Preparation method of light aging-resistant outdoor recombinant bamboo wood board

A technology of recombining bamboo and light aging resistance, which is applied in the jointing of wooden veneers, wood treatment, impregnating wood, etc., can solve the problems of water resistance, poor weather resistance, weak light aging resistance, and easy mildew, etc., to improve light aging resistance Performance, improvement of water resistance, effect of color protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

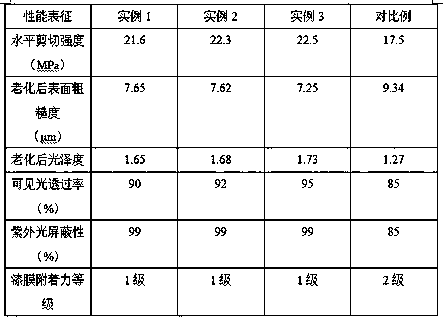

Examples

example 1

[0021] Saw the hemp bamboo into a 1m-long bamboo tube, divide it into 4 pieces along the longitudinal direction, send the divided bamboo material to the bamboo wood rolling and splitting machine, roll it flat and remove the green and yellow, and then divide it from the chord direction of the bamboo piece 2. To obtain bamboo bundles, put the bamboo bundles into a bamboo decomposer to decompose twice, and decompose them into fibrous bamboo bundles with uniform thickness and place them on a steamer. The steamer is filled with camphor oil and carried out under steam protection atmosphere. Smoked for 2 hours, controlled at 200°C, placed in a drying oven and dried to a moisture content of 6% after smoking to obtain pretreated bamboo bundles, which were impregnated in phenolic resin with a solid content of 20% for 4 minutes, controlled The amount of dipping is 12%, and then placed in a drying oven to dry to a moisture content of 8%, and the dipped bamboo bundles are obtained, and the ...

example 2

[0023] Saw the hemp bamboo into 1.5m long bamboo tubes, divide them into 6 pieces along the longitudinal direction, send the divided bamboo materials to the bamboo wood rolling and splitting machine, roll them flat and remove green and yellow, and then divide them from the chord direction of the bamboo pieces For two, get bamboo bundles, put the bamboo bundles into the bamboo decomposing machine and decompose twice, and decompose into fibrous bamboo bundles with uniform thickness and place them on the steamer. The steamer is equipped with camphor oil. Carry out smoking treatment for 2.5 hours, control the temperature at 220°C, put it in a drying oven and dry it to a moisture content of 7% after smoking, and obtain pretreated bamboo bundles, and impregnate the pretreated bamboo bundles in phenolic resin with a solid content of 20% for 5 minutes , control the amount of dipping to 13%, and then place it in a drying oven to dry to a moisture content of 9%. The bamboo bundles are tr...

example 3

[0025] Saw the hemp bamboo into 2m long bamboo tubes, divide them into 8 pieces along the longitudinal direction, send the divided bamboo materials to the bamboo wood rolling and splitting machine, roll them flat and remove green and yellow, and then divide them into 8 pieces from the chord direction of the bamboo pieces 2. To obtain bamboo bundles, put the bamboo bundles into a bamboo decomposer and decompose 3 times, and decompose into fibrous bamboo bundles with uniform thickness and put them on the steamer. The steamer is equipped with camphor oil, and it is carried out under the steam protection atmosphere. Smoked for 3 hours, controlled at 240°C, placed in a drying oven to dry to a moisture content of 8% after smoking, to obtain pretreated bamboo bundles, which were impregnated in phenolic resin with a solid content of 20% for 6 minutes, controlled The amount of dipping is 14%, and then placed in a drying oven to dry until the moisture content is 10%. The dipped bamboo bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com