Patents

Literature

94results about How to "Improve light aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power cable insulating layer material and preparing method thereof

InactiveCN104140613AGood weather resistanceGood solvent resistancePlastic/resin/waxes insulatorsEpoxyPolyvinyl chloride

The invention relates to a power cable insulating layer material and a preparing method thereof. The material comprises, by weight, 70 parts of polyvinyl chloride, 3 parts of ethylene-vinyl acetate copolymer, 10 parts of polyvinylidene chloride, 10 parts of methyl vinyl silicone rubber, 15 parts of GNA type chloroprene rubber, 5-6 parts of epoxy fatty acid essien ester, 1 part of barium stearate, 10 parts of aluminum hydroxide, 5 parts of compatilizer, 8-10 parts of fire resistant systems and 0.1 part of antioxygen. The prepared fire resistant cable material is obvious in synergistic effect, good in antioxidant effect, high in stability and obvious in fire resistant effect, and has wide application prospects.

Owner:STATE GRID CORP OF CHINA +1

Prepn process of polymer coated silica composite particle

InactiveCN101089055AGood compatibilityImprove toughnessPigment treatment with macromolecular organic compoundsPolymer scienceEmulsion

The preparation process of polymer coated silica composite particle includes the following steps: 1. preparing hydrophilic silica, amino silane coupler in the amount of 2-20 wt% hydrophilic silica, and carboxyl group containing copolymer in such amount as the molar ratio between the carboxyl groups in the copolymer and the amino groups in the amino silane coupler of 1-2 to 1; 2. compounding the amino silane coupler into water solution or organic solution, and compounding the carboxyl group containing copolymer into solution or emulsion; and 3. mixing the water solution or organic solution of amino silane coupler with silica through spraying or soaking, mixing the solution or emulsion of carboxyl group containing copolymer with the amino silane coupler treated silica, and drying to obtain polymer coated silica composite particle possessing excellent hydrophobic performance.

Owner:WUHAN UNIV OF TECH

Nylon composite material special for electric wire and cable jacket and preparation method thereof

ActiveCN102020842AImprove heat resistanceImprove light aging resistanceInsulated cablesInsulated conductorsPropanoic acidPhenol

The invention provides a nylon composite material special for an electric wire and cable jacket, which is prepared from the following components by mass percent: 86-100% of nylon 6, 0.1-2.0% of main antioxygen, 0.1-2.0% of auxiliary antioxygen, 0.1-2.0% of lubricant release agent, 0.1-2.0% of light stabilizer, 0.1-2.0% of lubricant, 0.1-2.0% of nucleating agent and 0.3-2.0% of tackifier, wherein the main antioxygen is a hindered phenol antioxygen, the auxiliary antioxygen is thiodi-propionic acid diester or phosphite ester, the lubricant release agent is calcium stearate, the light stabilizer is a hindered amine light stabilizer, the lubricant is ethylene double hard ester amide (EBS), silicone powder or a compositor of the ethylene double hard ester amide (EBS) and silicone powder, the nucleating agent is nano talcum powder, and the tackifier is nylon 6 containing reactive groups. The nylon composite material has the advantanges of simple formula and cheap, easily available components and low cost, and the electric wire and cable jacket prepared from the nylon composite material can prevent white ants and mousse, has abrasion resistance and corrosion resistance, is durable in use and is non-toxic and environment-friendly.

Owner:辰东意普万新材料(广东)有限公司

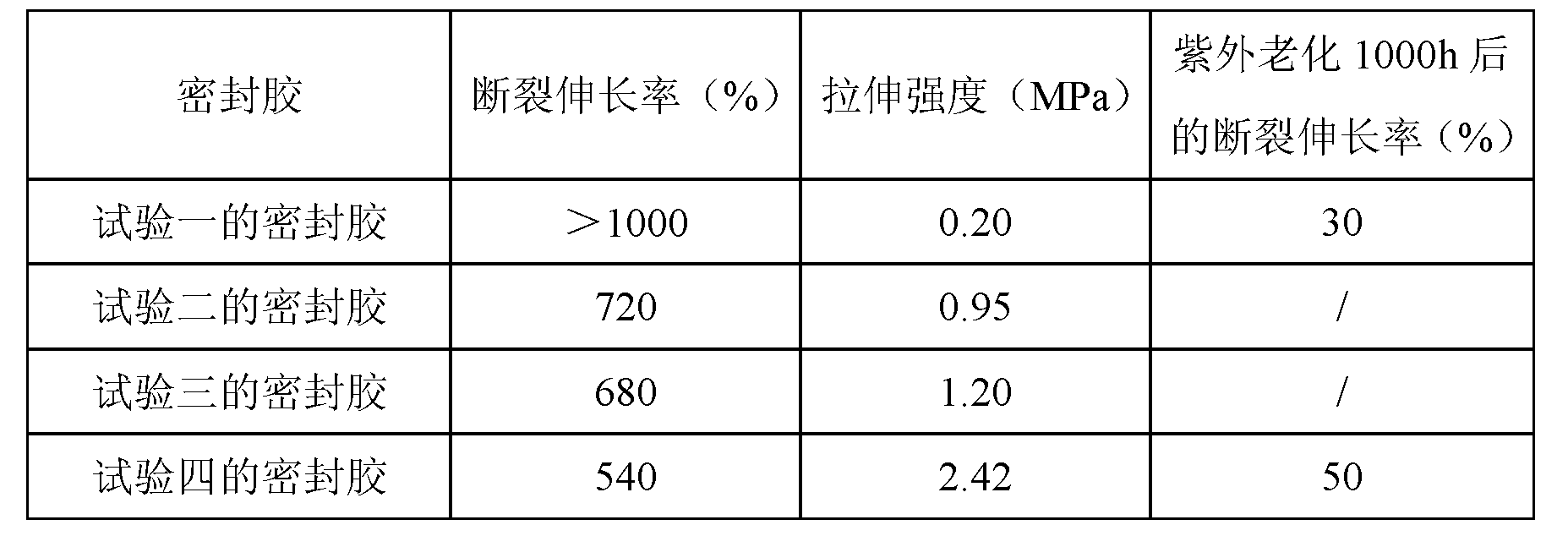

Lignin-containing polyurethane sealant and preparation method thereof

InactiveCN103215005AImprove aging resistanceImprove light aging resistanceNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePlasticizer

The invention discloses lignin-containing polyurethane sealant and a preparation method thereof, and relates to sealant and a preparation method thereof. In order to solve the technical problem that the existing polyurethane sealant is easily aged due to ultraviolet light, the lignin-containing polyurethane sealant is prepared from a lignin-containing prepolymer, catalyst, latent curing agent, plasticizer and filler. The preparation method of the lignin-containing polyurethane sealant comprises the following steps of: preparing the lignin-containing prepolymer; and stirring the lignin-containing prepolyer, the catalyst, the latent curing agent, the plasticizer and the filler for one hour at 80 DEG C to obtain the lignin-containing polyurethane sealant. After the ageing is quickened up by 1000 hours by the ultraviolet light, the fracturing elongation retention of the lignin-containing polyurethane sealant can reach 50%. The invention belongs to the preparation field of the sealant.

Owner:NORTHEAST FORESTRY UNIVERSITY

Light aging resistant polypropylene composition and preparation method thereof

ActiveCN101759922AGood long-term light aging resistanceGuaranteed light aging resistancePolypropylene compositesPolymer science

The invention discloses a light aging resistant polypropylene composition. The light aging resistant polypropylene composition is prepared from the following raw materials in percentage by weight: polypropylene 55-99, inorganic filler 0-42, flexibilizer POE 0-20, light stabilizer 0.1-0.5, antioxidant 0.1-1 and other assistants 0-5. The invention has the advantages that: 1, a macro-molecular-weight hindered-amine light stabilizer is added in the polypropylene composition, so the polypropylene composite material prepared has high long-term light aging resistance; 2, the prepared polypropylene composition can ensure the light aging resistance of a material and prevent the physical mechanical properties of the material from being influenced; and 3, the method for improving the light aging resistance of the polypropylene composition, which is provided by the invention, has an extremely simple preparation process and low production cost.

Owner:CHONGQNG PRET NEW MATERIAL +2

Illumination aging resisting polycarbonate/styryl resin composition and preparing method thereof

ActiveCN101210105AImprove anti-separation performanceGood light aging resistanceMolecular sievePolycarbonate

The invention discloses a polycarbonate / styryl resin composition which has light fastness and aging resistance and a preparation method thereof. The components and mixture ratio (weight proportion) of the composition are that: 50 percent-80 percent of polycarbonate, 10 percent-50 percent of styryl resin, 0.1-5 percent of molecular sieve, 0.1-1.0 percent of antioxidant 168, 0.1-1.0 percent of antioxidant 245, 0.1-2.0 percent of ultraviolet absorber, 0.1-2.0 percent of free radical quencher, etc. The resin composition prepared by the technical proposal of the invention can not only improve the anti-precipitation efficiency of light stabilizer in a composite material system to lead the prepared polycarbonate / styryl resin composition has better light fastness and aging resistance performance, but also has the advantage that all the physical mechanical performances and thermodynamic property of the material are basically not affected; furthermore, the method presented for improving the light fastness and aging resistance of polycarbonate / styryl resin composition has simple preparation technique and low production cost.

Owner:CHONGQNG PRET NEW MATERIAL +2

Nano titanium dioxide-modified composite water-based ink and preparation method thereof

ActiveCN104629532AImprove hydrophilicityReduce usageInksPigment treatment with organosilicon compoundsWater basedAlkane

The invention belongs to the field of water-based ink design and discloses nano titanium dioxide-modified composite water-based ink which comprises nano titanium dioxide-modified water-based acrylic resin, water-based polyester resin, water, ethanol, pigment, an antifoaming agent, a dispersing agent, a leveling agent and a buffer agent. The preparation process of the nano titanium dioxide-modified composite water-based ink comprises the following steps: preparing silane coupling agent modified inorganic nanoparticles from nano titanium dioxide, ethanol, water and gamma-methacryloxy propyl trimethoxyl silane; preparing nano titanium dioxide modified water-based acrylic resin from an alkane-based acrylate monomer, a hydroxyalkyl acrylate monomer, the silane coupling agent modified inorganic nanoparticles, polyethylene glycol, a water-soluble initiator, an emulsifier and water; and finally, preparing the nano titanium dioxide-modified composite water-based ink from the nano titanium dioxide modified water-based acrylic resin, water-based polyester resin, water, ethanol, pigment, an anti-foaming agent, a dispersing agent, a leveling agent and a buffer agent. The water-based ink is resistant to photoaging and antibacterial and mould-proof.

Owner:长兴艾飞特科技股份有限公司

Polypropylene composite material with excellent illumination aging resisting performance and preparing method thereof

InactiveCN101210088AGood light aging resistanceImprove anti-separation performanceMolecular sievePolypropylene composites

The invention discloses a polypropylene composite material that has excellent light and aging resistant performance and a preparation method thereof. The polypropylene composite material that has excellent light and aging resistant performance consists of raw materials comprising 55 to 95wt percent of polypropylene, 0 to 40wt percent of inorganic filler, 0 to 20wt percent of toughener POE, 0.1 to 5wt percent of molecular sieve activator powder, 0.1 to 1wt percent of main chemical inhibitor, 0.1 to 1wt percent of secondary chemical inhibitor, 0.1 to 2wt percent of light stabilizer agent and 0 to 5.0wt percent of other additives. By adding powder molecular sieve into basic formulation of the polypropylene composite material, the dispersibility of the light stabilizer agent in the polypropylene composite material is effectively improved, thus improving the light and aging resistant performance of the polypropylene composite material.

Owner:SHANGHAI PRET COMPOSITES

Antiaging water-resistant architectural paint and preparation method thereof

ActiveCN105505083AImprove light aging resistanceGood antibacterial propertiesAntifouling/underwater paintsPaints with biocidesChemistryEmulsion

The invention discloses an antiaging waterproof building paint and a preparation method thereof. The antiaging water-resistant architectural paint is prepared from the following raw materials in parts by weight: 35-50 parts of acrylate emulsion, 5-15 parts of polyvinyl alcohol, 5-10 parts of 2-methoxy-4-methylphenol, 5-15 parts of ethylene glycol, 3-8 parts of ethylene-vinyl acetate copolymer emulsion, 5-10 parts of titanium dioxide, 1-3 parts of sodium dodecylsulfate, 0.1-1 part of dimethyl silicone oil, 1-5 parts of propylene glycol methyl ether acetate, 0.1-1.0 part of antimicrobial agent and 0.1-1.0 part of ultraviolet absorbent. The types and consumptions of the ultraviolet absorbent and antimicrobial agent suitable for the external wall paint are selected according to reasonable proportioning, thereby enhancing the illumination aging resistance; and the paint has favorable antimicrobial property.

Owner:HUNAN XIANFENG BUILDING MATERIAL

Rubber material for agriculture vehicle tire

InactiveCN104403140AHigh tensile strengthHigh tear strengthSpecial tyresRubber materialAluminium hydroxide

The invention discloses a rubber material for agriculture vehicle tires. The rubber material is prepared from the following raw materials in parts by weight: 40-50 parts of natural rubber, 10-14 parts of epoxy natural rubber, 15-20 parts of silicon dioxide, 2-4 parts of a silane coupling agent, 20-30 parts of brominated butyl rubber, 20-30 parts of superfine glass bead, 30-40 parts of carbon black N660, 20-30 parts of light calcium carbonate, 1-2 parts of tetramethyl thiuram disulfide, 1-2 parts of diisopropylbenzene peroxide, 2-3 parts of N-cyclohexyl-2-benzothiazole sulfonamide, 2-4 parts of zinc oxide, 1-2 parts of an accelerant DM, 0.5-1.0 part of an accelerant CZ, 1-2 parts of N-phenyl-N'-(1,3-dimethyl)-p-phenylenediamine, 1-2 parts of 2,2'-methylene-bi(4-methyl-6-tertiary butyl phenol), 1-2 parts of petroleum oil, 2-5 parts of stearic acid, 1-2 parts of protecting wax OK5194, 5-6 parts of rubber tackifying resin A-90, 5-8 parts of antimonous oxide, 5-10 parts of molybdenum trioxide and 20-30 parts of aluminium hydroxide.

Owner:QIAOJIAN NEW ENERGY TECH SUZHOU

Manufacturing method of weather-resistant, waterproof and high-quality special paper for printing

InactiveCN108914675AReduce pollutionReduce dependencePaper coatingPaper/cardboardFiberPulp and paper industry

The invention relates to the field of preparation of consumables of printing products, in particular to a manufacturing method of weather-resistant, waterproof and high-quality special paper for printing. The manufacturing method comprises the following steps of preparation of initial paper pulp, preparation of a toughening additive, preparation of papercopying pulp, preparation of paper blanks, preparation of an adhesive film solution, and applying of the adhesive film layer. The prepared paper has the advantages that the strength is high, and the printing effect is excellent; the water-resistant, oil-resistant, chemical-resistant and aging-resistant properties are realized; the heat insulation property is good; the certain flame-retardant effect is realized; the paper is flat in surface,is difficult to warp, and is suitable for drum printing; by adopting a large amount of waste paper pulp fiber, the resource is saved, the weight of the paper is light, and the certain fluorescent property is realized; when the paper is used as the advertisement paper, the vision effect is improved; the good bacteria-inhibiting and insect-preventing effects are realized; the added components are free from poison and harm, the safe and environment-friendly effects are realized, and the higher practical value and good application prospect are realized.

Owner:安徽古耐家居有限公司

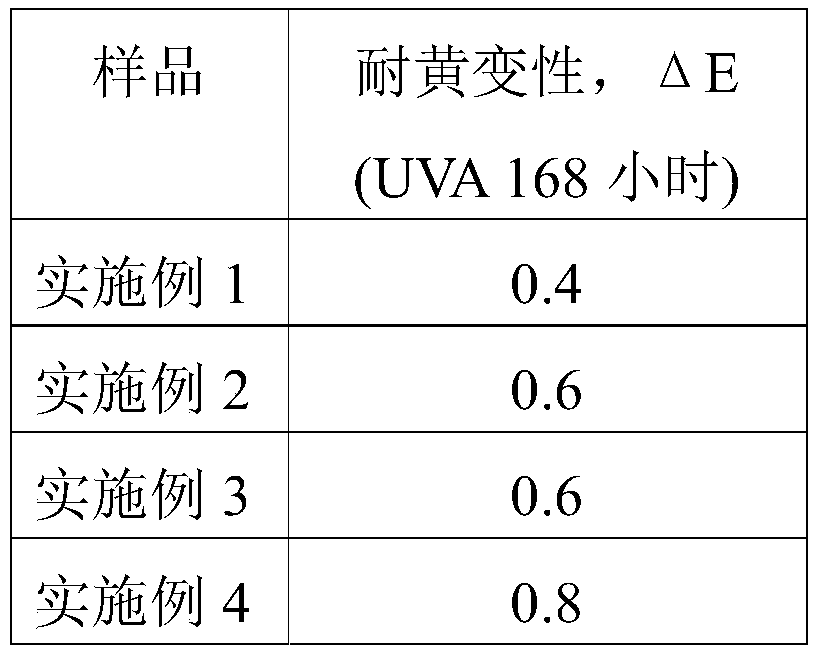

Preparation method of light aging-resistant outdoor recombinant bamboo wood board

InactiveCN108214751ALong-term bacteriostasisImprove water resistanceWood treatment detailsCane mechanical workingFiberAging resistance

The invention relates to a preparation method of a light aging-resistant outdoor recombinant bamboo wood board and belongs to the technical field of bamboo products. By fumigating bamboo bundles, lignin is cracked and crosslinked to form a more stable structure and generate many phenol components and antioxidant components, absorption of ultraviolet light is reduced obviously, and the light aging-resistance of the material is improved. Meanwhile, pores generated by cracking and crosslinking lignin cure and lock camphor oil in the bamboo bundles to achieve the purpose of continuously releasingthe camphor oil; the camphor oil and the generated many phenol components and antioxidant components form a barrier to coat the bamboo bundles to hinder permeation of water, so that the water resistance and the durability of the bamboo bundles are improved. By veneering the surfaces of the recombinant bamboos with fiber cloth layers, an ultraviolet shielding system suitable for the recombinant bamboos is constructed, and is high in ultraviolet shielding property and high in visible light transmittance. The light aging-resistant outdoor recombinant bamboo wood board also has a good protective effect to the shielding system while protecting a base material, and the color and luster of the recombinant bamboos can be protected effectively.

Owner:汪逸凡

Process for preparing propaganda color page printing paper

InactiveCN108978323AReduce dependenceReduce pollutionPaper coatingReinforcing agents additionFiberFluorescence

The invention relates to the field of preparation of printed matter consumables, in particular to a process for preparing propaganda color page printing paper. The process includes relevant steps of preparing preliminary paper pulp; allocating additive auxiliaries; preparing papermaking slurry; preparing paper blanks; preparing adhesive film solution; applying adhesive film layers. The process hasthe advantages that paper prepared by the aid of the process is high in strength and good in heat insulation, and is water-resistant, oil-resistant, chemical-resistant and aging-resistant, excellentprinting effects can be realized, and certain flame-retardant effects can be realized; the surfaces of the paper are flat and are difficult to warp, and the paper is applicable to cylinder printing; the propaganda color page printing paper is made of large quantities of waste paper pulp fibers, accordingly, resources can be saved, the paper is light and has certain fluorescence performance, visualeffects can be enhanced if the paper is used as the propaganda color page printing paper, and excellent antibacterial and insect prevention effects further can be realized; various added components are nontoxic, harmless, safe and environmentally friendly, and accordingly the process has a high practical value and an excellent application prospect.

Owner:合肥晶诺知识产权信息服务有限责任公司

Special filler for high-strength anti-aging capacitor thin films and preparation method thereof

The invention relates to special filler for high-strength anti-aging capacitor thin films. The special filler is prepared from the following materials in parts by weight: 5-7 parts of carbon black, 3-5 parts of calcium carbonate, 1-1.5 parts of dioctyl sebacate, 1-2 parts of lithium carbide, 4-5 parts of lithium-based bentonite, 3-4 parts of calcined kaolin, 4-6 parts of butadiene rubber, 0.7-1.2 parts of sulfur, 1.5-1.8 parts of cyanuric zinc, 3-5 parts of nanometer titanium, 7-9 parts of zinc oxide, 50-55 parts of clay, a proper amount of 4-6% hydrochloric acid, a proper amount of water and 15-20 parts of aid. The special filler disclosed by the invention has the advantages that the tearing strength and impact strength of polypropylene thin films can be greatly increased; the light aging resistance of the thin films is increased by virtue of adding the nanometer titanium and the carbon black; the cost is reduced by virtue of using the clay; by virtue of using the aid, the dispersity and reinforcing performance of the special filler can be increased, the strength and impact toughness of the thin films can be increased.

Owner:ANHUI JIANGWEI PRECISION IND

Environment-friendly stable-light-emission polyvinyl chloride shoe sole material and preparation method thereof

ActiveCN104817791AEfficient killingImprove light aging resistanceSolesPhotoluminescencePolyvinyl chloride

The invention discloses an environment-friendly stable-light-emission polyvinyl chloride shoe sole material which comprises the following components in parts by weight: 30-60 parts of polyvinyl chloride resin, 10-15 parts of photoluminescent material, 5-10 parts of nano titanium oxide, 2-8 parts of acrylate impact-resistance modifier, 1-5 parts of polymethyl siloxane, 1-3 parts of crosslinking agent, 2-6 parts of stabilizer and 2-5 parts of foaming agent. The invention also discloses a preparation method of the polyvinyl chloride shoe sole material. The light-emitting polyvinyl chloride shoe sole material disclosed by the invention has the advantages of stable light-emission property, uniform light emission, favorable mechanical properties, favorable heat resistance, high toughness and no toxicity, and is beneficial to environment friendliness.

Owner:东莞市汇科达鞋业有限公司

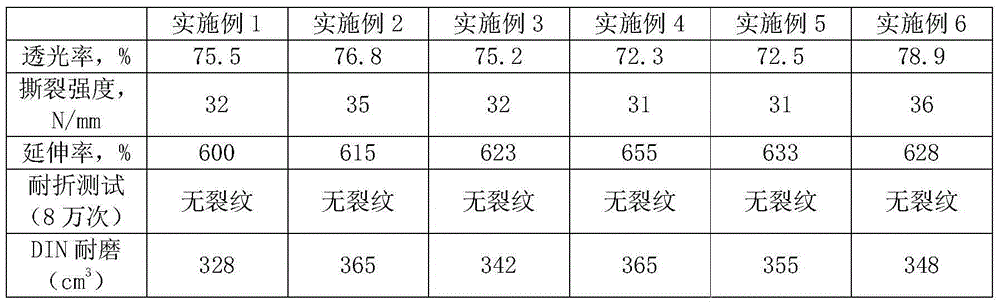

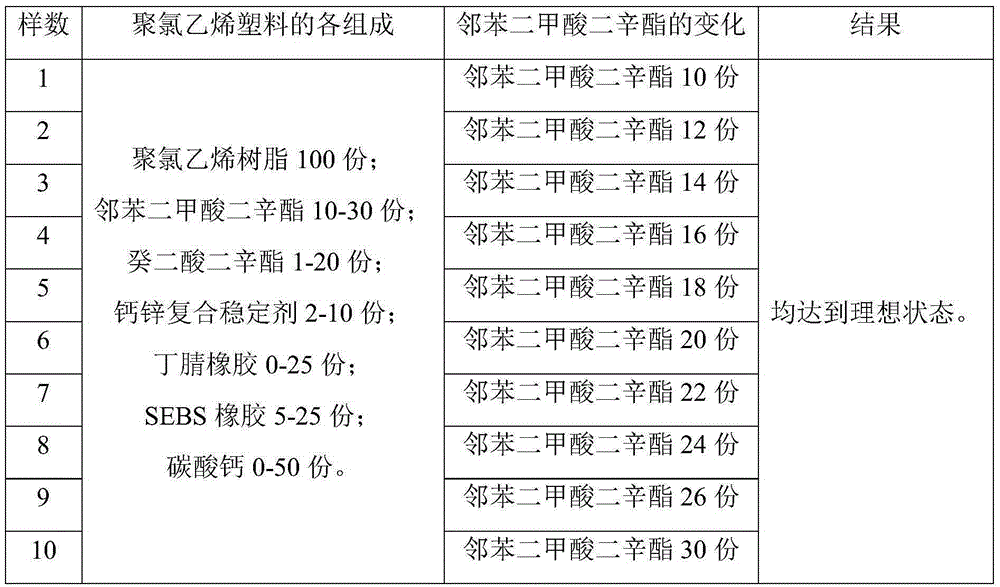

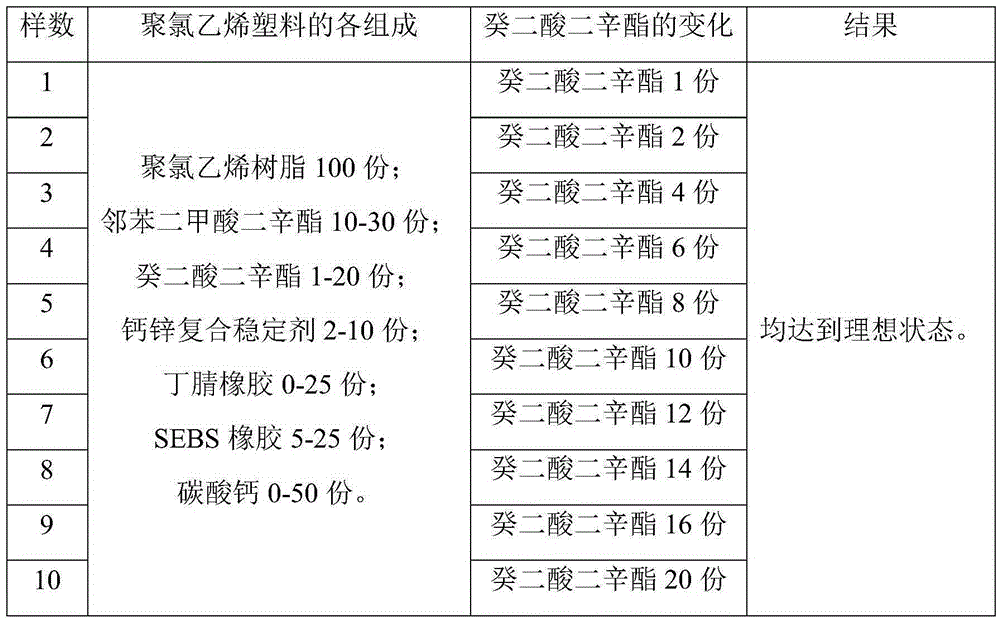

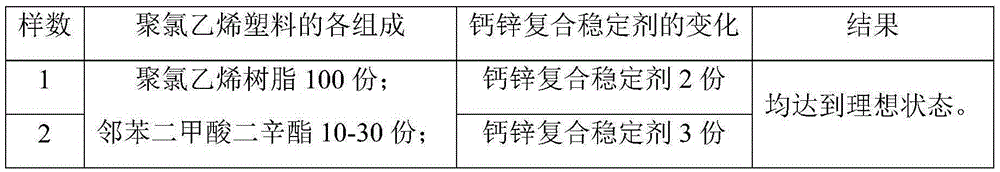

Making method of polyvinyl chloride plastic, and making method of charging pile connecting cable sheath material

InactiveCN105385066AGood weather resistanceImprove heat resistancePlastic/resin/waxes insulatorsNitrile rubberPlasticizer

The invention discloses a making method of a polyvinyl chloride plastic, and a making method of a charging pile connecting cable sheath material. The making method of the polyvinyl chloride plastic is characterized in that the polyvinyl chloride plastic adopts SEBS rubber and nitrile rubber as auxiliary plasticizers, and concretely comprises 100 parts of polyvinyl chloride resin, 10-30 parts of dicapryl phthalate, 1-20 parts of dioctyl sebacate, 2-10 parts of a calcium and zinc composite stabilizer, 0-25 parts of the nitrile rubber, 5-25 parts of the SEBS rubber and 0-50 parts of calcium carbonate. The SEBS rubber is a linear or star-shaped triblock copolymer with styrene as an end segment and an ethylene-butylene copolymer obtained after butadiene hydrogenation as a middle elastic copolymer. The nitrile rubber with the acrylonitrile content of 25-35% is used as a compatilizer in the making process of the polyvinyl chloride plastic. The invention also discloses a making method of the charging pile connecting cable sheath material made from the polyvinyl chloride plastic.

Owner:SUZHOU HENGLI COMM MATERIAL

Waterproof thermal insulation coating for building exterior wall and preparation method thereof

InactiveCN111826049AGood high and low temperature resistanceImprove light aging resistanceCoatingsThermal insulationEmulsion

The invention discloses a waterproof thermal insulation coating for a building external wall and a preparation method thereof. The waterproof thermal insulation coating is prepared from the followingraw materials in parts by weight: 10-20 parts of hollow glass beads, 30-40 parts of modified attapulgite filler, 30-60 parts of modified styrene-acrylic emulsion, 0.3-5 parts of a coalescing agent, 0.2-2 parts of a defoaming agent, 0.2-3 parts of a preservative and 0.6-4 parts of a dispersing agent. According to the invention, silicon is introduced into the styrene-acrylic emulsion; the high and low temperature resistance, the illumination aging resistance, the water resistance and the oxidation resistance of the styrene-acrylic emulsion are improved; therefore, the prepared coating has good waterproof and anti-aging properties; meanwhile, the solid-phase material is prepared into a slurry state and then is mixed with the styrene-acrylic emulsion and thus all materials can be uniformly mixed; in addition, the hollow glass beads are finally added into the emulsion mixture to be uniformly mixed so that the structural integrity of the hollow glass beads can be guaranteed, the hollow glassbeads are uniformly dispersed, and a good heat preservation and insulation effect is achieved.

Owner:马鞍山市金韩防水保温工程股份有限公司

Light aging-resistant antitarnish ceramic vessel and preparation method thereof

InactiveCN104973849AExcellent UV shielding effectImprove light aging resistanceClaywaresButter cocoaCarbon black

The invention discloses a light aging-resistant antitarnish ceramic vessel and a preparation method thereof. The light aging-resistant antitarnish ceramic vessel is prepared from 21-33 parts by weight of dickite, 16-28 parts by weight of opal, 14-25 parts by weight of boehmite, 12-23 parts by weight of polyhalite, 10-15 parts by weight of vulcanic ash, 20-30 parts by weight of pebble shred, 5-10 parts by weight of nanometer titanium nitride, 4-8 parts by weight of nanometer zinc oxide, 8-12 parts by weight of pigment carbon black, 3-5 parts by weight of cocoa butter, 4-8 parts by weight of gum dammar, 3-5 parts by weight of ferric pyrophosphate and 5-8 parts by weight of nano-antibacterial powder. The nanometer titanium nitride, nanometer zinc oxide, pigment carbon black and cocoa butter are mixed according to a specific ratio and produce synergism. Through use of the above materials in dickite, opal, boehmite, polyhalite and pebble shred, good ultraviolet ray shielding effects are obtained, ceramic vessel light aging resistance is substantially improved and chemical stability and wear resistance of the ceramic vessel are improved.

Owner:安徽省德邦瓷业有限公司

Method for preparing hydrophobic light-aging-resistant composite wood loaded with titanium dioxide

InactiveCN107627419AImprove hydrophobicityImprove light aging resistanceWood treatment detailsWood impregnation detailsAlcoholRoom temperature

The invention discloses a method for preparing hydrophobic light-aging-resistant composite wood loaded with titanium dioxide. The method is characterized by comprising the following steps: ultrasonically cleaning a wood sample, and then drying the cleaned wood sample to reach the constant weight; dropwise adding absolute ethyl alcohol into tetra-n-butyl titanate for uniform stirring and mixing, dropwise adding a sodium dodecyl sulfate aqueous solution, adjusting the pH value, continuing to stir till titanium dioxide sol is obtained, and equally diving the titanium dioxide sol into two parts; putting the pretreated wood sample into a hydrothermal reaction kettle, adding one part of the titanium dioxide sol, enclosing the hydrothermal reaction kettle, putting the enclosed hydrothermal reaction kettle into an oven, raising the temperature, keeping the constant temperature, cooling to the room temperature, taking out the treated wood ample for ultrasonic cleaning, and drying in the vacuumstate so as to obtain a titanium dioxide / wood composite material; and adding ethanol into the other part of the titanium dioxide sol to prepare a titanium dioxide ethanol solution, putting the composite material into the titanium dioxide ethanol solution for sufficient immersion, drying the immersed composite material, immersing the dried composite material into a low-surface-energy solution for treatment, and then drying so as to obtain the composite wood.

Owner:JMINDUSTRIES GRP

Preparation method of environment-friendly high-quality advertising consumable paper

InactiveCN108894056AReduce dependenceIncrease the areaSpecial paperPaper coatingFiberAging resistance

The invention relates to the field of preparation of printed product consumables and particularly relates to a preparation method of environment-friendly high-quality advertising consumable paper. Thepreparation method comprises the following relevant steps: preparing preliminary paper pulp, preparing an enhancing aid, preparing papermaking pulp, preparing a paper base, preparing a glue film solution, and applying a glue film layer. The prepared advertising consumable paper is high in strength, excellent in printing effect and good in water tolerance, oil resistance, chemical resistance, ageing resistance and adiabaticity, has a certain flame-retardant effect, and the surface of the paper is flat, is unlikely to be warped and is applicable to roller printing; by utilizing a large amount of waste paper pulp fibers, the resource is saved; and the paper is light, has a certain fluorescence property, is capable of improving the vision effect when being used as advertising paper and has good antibacterial and insect-prevention effects, and each added component is toxic-free and harmless, so that the advertising consumable paper is safe and environment-friendly and has relatively high practical value and good application prospects.

Owner:泾县道旺环保科技有限公司

Aging-resistant aluminum oxide-nylon heat conducting composite material for LED lamps and preparation method of composite material

InactiveCN106009646AImprove light aging resistanceImprove impact resistanceCarbon fibersShock resistance

Provided is an aging-resistant aluminum oxide-nylon heat conducting composite material for LED lamps. The composite material is prepared from, by weight, 200 parts of nylon 6, 8-10 parts of nano-zinc oxide, 30-40 parts of aluminum oxide, 5-8 parts of zirconium tungstate, 20-30 parts of carbon fibers, 50-60 parts of acetone, 80-100 parts of 60%-70% nitric acid, 70-80 parts of a 1%-3% silane coupling agent water solution, 8-10 parts of acetic acid, 15-20 parts of isophorone diisocyanate, 20-25 parts of pentaerythritol triacrylate, 0.4-1 part of a catalyst, 0.4-2 parts of a polymerization inhibitor, 3-5 parts of gelatin, 150-170 parts of tetrahydrofuran, 80-100 parts of toluene and an appropriate amount of deionized water. According to the composite material, nano-zinc oxide is adopted, and therefore the light aging resistance, the shock resistance and the toughness of plastic are improved; surface modification is conducted on the carbon fibers, aluminum oxide is coated with high polymers, and therefore the compatibility of the carbon fibers, aluminum oxide and the nylon 6 is enhanced.

Owner:BENGBU GAOHUA ELECTRONICS

TPO automotive interior material of graphene reinforced EPDM rubber and preparation method and application thereof

ActiveCN109096567AReduce process and raw material costsImprove light aging resistancePolypropylenePolyolefin

The invention provides a TPO automotive interior material of a graphene reinforced EPDM rubber and a preparation method and application thereof. The TPO automotive interior material sequentially includes a TPO skin layer, a foam layer and a back coat layer in order from bottom to top. The preparation method comprises the steps of: preparing a graphene-containing EPDM masterbatch by a twin-screw extrusion method, and mixing a TPO component, a graphene reinforced EPDM rubber component, a polyolefin elastomer component, a polypropylene component and a pigment component through a metering device to prepare a TPO skin material. The preparation method is simple and controllable, good in repeatability and low in production cost. The TPO automotive interior material prepared by the method does notneed to add a light stabilizer and has the advantages of light aging resistance, heat resistance, static resistance and the like. The TPO automotive interior material can improve quality and comprehensive performances of finished leather when used for automobile leather. The soft TPO material prepared from the method has the advantages of being comfortable to use and low in odor and VOC, can be recycled and is green and environmentally friendly.

Owner:SUZHOU RUIGAO NEW MATERIAL CO LTD

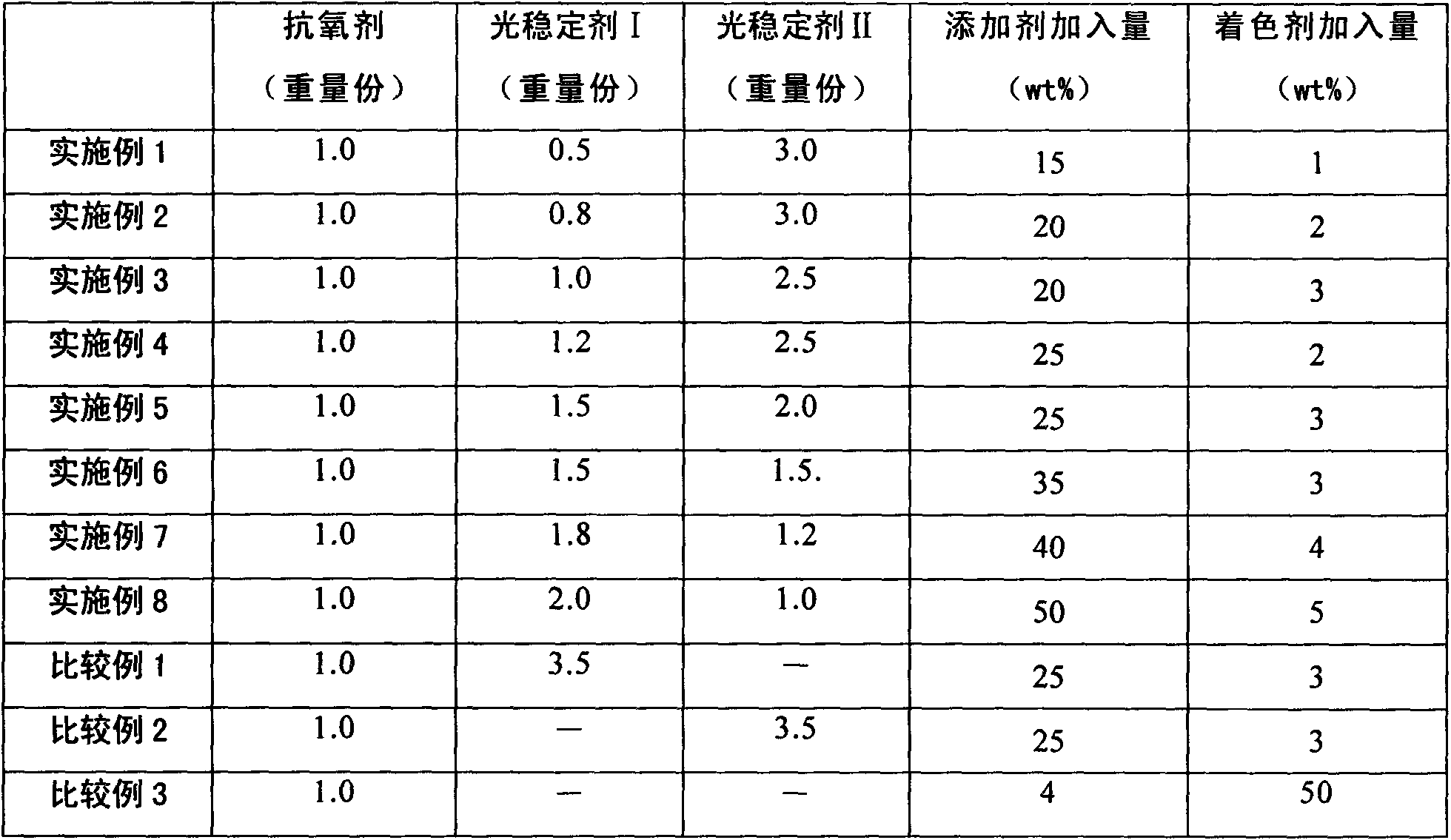

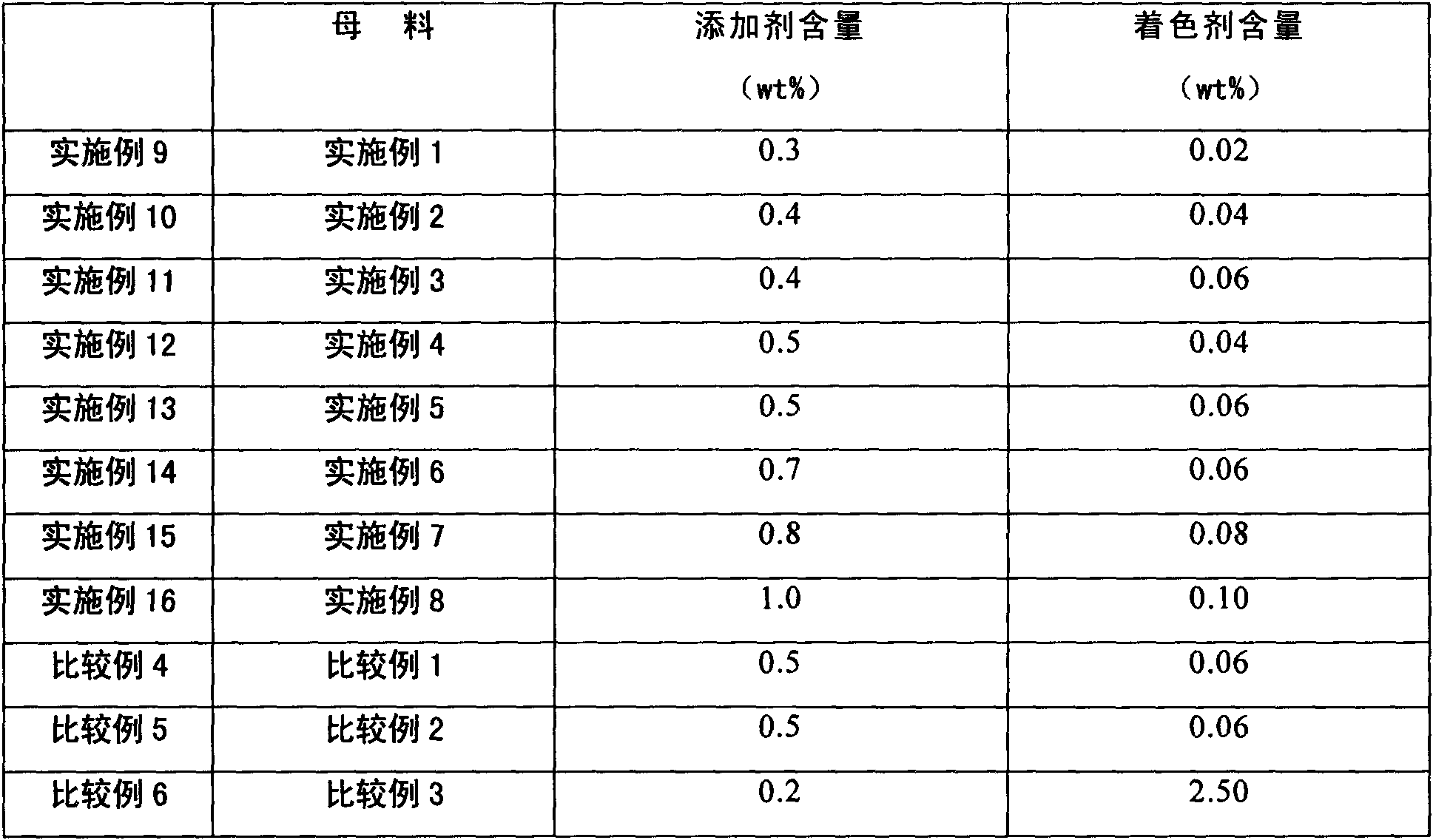

Method for preparing special polyethylene resin composition for pipe by master batch method

InactiveCN103012813AImprove light aging resistanceSolve the light aging resistance is difficult to achieveDiaminePermanent Orange

The invention discloses a method for preparing a special polyethylene resin composition for a pipe by a master batch method, which comprises the following steps of: 1) mixing polyethylene resin serving as a carrier, a coloring agent and an additive and stirring uniformly; and performing melting mixing granulation by a twin-screw extruder to obtain master batch, wherein the coloring agent is permanent orange G or phthalocyanine blue; the coloring agent comprises an antioxidant B225, a light stabilizer 2'-(2'-hydroxy-3'-tertiary butyl-5'-methylphenyl)-5-chlorobenzotriazole and N'-bis(2,2,6,6-tetramethyl-4-piperidyl)hexamethylene diamine; the amount of the coloring agent is 1-5% by weight; and the amount of the additive is 15-50% by weight; and 2) proportionally mixing the master batch and the resin base material and stirring uniformly, and performing melting mixing granulation by a screw extruder to obtain a product of polyethylene resin composition, wherein the content of the coloring agent is 0.02-0.10% by weight, and the content of the additive is 0.3-1.0% by weight. Through the invention, the light aging resistance of the prepared polyethylene material is obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

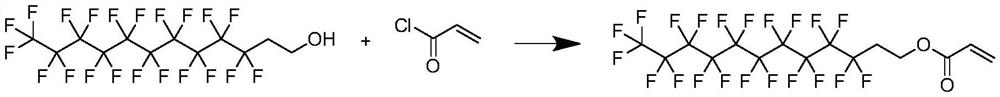

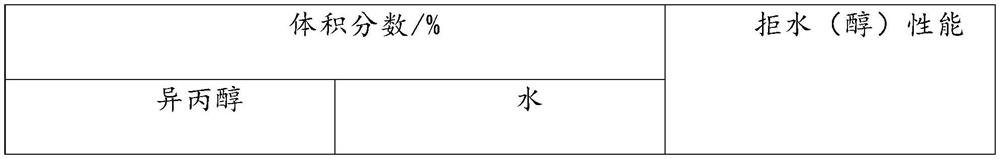

Anti-static, anti-alcohol and anti-plasma medical non-woven fabric

ActiveCN113699788AGood antibacterialImprove antistatic performanceBiochemical fibre treatmentLiquid repellent fibresPotassium persulfatePolyester

The invention belongs to the technical field of medical non-woven fabric preparation, and relates to an anti-static, anti-alcohol and anti-plasma medical non-woven fabric. The medical non-woven fabric is prepared from the following raw materials in parts by weight of 50 parts of PP resin, 20-40 parts of a melt-blown PP material, 500-800 parts of anti-static, anti-alcohol and anti-plasma slurry, 20 parts of polyester fiber, 1-3 parts of organic montmorillonite, 15-20 parts of carbon fiber, 1 part of a lubricant and 1 part of an antioxidant. The raw materials are subjected to melt spinning and hot rolling to form cloth, and then the cloth is soaked in the anti-static, anti-alcohol and anti-plasma slurry, wherein the anti-static, anti-alcohol and anti-plasma slurry is obtained by enabling modified graphene oxide, a fluorine-containing monomer, a chitosan quaternary ammonium salt monomer and methyl acrylate to be subjected to a polymerization reaction under the action of an initiator-potassium persulfate and performing diluting; and by adding the anti-static, anti-alcohol and anti-plasma slurry, the non-woven fabric is endowed with excellent anti-bacterial, anti-static, anti-alcohol and anti-plasma properties, so that the non-woven fabric can be better applied to the field of medical supplies.

Owner:江阴市宏勇医疗科技发展有限公司

High-density polyethylene resin composition for floating photovoltaic barrel and preparation method of high-density polyethylene resin composition

ActiveCN112679835AGood weather resistanceImprove toughnessBulk chemical productionLamellar crystalsPolymer science

The invention belongs to the technical field of high polymer materials, and particularly relates to a high-density polyethylene resin composition for a floating photovoltaic barrel and a preparation method of the high-density polyethylene resin composition. The composition is prepared from the following components in parts by mass: 100 parts of high-density polyethylene; 0.1-0.2 part of a light stabilizer; 0.1-0.15 part of an antioxidant; 0.05-0.3 part of zinc oxide. In the high-density polyethylene resin, the mass percentage content of lamellar crystals with the thickness smaller than 6.1 nm is 2.0-4.0%, the mass percentage content of lamellar crystals with the thickness larger than 16.6 nm is 42.0-59.0%, and the mass ratio of the lamellar crystals with the thickness larger than 16.6 nm to the lamellar crystals with the thickness smaller than 6.1 nm is 16-20: 1. The high-density polyethylene resin composition has good weather resistance, rigidity and toughness and processability, meanwhile, zinc oxide and DDHI are added, the light aging resistance of the material is improved, the performance and the service life of a photovoltaic barrel are guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

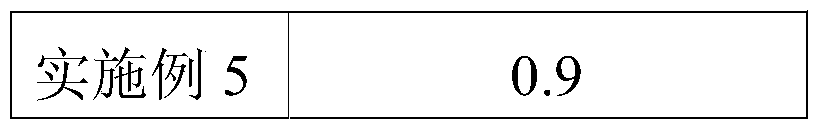

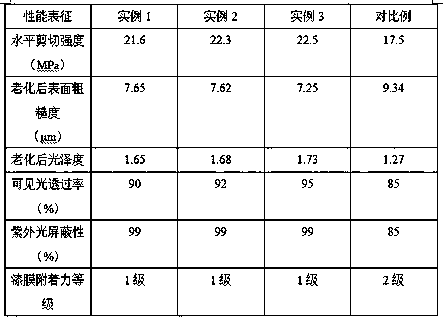

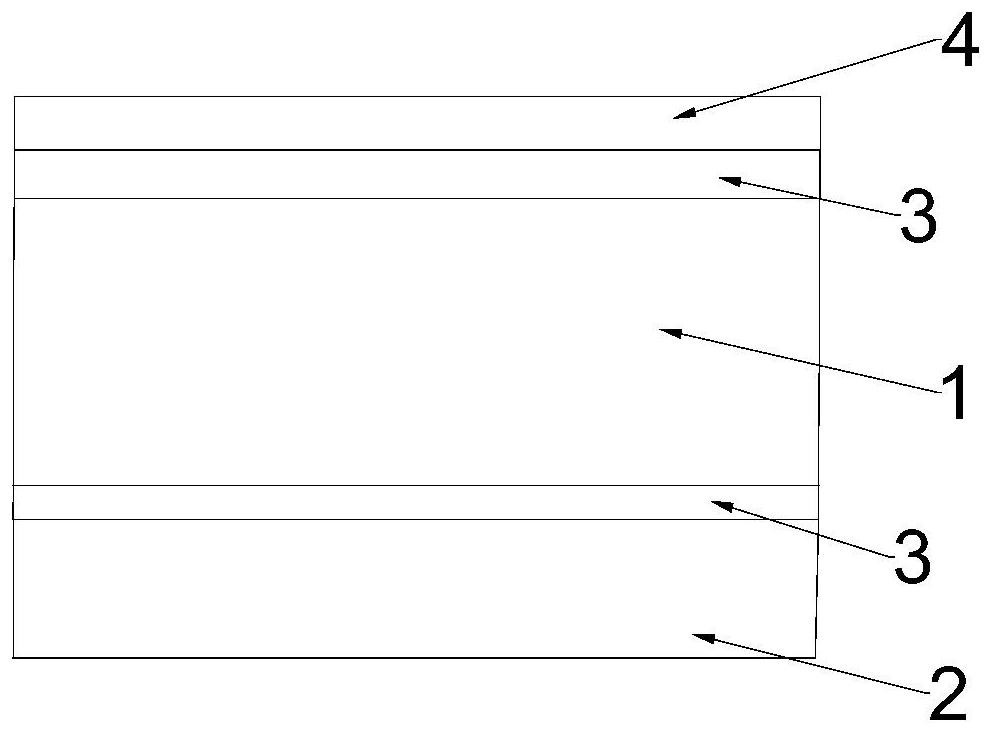

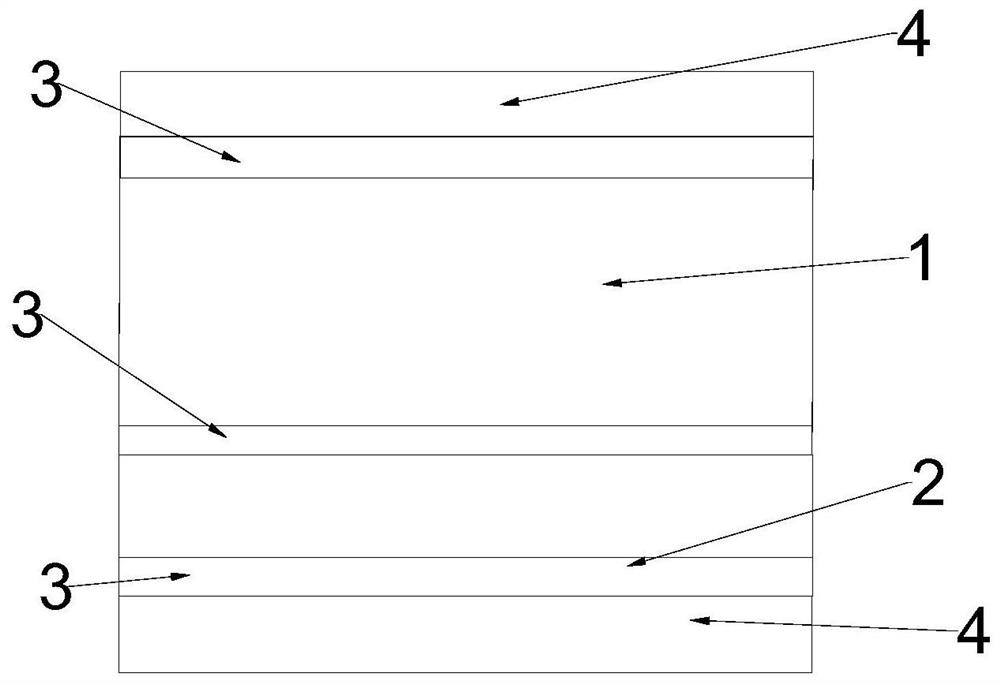

Multilayer extrusion type transparent solar photovoltaic backboard

PendingCN111775531AImprove hydrolysis resistanceImprove light aging resistanceSynthetic resin layered productsElectrical equipmentTransmittanceProtection layer

The invention discloses a multilayer extrusion type transparent solar photovoltaic backboard, which comprises a transparent outer layer and a transparent inner layer, and is characterized in that thetransparent outer layer is made of a transparent modified material with hydrolysis resistance, light aging resistance, high temperature resistance and high water vapor barrier property, and the transparent inner layer is made of a transparent modified material. A blocking protection layer can be arranged on the side, away from the transparent inner layer, of the transparent outer layer. A blockingprotection layer can be arranged on the side, away from the transparent outer layer, of the transparent inner layer. Glue can be arranged between the transparent outer layer and the transparent innerlayer, between the blocking protective layer and the transparent inner layer and between the blocking protective layer and the transparent outer layer. The transparent solar photovoltaic backboard has excellent hydrolysis resistance and light aging resistance, high water vapor barrier property, high interlayer peeling strength, simple manufacturing process and good light transmittance, does not contain fluorine, is convenient to recycle, can reduce the weight of a component, and reduces the problems of solvent recycling pollution and the like in the production process of the composite back plate.

Owner:浙江中聚材料有限公司

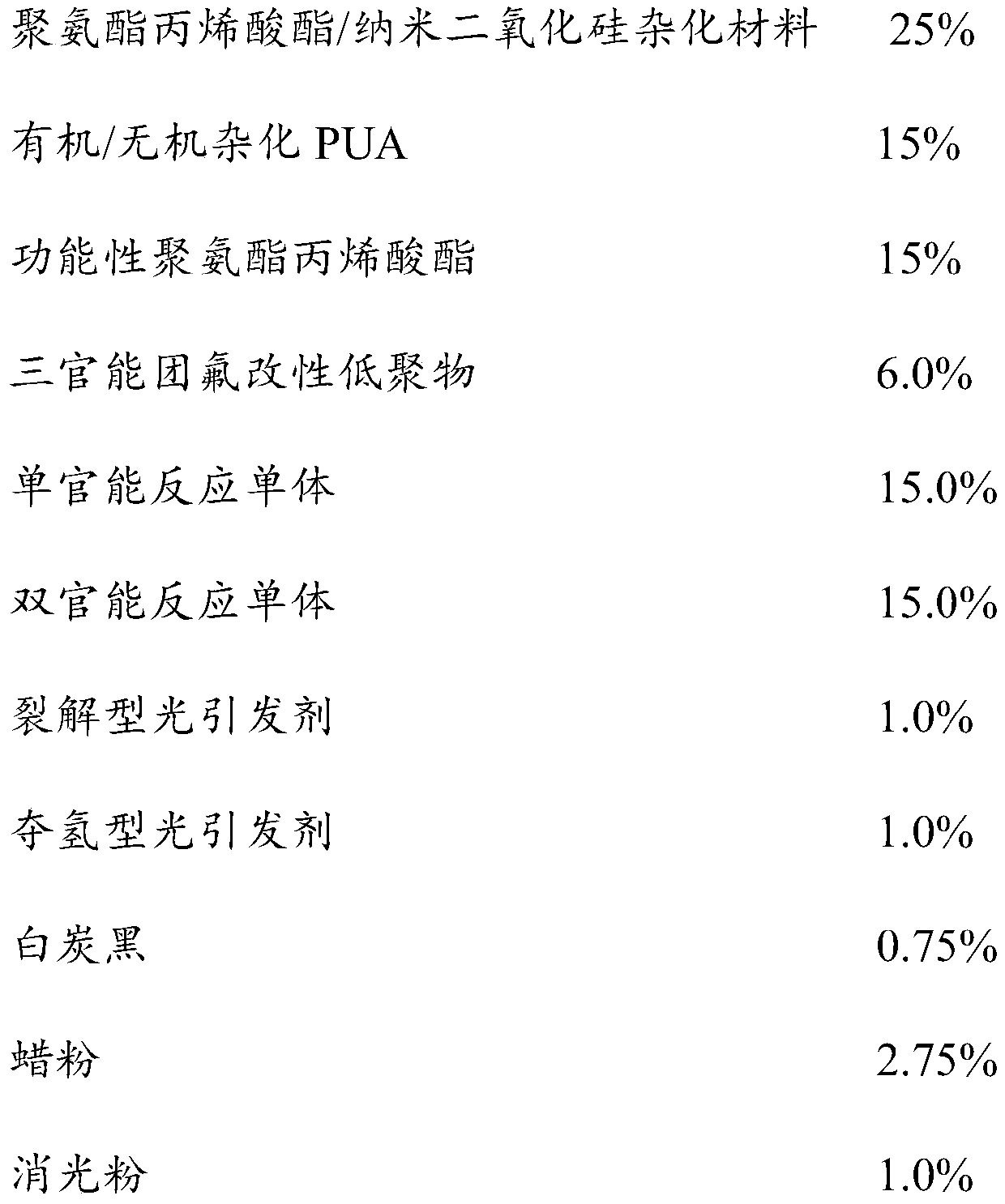

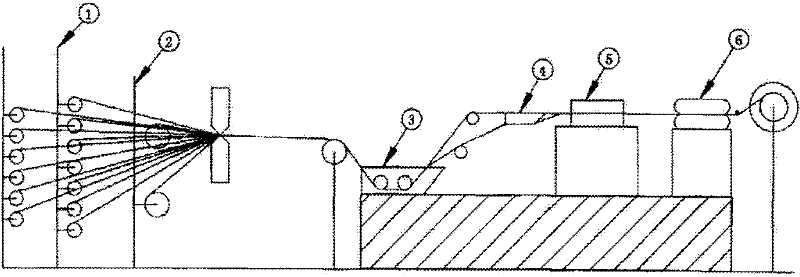

3D printing photocuring material and underwater curing after-treatment processing technology thereof

The invention discloses a 3D printing photocuring material and an underwater curing after-treatment processing technology thereof. The photocuring material is mainly prepared from, by weight, 20-50% of UV-curing nanometer organic-inorganic silicon hybridized resin, 5-25% of UV-curing self-repairing resin, 0.5-20% of fluorine-modified resin, 10-40% of a monomer diluent, 0.1-5% of a photoinitiator,0.1-1% of a pigment, 0.1-5% of a filler and 0.1-3% of an auxiliary agent. The 3D printing photocuring material is firstly subjected to curing forming by 3D printing DLP equipment with the UVA wavebandof 385 nm, and then subjected to the underwater curing after-treatment processing technology. The 3D printing photocuring material obtained by means of the technology has the tensile strength of 68-80 Mpa and the bending strength of 53-61 Mpa, the scratch resistance is excellent, tiny scratches can be quickly repaired, no mark is left, the surface smoothness level is nabla 10-nabla 11, the size change is within the range of 0-0.10 mm after long-time placement, and the light aging resistance reaches 300 h.

Owner:WUXI CITY CASHEW NEW MATERIALS CO LTD

Special filler for ultraviolet-resistant capacitor films and preparation method thereof

The invention relates to a special filler for ultraviolet-resistant capacitor films, which is prepared from the following raw materials in parts by weight: 4-6 parts of calcium hydroxide, 3-5 parts of magnesium oxide, 0.4-0.7 part of palm wax, 1-2 parts of aluminum dihydrogen phosphate, 0.1-0.2 part of sodium dodecyl benzene sulfonate, 0.2-0.4 part of stearic acid, 6-8 parts of titanium dioxide, 2-3 parts of silicon dioxide, 0.3-0.4 part of aluminum isopropoxide, 60-65 parts of clay, a right amount of 4-6% hydrochloric acid, a right amount of water and 15-20 parts of assistant. The titanium dioxide and silicon dioxide added to the filler can enhance the ultraviolet resistance of the film, so that the filler has favorable reinforcing action and can greatly enhance the light aging resistance, tearing strength and impact strength of the polypropylene film; by using the clay, the cost is lowered; and the assistant can enhance the dispersity and reinforcing performance of the filler and also enhance the strength and impact resistance of the film.

Owner:ANHUI JIANGWEI PRECISION IND

Polymethyl methacrylate-nano cerium oxide coating modification calcium carbonate powder and preparing method thereof

InactiveCN106590045AImprove toughnessImprove heat resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsDispersityThermal ageing

The invention discloses polymethyl methacrylate-nano cerium oxide coating modification calcium carbonate powder. The preparing method includes the steps that titanate coupling agent / ethanol solution wet method ball grinding pretreatment is carried out on calcium carbonate to improve dispersity and surface reactivity, calcium carbonate powder obtained after pre-modification is mixed with nano cerium oxide and methyl methacrylate monomers to react, a polymethyl methacrylate / nano cerium oxide composite membrane layer is generated on the surface through in-situ polymerization, modified calcium carbonate powder has good compatibility with a resin matrix, unique characteristics are endowed to the powder by rare earth oxide, tenacity, thermal ageing resistance, light ageing resistance and electromagnetic radiation resistance of plastic can be improved, and added value is effectively increased.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

Composite material cable core

InactiveCN102222542AGood processing thermal stabilityImprove heat resistanceInsulated cablesInsulated conductorsLow elastic modulusFiber

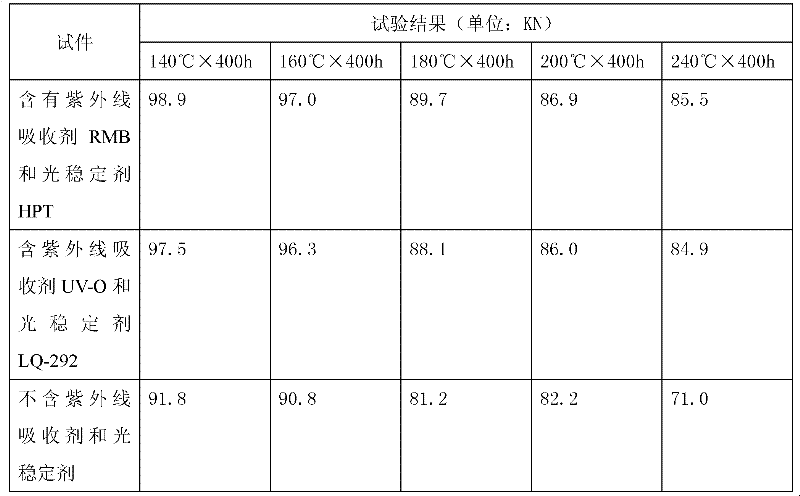

The invention relates to a composite material cable core which is composed of an inner layer and an outer layer; heat-resisting resin is taken as a matrix for the inner layer, and a high-strength ultra-long continuous fiber is taken as a reinforcing material; and hindered anime light stabilizers and ultraviolet absorbers are added in the heat-resisting resin of the inner layer and the outer layer. The cable core provided by the invention has favorable performances of ultraviolet resistance, aging resistance and even heat resistance.

Owner:CHANGZHOU HONGZELAN WIRE & CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com