shelf lifeFood preparationOil and greaseEngineering

The invention mainly relates to a frying process for lowering the acid value of oil in red camphor oil hotpot soup base. The frying process comprises the following steps: a, preparing materials; b, frying; c, continually frying; d, decocting; e, bagging. In the step b, frying is performed at the temperature of 70-130 DEG C and under the pressure of 0.1-0.5MPa; in the step c, continual frying is performed at the temperature of 70-130 DEG C and under the pressure of 0.1-0.5MPa. According to the frying process for lowering the acid value of oil in red camphor oil hotpot soup base, oil oxidation and the extraction effects of seasonings are controlled accurately by means of synergistic research of temperature, pressure and the like, so that the maximum yield and a low acid value are achieved.

Owner:CHONGQING UNIV OF EDUCATION

Mixing formula of jerusalem artichoke pickled vegetables and preparation method of jerusalem artichoke pickled vegetables

InactiveCN102793133AUnique tasteShorten the production cycleFood preparationDietary RequirementsSodium Glutamate

The invention discloses a mixing formula of jerusalem artichoke pickled vegetables and a preparation method of the jerusalem artichoke pickled vegetables. A formula required to be mixed in every 100kg of jerusalem artichoke comprises 3-10kg of white granulated sugar, 1-5kg of soy sauce, 8-18kg of spiced vinegar, 0.5-5kg of sodium glutamate, 0.5-3kg of sesame oil, 0.2-5kg of red camphor oil, 3-10kg of ground pepper, 0.2-1kg of citric acid and 2-10kg of high maltose. A preparation process of the jerusalem artichoke pickled vegetables comprises pickling; picking; washing, desalting and dehydrating; pickling, dehalogenation and mixing, thus the jerusalem artichoke pickled vegetables are obtained. By adopting the preparation method disclosed by the invention, a product period of a product can be shortened, equipment investment is reduced, and processes are reduced; and the obtained jerusalem artichoke pickled vegetables are rich in sauce flavour and unique in taste, has low sugar and low salt and meets modern healthy dietary requirement, and the product is convenient to carry and eat.

Owner:JIANGSU HENGSHUN VINEGAR IND

Novel mosquito repellent spray

InactiveCN104041541AHas mosquito repellent effectPurify indoor airBiocidePest repellentsCypermethrinEucalyptus oil

Owner:QINGDAO BOHONG MARINE BIOTECH

Composition for ceramic painting, preparation method of composition and ceramic painting method

ActiveCN106590036AReduce the painting processImprove drawing efficiencyPigmenting treatmentDecorative surface effectsSolventCAMPHOR OIL

The invention discloses a composition for ceramic painting, a preparation method of the composition and a ceramic painting method, and belongs to the field of ceramic painting. The composition for ceramic painting comprises the following raw materials in parts by weight: 30-70 parts of pigment, 10-30 parts of thickened glass white, 8-20 parts of transparent glass white, 1-10 parts of a solvent, 0.1-5 parts of oil, and 1-20 parts of camphor oil. The composition for ceramic painting, provided by the invention, enables the colored glaze to be comprehensively utilized, painting procedures are reduced, the sintering is successful at once, and the painting efficiency is improved.

Owner:常炳华

Mushroom sauce and preparation method thereof

The invention discloses a mushroom sauce and a preparation method thereof, wherein the mushroom sauce comprises the following raw materials in parts by weight: 30-40 parts of lentinus edodes, 30-40 parts of straw mushroom, 30-40 parts of coprinus comatus, 40-60 parts of fermented soya beans, 10-20 parts of peanut, 10-20 parts of vegetable oil, 4-8 parts of table salt, 5-9 parts of monosodium glutamate, 20-30 parts of red camphor oil, 5-9 parts of ginger, 3-5 parts of anise, 3-5 parts of cassia bark, and 3-5 parts of fructus foeniculi. With various mushrooms as raw materials, the mushrooms contain various human body essential amino acids, can enhance the appetite, tonify spleen, benefit qi and improve human body immunity, is rich in nutrients and unique in flavor, is green and healthy, and is green good food for the young and the old to eat.

Owner:刘韶娜

Microbial deodorant and preparation method thereof

The invention discloses a microbial deodorizer, comprising water and a deodorizer stock solution composed of essence, an emulsifier and aerobic bacteria, wherein the aerobic bacteria comprise micrococcus and bacilliform bacteria; the emulsifier comprises polyoxyethylene sorbitan fatty acid ester and fatty alcohol-polyoxyethylene ether; the essence comprises camphor oil, eudesmol, terpilenol and terpinene; and the deodorizer stock solution further comprises amylase, bacillus, saccharomycetes, lactic acid bacteria and actinomycetes. The microbial deodorizer with the above structure has the advantages of low production cost, short fermentation period, simplicity and convenience in operation, no secondary pollution and the like; and meanwhile, an acidic deodorizer solution is unfavorable for the survival of spoilage microorganisms, so the purposes of resisting bacteria and inhibiting odor are achieved, and the deodorizer solution can play a role at various temperatures, in a wide pH valuerange and in a low-oxygen environment and is high in adaptability.

Owner:保定市隆澳环境治理有限公司

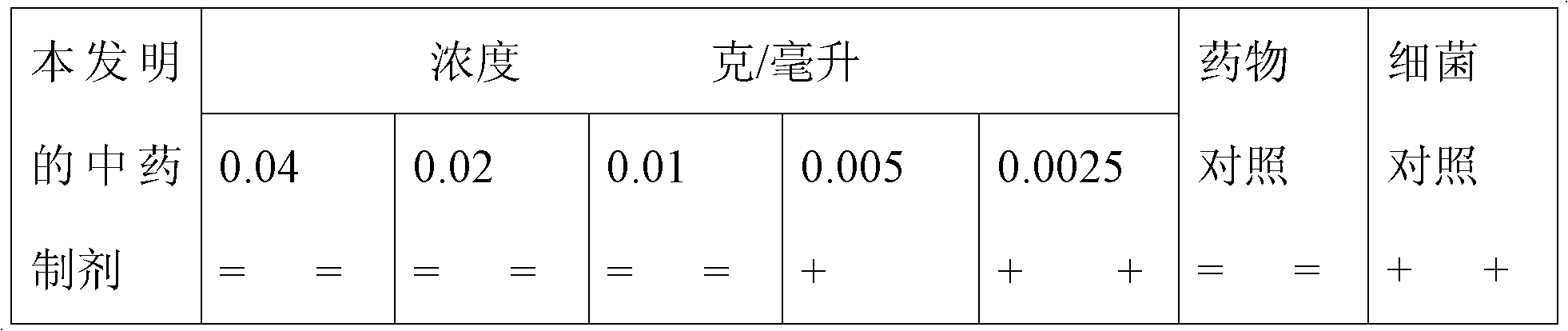

A kind of external preparation of traditional Chinese medicine and its application

InactiveCN102283899AQuick resultsInhibition transitionAntimycoticsAerosol deliveryBiotechnologyAntiinflammatory drug

The invention relates to a traditional Chinese preparation, and particularly relates to an antibacterial and anti-inflammatory traditional Chinese medicine external preparation. The traditional Chinese medicine external preparation comprises the following specific formula in parts by weight: 20-32 parts of camphor oil, 20-32 parts of eucalyptus oil, 20-32 parts of selinum oil and 20-32 parts of hydnocarpus oil. The main dosage form of the traditional Chinese medicine external preparation is ointment, and the traditional Chinese medicine external preparation has wide applications in preparation of antibacterial and anti-inflammatory drugs as well as skin disease drugs. The traditional Chinese medicine external preparation has the advantages of rapidness in acting, high bacterium inhibitingrate, high clinical effective rate (98.24%), convenience in use, wide application range and no toxic or side effect.

Owner:HUNAN PUTIANCHUN BIOLOGICAL TECH

Long-acting eco-friendly floor insect-prevention particles

The invention relates to a floor insect-prevention agent and especially relates to long-acting eco-friendly floor insect-prevention particles. The long-acting eco-friendly floor insect-prevention particles are prepared from 60 to 80 parts by weight of rosin, 10 to 30 parts by weight of permethrin, 5 to 10 parts by weight of camphor oil, 15 to 25 parts by weight of soybean meal, 10 to 20 parts by weight of boric acid powder, 2 to 12 parts by weight of piperonyl butoxide, 20 to 30 parts by weight of cooked sunflower seeds, 10 to 15 parts by weight of manchurian wildginger and an appropriate amount of water. The long-acting eco-friendly floor insect-prevention particles have mothproof and insect-killing effects on bamboo and wood floors and keels. Through being detected by a health defensive department, the long-acting eco-friendly floor insect-prevention particles can thoroughly prevent and kill insects such as white ants, cockroaches and bugs. The long-acting eco-friendly floor insect-prevention particles also have effects of adjusting moisture and killing harmful bacteria. The long-acting eco-friendly floor insect-prevention particles are green eco-friendly preparations having high efficiency, long acting time, no toxicity, no smell, no pollution on the environment, no damage on a human body, and good social benefits.

Owner:王春鹏

Safe high-efficiency and long-acting mothproofing agent and its prepn

InactiveCN1526286AImprove adsorption capacityTake advantage ofBiocideAnimal repellantsMildewPyrethrin

The safe high-efficiency and long-acting mothproofing agent is prepared with camphor wood powder as carrier, dextrad camphor oil as solvent, dextrad camphor extracted from lauraceae plant as mothproofing agent and mildew inhibitor, and pyrethroid with excellent moth killing effect, and through certain technological process. The present invention combines moth expelling and moth killing effects, has high efficiency, long action and low toxicity, and is environment friendly.

Owner:彭长荣

Massage oil

The invention discloses a massage oil which is prepared by mixing wintergreen juice, rosemary juice, aloe juice, crying water, eucalyptus oil, retinol, peppermint oil, lavender essential oil, tea tree oil, camphor oil vitamin A and the like. The massage oil has the functions of soothing the skin, relieving the pain, reducing the wrinkles and eliminating the comedoes, and thus, is a high-grade low-cost massage oil.

Owner:孙红燕

Formula and preparing method of instant dried small shrimp sauce

ActiveCN103461959ALow in salt and high in calciumDeliciousFood preparationMonosodium glutamateVitamin C

The invention discloses a formula and a preparing method of instant dried small shrimp sauce. The instant dried small shrimp sauce is made from salted and fermented soya paste, dried small shrimps, pepper, red camphor oil, white granulated sugar, modified starch, monosodium glutamate, garlic, ginger, vitamin C, potassium sorbate and purified water by adopting a method which comprising the steps of pretreating the raw materials, sequentially adding the raw materials for decocting, and thermally filling. The raw materials adopted in the invention are simple and easy to purchase, and low in cost, and the preparing method is simple, and the instant dried small shrimp sauce can be produced in batch; the instant dried small shrimp sauce prepared by using the preparing method has the advantages of being capable of being instant by opening a bottle, low in salt and high in calcium, low in fishiness, delicious in taste, and large in market prospect.

Owner:JIANGSU HENGSHUN VINEGAR IND

Waste plastic regenerated material, regenerated product, and regeneration method thereof

The invention relates to a waste plastic regenerated material, a regenerated product, and a regeneration method thereof. The waste plastic recycled material is prepared from the following raw materials in parts by weight: 65-75 parts of waste plastic and 5-15 parts of new plastic which are used as base materials; 5-15 parts of stone powder, 5-15 parts of glass fiber powder and 0-5 parts of straw powder which are used as fillers; and 1-5 parts of a lubricant, 1-5 parts of a stabilizer, 2-5 parts of a compatilizer, 2-4 parts of a flexibilizer, 1-3 parts of an antioxidant, 3-8 parts of a couplingagent, 1-2 parts of titanium dioxide, 0.5-1 part of zirconium oxide and 1-2 parts of camphor oil which are used as addition aids. In the invention, the raw materials are subjected to melting, mixing,stirring, cooling and forming processes to prepare the plastic regenerated product. The method is suitable for recycling various waste plastics, can effectively improve the comprehensive performanceof the recycled plastics in various aspects, and is extremely wide in application range of finished products, simple in regeneration process, low in production cost and easy to popularize.

Owner:王明华

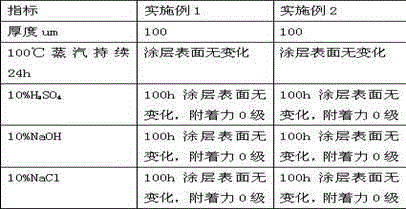

High-temperature-resistant anti-corrosion coating for power distribution system and preparation technology of coating

InactiveCN105368113AImprove corrosion resistanceSimple manufacturing methodAntifouling/underwater paintsPaints with biocidesFennel extractDistribution power system

The invention belongs to the technical field of power distribution system protection, and discloses a high-temperature-resistant anti-corrosion coating for a power distribution system. The high-temperature-resistant anti-corrosion coating for the power distribution system is prepared from, by weight, 8-10 parts of triethanolamine oleic soap, 7-8 parts of dimethyl phthalate, 6-7 parts of n-butanol, 5-6 parts of emulsified silicone oil, 3-4 parts of lithium-base bentonite, 2-3 parts of sodium citrate, 2-3 parts of isobornyl acetate, 2-3 parts of camphor oil, 1-2 parts of sodium water glass, 1-2 parts of aluminium nitride, 1-2 parts of tobacco extract and 1-2 parts of fennel extract. The high-temperature-resistant anti-corrosion coating for the power distribution system has the multiple functions of resisting high temperature and corrosion and repelling birds.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

Compound type micro-nano biological repellent and use method thereof

InactiveCN105941496AEffective dissolutionImprove stabilityBiocidePest repellentsMicro nanoEnvironmental resistance

The invention discloses a compound type micro-nano biological repellent and a use method thereof. The compound type micro-nano biological repellent is characterized by being prepared from a component A, a component B and a component C through mixing, wherein the component A is prepared from a component A1, a component A2 and a component A3 through mixing, the component A1 is one or a mixture of micro-nano particles prepared from active ingredients of carophyllin, litsea cubeba oil, cinnamon oil, honeylocust leaf oil and camphor oil, the component A2 is a micro-nano particle prepared from an active ingredient of capsicin, and the component A3 is one or a mixture of micro-nano particles prepared from active ingredients of gland extracts of cats and foxes; the component B is one or a mixture of micro-nano particles prepared from active ingredients of orange flower oil, black pepper oil, artemisia selengensis and small-leaf mugwort; the component C is one or a mixture of micro-nano particles prepared from active ingredients of neem oil, Citrus junos and asarum oil. The compound type micro-nano biological repellent is environment-friendly and non-toxic, is not harmful to people and livestock and cannot influence the environment.

Owner:张洋祎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com